Thermoelectric Generators In High-Altitude Aviation Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Aviation Background & Objectives

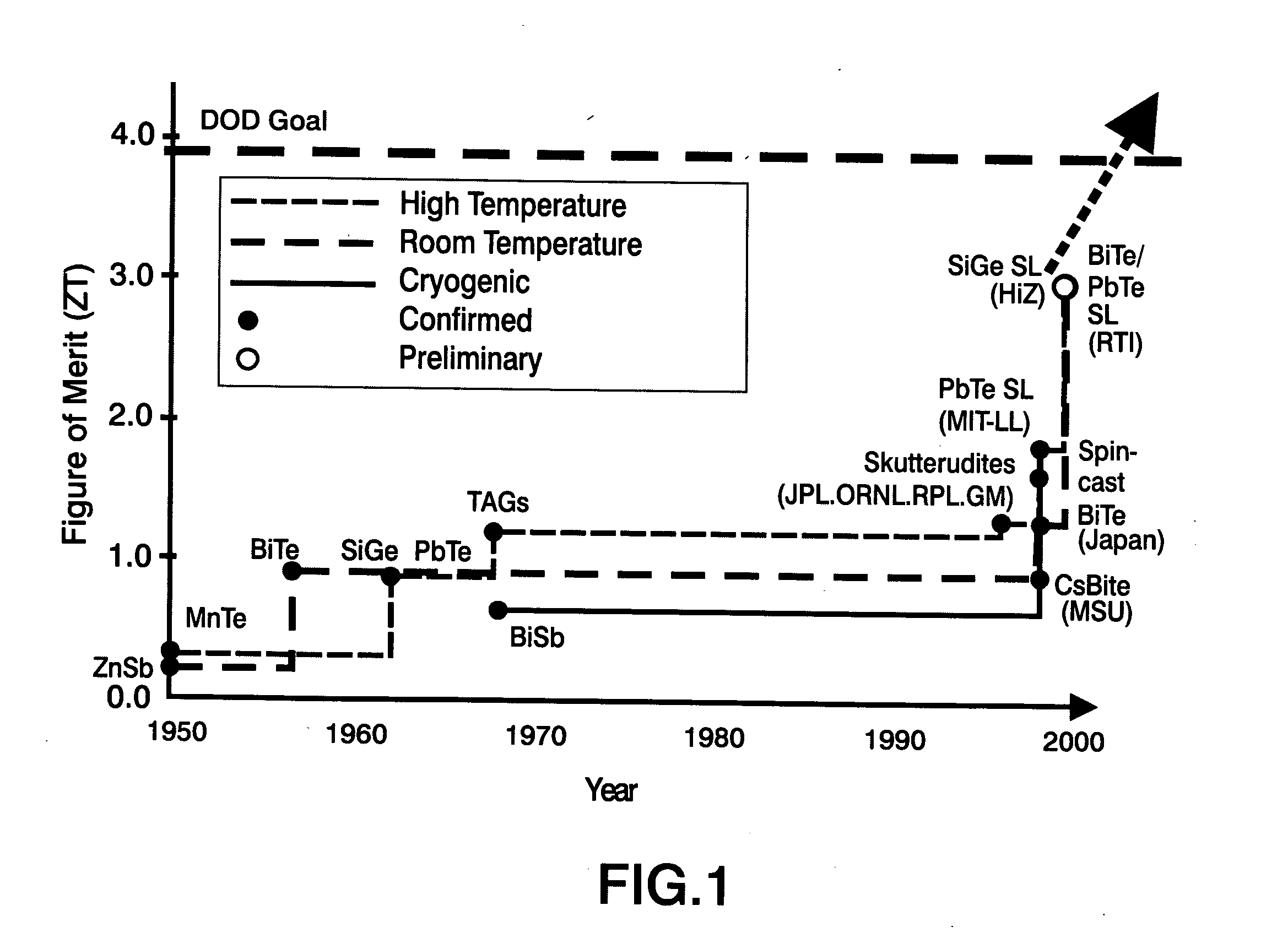

Thermoelectric Generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect. These solid-state devices, which convert temperature differentials directly into electrical energy, have found applications across various industries, including space exploration, automotive, and increasingly, aviation. The aviation sector's interest in TEGs has grown substantially over the past decade, driven by the industry's push toward more efficient, sustainable, and reliable power generation systems.

In high-altitude aviation environments, where temperature differentials between the aircraft's exterior surfaces and engine components can exceed 200°C, TEGs present a compelling opportunity for energy harvesting. Historically, aircraft have relied primarily on conventional power generation methods such as engine-driven generators and auxiliary power units (APUs), which contribute to fuel consumption and emissions. The integration of TEGs offers a pathway to capture waste heat that would otherwise be dissipated, potentially reducing the overall energy footprint of aircraft operations.

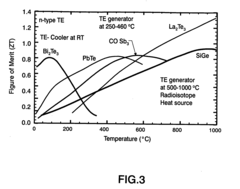

The technological evolution of TEG materials has been marked by significant advancements, moving from traditional bismuth telluride compounds to more sophisticated materials such as skutterudites, half-Heusler alloys, and silicon-germanium alloys. These newer materials demonstrate improved efficiency and performance at the high-temperature differentials characteristic of aviation applications, with some laboratory prototypes achieving conversion efficiencies approaching 10-12% under optimal conditions.

The primary technical objectives for TEG implementation in high-altitude aviation systems include enhancing energy conversion efficiency, reducing weight penalties, ensuring durability under extreme operational conditions, and achieving cost-effectiveness for widespread adoption. Current research focuses on developing TEG systems capable of withstanding the harsh vibration, pressure, and temperature cycling environments inherent to aviation while maintaining stable performance over thousands of flight hours.

Industry projections suggest that successful integration of TEGs into aviation systems could potentially recover 1-3% of otherwise wasted energy, translating to significant fuel savings across global fleets. Additionally, TEGs could provide supplementary power for critical avionics systems, enhancing redundancy and safety in high-altitude operations where traditional power systems may be strained.

Looking forward, the technological trajectory for aviation TEGs is oriented toward multi-material systems that optimize performance across varying temperature ranges, flexible form factors that can conform to complex aircraft geometries, and hybrid systems that combine TEGs with other energy harvesting technologies to maximize overall efficiency. These developments align with broader industry initiatives toward electrification and sustainable aviation practices.

In high-altitude aviation environments, where temperature differentials between the aircraft's exterior surfaces and engine components can exceed 200°C, TEGs present a compelling opportunity for energy harvesting. Historically, aircraft have relied primarily on conventional power generation methods such as engine-driven generators and auxiliary power units (APUs), which contribute to fuel consumption and emissions. The integration of TEGs offers a pathway to capture waste heat that would otherwise be dissipated, potentially reducing the overall energy footprint of aircraft operations.

The technological evolution of TEG materials has been marked by significant advancements, moving from traditional bismuth telluride compounds to more sophisticated materials such as skutterudites, half-Heusler alloys, and silicon-germanium alloys. These newer materials demonstrate improved efficiency and performance at the high-temperature differentials characteristic of aviation applications, with some laboratory prototypes achieving conversion efficiencies approaching 10-12% under optimal conditions.

The primary technical objectives for TEG implementation in high-altitude aviation systems include enhancing energy conversion efficiency, reducing weight penalties, ensuring durability under extreme operational conditions, and achieving cost-effectiveness for widespread adoption. Current research focuses on developing TEG systems capable of withstanding the harsh vibration, pressure, and temperature cycling environments inherent to aviation while maintaining stable performance over thousands of flight hours.

Industry projections suggest that successful integration of TEGs into aviation systems could potentially recover 1-3% of otherwise wasted energy, translating to significant fuel savings across global fleets. Additionally, TEGs could provide supplementary power for critical avionics systems, enhancing redundancy and safety in high-altitude operations where traditional power systems may be strained.

Looking forward, the technological trajectory for aviation TEGs is oriented toward multi-material systems that optimize performance across varying temperature ranges, flexible form factors that can conform to complex aircraft geometries, and hybrid systems that combine TEGs with other energy harvesting technologies to maximize overall efficiency. These developments align with broader industry initiatives toward electrification and sustainable aviation practices.

Market Demand Analysis for Aviation TEGs

The aviation industry's interest in Thermoelectric Generators (TEGs) has been steadily growing, driven by the increasing demand for more efficient and sustainable power generation solutions in high-altitude environments. Market research indicates that the global aviation TEG market is projected to grow significantly over the next decade, with a compound annual growth rate exceeding 8% through 2030.

This growth is primarily fueled by the aviation industry's push toward more electric aircraft (MEA) architectures, where traditional pneumatic and hydraulic systems are being replaced by electrical systems. High-altitude aviation presents unique thermal gradients that can be effectively harnessed by TEGs, creating an attractive opportunity for supplementary power generation without additional fuel consumption.

Commercial airlines represent the largest market segment for aviation TEGs, as they seek technologies that can reduce operational costs and meet increasingly stringent environmental regulations. The potential fuel savings from TEG implementation in long-haul aircraft could translate to millions of dollars annually per fleet, creating a compelling economic case for adoption.

Military aviation constitutes another significant market segment, where TEGs offer advantages beyond fuel efficiency. The ability to generate power silently and with minimal maintenance makes TEGs particularly valuable for reconnaissance and surveillance aircraft operating at high altitudes. Defense departments globally have allocated substantial research funding toward TEG integration in next-generation aircraft designs.

Market demand is further bolstered by the unmanned aerial vehicle (UAV) sector, where power generation and management remain critical challenges for extended high-altitude operations. TEGs could potentially extend mission durations by 15-30% for certain high-altitude long-endurance (HALE) platforms, representing a significant operational advantage.

Regional analysis reveals that North America currently dominates the aviation TEG market, followed by Europe and Asia-Pacific. However, the fastest growth is anticipated in emerging aviation markets across Asia, where rapid expansion of commercial fleets and increasing defense budgets are creating new opportunities for advanced power generation technologies.

Customer requirements analysis shows that aviation stakeholders prioritize reliability, weight efficiency, and integration compatibility when evaluating TEG solutions. The market currently favors TEG systems that can achieve power densities above 1 W/cm² while maintaining specific power ratings exceeding 100 W/kg, thresholds that represent significant technical challenges for current TEG technologies.

Despite positive growth indicators, market penetration faces headwinds from the aviation industry's traditionally long certification cycles and conservative approach to adopting new technologies. The path to widespread implementation will likely require demonstration programs and strategic partnerships between TEG manufacturers and established aerospace system integrators.

This growth is primarily fueled by the aviation industry's push toward more electric aircraft (MEA) architectures, where traditional pneumatic and hydraulic systems are being replaced by electrical systems. High-altitude aviation presents unique thermal gradients that can be effectively harnessed by TEGs, creating an attractive opportunity for supplementary power generation without additional fuel consumption.

Commercial airlines represent the largest market segment for aviation TEGs, as they seek technologies that can reduce operational costs and meet increasingly stringent environmental regulations. The potential fuel savings from TEG implementation in long-haul aircraft could translate to millions of dollars annually per fleet, creating a compelling economic case for adoption.

Military aviation constitutes another significant market segment, where TEGs offer advantages beyond fuel efficiency. The ability to generate power silently and with minimal maintenance makes TEGs particularly valuable for reconnaissance and surveillance aircraft operating at high altitudes. Defense departments globally have allocated substantial research funding toward TEG integration in next-generation aircraft designs.

Market demand is further bolstered by the unmanned aerial vehicle (UAV) sector, where power generation and management remain critical challenges for extended high-altitude operations. TEGs could potentially extend mission durations by 15-30% for certain high-altitude long-endurance (HALE) platforms, representing a significant operational advantage.

Regional analysis reveals that North America currently dominates the aviation TEG market, followed by Europe and Asia-Pacific. However, the fastest growth is anticipated in emerging aviation markets across Asia, where rapid expansion of commercial fleets and increasing defense budgets are creating new opportunities for advanced power generation technologies.

Customer requirements analysis shows that aviation stakeholders prioritize reliability, weight efficiency, and integration compatibility when evaluating TEG solutions. The market currently favors TEG systems that can achieve power densities above 1 W/cm² while maintaining specific power ratings exceeding 100 W/kg, thresholds that represent significant technical challenges for current TEG technologies.

Despite positive growth indicators, market penetration faces headwinds from the aviation industry's traditionally long certification cycles and conservative approach to adopting new technologies. The path to widespread implementation will likely require demonstration programs and strategic partnerships between TEG manufacturers and established aerospace system integrators.

Current TEG Technology Challenges in Aviation

The integration of Thermoelectric Generators (TEGs) into high-altitude aviation systems faces significant technical challenges despite their promising potential. One primary obstacle is the low conversion efficiency of current TEG materials, typically ranging between 5-8% in aviation applications. This efficiency limitation becomes particularly problematic in weight-sensitive aircraft systems where power-to-weight ratios are critical performance metrics. The harsh operating conditions at high altitudes further exacerbate these challenges, with temperature differentials fluctuating dramatically during flight cycles.

Material durability presents another substantial hurdle. TEG components must withstand extreme temperature variations, from -60°C at cruising altitudes to potentially over 200°C near engine components. These thermal cycling conditions accelerate material degradation, reducing operational lifespan and reliability. Additionally, the vibration and mechanical stress inherent in aviation environments can compromise the structural integrity of thermoelectric junctions and interconnects, leading to performance deterioration over time.

Integration complexity with existing aircraft systems poses significant engineering challenges. TEGs require careful thermal management to maintain optimal temperature differentials while avoiding interference with critical aircraft systems. The limited installation space in aircraft further constrains design options, often necessitating custom configurations that increase manufacturing complexity and costs.

Power management and conditioning represent another technical barrier. The electrical output from TEGs varies with temperature differentials, requiring sophisticated power electronics to deliver stable power to aircraft systems. These additional components add weight and complexity, potentially offsetting the benefits gained from the TEG implementation.

Regulatory compliance and certification present non-technical but equally significant challenges. Aviation safety standards demand extensive testing and validation of new technologies, particularly those affecting power systems. The certification process for TEG integration can be lengthy and costly, deterring rapid adoption despite technical merits.

Manufacturing scalability remains problematic for aviation-grade TEGs. Current production methods for high-performance thermoelectric materials often involve complex processes that are difficult to scale economically. The precision required for aviation applications further increases manufacturing costs, making widespread implementation financially challenging for aircraft manufacturers.

Lastly, the lack of standardized testing protocols specifically for aviation TEG applications complicates performance comparison and validation across different systems and manufacturers. This absence of industry standards hinders technology maturation and slows the development of optimized solutions for specific aviation use cases.

Material durability presents another substantial hurdle. TEG components must withstand extreme temperature variations, from -60°C at cruising altitudes to potentially over 200°C near engine components. These thermal cycling conditions accelerate material degradation, reducing operational lifespan and reliability. Additionally, the vibration and mechanical stress inherent in aviation environments can compromise the structural integrity of thermoelectric junctions and interconnects, leading to performance deterioration over time.

Integration complexity with existing aircraft systems poses significant engineering challenges. TEGs require careful thermal management to maintain optimal temperature differentials while avoiding interference with critical aircraft systems. The limited installation space in aircraft further constrains design options, often necessitating custom configurations that increase manufacturing complexity and costs.

Power management and conditioning represent another technical barrier. The electrical output from TEGs varies with temperature differentials, requiring sophisticated power electronics to deliver stable power to aircraft systems. These additional components add weight and complexity, potentially offsetting the benefits gained from the TEG implementation.

Regulatory compliance and certification present non-technical but equally significant challenges. Aviation safety standards demand extensive testing and validation of new technologies, particularly those affecting power systems. The certification process for TEG integration can be lengthy and costly, deterring rapid adoption despite technical merits.

Manufacturing scalability remains problematic for aviation-grade TEGs. Current production methods for high-performance thermoelectric materials often involve complex processes that are difficult to scale economically. The precision required for aviation applications further increases manufacturing costs, making widespread implementation financially challenging for aircraft manufacturers.

Lastly, the lack of standardized testing protocols specifically for aviation TEG applications complicates performance comparison and validation across different systems and manufacturers. This absence of industry standards hinders technology maturation and slows the development of optimized solutions for specific aviation use cases.

Current TEG Implementation Solutions

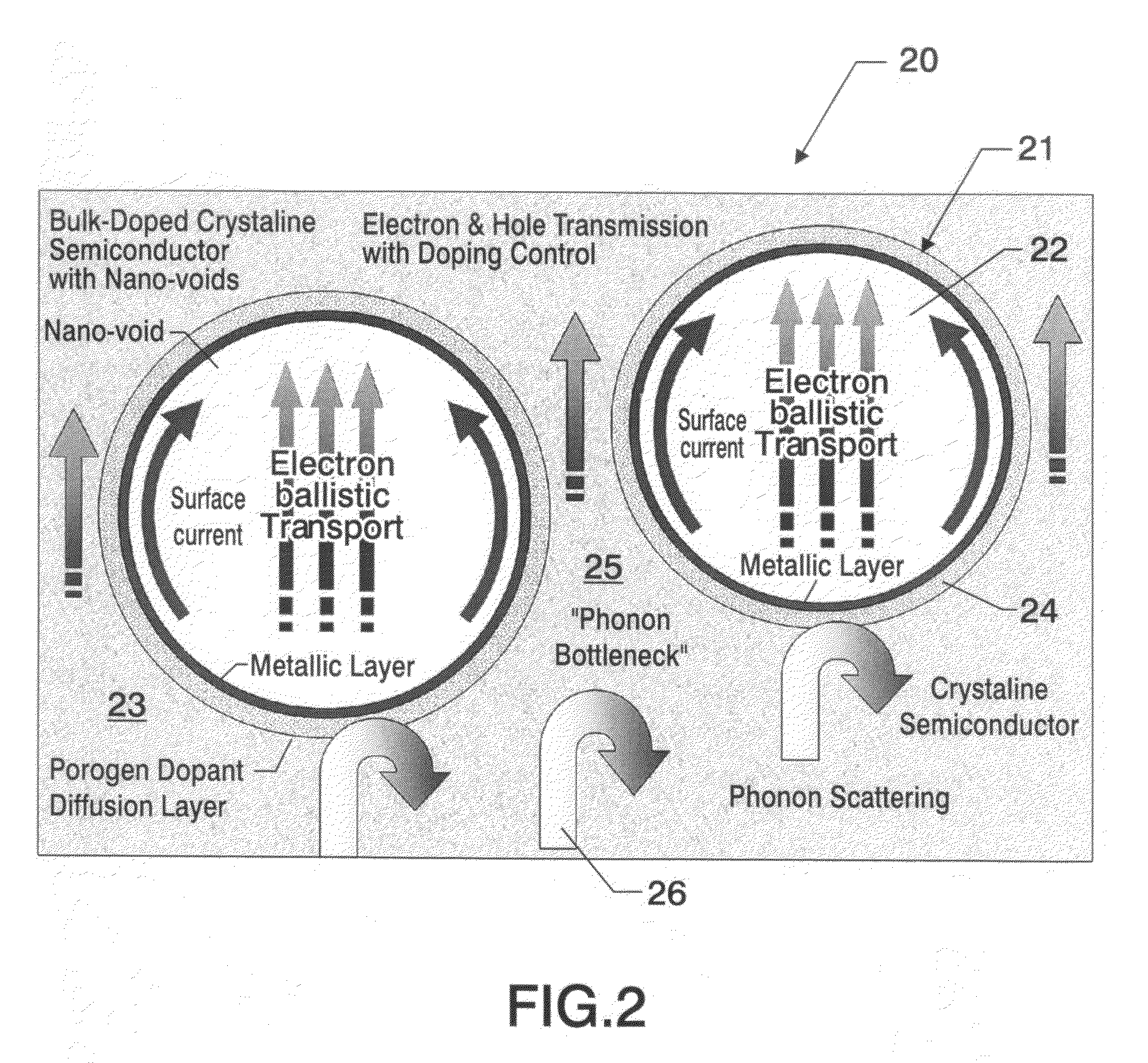

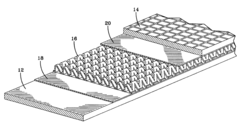

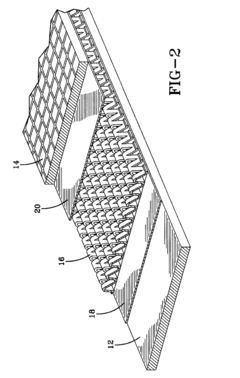

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to improve energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel junction configurations that enhance the Seebeck effect. Advanced material compositions and structural arrangements help maximize the temperature differential across the device, leading to improved power generation capabilities.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel junction configurations that improve the Seebeck effect. Advanced material compositions and structural arrangements help optimize the temperature gradient across the device, resulting in more efficient conversion of heat into electrical energy.

- Waste heat recovery applications: Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Implementation strategies include integration with exhaust systems, industrial processes, and power generation facilities, providing supplementary power while improving overall energy efficiency of the primary systems.

- Portable and wearable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for portable and wearable applications, utilizing body heat or environmental temperature differences. These compact devices can power small electronics, medical devices, and IoT sensors without requiring battery replacement. Design considerations focus on flexibility, comfort, and maximizing power output from relatively small temperature differentials available in wearable contexts.

- Modeling and simulation of thermoelectric systems: Advanced computational methods are used to model and simulate thermoelectric generator performance under various operating conditions. These approaches include finite element analysis, multiphysics simulations, and predictive algorithms that help optimize design parameters before physical prototyping. Simulation tools enable researchers to predict efficiency, power output, and thermal management requirements for different generator configurations and operating environments.

- Historical and fundamental thermoelectric technologies: Fundamental thermoelectric technologies establish the core principles and early implementations of thermoelectric generators. These include basic semiconductor junction designs, classical thermocouple arrangements, and foundational materials research that established the viability of direct heat-to-electricity conversion. Historical developments in this field have led to the modern understanding of thermoelectric effects and continue to inform contemporary research directions.

02 Waste heat recovery applications

Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. The technology is particularly valuable in manufacturing processes, vehicle exhaust systems, and power plants where significant heat is generated as a byproduct of primary operations.Expand Specific Solutions03 Portable and wearable thermoelectric power generation

Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices harvest body heat or environmental temperature differentials to power small electronics, medical devices, and sensors. The technology enables self-powered wearable systems that eliminate the need for battery replacement in remote monitoring applications and personal electronic devices.Expand Specific Solutions04 Efficiency enhancement techniques

Various methods are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded architectures, thermal concentration techniques, and improved electrical contact methods. Advanced manufacturing processes and novel geometrical configurations help reduce thermal and electrical resistance, leading to higher power output and conversion efficiency.Expand Specific Solutions05 Modeling and simulation of thermoelectric systems

Computational modeling and simulation tools are essential for designing and optimizing thermoelectric generators. These approaches enable prediction of performance under various operating conditions, material selection optimization, and system-level integration analysis. Advanced algorithms account for thermal management, electrical load matching, and transient behavior to maximize power output and reliability in real-world applications.Expand Specific Solutions

Key Industry Players in Aviation TEGs

The thermoelectric generator market in high-altitude aviation systems is in an early growth phase, with increasing interest due to energy efficiency demands. Market size remains modest but is expanding as aerospace companies seek sustainable power solutions. Technologically, the field shows moderate maturity with established players like Boeing, Lockheed Martin, and Rolls-Royce leading commercial development, while research institutions such as Nanjing University of Aeronautics & Astronautics and University of Washington drive innovation. Airbus, Safran, and NASA are advancing integration capabilities, focusing on weight reduction and efficiency improvements. The competitive landscape features strategic partnerships between aerospace manufacturers and specialized technology providers, with emerging companies like Atomos Nuclear & Space bringing disruptive approaches to this niche but promising application area.

The Boeing Co.

Technical Solution: Boeing has developed advanced thermoelectric generator (TEG) systems specifically designed for high-altitude aviation applications. Their technology harvests waste heat from aircraft engines and converts it into usable electrical power through the Seebeck effect. Boeing's TEGs utilize bismuth telluride and lead telluride semiconductor materials optimized for the temperature differentials experienced at cruising altitudes (30,000-40,000 feet). The company has integrated these generators into their latest aircraft models to supplement the primary electrical systems, reducing fuel consumption by approximately 1.5-2% by decreasing the load on engine-driven generators. Boeing's TEG systems are designed with a modular architecture that allows for easy maintenance and replacement, with each module capable of producing 50-100W of power depending on flight conditions and heat availability.

Strengths: Highly optimized for commercial aviation applications with proven fuel savings; modular design allows for scalability and easy maintenance. Weaknesses: Performance still limited by the inherently low conversion efficiency of thermoelectric materials (typically 5-8%); system adds weight which partially offsets fuel savings benefits.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has pioneered high-performance thermoelectric generators for military and reconnaissance aircraft operating at extreme altitudes. Their proprietary TEG technology utilizes advanced skutterudite and half-Heusler alloys that maintain efficiency at the severe temperature gradients encountered in stratospheric flight (above 50,000 feet). These materials achieve conversion efficiencies approaching 12% in operational conditions, significantly higher than conventional TEGs. Lockheed's system integrates directly with aircraft thermal management systems, capturing waste heat from both propulsion and avionics cooling systems. The company has implemented these TEGs in their high-altitude reconnaissance platforms, where they provide supplementary power for critical sensor systems and reduce the infrared signature of the aircraft by efficiently removing waste heat. The generators are designed to withstand extreme environmental conditions including rapid temperature changes and low atmospheric pressure.

Strengths: Superior performance at extreme altitudes; dual-purpose design that both generates power and assists with thermal management; reduced infrared signature provides tactical advantages for military applications. Weaknesses: Higher manufacturing costs due to specialized materials; requires more complex integration with aircraft systems; primarily optimized for specialized military rather than commercial applications.

Core TEG Patents & Technical Literature

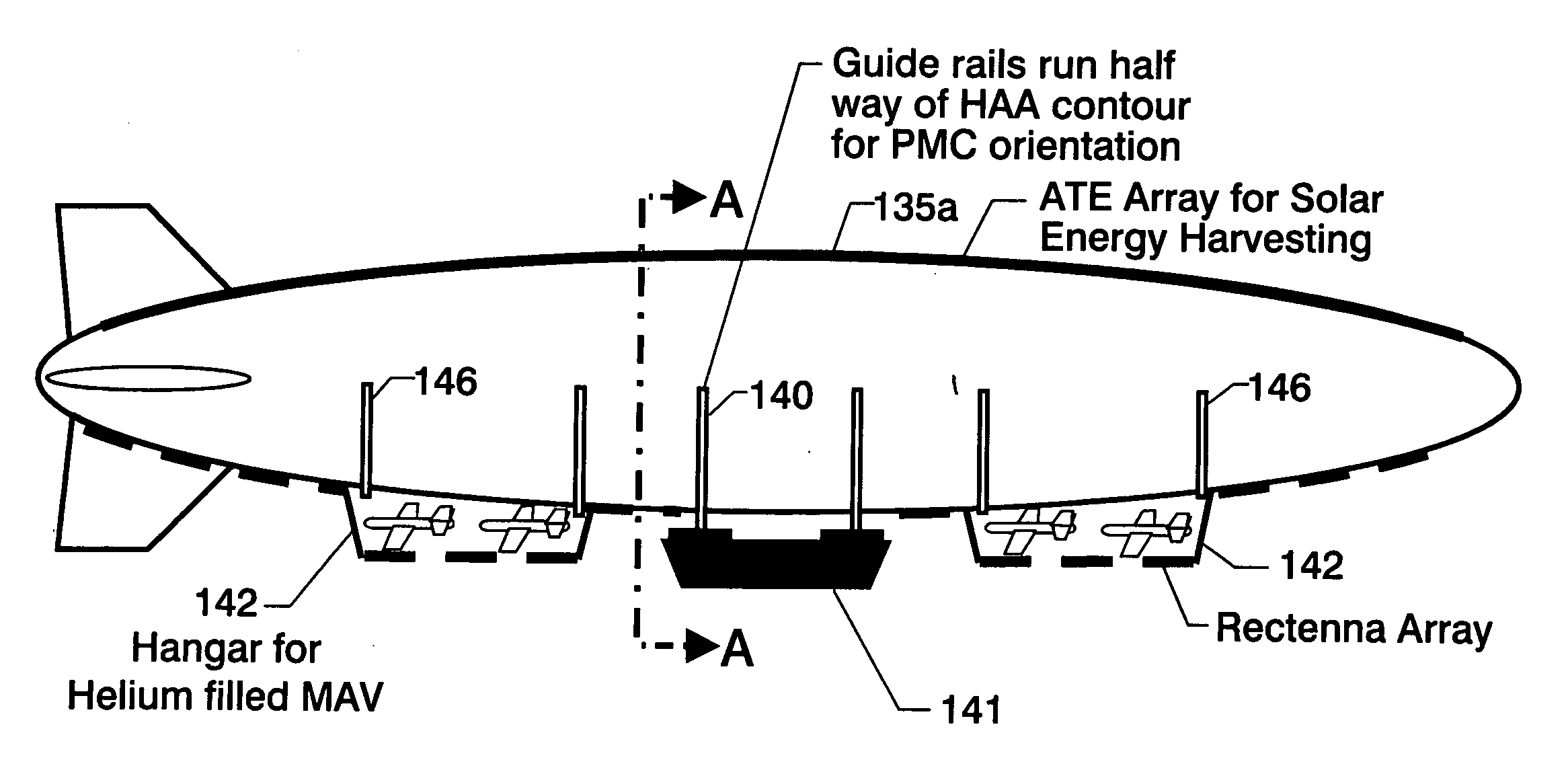

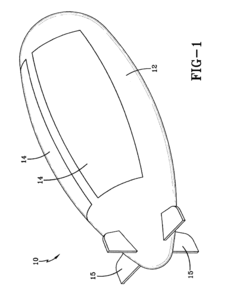

High Altitude Airship Configuration And Power Technology And Method For Operation Of Same

PatentInactiveUS20090072078A1

Innovation

- An advanced thermoelectric energy conversion system with multiple thermoelectric layers, each optimized for specific temperature ranges, utilizing nanovoid-imbedded materials like bismuth telluride and silicon-germanium to enhance electrical conductivity while reducing thermal conductivity, allowing for efficient solar energy harvesting and storage.

Thermocouple array for generating electrical power for lighter than air vehicles

PatentInactiveUS20090217962A1

Innovation

- A thermoelectric apparatus integrated into lighter-than-air vehicles, featuring a gas impervious outer fabric with photovoltaic cells and a thermocouple array that generates electricity from the temperature difference between the photovoltaic cells and the helium lifting gas, allowing for continuous power generation day and night.

High-Altitude Environmental Considerations

The extreme conditions present at high altitudes pose significant challenges for thermoelectric generator (TEG) implementation in aviation systems. At cruising altitudes of 30,000-40,000 feet, ambient temperatures can plummet to -60°C (-76°F), creating substantial thermal stress on TEG materials and components. These extreme temperature differentials, while potentially beneficial for thermoelectric conversion, require specialized material selection to prevent thermal fatigue and maintain structural integrity over thousands of flight cycles.

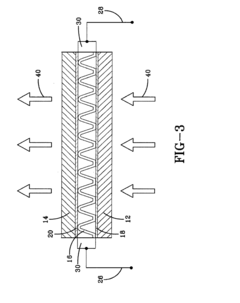

Atmospheric pressure at high altitudes drops to approximately 20% of sea-level values, affecting heat transfer mechanisms critical to TEG operation. The reduced air density diminishes convective cooling efficiency, necessitating alternative heat dissipation strategies for the cold side of thermoelectric modules. This pressure differential also impacts the mechanical design of TEG housings and seals, requiring robust engineering solutions to prevent pressure-related failures.

Radiation exposure presents another significant environmental consideration. At high altitudes, cosmic radiation intensity increases substantially, potentially degrading semiconductor materials commonly used in thermoelectric devices. Long-term exposure may alter doping profiles and carrier concentrations, gradually reducing conversion efficiency. TEG systems for high-altitude applications must incorporate radiation-hardened components or shielding strategies to maintain performance over the operational lifespan of aircraft systems.

Humidity variations between ground-level maintenance and high-altitude operation create condensation and icing risks. Moisture ingress followed by freezing can damage thermoelectric junctions and electrical connections. Effective moisture barriers and condensation management systems must be integrated into TEG designs to prevent water-related degradation mechanisms.

Vibration and mechanical stress profiles in aviation environments further complicate TEG implementation. Aircraft experience complex vibration patterns during takeoff, turbulence, and landing. These mechanical stresses can compromise thermoelectric module integrity, particularly at material interfaces and electrical connections. Vibration isolation systems and flexible mounting solutions must be developed to protect sensitive thermoelectric components while maintaining thermal contact with heat sources.

The combination of these environmental factors necessitates comprehensive testing protocols that simulate the multifaceted conditions of high-altitude operation. Accelerated life testing under combined stressors (temperature cycling, pressure variation, vibration, and radiation exposure) is essential to validate TEG reliability for aviation applications.

Atmospheric pressure at high altitudes drops to approximately 20% of sea-level values, affecting heat transfer mechanisms critical to TEG operation. The reduced air density diminishes convective cooling efficiency, necessitating alternative heat dissipation strategies for the cold side of thermoelectric modules. This pressure differential also impacts the mechanical design of TEG housings and seals, requiring robust engineering solutions to prevent pressure-related failures.

Radiation exposure presents another significant environmental consideration. At high altitudes, cosmic radiation intensity increases substantially, potentially degrading semiconductor materials commonly used in thermoelectric devices. Long-term exposure may alter doping profiles and carrier concentrations, gradually reducing conversion efficiency. TEG systems for high-altitude applications must incorporate radiation-hardened components or shielding strategies to maintain performance over the operational lifespan of aircraft systems.

Humidity variations between ground-level maintenance and high-altitude operation create condensation and icing risks. Moisture ingress followed by freezing can damage thermoelectric junctions and electrical connections. Effective moisture barriers and condensation management systems must be integrated into TEG designs to prevent water-related degradation mechanisms.

Vibration and mechanical stress profiles in aviation environments further complicate TEG implementation. Aircraft experience complex vibration patterns during takeoff, turbulence, and landing. These mechanical stresses can compromise thermoelectric module integrity, particularly at material interfaces and electrical connections. Vibration isolation systems and flexible mounting solutions must be developed to protect sensitive thermoelectric components while maintaining thermal contact with heat sources.

The combination of these environmental factors necessitates comprehensive testing protocols that simulate the multifaceted conditions of high-altitude operation. Accelerated life testing under combined stressors (temperature cycling, pressure variation, vibration, and radiation exposure) is essential to validate TEG reliability for aviation applications.

Energy Efficiency & Weight Optimization

The integration of Thermoelectric Generators (TEGs) in high-altitude aviation systems presents significant challenges and opportunities in energy efficiency and weight optimization. Current TEG implementations face a critical trade-off between power generation capacity and weight considerations, with conventional systems adding approximately 2.5-3.5 kg per kilowatt of generation capacity. This weight penalty directly impacts aircraft fuel consumption, with estimates suggesting each additional kilogram requires approximately 0.03-0.05 kg of extra fuel per flight hour at cruising altitude.

Recent advancements in materials science have yielded promising developments in lightweight thermoelectric materials. Bismuth telluride (Bi₂Te₃) alloys enhanced with nanoscale structures have demonstrated 15-20% improvements in power-to-weight ratios compared to traditional formulations. More experimental materials incorporating graphene and carbon nanotubes have shown potential for up to 35% weight reduction while maintaining comparable energy conversion efficiencies in laboratory settings.

Thermal management systems represent another critical aspect of TEG optimization. The temperature differential between the hot and cold sides of thermoelectric modules directly influences energy conversion efficiency. Advanced heat sink designs utilizing aluminum-silicon carbide composites have reduced cooling system weight by 18-22% while improving heat dissipation by 10-15%. Implementation of microfluidic cooling channels has further enhanced thermal management efficiency in prototype systems.

Energy harvesting efficiency remains a fundamental challenge, with current aviation-grade TEGs typically operating at 5-8% conversion efficiency. Theoretical models suggest that optimized systems could potentially achieve 12-15% efficiency through improved material interfaces and reduced thermal resistance. Each percentage point improvement in efficiency translates to approximately 10-12% reduction in required system weight for equivalent power output.

System integration approaches have evolved toward modular designs that allow for strategic placement of TEG units throughout the aircraft. This distributed architecture optimizes weight distribution while capitalizing on various temperature differentials available in different zones of the aircraft. Computational fluid dynamics modeling indicates that strategic placement can improve overall system efficiency by 8-13% compared to centralized implementations.

Manufacturing techniques have also contributed significantly to weight optimization. Additive manufacturing processes have enabled the production of complex, lightweight support structures that reduce non-functional mass by up to 25% compared to conventionally manufactured components. These techniques allow for topology-optimized designs that maintain structural integrity while minimizing material usage in non-critical areas.

Recent advancements in materials science have yielded promising developments in lightweight thermoelectric materials. Bismuth telluride (Bi₂Te₃) alloys enhanced with nanoscale structures have demonstrated 15-20% improvements in power-to-weight ratios compared to traditional formulations. More experimental materials incorporating graphene and carbon nanotubes have shown potential for up to 35% weight reduction while maintaining comparable energy conversion efficiencies in laboratory settings.

Thermal management systems represent another critical aspect of TEG optimization. The temperature differential between the hot and cold sides of thermoelectric modules directly influences energy conversion efficiency. Advanced heat sink designs utilizing aluminum-silicon carbide composites have reduced cooling system weight by 18-22% while improving heat dissipation by 10-15%. Implementation of microfluidic cooling channels has further enhanced thermal management efficiency in prototype systems.

Energy harvesting efficiency remains a fundamental challenge, with current aviation-grade TEGs typically operating at 5-8% conversion efficiency. Theoretical models suggest that optimized systems could potentially achieve 12-15% efficiency through improved material interfaces and reduced thermal resistance. Each percentage point improvement in efficiency translates to approximately 10-12% reduction in required system weight for equivalent power output.

System integration approaches have evolved toward modular designs that allow for strategic placement of TEG units throughout the aircraft. This distributed architecture optimizes weight distribution while capitalizing on various temperature differentials available in different zones of the aircraft. Computational fluid dynamics modeling indicates that strategic placement can improve overall system efficiency by 8-13% compared to centralized implementations.

Manufacturing techniques have also contributed significantly to weight optimization. Additive manufacturing processes have enabled the production of complex, lightweight support structures that reduce non-functional mass by up to 25% compared to conventionally manufactured components. These techniques allow for topology-optimized designs that maintain structural integrity while minimizing material usage in non-critical areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!