The Role of Vacuum Pumps in Novel Semiconductor Metrology

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution in Semiconductor Metrology

The evolution of vacuum pumps in semiconductor metrology has been a critical factor in the advancement of the semiconductor industry. Initially, basic mechanical pumps were used to create low-pressure environments for early semiconductor manufacturing processes. As the industry progressed, the demand for higher vacuum levels and cleaner environments led to significant improvements in pump technology.

In the 1960s and 1970s, the introduction of turbomolecular pumps marked a significant milestone. These pumps could achieve much higher vacuum levels than their predecessors, enabling more precise measurements and cleaner manufacturing environments. This advancement was crucial for the development of more complex integrated circuits and the miniaturization of semiconductor devices.

The 1980s saw the emergence of dry pumps, which eliminated the need for oil in the pumping mechanism. This innovation greatly reduced contamination risks in semiconductor processes, a critical factor as device geometries continued to shrink. Dry pumps quickly became the standard in semiconductor fabrication facilities, supporting the industry's move towards sub-micron technologies.

In the 1990s and early 2000s, the focus shifted towards improving pump efficiency and reducing particle generation. Multi-stage dry pumps were developed, combining different pumping technologies to achieve optimal performance across a wide range of pressure regimes. This era also saw the integration of advanced control systems, allowing for more precise vacuum management and better process control.

The turn of the millennium brought about a new challenge: the need for ultra-high vacuum (UHV) conditions in advanced metrology techniques. This led to the development of specialized UHV pumps, capable of achieving pressures as low as 10^-12 mbar. These pumps played a crucial role in enabling cutting-edge metrology techniques such as X-ray photoelectron spectroscopy (XPS) and transmission electron microscopy (TEM) for semiconductor analysis.

Recent years have seen a focus on energy efficiency and environmental considerations. Modern vacuum pumps for semiconductor metrology are designed to consume less power while maintaining high performance. Additionally, there's been a trend towards modular pump designs, allowing for easier maintenance and upgrades, which is crucial in the fast-paced semiconductor industry.

The latest developments in vacuum pump technology for semiconductor metrology include the integration of smart features and Industry 4.0 concepts. These pumps now incorporate sensors and data analytics capabilities, enabling predictive maintenance and real-time performance optimization. This not only improves the reliability of metrology processes but also contributes to overall fab efficiency.

In the 1960s and 1970s, the introduction of turbomolecular pumps marked a significant milestone. These pumps could achieve much higher vacuum levels than their predecessors, enabling more precise measurements and cleaner manufacturing environments. This advancement was crucial for the development of more complex integrated circuits and the miniaturization of semiconductor devices.

The 1980s saw the emergence of dry pumps, which eliminated the need for oil in the pumping mechanism. This innovation greatly reduced contamination risks in semiconductor processes, a critical factor as device geometries continued to shrink. Dry pumps quickly became the standard in semiconductor fabrication facilities, supporting the industry's move towards sub-micron technologies.

In the 1990s and early 2000s, the focus shifted towards improving pump efficiency and reducing particle generation. Multi-stage dry pumps were developed, combining different pumping technologies to achieve optimal performance across a wide range of pressure regimes. This era also saw the integration of advanced control systems, allowing for more precise vacuum management and better process control.

The turn of the millennium brought about a new challenge: the need for ultra-high vacuum (UHV) conditions in advanced metrology techniques. This led to the development of specialized UHV pumps, capable of achieving pressures as low as 10^-12 mbar. These pumps played a crucial role in enabling cutting-edge metrology techniques such as X-ray photoelectron spectroscopy (XPS) and transmission electron microscopy (TEM) for semiconductor analysis.

Recent years have seen a focus on energy efficiency and environmental considerations. Modern vacuum pumps for semiconductor metrology are designed to consume less power while maintaining high performance. Additionally, there's been a trend towards modular pump designs, allowing for easier maintenance and upgrades, which is crucial in the fast-paced semiconductor industry.

The latest developments in vacuum pump technology for semiconductor metrology include the integration of smart features and Industry 4.0 concepts. These pumps now incorporate sensors and data analytics capabilities, enabling predictive maintenance and real-time performance optimization. This not only improves the reliability of metrology processes but also contributes to overall fab efficiency.

Market Demand Analysis for Advanced Metrology Solutions

The semiconductor industry's relentless pursuit of miniaturization and increased performance has driven the demand for advanced metrology solutions. As chip manufacturers push the boundaries of Moore's Law, the need for precise measurement and characterization tools has become more critical than ever. The market for advanced metrology solutions in the semiconductor sector is experiencing robust growth, fueled by the increasing complexity of chip designs and the adoption of new materials and processes.

The global semiconductor metrology and inspection equipment market is projected to expand significantly in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily driven by the transition to smaller node sizes, the introduction of 3D chip architectures, and the rising demand for quality control in semiconductor manufacturing. Advanced metrology solutions, including those incorporating vacuum pump technology, are essential for ensuring the accuracy and reliability of these cutting-edge semiconductor devices.

One of the key factors driving market demand is the increasing adoption of extreme ultraviolet (EUV) lithography in semiconductor fabrication. EUV technology requires ultra-high vacuum environments, creating a surge in demand for advanced vacuum pumps capable of maintaining the stringent pressure requirements. This has opened up new opportunities for vacuum pump manufacturers to develop specialized solutions tailored to the needs of EUV lithography systems.

Furthermore, the growing importance of process control and yield management in semiconductor manufacturing has led to increased investment in in-line metrology solutions. These systems, which often rely on vacuum technology for sample preparation and measurement accuracy, are becoming indispensable for chip manufacturers seeking to optimize their production processes and minimize defects.

The market for advanced metrology solutions is also being shaped by the emergence of new semiconductor materials and structures, such as wide-bandgap semiconductors and advanced packaging technologies. These developments require novel measurement techniques and equipment, creating opportunities for innovation in vacuum-based metrology systems.

Geographically, the Asia-Pacific region, particularly countries like Taiwan, South Korea, and China, represents the largest market for advanced semiconductor metrology solutions. This is due to the concentration of semiconductor manufacturing facilities in these countries. However, significant demand also exists in North America and Europe, driven by research and development activities and the presence of leading semiconductor equipment manufacturers.

In conclusion, the market demand for advanced metrology solutions in the semiconductor industry is robust and growing, with vacuum pump technology playing a crucial role in enabling the next generation of measurement and inspection capabilities. As the industry continues to evolve, the demand for more sophisticated and precise metrology tools is expected to intensify, presenting significant opportunities for innovation and market growth in this sector.

The global semiconductor metrology and inspection equipment market is projected to expand significantly in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily driven by the transition to smaller node sizes, the introduction of 3D chip architectures, and the rising demand for quality control in semiconductor manufacturing. Advanced metrology solutions, including those incorporating vacuum pump technology, are essential for ensuring the accuracy and reliability of these cutting-edge semiconductor devices.

One of the key factors driving market demand is the increasing adoption of extreme ultraviolet (EUV) lithography in semiconductor fabrication. EUV technology requires ultra-high vacuum environments, creating a surge in demand for advanced vacuum pumps capable of maintaining the stringent pressure requirements. This has opened up new opportunities for vacuum pump manufacturers to develop specialized solutions tailored to the needs of EUV lithography systems.

Furthermore, the growing importance of process control and yield management in semiconductor manufacturing has led to increased investment in in-line metrology solutions. These systems, which often rely on vacuum technology for sample preparation and measurement accuracy, are becoming indispensable for chip manufacturers seeking to optimize their production processes and minimize defects.

The market for advanced metrology solutions is also being shaped by the emergence of new semiconductor materials and structures, such as wide-bandgap semiconductors and advanced packaging technologies. These developments require novel measurement techniques and equipment, creating opportunities for innovation in vacuum-based metrology systems.

Geographically, the Asia-Pacific region, particularly countries like Taiwan, South Korea, and China, represents the largest market for advanced semiconductor metrology solutions. This is due to the concentration of semiconductor manufacturing facilities in these countries. However, significant demand also exists in North America and Europe, driven by research and development activities and the presence of leading semiconductor equipment manufacturers.

In conclusion, the market demand for advanced metrology solutions in the semiconductor industry is robust and growing, with vacuum pump technology playing a crucial role in enabling the next generation of measurement and inspection capabilities. As the industry continues to evolve, the demand for more sophisticated and precise metrology tools is expected to intensify, presenting significant opportunities for innovation and market growth in this sector.

Current Challenges in Vacuum-Based Semiconductor Metrology

Vacuum-based semiconductor metrology faces several significant challenges in the current landscape of advanced semiconductor manufacturing. One of the primary issues is the increasing demand for higher vacuum levels as semiconductor devices continue to shrink in size. Traditional vacuum pumps struggle to achieve and maintain the ultra-high vacuum conditions required for precise measurements and analysis of nanoscale structures.

The contamination control in vacuum systems presents another major challenge. As device features become smaller, even minute particles or molecular contaminants can significantly impact measurement accuracy. Vacuum pumps must not only create high vacuum conditions but also ensure that the vacuum environment remains free from potential contaminants that could interfere with metrology processes.

Stability and repeatability of vacuum conditions pose additional difficulties. Fluctuations in vacuum levels can lead to inconsistent measurements, affecting the reliability of metrology data. Achieving and maintaining stable vacuum conditions over extended periods is crucial for accurate and reproducible results, particularly in high-volume manufacturing environments.

The integration of vacuum systems with advanced metrology tools presents its own set of challenges. As metrology equipment becomes more sophisticated, vacuum pumps must be seamlessly incorporated into complex systems without introducing vibrations or other disturbances that could compromise measurement precision. This integration requires careful design considerations and advanced control systems.

Energy efficiency and environmental concerns are also becoming increasingly important in vacuum-based semiconductor metrology. Traditional vacuum pumps often consume significant amounts of energy and may use environmentally harmful substances. Developing more energy-efficient and environmentally friendly vacuum solutions without compromising performance is a pressing challenge for the industry.

The speed of vacuum generation and recovery is another critical factor, especially in high-throughput manufacturing environments. Rapid pump-down times and quick recovery after venting are essential for maintaining productivity. However, achieving these speeds while ensuring the required vacuum quality and stability remains a significant technical hurdle.

Lastly, the cost-effectiveness of vacuum systems in semiconductor metrology is an ongoing challenge. As the complexity and performance requirements of vacuum pumps increase, so does their cost. Balancing the need for advanced vacuum technology with economic considerations is crucial for widespread adoption in the semiconductor industry.

The contamination control in vacuum systems presents another major challenge. As device features become smaller, even minute particles or molecular contaminants can significantly impact measurement accuracy. Vacuum pumps must not only create high vacuum conditions but also ensure that the vacuum environment remains free from potential contaminants that could interfere with metrology processes.

Stability and repeatability of vacuum conditions pose additional difficulties. Fluctuations in vacuum levels can lead to inconsistent measurements, affecting the reliability of metrology data. Achieving and maintaining stable vacuum conditions over extended periods is crucial for accurate and reproducible results, particularly in high-volume manufacturing environments.

The integration of vacuum systems with advanced metrology tools presents its own set of challenges. As metrology equipment becomes more sophisticated, vacuum pumps must be seamlessly incorporated into complex systems without introducing vibrations or other disturbances that could compromise measurement precision. This integration requires careful design considerations and advanced control systems.

Energy efficiency and environmental concerns are also becoming increasingly important in vacuum-based semiconductor metrology. Traditional vacuum pumps often consume significant amounts of energy and may use environmentally harmful substances. Developing more energy-efficient and environmentally friendly vacuum solutions without compromising performance is a pressing challenge for the industry.

The speed of vacuum generation and recovery is another critical factor, especially in high-throughput manufacturing environments. Rapid pump-down times and quick recovery after venting are essential for maintaining productivity. However, achieving these speeds while ensuring the required vacuum quality and stability remains a significant technical hurdle.

Lastly, the cost-effectiveness of vacuum systems in semiconductor metrology is an ongoing challenge. As the complexity and performance requirements of vacuum pumps increase, so does their cost. Balancing the need for advanced vacuum technology with economic considerations is crucial for widespread adoption in the semiconductor industry.

Existing Vacuum Pump Solutions for Metrology Applications

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, reduced power consumption, and improved vacuum levels.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.

- Integration of vacuum pumps in larger systems: Vacuum pumps have been integrated into larger systems and equipment to enhance overall functionality. This integration involves incorporating pumps into processing tools, analytical instruments, or production lines. The integrated designs often focus on compact arrangements, efficient interfaces, and optimized control systems to improve the performance of the entire apparatus.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology spans several decades, with significant advancements in pump designs and operating principles. Historical patents showcase early innovations in rotary pumps, piston pumps, and diffusion pumps. These developments laid the foundation for modern vacuum technology and continue to influence current pump designs.

- Energy-efficient and environmentally friendly vacuum pumps: Recent innovations in vacuum pump technology focus on improving energy efficiency and reducing environmental impact. These developments include the use of advanced materials, optimized motor designs, and intelligent control systems. Some pumps incorporate heat recovery mechanisms or utilize alternative working fluids to minimize energy consumption and environmental footprint.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and maintain ultra-high vacuum levels required in semiconductor fabrication. Features may include corrosion-resistant materials, contamination control mechanisms, and integration with process control systems.Expand Specific Solutions03 Energy-efficient vacuum pump systems

Energy efficiency in vacuum pump systems has been a focus of recent innovations. These developments include variable speed drives, heat recovery systems, and intelligent control algorithms. Such features allow for optimized power consumption based on demand, reducing overall energy usage and operational costs.Expand Specific Solutions04 Vacuum pump noise reduction techniques

Various methods have been implemented to reduce noise levels in vacuum pumps. These include acoustic enclosures, vibration isolation systems, and redesigned pump components to minimize noise generation. Such improvements contribute to a quieter working environment and reduced noise pollution in industrial settings.Expand Specific Solutions05 Multi-stage vacuum pump configurations

Multi-stage vacuum pump designs have been developed to achieve higher vacuum levels and improved pumping efficiency. These configurations may combine different pump types in series or parallel arrangements, allowing for optimized performance across a wide range of pressure conditions. Such designs can offer benefits in terms of ultimate vacuum, pumping speed, and flexibility in various applications.Expand Specific Solutions

Key Players in Semiconductor Metrology Equipment

The vacuum pump market for semiconductor metrology is in a mature growth phase, with a significant global market size driven by the increasing demand for advanced semiconductor devices. The technology has reached a high level of maturity, with established players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Applied Materials, Inc. leading the field. These companies offer sophisticated vacuum solutions tailored for precise semiconductor measurements. Emerging players such as Beijing NAURA Microelectronics Equipment Co., Ltd. and Maiwei Technology (Zhuhai) Co., Ltd. are also entering the market, particularly in the Asian region, indicating a competitive and innovative landscape. The industry continues to evolve with ongoing research and development efforts to meet the ever-increasing demands of semiconductor manufacturing processes.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for semiconductor metrology applications. Their latest innovation includes the iXM series of dry pumps, which utilize a unique screw mechanism to achieve high pumping speeds and ultimate pressures. These pumps incorporate intelligent control systems that optimize performance based on process requirements, resulting in improved energy efficiency and reduced maintenance needs. Edwards has also introduced the nEXT turbomolecular pump series, featuring active magnetic bearings and advanced rotor designs, which provide exceptional pumping performance for ultra-high vacuum environments required in advanced metrology tools[1][3]. The company's vacuum solutions are designed to minimize vibration and acoustic noise, critical factors in precise semiconductor measurements.

Strengths: High pumping efficiency, low vibration, and advanced control systems. Weaknesses: Higher initial cost compared to conventional pumps, may require specialized maintenance.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed integrated vacuum solutions for their semiconductor metrology equipment, focusing on in-situ and in-line measurement techniques. Their E-Beam Review and Inspection systems utilize specialized vacuum environments to enable high-resolution imaging and analysis of semiconductor structures. The company's PROVision® system incorporates advanced vacuum technology to facilitate 3D profile measurements of complex semiconductor features. Applied Materials has also introduced the UVision® 7 system, which uses vacuum ultraviolet light for defect inspection, requiring precise vacuum control to maintain optimal measurement conditions. These systems often employ custom-designed vacuum chambers and pumping configurations to achieve the necessary pressure levels and stability for nanoscale measurements[2][5].

Strengths: Integrated solutions tailored for specific metrology applications, high-precision vacuum control. Weaknesses: Proprietary systems may limit compatibility with other equipment.

Innovative Vacuum Technologies for Precise Measurements

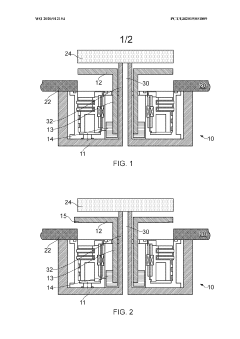

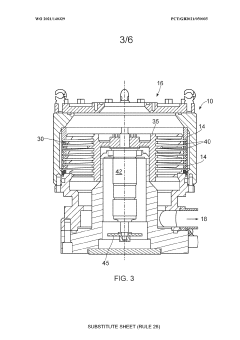

Vacuum pump with through channel and vacuum chamber

PatentWO2020012154A1

Innovation

- A vacuum pump design featuring a rotor, stator, and a controllable valve plate with an axial passage for central substrate mounting and power connections, allowing for uniform gas flow and fast pressure control, along with the option of magnetic levitation for rotor positioning and actuator-controlled axial movement of the valve plate to optimize inlet conductance.

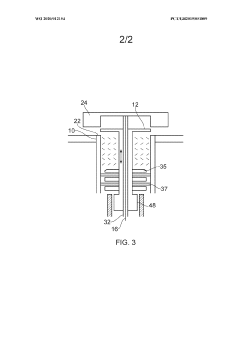

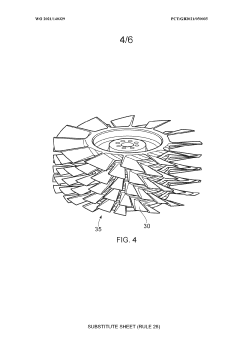

Vacuum pump, vacuum pump set for evacuating a semiconductor processing chamber and method of evacuating a semiconductor processing chamber

PatentWO2021140329A1

Innovation

- A vacuum pump with a rotor and stator design featuring angled blades on a helical path, magnetically levitated bearings, and high transparency perforated elements, allowing effective pumping between 1 mbar and 5 × 10^2 mbar, backed by a roots blower for enhanced performance across the transitional flow regime.

Environmental Impact of Vacuum Pump Technologies

The environmental impact of vacuum pump technologies in semiconductor metrology is a critical consideration as the industry strives for sustainability. Vacuum pumps, essential in creating the ultra-clean environments required for semiconductor manufacturing and metrology, consume significant energy and resources. The primary environmental concerns stem from their energy consumption, the use of potentially harmful working fluids, and the disposal of pump components at the end of their lifecycle.

Energy efficiency is a key focus in vacuum pump design for semiconductor applications. Modern pumps incorporate advanced motor technologies and intelligent control systems to optimize power consumption. Variable speed drives allow pumps to adjust their operation based on demand, reducing unnecessary energy use during idle periods. Additionally, heat recovery systems are being implemented to capture and repurpose the thermal energy generated by pump operation, further improving overall energy efficiency.

The choice of working fluids in vacuum pumps also has significant environmental implications. Traditional oil-sealed pumps, while effective, pose risks of oil contamination and require frequent oil changes, generating hazardous waste. Dry pumps, which operate without oil, have gained popularity in semiconductor metrology due to their cleaner operation and reduced environmental impact. However, these pumps often rely on perfluoropolyether (PFPE) lubricants, which have high global warming potential. Research is ongoing to develop more environmentally friendly alternatives.

Waste management is another crucial aspect of vacuum pump environmental impact. The semiconductor industry's stringent cleanliness requirements often necessitate frequent pump maintenance and replacement. This generates substantial electronic and mechanical waste, including components that may contain hazardous materials. Manufacturers are increasingly focusing on designing pumps with longer lifespans and using materials that are easier to recycle or dispose of safely.

Water consumption is an often-overlooked environmental factor in vacuum pump operation. Many pump cooling systems rely on water, contributing to the semiconductor industry's significant water footprint. Efforts are being made to develop air-cooled systems and closed-loop cooling technologies to reduce water usage without compromising pump performance.

As the semiconductor industry continues to advance, the demand for more precise metrology tools increases, potentially leading to even more sophisticated vacuum pump technologies. This evolution presents both challenges and opportunities for environmental sustainability. Future developments in vacuum pump technology for semiconductor metrology are likely to focus on further improving energy efficiency, developing eco-friendly working fluids, enhancing recyclability, and minimizing resource consumption throughout the pump's lifecycle.

Energy efficiency is a key focus in vacuum pump design for semiconductor applications. Modern pumps incorporate advanced motor technologies and intelligent control systems to optimize power consumption. Variable speed drives allow pumps to adjust their operation based on demand, reducing unnecessary energy use during idle periods. Additionally, heat recovery systems are being implemented to capture and repurpose the thermal energy generated by pump operation, further improving overall energy efficiency.

The choice of working fluids in vacuum pumps also has significant environmental implications. Traditional oil-sealed pumps, while effective, pose risks of oil contamination and require frequent oil changes, generating hazardous waste. Dry pumps, which operate without oil, have gained popularity in semiconductor metrology due to their cleaner operation and reduced environmental impact. However, these pumps often rely on perfluoropolyether (PFPE) lubricants, which have high global warming potential. Research is ongoing to develop more environmentally friendly alternatives.

Waste management is another crucial aspect of vacuum pump environmental impact. The semiconductor industry's stringent cleanliness requirements often necessitate frequent pump maintenance and replacement. This generates substantial electronic and mechanical waste, including components that may contain hazardous materials. Manufacturers are increasingly focusing on designing pumps with longer lifespans and using materials that are easier to recycle or dispose of safely.

Water consumption is an often-overlooked environmental factor in vacuum pump operation. Many pump cooling systems rely on water, contributing to the semiconductor industry's significant water footprint. Efforts are being made to develop air-cooled systems and closed-loop cooling technologies to reduce water usage without compromising pump performance.

As the semiconductor industry continues to advance, the demand for more precise metrology tools increases, potentially leading to even more sophisticated vacuum pump technologies. This evolution presents both challenges and opportunities for environmental sustainability. Future developments in vacuum pump technology for semiconductor metrology are likely to focus on further improving energy efficiency, developing eco-friendly working fluids, enhancing recyclability, and minimizing resource consumption throughout the pump's lifecycle.

Integration with Industry 4.0 and Smart Manufacturing

The integration of vacuum pumps in novel semiconductor metrology with Industry 4.0 and smart manufacturing principles is revolutionizing the semiconductor industry. This convergence is driving enhanced efficiency, productivity, and quality control in semiconductor fabrication processes. Advanced vacuum pumps are now being equipped with smart sensors and IoT connectivity, enabling real-time monitoring and data collection. This integration allows for predictive maintenance, reducing downtime and optimizing performance.

Smart manufacturing systems utilize the data gathered from vacuum pumps to make informed decisions about process parameters and equipment health. Machine learning algorithms analyze this data to identify patterns and anomalies, facilitating proactive interventions and continuous improvement. The integration also enables remote monitoring and control of vacuum systems, allowing for centralized management of multiple fabrication facilities.

Industry 4.0 concepts such as digital twins are being applied to vacuum pump systems in semiconductor metrology. These virtual replicas of physical pump systems enable simulation and optimization of performance under various conditions, leading to improved design and operation. Additionally, the integration of vacuum pumps with broader smart manufacturing ecosystems allows for seamless coordination with other process equipment, enhancing overall production efficiency.

The adoption of Industry 4.0 principles in vacuum pump technology is driving advancements in energy efficiency. Smart systems can optimize pump operation based on real-time demand, reducing energy consumption and environmental impact. This aligns with the semiconductor industry's growing focus on sustainability and green manufacturing practices.

Furthermore, the integration of vacuum pumps with smart manufacturing systems is enhancing traceability and quality control in semiconductor metrology. Detailed data on vacuum conditions during critical measurement processes can be correlated with product quality metrics, enabling more precise control and optimization of manufacturing parameters. This level of integration and data utilization is crucial for meeting the increasingly stringent requirements of advanced semiconductor technologies.

As the semiconductor industry continues to push the boundaries of miniaturization and complexity, the role of vacuum pumps in metrology becomes even more critical. The integration with Industry 4.0 and smart manufacturing principles ensures that vacuum systems can keep pace with these advancements, providing the precision and reliability needed for next-generation semiconductor devices. This convergence is not only improving current processes but also paving the way for future innovations in semiconductor manufacturing and metrology techniques.

Smart manufacturing systems utilize the data gathered from vacuum pumps to make informed decisions about process parameters and equipment health. Machine learning algorithms analyze this data to identify patterns and anomalies, facilitating proactive interventions and continuous improvement. The integration also enables remote monitoring and control of vacuum systems, allowing for centralized management of multiple fabrication facilities.

Industry 4.0 concepts such as digital twins are being applied to vacuum pump systems in semiconductor metrology. These virtual replicas of physical pump systems enable simulation and optimization of performance under various conditions, leading to improved design and operation. Additionally, the integration of vacuum pumps with broader smart manufacturing ecosystems allows for seamless coordination with other process equipment, enhancing overall production efficiency.

The adoption of Industry 4.0 principles in vacuum pump technology is driving advancements in energy efficiency. Smart systems can optimize pump operation based on real-time demand, reducing energy consumption and environmental impact. This aligns with the semiconductor industry's growing focus on sustainability and green manufacturing practices.

Furthermore, the integration of vacuum pumps with smart manufacturing systems is enhancing traceability and quality control in semiconductor metrology. Detailed data on vacuum conditions during critical measurement processes can be correlated with product quality metrics, enabling more precise control and optimization of manufacturing parameters. This level of integration and data utilization is crucial for meeting the increasingly stringent requirements of advanced semiconductor technologies.

As the semiconductor industry continues to push the boundaries of miniaturization and complexity, the role of vacuum pumps in metrology becomes even more critical. The integration with Industry 4.0 and smart manufacturing principles ensures that vacuum systems can keep pace with these advancements, providing the precision and reliability needed for next-generation semiconductor devices. This convergence is not only improving current processes but also paving the way for future innovations in semiconductor manufacturing and metrology techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!