The Role of Vacuum Pumps in Nanoparticle Dispersion Techniques

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution and Objectives

Vacuum pumps have played a pivotal role in the evolution of nanoparticle dispersion techniques, marking significant milestones in the field of nanotechnology. The journey of vacuum pump technology in this domain began in the mid-20th century, with the advent of early vacuum-based particle manipulation methods. As nanotechnology gained momentum, the demand for more precise and efficient vacuum systems grew exponentially.

The primary objective of vacuum pump technology in nanoparticle dispersion is to create and maintain controlled environments that facilitate the uniform distribution of nanoparticles. This goal has driven continuous innovation in pump design, capacity, and operational efficiency. Over the decades, vacuum pumps have evolved from simple mechanical devices to sophisticated, digitally controlled systems capable of achieving ultra-high vacuum levels.

A key trend in this technological evolution has been the miniaturization of vacuum pumps, aligning with the overall trajectory of nanotechnology. This trend has enabled the integration of vacuum systems into compact laboratory equipment, significantly enhancing the accessibility and applicability of nanoparticle dispersion techniques across various research and industrial settings.

Another notable development has been the improvement in vacuum pump reliability and contamination control. As nanoparticle research often requires pristine environments, modern vacuum pumps have been engineered to minimize oil backstreaming and particle generation, ensuring the integrity of nanoparticle samples.

The advent of dry pumping technologies marked a revolutionary step in this field. These oil-free systems eliminated the risk of hydrocarbon contamination, a critical factor in many nanoparticle applications. This innovation opened new possibilities in areas such as semiconductor manufacturing and advanced materials research, where even minute impurities can have significant impacts.

Looking forward, the objectives for vacuum pump technology in nanoparticle dispersion are multifaceted. There is a push towards developing pumps with higher energy efficiency and lower environmental impact, aligning with global sustainability goals. Additionally, there is a growing focus on smart vacuum systems that can adapt to varying process conditions, optimizing dispersion parameters in real-time.

Researchers and engineers are also exploring the integration of vacuum pump technology with other emerging fields, such as artificial intelligence and IoT. The vision is to create intelligent dispersion systems that can predict and prevent issues, automate complex processes, and provide unprecedented levels of control over nanoparticle manipulation.

The primary objective of vacuum pump technology in nanoparticle dispersion is to create and maintain controlled environments that facilitate the uniform distribution of nanoparticles. This goal has driven continuous innovation in pump design, capacity, and operational efficiency. Over the decades, vacuum pumps have evolved from simple mechanical devices to sophisticated, digitally controlled systems capable of achieving ultra-high vacuum levels.

A key trend in this technological evolution has been the miniaturization of vacuum pumps, aligning with the overall trajectory of nanotechnology. This trend has enabled the integration of vacuum systems into compact laboratory equipment, significantly enhancing the accessibility and applicability of nanoparticle dispersion techniques across various research and industrial settings.

Another notable development has been the improvement in vacuum pump reliability and contamination control. As nanoparticle research often requires pristine environments, modern vacuum pumps have been engineered to minimize oil backstreaming and particle generation, ensuring the integrity of nanoparticle samples.

The advent of dry pumping technologies marked a revolutionary step in this field. These oil-free systems eliminated the risk of hydrocarbon contamination, a critical factor in many nanoparticle applications. This innovation opened new possibilities in areas such as semiconductor manufacturing and advanced materials research, where even minute impurities can have significant impacts.

Looking forward, the objectives for vacuum pump technology in nanoparticle dispersion are multifaceted. There is a push towards developing pumps with higher energy efficiency and lower environmental impact, aligning with global sustainability goals. Additionally, there is a growing focus on smart vacuum systems that can adapt to varying process conditions, optimizing dispersion parameters in real-time.

Researchers and engineers are also exploring the integration of vacuum pump technology with other emerging fields, such as artificial intelligence and IoT. The vision is to create intelligent dispersion systems that can predict and prevent issues, automate complex processes, and provide unprecedented levels of control over nanoparticle manipulation.

Nanoparticle Dispersion Market Analysis

The nanoparticle dispersion market has been experiencing significant growth in recent years, driven by the increasing demand for nanotechnology applications across various industries. This market is primarily fueled by the rising adoption of nanoparticles in sectors such as electronics, healthcare, energy, and materials science. The global nanoparticle dispersion market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the key factors contributing to market growth is the expanding use of nanoparticles in advanced materials and coatings. Industries such as automotive, aerospace, and construction are increasingly incorporating nanoparticle dispersions to enhance product performance and durability. Additionally, the healthcare sector has emerged as a major consumer of nanoparticle dispersions, particularly in drug delivery systems and diagnostic applications.

The market is characterized by a high degree of fragmentation, with numerous players competing for market share. Key market participants include established chemical companies, specialized nanotechnology firms, and research institutions. The competitive landscape is marked by continuous innovation and research and development efforts to improve dispersion techniques and expand application areas.

Geographically, North America and Europe currently dominate the nanoparticle dispersion market, owing to their advanced technological infrastructure and significant investments in research and development. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, government support for nanotechnology research, and rising demand from end-use industries.

The role of vacuum pumps in nanoparticle dispersion techniques has become increasingly important, as they play a crucial role in creating controlled environments for nanoparticle synthesis and dispersion. Vacuum technology enables precise control over particle size, distribution, and purity, which are critical factors in many applications. As a result, the demand for advanced vacuum pump systems tailored for nanoparticle dispersion processes is expected to grow in tandem with the overall market.

Challenges facing the nanoparticle dispersion market include concerns over the environmental and health impacts of nanoparticles, as well as the need for standardization in production and characterization methods. These factors may influence market growth and regulatory landscapes in the coming years. Despite these challenges, the market outlook remains positive, driven by ongoing technological advancements and the expanding range of applications for nanoparticle dispersions across various industries.

One of the key factors contributing to market growth is the expanding use of nanoparticles in advanced materials and coatings. Industries such as automotive, aerospace, and construction are increasingly incorporating nanoparticle dispersions to enhance product performance and durability. Additionally, the healthcare sector has emerged as a major consumer of nanoparticle dispersions, particularly in drug delivery systems and diagnostic applications.

The market is characterized by a high degree of fragmentation, with numerous players competing for market share. Key market participants include established chemical companies, specialized nanotechnology firms, and research institutions. The competitive landscape is marked by continuous innovation and research and development efforts to improve dispersion techniques and expand application areas.

Geographically, North America and Europe currently dominate the nanoparticle dispersion market, owing to their advanced technological infrastructure and significant investments in research and development. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, government support for nanotechnology research, and rising demand from end-use industries.

The role of vacuum pumps in nanoparticle dispersion techniques has become increasingly important, as they play a crucial role in creating controlled environments for nanoparticle synthesis and dispersion. Vacuum technology enables precise control over particle size, distribution, and purity, which are critical factors in many applications. As a result, the demand for advanced vacuum pump systems tailored for nanoparticle dispersion processes is expected to grow in tandem with the overall market.

Challenges facing the nanoparticle dispersion market include concerns over the environmental and health impacts of nanoparticles, as well as the need for standardization in production and characterization methods. These factors may influence market growth and regulatory landscapes in the coming years. Despite these challenges, the market outlook remains positive, driven by ongoing technological advancements and the expanding range of applications for nanoparticle dispersions across various industries.

Vacuum Pump Challenges in Nanoparticle Dispersion

Vacuum pumps play a crucial role in nanoparticle dispersion techniques, yet they face several significant challenges that can impact the efficiency and effectiveness of the process. One of the primary issues is maintaining consistent vacuum levels throughout the dispersion process. Fluctuations in vacuum pressure can lead to inconsistent particle sizes and distribution, compromising the quality of the final product.

Another challenge lies in the potential contamination of nanoparticles during the vacuum pumping process. Even minute amounts of oil or other contaminants from the pump can significantly alter the properties of the nanoparticles, affecting their intended functionality. This necessitates the use of oil-free or specially designed pumps, which can be more expensive and may have limitations in terms of achievable vacuum levels.

The handling of potentially hazardous nanoparticles poses an additional challenge. Some nanoparticles may be toxic or reactive, requiring specialized containment and filtration systems to prevent their release into the environment or exposure to operators. This adds complexity to the pump design and increases the overall cost of the dispersion system.

Scaling up vacuum-based nanoparticle dispersion techniques for industrial production presents its own set of challenges. Larger-scale operations require more powerful pumps and sophisticated control systems to maintain uniform conditions across larger volumes. This can lead to increased energy consumption and higher operational costs.

The durability of vacuum pumps in nanoparticle dispersion applications is also a concern. The abrasive nature of some nanoparticles can cause accelerated wear on pump components, leading to more frequent maintenance and replacement. This not only increases downtime but also adds to the overall cost of operation.

Furthermore, achieving ultra-high vacuum levels, which may be necessary for certain nanoparticle dispersion techniques, presents technical difficulties. It requires specialized pump designs and materials that can withstand extreme conditions while maintaining performance over extended periods.

Lastly, the integration of vacuum pumps with other components of the nanoparticle dispersion system can be challenging. Ensuring seamless operation with various sensors, control systems, and dispersion mechanisms requires careful design and engineering, often necessitating custom solutions for specific applications.

Another challenge lies in the potential contamination of nanoparticles during the vacuum pumping process. Even minute amounts of oil or other contaminants from the pump can significantly alter the properties of the nanoparticles, affecting their intended functionality. This necessitates the use of oil-free or specially designed pumps, which can be more expensive and may have limitations in terms of achievable vacuum levels.

The handling of potentially hazardous nanoparticles poses an additional challenge. Some nanoparticles may be toxic or reactive, requiring specialized containment and filtration systems to prevent their release into the environment or exposure to operators. This adds complexity to the pump design and increases the overall cost of the dispersion system.

Scaling up vacuum-based nanoparticle dispersion techniques for industrial production presents its own set of challenges. Larger-scale operations require more powerful pumps and sophisticated control systems to maintain uniform conditions across larger volumes. This can lead to increased energy consumption and higher operational costs.

The durability of vacuum pumps in nanoparticle dispersion applications is also a concern. The abrasive nature of some nanoparticles can cause accelerated wear on pump components, leading to more frequent maintenance and replacement. This not only increases downtime but also adds to the overall cost of operation.

Furthermore, achieving ultra-high vacuum levels, which may be necessary for certain nanoparticle dispersion techniques, presents technical difficulties. It requires specialized pump designs and materials that can withstand extreme conditions while maintaining performance over extended periods.

Lastly, the integration of vacuum pumps with other components of the nanoparticle dispersion system can be challenging. Ensuring seamless operation with various sensors, control systems, and dispersion mechanisms requires careful design and engineering, often necessitating custom solutions for specific applications.

Current Vacuum Pump Solutions

01 Vacuum pump design for improved dispersion

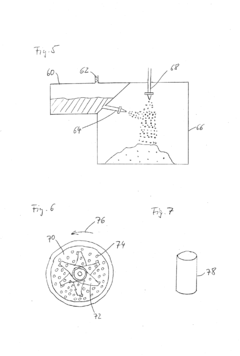

Advanced vacuum pump designs focus on enhancing dispersion capabilities. These pumps incorporate specialized features to improve the distribution and mixing of particles or fluids within a vacuum environment. The designs may include optimized impeller shapes, innovative chamber configurations, or advanced flow control mechanisms to achieve better dispersion results.- Vacuum pump design for improved dispersion: Specialized vacuum pump designs are developed to enhance dispersion capabilities in various applications. These pumps incorporate features that optimize the dispersion of particles or fluids while maintaining efficient vacuum performance. The designs may include modified impeller shapes, advanced sealing mechanisms, or innovative flow channels to achieve better dispersion results.

- Dispersion systems integrated with vacuum pumps: Integrated systems combining vacuum pumps with dispersion mechanisms are created to streamline processes in industries such as chemical processing, pharmaceuticals, and materials science. These systems often feature specialized nozzles, mixing chambers, or atomization devices directly coupled with vacuum pumps to achieve precise control over dispersion while maintaining a controlled pressure environment.

- Vacuum-assisted dispersion in material processing: Vacuum pumps are utilized in material processing applications to enhance dispersion of particles or components within a matrix. This technique is particularly useful in the production of composites, coatings, and advanced materials. The vacuum environment helps remove air bubbles, reduce agglomeration, and promote uniform distribution of dispersed phases.

- Control systems for vacuum pump dispersion: Advanced control systems are developed to optimize the performance of vacuum pumps in dispersion applications. These systems may incorporate sensors, feedback loops, and intelligent algorithms to adjust pump parameters in real-time, ensuring consistent and efficient dispersion across various operating conditions. The control systems can also integrate with other process equipment for seamless operation.

- Energy-efficient vacuum pumps for dispersion processes: Energy-efficient vacuum pump designs are created specifically for dispersion applications. These pumps incorporate features such as variable speed drives, optimized motor designs, and advanced materials to reduce energy consumption while maintaining high performance in dispersion processes. The focus is on achieving sustainability and cost-effectiveness in industrial dispersion operations.

02 Dispersion systems integrated with vacuum technology

Integrated systems combine vacuum pumps with dispersion mechanisms to create efficient and compact solutions. These systems may incorporate features such as in-line mixers, atomizers, or specialized nozzles within the vacuum pump assembly. This integration allows for simultaneous vacuum creation and material dispersion, enhancing overall process efficiency.Expand Specific Solutions03 Vacuum-assisted dispersion for nanomaterials

Specialized vacuum pump configurations are developed for the dispersion of nanomaterials. These systems utilize precise vacuum control and customized dispersion mechanisms to prevent agglomeration and ensure uniform distribution of nanoparticles. The technology may involve pulsed vacuum application or controlled pressure differentials to achieve optimal dispersion results.Expand Specific Solutions04 Energy-efficient vacuum pumps for dispersion processes

Energy-efficient vacuum pump designs are developed specifically for dispersion applications. These pumps incorporate features such as variable speed drives, optimized motor designs, and intelligent control systems to minimize energy consumption while maintaining effective dispersion capabilities. The focus is on reducing operational costs and environmental impact in industrial dispersion processes.Expand Specific Solutions05 Multi-stage vacuum pumps for enhanced dispersion control

Multi-stage vacuum pump systems are designed to provide precise control over the dispersion process. These systems utilize a series of pump stages with different characteristics to achieve optimal vacuum levels and dispersion results. The multi-stage approach allows for better control over pressure gradients, flow rates, and particle distribution throughout the dispersion process.Expand Specific Solutions

Key Players in Vacuum Pump Industry

The vacuum pump industry for nanoparticle dispersion techniques is in a growth phase, driven by increasing demand in semiconductor, pharmaceutical, and materials science sectors. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Pfeiffer Vacuum GmbH, Edwards Vacuum LLC, and Applied Materials, Inc. leading innovation. These firms are developing more efficient and precise vacuum pumps, integrating advanced control systems and materials. The competitive landscape is characterized by a mix of established players and emerging specialists, with ongoing research collaborations between industry and academia, such as Shandong University and Auburn University, pushing the boundaries of nanoparticle dispersion technology.

Pfeiffer Vacuum GmbH

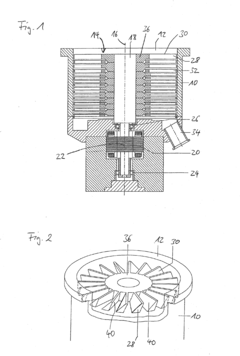

Technical Solution: Pfeiffer Vacuum GmbH has developed advanced vacuum pump technologies specifically tailored for nanoparticle dispersion techniques. Their HiPace turbomolecular pumps, combined with multi-stage Roots pumps, create ultra-high vacuum environments essential for precise nanoparticle manipulation[1]. The company's ACP series of dry multi-stage Roots pumps offers oil-free operation, crucial for maintaining sample purity in nanoparticle research[2]. Pfeiffer's vacuum systems integrate smart sensors and control units, allowing real-time adjustment of pumping speeds and pressures to optimize nanoparticle dispersion processes[3]. Their pumps also feature advanced cooling systems to maintain stable performance during extended operation, which is critical for consistent nanoparticle production[4].

Strengths: High precision control, oil-free operation, and advanced cooling systems ensure sample purity and process stability. Weaknesses: Higher initial cost compared to simpler vacuum systems, and may require specialized maintenance.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed innovative vacuum-based solutions for nanoparticle dispersion in semiconductor manufacturing. Their Endura platform incorporates advanced PVD (Physical Vapor Deposition) technology with high-vacuum chambers to achieve uniform nanoparticle deposition[5]. The company's proprietary iSYS vacuum control system enables precise management of chamber pressures, critical for controlling nanoparticle size and distribution[6]. Applied Materials has also introduced the Producer GT system, which combines PECVD (Plasma-Enhanced Chemical Vapor Deposition) with vacuum technology to create nanostructured films with dispersed nanoparticles[7]. Their vacuum systems are integrated with in-situ metrology tools, allowing real-time monitoring and adjustment of nanoparticle dispersion processes[8].

Strengths: Highly integrated systems with advanced process control and in-situ monitoring capabilities. Weaknesses: Primarily focused on semiconductor applications, which may limit versatility in other nanoparticle dispersion fields.

Core Vacuum Pump Innovations

Vacuum pump

PatentActiveEP2740943A2

Innovation

- Incorporating nanoparticles into the material of pump components, such as rotor disks, to enhance mechanical and thermal resistance, using a metal matrix with nanoparticles like carbon nanotubes that improve strength and heat resistance while maintaining metallic properties, allowing for increased operational reliability and longevity.

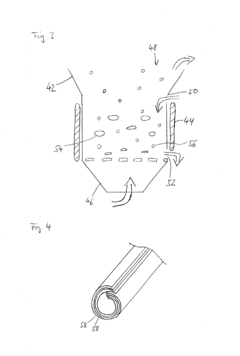

Nanopump for transporting and purifying liquid through nanomembranes

PatentWO2018106095A1

Innovation

- A nanopump design utilizing three or more autonomous sources of surface acoustic waves to filter and clean nanochannels, regenerating and purifying the membrane nanochannels while removing contaminants, ensuring continuous operation.

Environmental Impact Assessment

The use of vacuum pumps in nanoparticle dispersion techniques has significant environmental implications that warrant careful consideration. These pumps play a crucial role in creating controlled environments for nanoparticle synthesis and manipulation, but their operation can have both direct and indirect environmental impacts.

One of the primary environmental concerns associated with vacuum pumps is their energy consumption. High-performance vacuum systems often require substantial electrical power to operate, contributing to increased energy demand and associated greenhouse gas emissions. This is particularly relevant in large-scale industrial applications where multiple pumps may be running continuously. To mitigate this impact, research into more energy-efficient pump designs and the integration of renewable energy sources for powering these systems is ongoing.

The disposal of vacuum pump oil and other consumables presents another environmental challenge. Many vacuum pumps use specialized oils that require periodic replacement. These oils can contain contaminants from the pumping process, including nanoparticles, making proper disposal critical to prevent environmental contamination. Implementing closed-loop recycling systems for pump oils and exploring alternative, more environmentally friendly lubricants are areas of active development in the field.

Noise pollution is an often-overlooked environmental impact of vacuum pump operation. High-capacity pumps can generate significant noise levels, potentially affecting both human workers and local ecosystems. This has led to increased focus on noise reduction technologies and the design of acoustically insulated pump housings to minimize sound propagation.

The production of nanoparticles itself, facilitated by vacuum pump technology, raises environmental concerns. While nanoparticles offer numerous benefits across various industries, their potential release into the environment during production or use poses risks to ecosystems and human health. Vacuum pumps play a critical role in containment and filtration systems designed to prevent nanoparticle escape, highlighting the importance of robust and well-maintained vacuum infrastructure in environmental protection strategies.

Water usage in vacuum pump cooling systems is another environmental consideration. Large-scale vacuum operations often require substantial water for cooling, potentially straining local water resources. Innovations in air-cooled pump designs and closed-loop cooling systems are being developed to address this issue, aiming to reduce water consumption in nanoparticle production facilities.

As the field of nanoparticle dispersion techniques continues to evolve, there is a growing emphasis on lifecycle assessment of the equipment involved, including vacuum pumps. This holistic approach considers environmental impacts from manufacturing through operation to eventual decommissioning, driving improvements in sustainable design and end-of-life management for vacuum pump systems.

One of the primary environmental concerns associated with vacuum pumps is their energy consumption. High-performance vacuum systems often require substantial electrical power to operate, contributing to increased energy demand and associated greenhouse gas emissions. This is particularly relevant in large-scale industrial applications where multiple pumps may be running continuously. To mitigate this impact, research into more energy-efficient pump designs and the integration of renewable energy sources for powering these systems is ongoing.

The disposal of vacuum pump oil and other consumables presents another environmental challenge. Many vacuum pumps use specialized oils that require periodic replacement. These oils can contain contaminants from the pumping process, including nanoparticles, making proper disposal critical to prevent environmental contamination. Implementing closed-loop recycling systems for pump oils and exploring alternative, more environmentally friendly lubricants are areas of active development in the field.

Noise pollution is an often-overlooked environmental impact of vacuum pump operation. High-capacity pumps can generate significant noise levels, potentially affecting both human workers and local ecosystems. This has led to increased focus on noise reduction technologies and the design of acoustically insulated pump housings to minimize sound propagation.

The production of nanoparticles itself, facilitated by vacuum pump technology, raises environmental concerns. While nanoparticles offer numerous benefits across various industries, their potential release into the environment during production or use poses risks to ecosystems and human health. Vacuum pumps play a critical role in containment and filtration systems designed to prevent nanoparticle escape, highlighting the importance of robust and well-maintained vacuum infrastructure in environmental protection strategies.

Water usage in vacuum pump cooling systems is another environmental consideration. Large-scale vacuum operations often require substantial water for cooling, potentially straining local water resources. Innovations in air-cooled pump designs and closed-loop cooling systems are being developed to address this issue, aiming to reduce water consumption in nanoparticle production facilities.

As the field of nanoparticle dispersion techniques continues to evolve, there is a growing emphasis on lifecycle assessment of the equipment involved, including vacuum pumps. This holistic approach considers environmental impacts from manufacturing through operation to eventual decommissioning, driving improvements in sustainable design and end-of-life management for vacuum pump systems.

Safety Protocols in Nanoparticle Handling

Safety protocols in nanoparticle handling are of paramount importance when working with vacuum pumps in nanoparticle dispersion techniques. The potential health risks associated with nanoparticle exposure necessitate stringent safety measures to protect researchers and laboratory personnel.

Proper personal protective equipment (PPE) is essential when handling nanoparticles. This includes wearing appropriate gloves, lab coats, and safety goggles. Respiratory protection, such as N95 respirators or powered air-purifying respirators (PAPRs), may be required depending on the specific nanoparticles and dispersion processes involved.

Engineered controls play a crucial role in minimizing exposure risks. The use of fume hoods or glove boxes with high-efficiency particulate air (HEPA) filtration systems is recommended when working with nanoparticles and vacuum pumps. These containment systems help prevent the release of nanoparticles into the laboratory environment.

Regular maintenance and inspection of vacuum pumps and associated equipment are essential to ensure their proper functioning and prevent potential leaks or malfunctions that could lead to nanoparticle release. Implementing a comprehensive maintenance schedule and documenting all inspections and repairs is crucial for maintaining a safe working environment.

Proper waste management protocols must be established for handling nanoparticle-contaminated materials. This includes the use of dedicated waste containers, proper labeling, and following appropriate disposal procedures. Vacuum pump oil and other potentially contaminated liquids should be treated as hazardous waste and disposed of accordingly.

Training and education are vital components of safety protocols in nanoparticle handling. All personnel working with nanoparticles and vacuum pumps should receive comprehensive training on proper handling techniques, potential hazards, and emergency procedures. Regular refresher courses and updates on new safety guidelines should be provided to ensure ongoing compliance.

Implementing a robust spill response plan is crucial for addressing accidental releases of nanoparticles. This plan should include procedures for containment, cleanup, and decontamination, as well as guidelines for reporting incidents and seeking medical attention if necessary.

Monitoring and surveillance programs should be established to assess potential exposure levels and evaluate the effectiveness of safety measures. This may include air sampling, surface wipe testing, and periodic health assessments for personnel working with nanoparticles.

Documentation and record-keeping are essential aspects of safety protocols. Maintaining detailed logs of nanoparticle handling activities, equipment maintenance, and any incidents or near-misses helps identify potential areas for improvement and ensures compliance with regulatory requirements.

By implementing these comprehensive safety protocols, researchers can minimize the risks associated with nanoparticle handling in vacuum pump-based dispersion techniques, ensuring a safer working environment and promoting responsible research practices in the field of nanotechnology.

Proper personal protective equipment (PPE) is essential when handling nanoparticles. This includes wearing appropriate gloves, lab coats, and safety goggles. Respiratory protection, such as N95 respirators or powered air-purifying respirators (PAPRs), may be required depending on the specific nanoparticles and dispersion processes involved.

Engineered controls play a crucial role in minimizing exposure risks. The use of fume hoods or glove boxes with high-efficiency particulate air (HEPA) filtration systems is recommended when working with nanoparticles and vacuum pumps. These containment systems help prevent the release of nanoparticles into the laboratory environment.

Regular maintenance and inspection of vacuum pumps and associated equipment are essential to ensure their proper functioning and prevent potential leaks or malfunctions that could lead to nanoparticle release. Implementing a comprehensive maintenance schedule and documenting all inspections and repairs is crucial for maintaining a safe working environment.

Proper waste management protocols must be established for handling nanoparticle-contaminated materials. This includes the use of dedicated waste containers, proper labeling, and following appropriate disposal procedures. Vacuum pump oil and other potentially contaminated liquids should be treated as hazardous waste and disposed of accordingly.

Training and education are vital components of safety protocols in nanoparticle handling. All personnel working with nanoparticles and vacuum pumps should receive comprehensive training on proper handling techniques, potential hazards, and emergency procedures. Regular refresher courses and updates on new safety guidelines should be provided to ensure ongoing compliance.

Implementing a robust spill response plan is crucial for addressing accidental releases of nanoparticles. This plan should include procedures for containment, cleanup, and decontamination, as well as guidelines for reporting incidents and seeking medical attention if necessary.

Monitoring and surveillance programs should be established to assess potential exposure levels and evaluate the effectiveness of safety measures. This may include air sampling, surface wipe testing, and periodic health assessments for personnel working with nanoparticles.

Documentation and record-keeping are essential aspects of safety protocols. Maintaining detailed logs of nanoparticle handling activities, equipment maintenance, and any incidents or near-misses helps identify potential areas for improvement and ensures compliance with regulatory requirements.

By implementing these comprehensive safety protocols, researchers can minimize the risks associated with nanoparticle handling in vacuum pump-based dispersion techniques, ensuring a safer working environment and promoting responsible research practices in the field of nanotechnology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!