Topology Optimization vs Finite Element Analysis: Which Improves Structural Integrity?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Analysis Evolution and Objectives

Structural analysis methodologies have undergone significant evolution over the past century, transforming from simple analytical calculations to sophisticated computational techniques. The journey began with classical mechanics approaches in the early 20th century, where engineers relied on simplified models and conservative assumptions to ensure structural integrity. The mid-century saw the emergence of matrix structural analysis methods, which laid the groundwork for modern computational approaches.

The introduction of Finite Element Analysis (FEA) in the 1960s marked a revolutionary advancement in structural engineering. This technique discretizes complex structures into smaller, manageable elements, allowing engineers to analyze stress distributions, deformations, and failure modes with unprecedented accuracy. FEA has since become the industry standard for structural verification across aerospace, automotive, civil, and mechanical engineering domains.

Topology Optimization (TO) represents the next evolutionary step, emerging in the 1980s but gaining significant traction only in the past two decades with advances in computational power. Unlike FEA, which primarily analyzes existing designs, TO generates optimal structural configurations by systematically removing material from a design space while maintaining performance requirements. This paradigm shift from "analyze and improve" to "generate optimal" has profound implications for structural design methodologies.

The convergence of these technologies aims to address several critical objectives in modern engineering. First, there is an increasing demand for lightweight structures that maintain or improve structural integrity—particularly important in transportation industries where weight directly impacts energy efficiency. Second, engineers seek to optimize material usage to reduce costs and environmental impact while ensuring safety factors are maintained. Third, there is growing pressure to accelerate design cycles while improving product performance.

Current research focuses on integrating these complementary approaches—using TO to generate innovative structural concepts and FEA to validate and refine these designs. This integration presents both opportunities and challenges, as the mathematical foundations and computational requirements differ significantly between the two methodologies.

The technical trajectory suggests a future where these approaches become more seamlessly integrated, potentially through machine learning algorithms that can predict structural performance without the computational overhead of traditional FEA. This evolution aims to enable real-time structural optimization that considers multiple physics domains simultaneously, moving beyond purely mechanical considerations to include thermal, electromagnetic, and fluid-structure interactions.

The introduction of Finite Element Analysis (FEA) in the 1960s marked a revolutionary advancement in structural engineering. This technique discretizes complex structures into smaller, manageable elements, allowing engineers to analyze stress distributions, deformations, and failure modes with unprecedented accuracy. FEA has since become the industry standard for structural verification across aerospace, automotive, civil, and mechanical engineering domains.

Topology Optimization (TO) represents the next evolutionary step, emerging in the 1980s but gaining significant traction only in the past two decades with advances in computational power. Unlike FEA, which primarily analyzes existing designs, TO generates optimal structural configurations by systematically removing material from a design space while maintaining performance requirements. This paradigm shift from "analyze and improve" to "generate optimal" has profound implications for structural design methodologies.

The convergence of these technologies aims to address several critical objectives in modern engineering. First, there is an increasing demand for lightweight structures that maintain or improve structural integrity—particularly important in transportation industries where weight directly impacts energy efficiency. Second, engineers seek to optimize material usage to reduce costs and environmental impact while ensuring safety factors are maintained. Third, there is growing pressure to accelerate design cycles while improving product performance.

Current research focuses on integrating these complementary approaches—using TO to generate innovative structural concepts and FEA to validate and refine these designs. This integration presents both opportunities and challenges, as the mathematical foundations and computational requirements differ significantly between the two methodologies.

The technical trajectory suggests a future where these approaches become more seamlessly integrated, potentially through machine learning algorithms that can predict structural performance without the computational overhead of traditional FEA. This evolution aims to enable real-time structural optimization that considers multiple physics domains simultaneously, moving beyond purely mechanical considerations to include thermal, electromagnetic, and fluid-structure interactions.

Market Applications and Industry Demand

The market for advanced structural analysis and optimization tools has experienced significant growth in recent years, driven by increasing demands for lightweight, high-performance structures across multiple industries. Topology Optimization (TO) and Finite Element Analysis (FEA) technologies have become critical enablers for companies seeking competitive advantages through improved structural integrity while reducing material usage and costs.

In the automotive sector, the push for electric vehicles has intensified the need for weight reduction while maintaining or enhancing structural performance. Major manufacturers report that topology optimization implementations have resulted in weight reductions of 20-30% in structural components while maintaining equivalent strength parameters. This market segment is projected to grow substantially as emission regulations tighten globally and manufacturers seek to extend EV range through weight optimization.

Aerospace applications represent another significant market driver, with commercial aircraft manufacturers implementing TO to redesign critical components. The aerospace industry values both technologies for different purposes: FEA for certification and validation processes, and TO for innovative design approaches that were previously unattainable through conventional methods. The combination of these technologies has enabled weight reductions that translate directly to fuel efficiency improvements and reduced operational costs.

The construction and civil engineering sectors have begun adopting these technologies more widely, particularly for complex architectural designs and infrastructure projects. Building information modeling (BIM) platforms increasingly incorporate structural optimization capabilities, expanding the market reach beyond traditional engineering firms to architectural practices and construction companies.

Medical device manufacturing represents an emerging market application, where topology optimization enables the design of patient-specific implants with optimized mechanical properties. This sector values the ability to create structures that mimic natural bone density patterns and load distribution characteristics.

Industrial equipment manufacturers have demonstrated growing interest in these technologies for optimizing components subject to complex loading conditions. The ability to reduce material while maintaining performance translates directly to cost savings in high-volume production environments.

Market analysis indicates that while FEA has reached maturity with widespread adoption across industries, topology optimization adoption is accelerating rapidly as software becomes more accessible and computational costs decrease. The integration of these technologies into cloud-based platforms has further expanded market reach to small and medium enterprises previously limited by computational infrastructure requirements.

In the automotive sector, the push for electric vehicles has intensified the need for weight reduction while maintaining or enhancing structural performance. Major manufacturers report that topology optimization implementations have resulted in weight reductions of 20-30% in structural components while maintaining equivalent strength parameters. This market segment is projected to grow substantially as emission regulations tighten globally and manufacturers seek to extend EV range through weight optimization.

Aerospace applications represent another significant market driver, with commercial aircraft manufacturers implementing TO to redesign critical components. The aerospace industry values both technologies for different purposes: FEA for certification and validation processes, and TO for innovative design approaches that were previously unattainable through conventional methods. The combination of these technologies has enabled weight reductions that translate directly to fuel efficiency improvements and reduced operational costs.

The construction and civil engineering sectors have begun adopting these technologies more widely, particularly for complex architectural designs and infrastructure projects. Building information modeling (BIM) platforms increasingly incorporate structural optimization capabilities, expanding the market reach beyond traditional engineering firms to architectural practices and construction companies.

Medical device manufacturing represents an emerging market application, where topology optimization enables the design of patient-specific implants with optimized mechanical properties. This sector values the ability to create structures that mimic natural bone density patterns and load distribution characteristics.

Industrial equipment manufacturers have demonstrated growing interest in these technologies for optimizing components subject to complex loading conditions. The ability to reduce material while maintaining performance translates directly to cost savings in high-volume production environments.

Market analysis indicates that while FEA has reached maturity with widespread adoption across industries, topology optimization adoption is accelerating rapidly as software becomes more accessible and computational costs decrease. The integration of these technologies into cloud-based platforms has further expanded market reach to small and medium enterprises previously limited by computational infrastructure requirements.

Current Methodologies and Technical Limitations

Finite Element Analysis (FEA) has been the cornerstone of structural engineering for decades, enabling engineers to simulate and analyze complex structures under various loading conditions. The methodology involves discretizing a continuous domain into finite elements, applying boundary conditions, and solving differential equations to determine stress, strain, and displacement distributions. While FEA provides detailed insights into structural behavior, it primarily serves as an analysis tool rather than a design optimization method.

Traditional FEA workflows typically involve iterative design modifications based on engineering intuition, followed by analysis to verify performance. This approach, though effective, often results in suboptimal designs that meet requirements but do not maximize structural efficiency. The process is time-consuming and heavily dependent on the engineer's experience and judgment.

Topology Optimization (TO) emerged as a computational design methodology that addresses these limitations by systematically determining the optimal material distribution within a design space. Unlike FEA, which analyzes a predefined structure, TO begins with a maximum design space and iteratively removes material from low-stress regions while maintaining structural integrity. This approach leads to organic, often lightweight structures that would be difficult to conceive through traditional design methods.

Despite their complementary nature, both methodologies face significant technical limitations. FEA accuracy depends heavily on mesh quality, element type selection, and boundary condition definitions. Complex geometries often require extremely fine meshes, leading to computational resource constraints and extended solution times. Additionally, nonlinear behaviors such as large deformations, contact mechanics, and material plasticity introduce further complexity and potential convergence issues.

Topology optimization faces its own set of challenges, particularly in manufacturing constraints. The organic, complex geometries generated by TO algorithms often include features that are difficult or impossible to manufacture using traditional methods. While additive manufacturing has alleviated some of these concerns, it introduces new considerations regarding material properties, build orientation, and support structures. Furthermore, TO results typically require significant post-processing and interpretation before they can be transformed into manufacturable designs.

Integration challenges between TO and FEA persist in current workflows. While TO utilizes FEA as its underlying solver, the transition from conceptual TO results to detailed FEA validation often requires substantial manual intervention. This disconnect can lead to performance discrepancies between the optimized concept and the final manufactured product. Additionally, most commercial TO implementations are limited to static structural problems, with multi-physics optimization remaining an active research area rather than a mature industrial capability.

Traditional FEA workflows typically involve iterative design modifications based on engineering intuition, followed by analysis to verify performance. This approach, though effective, often results in suboptimal designs that meet requirements but do not maximize structural efficiency. The process is time-consuming and heavily dependent on the engineer's experience and judgment.

Topology Optimization (TO) emerged as a computational design methodology that addresses these limitations by systematically determining the optimal material distribution within a design space. Unlike FEA, which analyzes a predefined structure, TO begins with a maximum design space and iteratively removes material from low-stress regions while maintaining structural integrity. This approach leads to organic, often lightweight structures that would be difficult to conceive through traditional design methods.

Despite their complementary nature, both methodologies face significant technical limitations. FEA accuracy depends heavily on mesh quality, element type selection, and boundary condition definitions. Complex geometries often require extremely fine meshes, leading to computational resource constraints and extended solution times. Additionally, nonlinear behaviors such as large deformations, contact mechanics, and material plasticity introduce further complexity and potential convergence issues.

Topology optimization faces its own set of challenges, particularly in manufacturing constraints. The organic, complex geometries generated by TO algorithms often include features that are difficult or impossible to manufacture using traditional methods. While additive manufacturing has alleviated some of these concerns, it introduces new considerations regarding material properties, build orientation, and support structures. Furthermore, TO results typically require significant post-processing and interpretation before they can be transformed into manufacturable designs.

Integration challenges between TO and FEA persist in current workflows. While TO utilizes FEA as its underlying solver, the transition from conceptual TO results to detailed FEA validation often requires substantial manual intervention. This disconnect can lead to performance discrepancies between the optimized concept and the final manufactured product. Additionally, most commercial TO implementations are limited to static structural problems, with multi-physics optimization remaining an active research area rather than a mature industrial capability.

Comparative Analysis of TO and FEA Approaches

01 Integration of topology optimization with finite element analysis

Topology optimization methods can be integrated with finite element analysis to design structures with optimal material distribution while maintaining structural integrity. This integration allows engineers to automatically generate designs that meet specific performance criteria such as stiffness, weight reduction, and stress constraints. The process typically involves iterative analysis where material is redistributed based on sensitivity analysis until an optimal solution is achieved.- Integration of topology optimization with finite element analysis: Topology optimization techniques can be integrated with finite element analysis to design structures with optimal material distribution. This integration allows for the creation of lightweight yet strong structures by removing unnecessary material while maintaining structural integrity. The process typically involves defining design objectives, constraints, and iteratively analyzing and optimizing the structure based on stress distribution and load paths.

- Multi-objective optimization for structural performance: Multi-objective optimization approaches can be applied to balance various structural performance criteria such as weight reduction, stress minimization, and stiffness maximization. These methods consider multiple competing objectives simultaneously to find optimal design solutions that satisfy structural integrity requirements while optimizing for factors like material usage, manufacturability, and cost-effectiveness.

- Advanced simulation techniques for structural integrity verification: Advanced simulation techniques enhance the accuracy of structural integrity assessments in topology-optimized designs. These include non-linear analysis, dynamic response simulation, fatigue analysis, and failure prediction methods. By applying these techniques, engineers can verify that topology-optimized structures will maintain their integrity under various loading conditions and throughout their intended service life.

- Manufacturing constraints in topology optimization: Incorporating manufacturing constraints into topology optimization ensures that the resulting designs are not only structurally sound but also manufacturable. These constraints may include minimum feature size, symmetry requirements, extrusion directions, and additive manufacturing considerations. By addressing manufacturing limitations during the optimization process, the gap between theoretical designs and practical implementation is reduced while maintaining structural integrity.

- Machine learning approaches for topology optimization: Machine learning techniques are increasingly being applied to enhance topology optimization processes and structural integrity assessments. These approaches can accelerate optimization by predicting structural performance without running full finite element analyses, identify patterns in successful designs, and suggest optimal configurations based on historical data. Machine learning also enables more efficient exploration of complex design spaces while ensuring structural requirements are met.

02 Multi-objective optimization for structural performance

Multi-objective optimization techniques are applied to balance competing structural requirements such as weight reduction, strength, and manufacturability. These approaches allow engineers to find Pareto-optimal solutions that represent the best trade-offs between different performance metrics. Advanced algorithms can handle multiple constraints simultaneously while ensuring the final design maintains structural integrity under various loading conditions.Expand Specific Solutions03 Simulation-driven design validation and verification

Simulation-driven approaches combine topology optimization with comprehensive verification processes to ensure structural integrity. These methods involve detailed stress analysis, fatigue assessment, and failure mode prediction to validate optimized designs before manufacturing. Virtual testing environments allow engineers to subject optimized structures to various loading scenarios, identifying potential weaknesses and refining designs accordingly.Expand Specific Solutions04 Manufacturing constraints in topology optimization

Incorporating manufacturing constraints into topology optimization ensures that structurally optimized designs remain producible. These constraints may include minimum feature size, symmetry requirements, extrusion directions, or specific manufacturing process limitations. By considering fabrication requirements during the optimization process, the resulting designs maintain structural integrity while being feasible to manufacture using conventional or additive manufacturing techniques.Expand Specific Solutions05 Machine learning approaches for structural optimization

Machine learning techniques are increasingly being applied to enhance topology optimization and structural analysis processes. These approaches can accelerate optimization by predicting structural performance without running full finite element analyses for every iteration. Neural networks and other AI methods can learn from previous optimization results to suggest improved initial designs or identify promising design spaces, while ensuring structural integrity requirements are maintained.Expand Specific Solutions

Leading Companies and Research Institutions

Topology Optimization and Finite Element Analysis are at a mature technological stage within the structural engineering field, with the market experiencing steady growth due to increasing demand for optimized design solutions. The global market size for these technologies is estimated to exceed $2 billion, driven by automotive, aerospace, and industrial applications. Leading players include ANSYS, Inc., which dominates with comprehensive simulation platforms, Siemens AG offering integrated digital twin solutions, and Dassault Systèmes with its SIMULIA suite. Academic institutions like Zhejiang University and Georgia Tech contribute significant research advancements. The competitive landscape features established engineering software providers alongside specialized firms like PLASTOMETREX, with increasing collaboration between industry and academia pushing technological boundaries in structural integrity optimization.

ANSYS, Inc.

Technical Solution: ANSYS has developed an integrated approach combining Topology Optimization (TO) and Finite Element Analysis (FEA) within their Mechanical suite. Their solution employs density-based methods where each element is assigned a density value between 0 and 1, representing void or solid material. The system iteratively removes low-stress elements while maintaining structural performance constraints. ANSYS's approach uniquely bridges the gap between conceptual design and validation by enabling seamless transitions between TO-generated concepts and detailed FEA validation. Their platform incorporates manufacturing constraints such as symmetry, extrusion directions, and minimum member size to ensure printability and manufacturability of optimized designs. Recent advancements include integration of lattice optimization capabilities allowing for variable density structures that balance weight reduction with mechanical performance requirements[1][3]. The system also incorporates multi-physics considerations, allowing simultaneous optimization for thermal, vibration, and structural loads.

Strengths: Seamless integration between TO and FEA in a single environment reduces iteration time and design cycles. Advanced manufacturing constraints ensure practical, producible designs. Weaknesses: Computationally intensive for complex models, requiring significant hardware resources. The solution quality depends heavily on proper initial constraint definition, which requires expert knowledge.

Siemens AG

Technical Solution: Siemens has pioneered a hybrid approach through their NX and Simcenter software suites that combines generative design principles with advanced FEA validation workflows. Their technology implements both SIMP (Solid Isotropic Material with Penalization) and level-set methods for topology optimization, allowing engineers to choose the most appropriate algorithm for specific applications. Siemens' solution differentiates itself through multi-disciplinary optimization capabilities that simultaneously consider structural, thermal, and fluid dynamics factors during the optimization process. The platform features adaptive meshing technology that automatically refines mesh density in critical regions during iterative optimization, improving accuracy while managing computational resources efficiently[2]. Their system incorporates machine learning algorithms that learn from previous optimization runs to suggest improved starting points and constraint definitions for new projects. Siemens also offers cloud-based computation options for handling extremely large models that exceed local computing capabilities, with built-in data security protocols for sensitive designs[4].

Strengths: Multi-disciplinary optimization capabilities provide more holistic design solutions. Advanced adaptive meshing reduces computational overhead while maintaining accuracy in critical areas. Weaknesses: Complex user interface with steep learning curve for new users. Higher licensing costs compared to some competitors, potentially limiting accessibility for smaller organizations.

Breakthrough Technologies in Structural Optimization

System for machine learning-based acceleration of a topology optimization process

PatentWO2020160099A9

Innovation

- A machine learning-based system using a fully connected deep neural network that learns from current topology optimization iterations, reducing the number of two-scale optimizations through initial training and online updates, and incorporates a two-scale topology optimization formulation with localized training to improve scalability and accuracy.

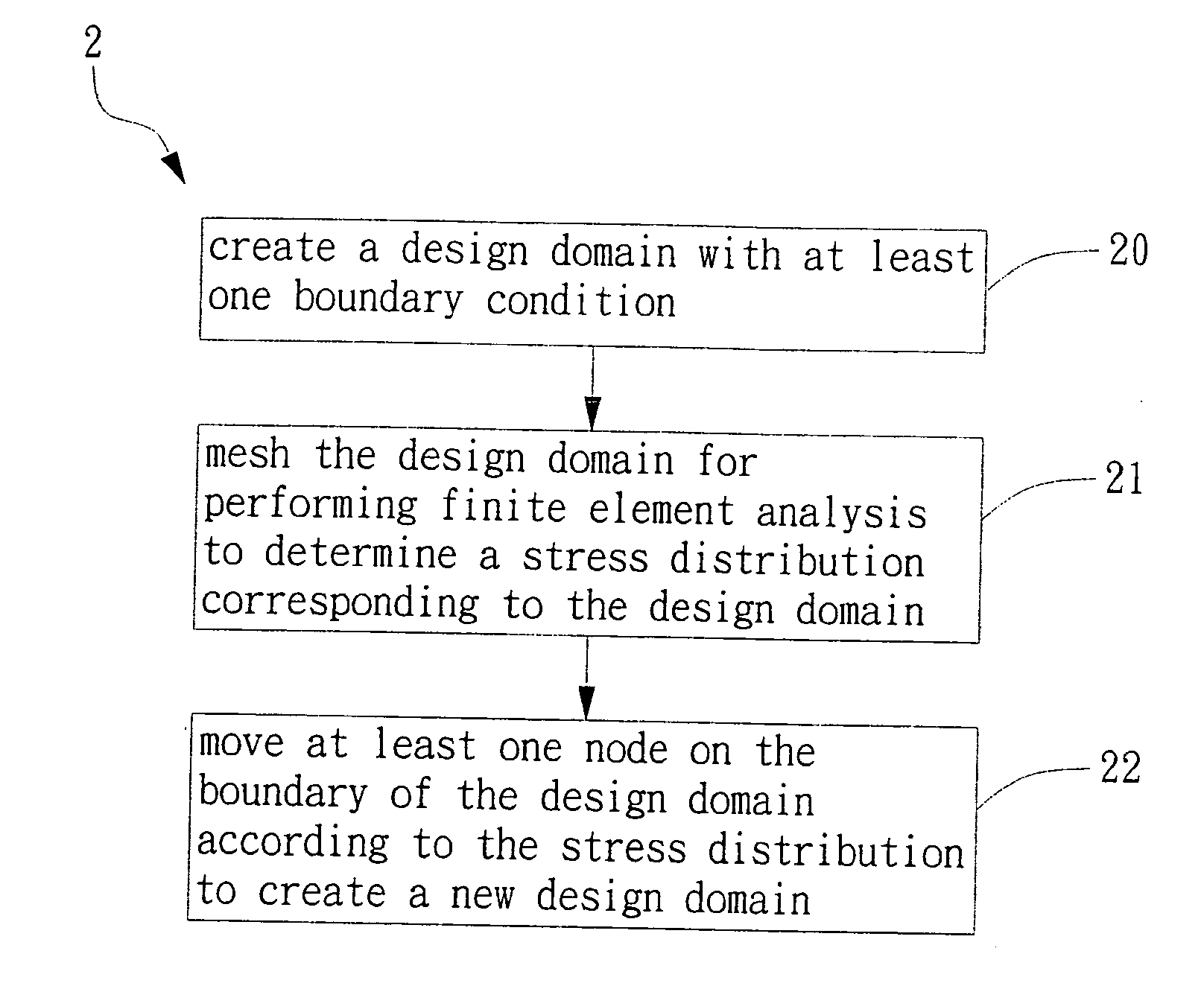

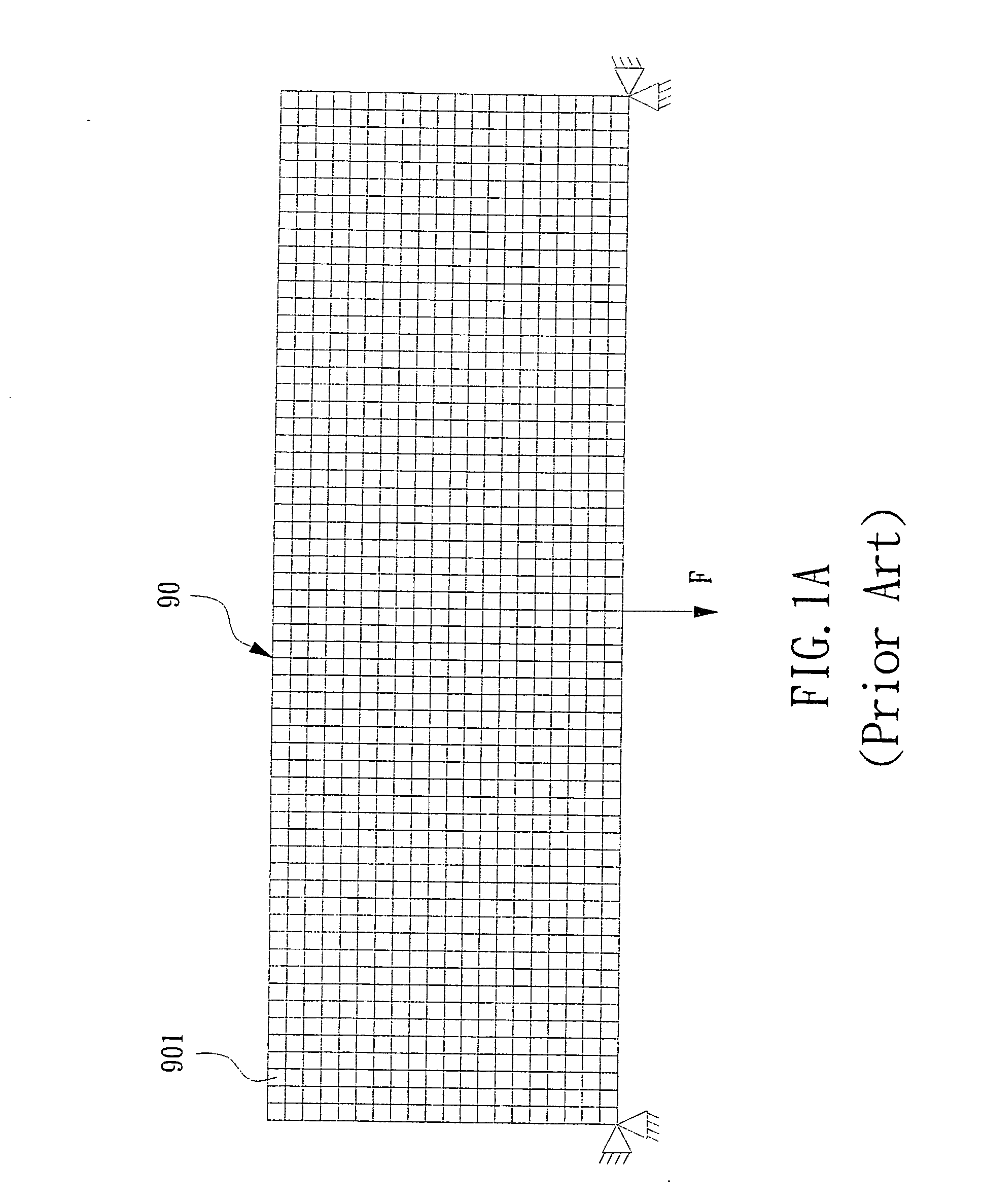

Method of evolutionary optimization algorithm for structure design

PatentInactiveUS20080183436A1

Innovation

- A method of evolutionary optimization that involves creating a design domain, meshing it for finite element analysis, moving boundary nodes based on stress distribution to create a new design domain, and iteratively refining the structure to overcome mesh dependency and the stair-case effect.

Computational Resource Requirements and Efficiency

The computational demands of Topology Optimization (TO) and Finite Element Analysis (FEA) represent a critical consideration for engineering teams evaluating these methodologies for structural integrity applications. FEA traditionally requires substantial computational resources, particularly for complex models with numerous elements and nonlinear analyses. A typical industrial FEA simulation may consume 8-32GB of RAM and require multi-core processors to complete within reasonable timeframes.

Topology Optimization significantly intensifies these computational requirements. The iterative nature of TO algorithms, which may require hundreds or thousands of FEA evaluations during the optimization process, creates an exponential increase in computational demand. Research indicates that TO processes commonly require 3-10 times the computational resources of a single FEA simulation, with memory requirements often exceeding 64GB for complex industrial applications.

Processing time presents another significant efficiency consideration. While a standard FEA simulation might complete in hours, a comprehensive TO process can extend to days or even weeks for complex structures. This time investment must be balanced against the potential material savings and performance improvements. Recent benchmarking studies demonstrate that cloud-based high-performance computing can reduce TO processing times by 60-80%, though at additional cost.

Efficiency improvements have emerged through several technological advancements. Adaptive meshing techniques reduce element counts in non-critical regions, decreasing computational overhead by 30-50% in some applications. GPU acceleration has shown particular promise, with specialized TO algorithms achieving 5-20x speedups compared to CPU-only implementations. Additionally, machine learning approaches are beginning to predict optimization outcomes with reduced simulation requirements, potentially cutting computational needs by 40-60%.

The software ecosystem also impacts computational efficiency. Commercial packages like Altair OptiStruct and ANSYS offer highly optimized solvers but require substantial licensing investments. Open-source alternatives like ToPy provide accessibility but often lack the computational efficiency of commercial solutions, sometimes requiring 2-3 times longer processing periods for equivalent problems.

For practical implementation, organizations must consider their computational infrastructure strategy. On-premises high-performance computing clusters offer consistent availability but require significant capital investment. Cloud-based solutions provide scalability and reduce upfront costs, though ongoing operational expenses and data security considerations must be evaluated. Hybrid approaches are increasingly common, with baseline simulations performed locally and intensive TO processes offloaded to cloud resources during peak demand periods.

Topology Optimization significantly intensifies these computational requirements. The iterative nature of TO algorithms, which may require hundreds or thousands of FEA evaluations during the optimization process, creates an exponential increase in computational demand. Research indicates that TO processes commonly require 3-10 times the computational resources of a single FEA simulation, with memory requirements often exceeding 64GB for complex industrial applications.

Processing time presents another significant efficiency consideration. While a standard FEA simulation might complete in hours, a comprehensive TO process can extend to days or even weeks for complex structures. This time investment must be balanced against the potential material savings and performance improvements. Recent benchmarking studies demonstrate that cloud-based high-performance computing can reduce TO processing times by 60-80%, though at additional cost.

Efficiency improvements have emerged through several technological advancements. Adaptive meshing techniques reduce element counts in non-critical regions, decreasing computational overhead by 30-50% in some applications. GPU acceleration has shown particular promise, with specialized TO algorithms achieving 5-20x speedups compared to CPU-only implementations. Additionally, machine learning approaches are beginning to predict optimization outcomes with reduced simulation requirements, potentially cutting computational needs by 40-60%.

The software ecosystem also impacts computational efficiency. Commercial packages like Altair OptiStruct and ANSYS offer highly optimized solvers but require substantial licensing investments. Open-source alternatives like ToPy provide accessibility but often lack the computational efficiency of commercial solutions, sometimes requiring 2-3 times longer processing periods for equivalent problems.

For practical implementation, organizations must consider their computational infrastructure strategy. On-premises high-performance computing clusters offer consistent availability but require significant capital investment. Cloud-based solutions provide scalability and reduce upfront costs, though ongoing operational expenses and data security considerations must be evaluated. Hybrid approaches are increasingly common, with baseline simulations performed locally and intensive TO processes offloaded to cloud resources during peak demand periods.

Implementation Challenges and Best Practices

Implementing Topology Optimization (TO) and Finite Element Analysis (FEA) presents distinct challenges that engineering teams must navigate carefully. The computational intensity of TO algorithms represents a significant hurdle, often requiring substantial processing power and memory resources, especially for complex three-dimensional structures. Organizations frequently face hardware limitations that necessitate simplification of models or extended calculation times, potentially compromising design quality or project timelines.

Integration challenges emerge when incorporating TO into existing engineering workflows. Many traditional CAD systems lack native support for the organic, mesh-based geometries that TO typically generates. This compatibility gap requires additional post-processing steps to convert optimized designs into manufacturable models, potentially introducing interpretation errors or losing optimization benefits during translation.

Manufacturing constraints pose another critical challenge. TO-generated designs often feature complex geometries that may be difficult or impossible to produce using conventional manufacturing methods. While additive manufacturing offers a solution, it introduces its own constraints related to build orientation, support structures, and material properties that must be considered during the optimization process.

Best practices for effective implementation include establishing clear design objectives and constraints before initiating optimization. Defining precise performance targets, manufacturing limitations, and boundary conditions ensures that optimization algorithms produce practical, manufacturable designs. Implementing multi-stage optimization approaches has proven effective, beginning with coarse models to explore design spaces broadly before refining promising concepts with higher-resolution analyses.

Verification protocols represent another essential practice. Optimized designs should undergo comprehensive FEA validation to confirm performance under various loading conditions and to identify potential failure modes not captured during the optimization process. This verification step helps prevent costly redesigns or failures in physical prototypes or final products.

Cross-disciplinary collaboration emerges as a crucial success factor. Effective implementation requires cooperation between structural engineers, manufacturing specialists, and materials scientists to balance theoretical optimization with practical production considerations. Organizations that establish formal communication channels between these disciplines typically achieve more successful implementation outcomes.

Training and knowledge development constitute the final best practice. Engineering teams require ongoing education in both TO principles and FEA techniques to effectively interpret results and make informed decisions. Organizations that invest in developing this expertise internally report more successful integration of these advanced methodologies into their standard design processes.

Integration challenges emerge when incorporating TO into existing engineering workflows. Many traditional CAD systems lack native support for the organic, mesh-based geometries that TO typically generates. This compatibility gap requires additional post-processing steps to convert optimized designs into manufacturable models, potentially introducing interpretation errors or losing optimization benefits during translation.

Manufacturing constraints pose another critical challenge. TO-generated designs often feature complex geometries that may be difficult or impossible to produce using conventional manufacturing methods. While additive manufacturing offers a solution, it introduces its own constraints related to build orientation, support structures, and material properties that must be considered during the optimization process.

Best practices for effective implementation include establishing clear design objectives and constraints before initiating optimization. Defining precise performance targets, manufacturing limitations, and boundary conditions ensures that optimization algorithms produce practical, manufacturable designs. Implementing multi-stage optimization approaches has proven effective, beginning with coarse models to explore design spaces broadly before refining promising concepts with higher-resolution analyses.

Verification protocols represent another essential practice. Optimized designs should undergo comprehensive FEA validation to confirm performance under various loading conditions and to identify potential failure modes not captured during the optimization process. This verification step helps prevent costly redesigns or failures in physical prototypes or final products.

Cross-disciplinary collaboration emerges as a crucial success factor. Effective implementation requires cooperation between structural engineers, manufacturing specialists, and materials scientists to balance theoretical optimization with practical production considerations. Organizations that establish formal communication channels between these disciplines typically achieve more successful implementation outcomes.

Training and knowledge development constitute the final best practice. Engineering teams require ongoing education in both TO principles and FEA techniques to effectively interpret results and make informed decisions. Organizations that invest in developing this expertise internally report more successful integration of these advanced methodologies into their standard design processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!