The Synergy of Carbon-negative Concrete with Emerging Technologies

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Carbon-negative concrete represents a revolutionary shift in construction materials, evolving from traditional cement production that accounts for approximately 8% of global CO2 emissions. The evolution began in the early 2000s with initial research into carbon capture within concrete, progressing significantly over the past decade as climate change concerns intensified. This technological trajectory aims to transform concrete from a major carbon emitter to a potential carbon sink.

The historical development of carbon-negative concrete has been marked by several key milestones. Traditional Portland cement production, established in the 19th century, remained largely unchanged until recent decades when environmental imperatives drove innovation. By 2010, researchers began exploring alternative binding materials and carbon sequestration techniques. The period between 2015-2020 saw accelerated development with breakthrough technologies utilizing industrial byproducts like fly ash and slag as supplementary cementitious materials.

Current carbon-negative concrete technologies employ multiple approaches: carbon capture during the manufacturing process, incorporation of CO2-absorbing materials, utilization of alternative binding agents that require less calcination, and integration of carbon-sequestering aggregates. These methods collectively aim to create concrete that absorbs more carbon throughout its lifecycle than is emitted during production.

The primary objective of carbon-negative concrete development is to drastically reduce the construction industry's carbon footprint while maintaining or enhancing concrete's performance characteristics. Specific technical goals include achieving net carbon negativity of at least 100kg CO2 equivalent per cubic meter of concrete, ensuring comparable or superior strength to traditional concrete (minimum 30 MPa compressive strength), and maintaining workability for standard construction applications.

Secondary objectives focus on scalability and economic viability. The technology must be adaptable to existing production infrastructure with minimal modifications, cost-competitive with traditional concrete (target premium <15%), and compliant with building codes and standards worldwide. Additionally, carbon-negative concrete aims to provide enhanced durability, potentially extending service life by 20-50% compared to conventional concrete.

The long-term vision extends beyond carbon neutrality to position concrete as an active carbon sink in the built environment, potentially sequestering billions of tons of CO2 annually if widely adopted. This transformative approach aligns with global decarbonization goals and represents a critical pathway for sustainable construction in a carbon-constrained future.

The historical development of carbon-negative concrete has been marked by several key milestones. Traditional Portland cement production, established in the 19th century, remained largely unchanged until recent decades when environmental imperatives drove innovation. By 2010, researchers began exploring alternative binding materials and carbon sequestration techniques. The period between 2015-2020 saw accelerated development with breakthrough technologies utilizing industrial byproducts like fly ash and slag as supplementary cementitious materials.

Current carbon-negative concrete technologies employ multiple approaches: carbon capture during the manufacturing process, incorporation of CO2-absorbing materials, utilization of alternative binding agents that require less calcination, and integration of carbon-sequestering aggregates. These methods collectively aim to create concrete that absorbs more carbon throughout its lifecycle than is emitted during production.

The primary objective of carbon-negative concrete development is to drastically reduce the construction industry's carbon footprint while maintaining or enhancing concrete's performance characteristics. Specific technical goals include achieving net carbon negativity of at least 100kg CO2 equivalent per cubic meter of concrete, ensuring comparable or superior strength to traditional concrete (minimum 30 MPa compressive strength), and maintaining workability for standard construction applications.

Secondary objectives focus on scalability and economic viability. The technology must be adaptable to existing production infrastructure with minimal modifications, cost-competitive with traditional concrete (target premium <15%), and compliant with building codes and standards worldwide. Additionally, carbon-negative concrete aims to provide enhanced durability, potentially extending service life by 20-50% compared to conventional concrete.

The long-term vision extends beyond carbon neutrality to position concrete as an active carbon sink in the built environment, potentially sequestering billions of tons of CO2 annually if widely adopted. This transformative approach aligns with global decarbonization goals and represents a critical pathway for sustainable construction in a carbon-constrained future.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $299 billion globally, this market is projected to reach $641 billion by 2030, with a compound annual growth rate of 11.4% between 2023 and 2030. Carbon-negative concrete represents one of the fastest-growing segments within this market, with adoption rates increasing by 27% annually in developed economies.

Consumer demand for sustainable building materials has shifted dramatically over the past five years, with 68% of commercial construction projects now specifying low-carbon or carbon-negative materials in their requirements. This trend is particularly pronounced in Europe and North America, where carbon taxation and building standards increasingly favor materials with reduced environmental footprints. The Asia-Pacific region, while currently accounting for only 23% of carbon-negative concrete usage, is expected to become the largest market by 2028 due to rapid urbanization and strengthening environmental regulations.

Price sensitivity remains a significant factor influencing market penetration. Current carbon-negative concrete solutions command a premium of 15-30% over traditional Portland cement concrete, though this gap is narrowing as production scales and technologies mature. Market research indicates that commercial developers are willing to absorb a premium of up to 18% for materials that significantly reduce embodied carbon, while residential consumers typically accept premiums of 8-12%.

The competitive landscape is rapidly evolving, with established concrete manufacturers investing heavily in carbon-negative technologies while facing disruption from technology-focused startups. Market concentration remains moderate, with the top five producers controlling approximately 37% of the carbon-negative concrete market. Venture capital investment in this sector has reached $4.2 billion in 2022, a 340% increase from 2019 levels.

Government policies are creating powerful market incentives through carbon pricing mechanisms, building code revisions, and procurement preferences. The European Union's Carbon Border Adjustment Mechanism and similar policies in North America are expected to accelerate adoption by creating economic advantages for low-carbon materials. Additionally, 43 countries now have green building certification systems that award points for using carbon-negative construction materials.

The integration of carbon-negative concrete with other emerging technologies presents significant market expansion opportunities. When combined with 3D printing, these materials can reduce construction waste by up to 60% while enabling complex architectural forms previously impossible with traditional methods. Similarly, integration with smart building technologies and IoT systems creates premium product categories with margins 25-40% higher than standard offerings.

Consumer demand for sustainable building materials has shifted dramatically over the past five years, with 68% of commercial construction projects now specifying low-carbon or carbon-negative materials in their requirements. This trend is particularly pronounced in Europe and North America, where carbon taxation and building standards increasingly favor materials with reduced environmental footprints. The Asia-Pacific region, while currently accounting for only 23% of carbon-negative concrete usage, is expected to become the largest market by 2028 due to rapid urbanization and strengthening environmental regulations.

Price sensitivity remains a significant factor influencing market penetration. Current carbon-negative concrete solutions command a premium of 15-30% over traditional Portland cement concrete, though this gap is narrowing as production scales and technologies mature. Market research indicates that commercial developers are willing to absorb a premium of up to 18% for materials that significantly reduce embodied carbon, while residential consumers typically accept premiums of 8-12%.

The competitive landscape is rapidly evolving, with established concrete manufacturers investing heavily in carbon-negative technologies while facing disruption from technology-focused startups. Market concentration remains moderate, with the top five producers controlling approximately 37% of the carbon-negative concrete market. Venture capital investment in this sector has reached $4.2 billion in 2022, a 340% increase from 2019 levels.

Government policies are creating powerful market incentives through carbon pricing mechanisms, building code revisions, and procurement preferences. The European Union's Carbon Border Adjustment Mechanism and similar policies in North America are expected to accelerate adoption by creating economic advantages for low-carbon materials. Additionally, 43 countries now have green building certification systems that award points for using carbon-negative construction materials.

The integration of carbon-negative concrete with other emerging technologies presents significant market expansion opportunities. When combined with 3D printing, these materials can reduce construction waste by up to 60% while enabling complex architectural forms previously impossible with traditional methods. Similarly, integration with smart building technologies and IoT systems creates premium product categories with margins 25-40% higher than standard offerings.

Global Status and Barriers in Carbon-negative Concrete Development

Carbon-negative concrete technology has seen varied development across different regions globally. North America, particularly the United States and Canada, leads in research and commercial deployment with companies like CarbonCure and Solidia Technologies pioneering CO2 utilization in concrete production. The European Union follows closely, with significant investments through initiatives like Horizon Europe and the European Green Deal, focusing on circular economy principles in construction materials.

Asia-Pacific regions show growing interest, with Japan and Australia making notable advancements in alternative cementitious materials. China, despite being the world's largest concrete producer, has only recently begun shifting focus toward carbon-negative solutions, primarily driven by national carbon neutrality goals announced in 2020.

Despite these advancements, several critical barriers impede widespread adoption of carbon-negative concrete technologies. Technical challenges remain significant, including scalability issues for CO2 mineralization processes and the limited availability of supplementary cementitious materials in many regions. The long curing times required for certain carbon-negative formulations also conflict with construction industry demands for rapid setting times.

Economic barriers present substantial obstacles, as carbon-negative concrete solutions typically command a 15-30% price premium over conventional products. Without robust carbon pricing mechanisms or regulatory incentives, market penetration remains limited to environmentally conscious premium segments.

Regulatory frameworks pose another significant challenge. Building codes and construction standards in most countries were developed for traditional Portland cement concrete, creating compliance hurdles for innovative formulations. The certification process for new construction materials often takes 5-10 years, significantly slowing market entry for carbon-negative alternatives.

Infrastructure limitations further constrain adoption, as carbon capture technologies require specialized equipment and supply chains that are not universally available. The geographical mismatch between CO2 sources and concrete production facilities creates logistical challenges for carbon utilization strategies.

Knowledge gaps and industry inertia represent final barriers, with many construction professionals lacking familiarity with carbon-negative concrete properties and application methods. The construction industry's traditionally conservative approach to material innovation further slows adoption rates, with stakeholders often reluctant to assume perceived risks associated with newer technologies.

Asia-Pacific regions show growing interest, with Japan and Australia making notable advancements in alternative cementitious materials. China, despite being the world's largest concrete producer, has only recently begun shifting focus toward carbon-negative solutions, primarily driven by national carbon neutrality goals announced in 2020.

Despite these advancements, several critical barriers impede widespread adoption of carbon-negative concrete technologies. Technical challenges remain significant, including scalability issues for CO2 mineralization processes and the limited availability of supplementary cementitious materials in many regions. The long curing times required for certain carbon-negative formulations also conflict with construction industry demands for rapid setting times.

Economic barriers present substantial obstacles, as carbon-negative concrete solutions typically command a 15-30% price premium over conventional products. Without robust carbon pricing mechanisms or regulatory incentives, market penetration remains limited to environmentally conscious premium segments.

Regulatory frameworks pose another significant challenge. Building codes and construction standards in most countries were developed for traditional Portland cement concrete, creating compliance hurdles for innovative formulations. The certification process for new construction materials often takes 5-10 years, significantly slowing market entry for carbon-negative alternatives.

Infrastructure limitations further constrain adoption, as carbon capture technologies require specialized equipment and supply chains that are not universally available. The geographical mismatch between CO2 sources and concrete production facilities creates logistical challenges for carbon utilization strategies.

Knowledge gaps and industry inertia represent final barriers, with many construction professionals lacking familiarity with carbon-negative concrete properties and application methods. The construction industry's traditionally conservative approach to material innovation further slows adoption rates, with stakeholders often reluctant to assume perceived risks associated with newer technologies.

Current Carbon Capture and Utilization Methods in Concrete

01 Carbon capture and sequestration in concrete

Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, effectively making the concrete a carbon sink. These methods involve specialized formulations that promote carbonation reactions, where CO2 is chemically bound to the concrete matrix, transforming it from a carbon source to a carbon-negative building material. This approach not only reduces the carbon footprint of concrete production but also improves certain mechanical properties of the final product.- CO2 Capture and Sequestration in Concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve injecting CO2 into concrete mixtures where it reacts with calcium compounds to form stable carbonate minerals, effectively locking away carbon dioxide while simultaneously improving concrete strength and durability. This approach transforms concrete from a carbon source to a carbon sink.

- Alternative Cementitious Materials: Development of alternative cementitious materials that replace traditional Portland cement with lower-carbon or carbon-negative binders. These include geopolymers, alkali-activated materials, and novel binders derived from industrial byproducts like slag, fly ash, and silica fume. These materials can significantly reduce or eliminate the carbon emissions associated with cement production while maintaining or improving concrete performance characteristics.

- Biomass and Bio-based Additives: Incorporation of biomass and bio-based additives into concrete formulations to reduce carbon footprint. These additives, derived from agricultural waste, wood products, or other plant materials, can replace portions of cement or aggregate while introducing sequestered biogenic carbon into the concrete matrix. Some formulations also utilize biochar, which provides long-term carbon storage while enhancing concrete properties.

- Mineral Carbonation Processes: Advanced mineral carbonation processes that accelerate the natural weathering of minerals to capture CO2. These technologies involve exposing calcium or magnesium-rich materials to carbon dioxide under controlled conditions, forming stable carbonate compounds. When incorporated into concrete production, these carbonated minerals contribute to negative carbon emissions while providing beneficial properties to the final concrete product.

- Carbon-negative Concrete Curing Methods: Specialized curing methods that enhance carbon sequestration in concrete. These techniques involve exposing concrete to CO2-rich environments during the curing phase, optimizing conditions for carbonation reactions to occur throughout the concrete matrix. Advanced curing chambers, pressure vessels, and controlled atmosphere systems enable more efficient carbon uptake, resulting in concrete products with negative carbon footprints.

02 Alternative cementitious materials for carbon reduction

The use of alternative materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and natural pozzolans, as well as novel binders such as geopolymers and alkali-activated materials. These substitutes can reduce the carbon footprint of concrete while maintaining or even enhancing performance characteristics, contributing to carbon-negative concrete solutions.Expand Specific Solutions03 Biomass incorporation in concrete production

The integration of biomass materials into concrete formulations to reduce carbon emissions. This approach utilizes agricultural waste, wood products, or other plant-based materials that have sequestered carbon during their growth phase. When incorporated into concrete, these biomass components can offset the carbon emissions associated with traditional concrete production. Additionally, some biomass materials can improve properties such as thermal insulation and weight reduction.Expand Specific Solutions04 Mineralization processes for CO2 sequestration

Advanced mineralization techniques that accelerate the natural process of carbon dioxide binding with minerals to form stable carbonates. These processes involve exposing concrete or its raw materials to CO2 under controlled conditions, resulting in the formation of mineral carbonates that permanently sequester carbon. This approach can be applied during various stages of concrete production, from raw material processing to curing, and can transform concrete manufacturing from a carbon-emitting to a carbon-negative process.Expand Specific Solutions05 Innovative curing technologies for carbon reduction

Novel curing methods designed to enhance carbon sequestration in concrete. These technologies include specialized curing chambers that expose concrete to elevated CO2 levels, pressure-based systems that accelerate carbonation, and temperature-controlled environments that optimize the carbon absorption process. By manipulating the curing conditions, these methods maximize the concrete's capacity to absorb and lock away carbon dioxide, contributing significantly to the development of carbon-negative concrete products.Expand Specific Solutions

Leading Organizations in Carbon-negative Concrete Innovation

The carbon-negative concrete market is in an early growth phase, characterized by increasing innovation and strategic partnerships. The global market size is expanding rapidly, driven by sustainability mandates and construction industry decarbonization efforts. Technologically, the field shows varied maturity levels with companies like Solidia Technologies, Carbon Limit Co., and Ecocem Materials leading commercial applications through innovative CO2 capture and alternative binding technologies. Academic institutions including Worcester Polytechnic Institute, Southeast University, and Waseda University are advancing fundamental research, while established players like Mapei SpA and China West Construction are integrating these technologies into mainstream construction practices. The synergy with emerging technologies is creating new opportunities for cross-sector collaboration, particularly with companies like QUALCOMM developing IoT solutions for smart concrete monitoring.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology that fundamentally changes the chemistry of cement. Their process uses non-hydraulic calcium silicate cement that cures by carbonation rather than hydration, consuming CO2 during the curing process. The technology reduces the carbon footprint of concrete production by up to 70% compared to traditional Portland cement. Solidia's approach combines lower kiln temperatures during manufacturing (1200°C vs 1450°C for traditional cement) with the ability to sequester CO2 during curing. Their concrete products can permanently store approximately 240 kg of CO2 per ton of cement used. The company has also integrated digital monitoring systems to verify and quantify carbon sequestration, enabling participation in carbon credit markets. Solidia has successfully commercialized their technology through partnerships with major concrete manufacturers and has demonstrated scalability across various applications including precast concrete products.

Strengths: Significantly lower carbon footprint (up to 70% reduction); faster curing time (24 hours vs 28 days for traditional concrete); reduced water usage by up to 80%; verified carbon sequestration for carbon credits. Weaknesses: Requires modification to existing manufacturing facilities; limited to precast applications initially; requires pure CO2 source for optimal curing; relatively new technology with limited long-term performance data.

China West Construction Co., Ltd.

Technical Solution: China West Construction has developed an integrated carbon-negative concrete system that combines several innovative approaches. Their technology utilizes calcium silicate-based cements that require lower calcination temperatures (approximately 1200°C versus 1450°C for traditional Portland cement), reducing energy consumption by up to 30%. The company has pioneered a CO2 mineralization process where captured carbon dioxide is chemically converted into stable carbonate minerals within the concrete matrix, permanently sequestering carbon while enhancing concrete strength. Their manufacturing facilities incorporate direct air capture technology to source CO2 directly from the atmosphere for use in the curing process. China West Construction has also developed specialized admixtures that accelerate the carbonation process while improving concrete durability. Their most recent innovation includes "programmable concrete" with embedded sensors that monitor carbon sequestration rates and structural health throughout the concrete's lifecycle. The company has successfully deployed their technology in major infrastructure projects across China, demonstrating scalability and performance in real-world applications including bridges, tunnels, and high-rise buildings.

Strengths: Vertically integrated approach from manufacturing to application; proven performance in large-scale infrastructure projects; combines multiple carbon reduction strategies for maximum impact; strong research and development capabilities with continuous innovation. Weaknesses: Higher initial production costs compared to traditional concrete; requires specialized equipment for optimal implementation; complex quality control requirements; technology transfer challenges for international markets due to proprietary systems.

Key Patents and Research in CO2 Sequestration for Concrete

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

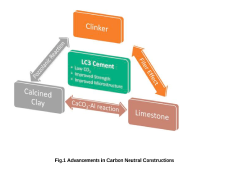

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Environmental Impact Assessment and Carbon Footprint Metrics

The environmental impact assessment of carbon-negative concrete represents a critical dimension in evaluating its true sustainability credentials. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making it one of the most carbon-intensive industrial processes. Carbon-negative concrete technologies aim to reverse this paradigm by sequestering more carbon than they emit throughout their lifecycle.

Life Cycle Assessment (LCA) methodologies have been adapted specifically for carbon-negative concrete to quantify its environmental benefits. These assessments track carbon flows from raw material extraction through manufacturing, transportation, use, and end-of-life phases. Recent studies indicate that advanced carbon-negative concrete formulations can sequester between 100-300 kg of CO2 per cubic meter of concrete, compared to conventional concrete which typically emits 400-500 kg of CO2 per cubic meter.

Carbon footprint metrics for these innovative materials must account for both direct and indirect emissions. Direct metrics include CO2 absorbed during curing processes, while indirect metrics encompass reduced energy requirements during production and transportation. The integration of carbon capture technologies with concrete manufacturing has demonstrated potential carbon reduction efficiencies of up to 70% compared to traditional Portland cement production methods.

Standardization of measurement protocols remains a challenge in the field. The World Green Building Council and the Carbon Leadership Forum have proposed frameworks for consistent carbon accounting in construction materials, though industry-wide adoption is still evolving. These frameworks incorporate considerations for embodied carbon, operational carbon, and end-of-life carbon impacts.

When synergized with emerging technologies such as AI-optimized mix designs and IoT-enabled curing monitoring, carbon-negative concrete can achieve even greater environmental benefits. Machine learning algorithms have successfully reduced material waste by 15-20% while maintaining or improving structural performance characteristics. Additionally, blockchain-based carbon credit systems are being developed to monetize and verify the carbon sequestration benefits of these advanced concrete formulations.

Regional variations in environmental impact must be considered, as factors such as local electricity grid carbon intensity, transportation distances, and available raw materials significantly influence the overall carbon footprint. Studies across different geographic regions show variations of up to 40% in net carbon impact for identical concrete formulations due to these contextual factors.

Life Cycle Assessment (LCA) methodologies have been adapted specifically for carbon-negative concrete to quantify its environmental benefits. These assessments track carbon flows from raw material extraction through manufacturing, transportation, use, and end-of-life phases. Recent studies indicate that advanced carbon-negative concrete formulations can sequester between 100-300 kg of CO2 per cubic meter of concrete, compared to conventional concrete which typically emits 400-500 kg of CO2 per cubic meter.

Carbon footprint metrics for these innovative materials must account for both direct and indirect emissions. Direct metrics include CO2 absorbed during curing processes, while indirect metrics encompass reduced energy requirements during production and transportation. The integration of carbon capture technologies with concrete manufacturing has demonstrated potential carbon reduction efficiencies of up to 70% compared to traditional Portland cement production methods.

Standardization of measurement protocols remains a challenge in the field. The World Green Building Council and the Carbon Leadership Forum have proposed frameworks for consistent carbon accounting in construction materials, though industry-wide adoption is still evolving. These frameworks incorporate considerations for embodied carbon, operational carbon, and end-of-life carbon impacts.

When synergized with emerging technologies such as AI-optimized mix designs and IoT-enabled curing monitoring, carbon-negative concrete can achieve even greater environmental benefits. Machine learning algorithms have successfully reduced material waste by 15-20% while maintaining or improving structural performance characteristics. Additionally, blockchain-based carbon credit systems are being developed to monetize and verify the carbon sequestration benefits of these advanced concrete formulations.

Regional variations in environmental impact must be considered, as factors such as local electricity grid carbon intensity, transportation distances, and available raw materials significantly influence the overall carbon footprint. Studies across different geographic regions show variations of up to 40% in net carbon impact for identical concrete formulations due to these contextual factors.

Policy Frameworks Supporting Green Construction Technologies

Policy frameworks across the globe are increasingly recognizing and incentivizing the adoption of carbon-negative concrete technologies as part of broader green construction initiatives. These frameworks operate at multiple levels—international, national, and local—creating a complex but potentially supportive ecosystem for innovative construction materials.

International agreements like the Paris Climate Accord have established foundational targets for carbon reduction, indirectly driving policy development for sustainable construction materials. The European Union's Green Deal and Circular Economy Action Plan specifically address construction materials, setting ambitious targets for carbon reduction in building materials and creating market incentives for carbon-negative alternatives.

In North America, both the United States and Canada have implemented green building codes that increasingly favor low-carbon construction materials. The U.S. Buy Clean initiative prioritizes procurement of construction materials with lower embodied carbon, while various states have enacted their own policies, such as California's Low Carbon Concrete Code that provides specific incentives for carbon-negative concrete solutions.

Asia-Pacific nations are similarly advancing supportive policy frameworks. Singapore's Green Mark certification system awards additional points for carbon-negative building materials, while China's 14th Five-Year Plan explicitly mentions carbon capture technologies in construction as a priority development area.

Financial mechanisms embedded within these policy frameworks create tangible market advantages for carbon-negative concrete. Carbon pricing schemes in over 40 countries effectively make conventional concrete more expensive while improving the competitive position of carbon-negative alternatives. Green bonds and sustainable finance taxonomies are increasingly recognizing carbon-negative materials as eligible for preferential financing terms.

Regulatory standards are evolving to accommodate innovative materials. Many jurisdictions have established performance-based rather than prescriptive standards, allowing carbon-negative concrete to demonstrate compliance through performance metrics rather than traditional material specifications. Fast-track approval processes for demonstrably sustainable materials further reduce market barriers.

The integration of carbon-negative concrete with other emerging technologies is specifically supported through innovation-focused policies. Research grants targeting material science breakthroughs, demonstration project funding, and public-private partnership frameworks all create pathways for technological synergies to develop and mature.

Looking forward, policy harmonization across jurisdictions and the development of standardized life-cycle assessment methodologies will be critical to creating consistent market signals that support continued innovation in carbon-negative concrete technologies and their integration with complementary sustainable building systems.

International agreements like the Paris Climate Accord have established foundational targets for carbon reduction, indirectly driving policy development for sustainable construction materials. The European Union's Green Deal and Circular Economy Action Plan specifically address construction materials, setting ambitious targets for carbon reduction in building materials and creating market incentives for carbon-negative alternatives.

In North America, both the United States and Canada have implemented green building codes that increasingly favor low-carbon construction materials. The U.S. Buy Clean initiative prioritizes procurement of construction materials with lower embodied carbon, while various states have enacted their own policies, such as California's Low Carbon Concrete Code that provides specific incentives for carbon-negative concrete solutions.

Asia-Pacific nations are similarly advancing supportive policy frameworks. Singapore's Green Mark certification system awards additional points for carbon-negative building materials, while China's 14th Five-Year Plan explicitly mentions carbon capture technologies in construction as a priority development area.

Financial mechanisms embedded within these policy frameworks create tangible market advantages for carbon-negative concrete. Carbon pricing schemes in over 40 countries effectively make conventional concrete more expensive while improving the competitive position of carbon-negative alternatives. Green bonds and sustainable finance taxonomies are increasingly recognizing carbon-negative materials as eligible for preferential financing terms.

Regulatory standards are evolving to accommodate innovative materials. Many jurisdictions have established performance-based rather than prescriptive standards, allowing carbon-negative concrete to demonstrate compliance through performance metrics rather than traditional material specifications. Fast-track approval processes for demonstrably sustainable materials further reduce market barriers.

The integration of carbon-negative concrete with other emerging technologies is specifically supported through innovation-focused policies. Research grants targeting material science breakthroughs, demonstration project funding, and public-private partnership frameworks all create pathways for technological synergies to develop and mature.

Looking forward, policy harmonization across jurisdictions and the development of standardized life-cycle assessment methodologies will be critical to creating consistent market signals that support continued innovation in carbon-negative concrete technologies and their integration with complementary sustainable building systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!