Utilizing Dual Mode ICP-MS for Comprehensive Elemental Analysis

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Technology Evolution and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the early 1980s. This analytical technique combines the high-temperature ICP source with a mass spectrometer to detect and quantify elements at ultra-trace levels. The evolution of ICP-MS technology has been driven by the increasing demand for more sensitive, accurate, and comprehensive elemental analysis across various industries including environmental monitoring, food safety, pharmaceutical research, and materials science.

The initial ICP-MS systems utilized quadrupole mass analyzers, offering reasonable sensitivity but limited resolution. Throughout the 1990s, significant advancements were made in interface design, ion optics, and detector technology, substantially improving detection limits and analytical precision. The introduction of collision/reaction cell technology in the late 1990s represented a pivotal development, addressing polyatomic interferences that had previously limited the technique's applicability for certain elements.

The early 2000s witnessed the emergence of high-resolution ICP-MS systems employing magnetic sector analyzers, providing superior resolution capabilities for complex sample matrices. Concurrently, time-of-flight ICP-MS systems were developed, enabling simultaneous multi-element detection with improved speed and efficiency. These technological innovations expanded the analytical capabilities of ICP-MS, making it an indispensable tool for elemental analysis across diverse scientific disciplines.

Dual mode ICP-MS represents the latest evolution in this technological trajectory, integrating multiple operational modes within a single instrument. This innovation allows analysts to switch between different analytical approaches—such as standard mode for routine analysis and collision/reaction mode for interference removal—without compromising performance or requiring separate instrumentation. The integration of these capabilities addresses the growing need for versatile analytical platforms capable of handling increasingly complex analytical challenges.

The primary objectives of dual mode ICP-MS technology development include enhancing analytical flexibility, improving detection capabilities for challenging elements, reducing analysis time, and minimizing sample preparation requirements. Additionally, there is a strong focus on expanding the dynamic range of concentration measurements, enabling simultaneous determination of major, minor, and trace elements within a single analytical run.

Future development trajectories for dual mode ICP-MS technology are likely to include further integration with complementary techniques such as chromatography and laser ablation, expansion of automation capabilities, and implementation of advanced data processing algorithms leveraging artificial intelligence. These advancements aim to establish more comprehensive elemental fingerprinting methodologies applicable to diverse sample types while maintaining the high throughput and sensitivity that have made ICP-MS a cornerstone of modern elemental analysis.

The initial ICP-MS systems utilized quadrupole mass analyzers, offering reasonable sensitivity but limited resolution. Throughout the 1990s, significant advancements were made in interface design, ion optics, and detector technology, substantially improving detection limits and analytical precision. The introduction of collision/reaction cell technology in the late 1990s represented a pivotal development, addressing polyatomic interferences that had previously limited the technique's applicability for certain elements.

The early 2000s witnessed the emergence of high-resolution ICP-MS systems employing magnetic sector analyzers, providing superior resolution capabilities for complex sample matrices. Concurrently, time-of-flight ICP-MS systems were developed, enabling simultaneous multi-element detection with improved speed and efficiency. These technological innovations expanded the analytical capabilities of ICP-MS, making it an indispensable tool for elemental analysis across diverse scientific disciplines.

Dual mode ICP-MS represents the latest evolution in this technological trajectory, integrating multiple operational modes within a single instrument. This innovation allows analysts to switch between different analytical approaches—such as standard mode for routine analysis and collision/reaction mode for interference removal—without compromising performance or requiring separate instrumentation. The integration of these capabilities addresses the growing need for versatile analytical platforms capable of handling increasingly complex analytical challenges.

The primary objectives of dual mode ICP-MS technology development include enhancing analytical flexibility, improving detection capabilities for challenging elements, reducing analysis time, and minimizing sample preparation requirements. Additionally, there is a strong focus on expanding the dynamic range of concentration measurements, enabling simultaneous determination of major, minor, and trace elements within a single analytical run.

Future development trajectories for dual mode ICP-MS technology are likely to include further integration with complementary techniques such as chromatography and laser ablation, expansion of automation capabilities, and implementation of advanced data processing algorithms leveraging artificial intelligence. These advancements aim to establish more comprehensive elemental fingerprinting methodologies applicable to diverse sample types while maintaining the high throughput and sensitivity that have made ICP-MS a cornerstone of modern elemental analysis.

Market Applications and Demand Analysis

The dual mode ICP-MS technology has witnessed significant market growth across multiple sectors due to its comprehensive elemental analysis capabilities. The global market for analytical instruments, including ICP-MS systems, is currently valued at approximately $60 billion, with a compound annual growth rate of 5.7%. Within this broader market, the ICP-MS segment specifically has been expanding at a faster rate of around 7.2% annually, driven by increasing demand for multi-elemental analysis with high sensitivity and accuracy.

The pharmaceutical and biotechnology sectors represent the largest market segment for dual mode ICP-MS technology, accounting for nearly 30% of the total market share. These industries require precise elemental analysis for drug development, quality control, and regulatory compliance. The ability of dual mode ICP-MS to detect both organic and inorganic elements at trace levels makes it particularly valuable for pharmaceutical applications where contamination control is critical.

Environmental monitoring constitutes the second-largest application area, representing approximately 25% of the market. Government regulations worldwide have become increasingly stringent regarding environmental pollutants, creating sustained demand for advanced analytical technologies. Dual mode ICP-MS systems offer the sensitivity required to detect heavy metals and other contaminants at parts-per-trillion levels, essential for compliance with evolving environmental standards.

The food and beverage industry has emerged as a rapidly growing market segment, currently accounting for 18% of dual mode ICP-MS applications. Consumer awareness regarding food safety has intensified scrutiny on potential contaminants, driving manufacturers to implement more rigorous testing protocols. The technology's ability to simultaneously analyze multiple elements makes it particularly efficient for high-throughput food safety testing environments.

Semiconductor and electronics manufacturing represents another significant growth area, comprising approximately 15% of the market. As miniaturization continues and performance requirements increase, the need for ultra-pure materials has become paramount. Dual mode ICP-MS provides the necessary sensitivity to detect trace impurities that could compromise semiconductor performance.

Geochemical analysis, clinical diagnostics, and nuclear industries collectively account for the remaining market share. Each of these sectors has specific analytical requirements that dual mode ICP-MS can address through its versatility and sensitivity. Market forecasts indicate that the clinical diagnostics segment may experience the highest growth rate in the coming years, potentially reaching 9.3% annual growth as personalized medicine advances and requires more sophisticated elemental analysis capabilities.

The pharmaceutical and biotechnology sectors represent the largest market segment for dual mode ICP-MS technology, accounting for nearly 30% of the total market share. These industries require precise elemental analysis for drug development, quality control, and regulatory compliance. The ability of dual mode ICP-MS to detect both organic and inorganic elements at trace levels makes it particularly valuable for pharmaceutical applications where contamination control is critical.

Environmental monitoring constitutes the second-largest application area, representing approximately 25% of the market. Government regulations worldwide have become increasingly stringent regarding environmental pollutants, creating sustained demand for advanced analytical technologies. Dual mode ICP-MS systems offer the sensitivity required to detect heavy metals and other contaminants at parts-per-trillion levels, essential for compliance with evolving environmental standards.

The food and beverage industry has emerged as a rapidly growing market segment, currently accounting for 18% of dual mode ICP-MS applications. Consumer awareness regarding food safety has intensified scrutiny on potential contaminants, driving manufacturers to implement more rigorous testing protocols. The technology's ability to simultaneously analyze multiple elements makes it particularly efficient for high-throughput food safety testing environments.

Semiconductor and electronics manufacturing represents another significant growth area, comprising approximately 15% of the market. As miniaturization continues and performance requirements increase, the need for ultra-pure materials has become paramount. Dual mode ICP-MS provides the necessary sensitivity to detect trace impurities that could compromise semiconductor performance.

Geochemical analysis, clinical diagnostics, and nuclear industries collectively account for the remaining market share. Each of these sectors has specific analytical requirements that dual mode ICP-MS can address through its versatility and sensitivity. Market forecasts indicate that the clinical diagnostics segment may experience the highest growth rate in the coming years, potentially reaching 9.3% annual growth as personalized medicine advances and requires more sophisticated elemental analysis capabilities.

Current Dual Mode ICP-MS Capabilities and Limitations

Dual Mode ICP-MS technology represents a significant advancement in elemental analysis capabilities, combining both standard and collision/reaction cell modes in a single instrument. Current systems offer detection limits in the parts-per-trillion (ppt) range for most elements, with a dynamic range spanning up to nine orders of magnitude. This exceptional sensitivity enables trace analysis in complex matrices that was previously unattainable with conventional analytical techniques.

The integration of collision/reaction cell technology with traditional quadrupole mass spectrometry has effectively addressed one of the most persistent challenges in ICP-MS analysis: polyatomic interferences. Modern dual mode systems can switch seamlessly between standard mode for interference-free elements and collision/reaction mode for problematic elements affected by spectral overlaps, all within a single analytical run.

Sample throughput capabilities have improved dramatically, with current systems capable of analyzing up to 60-80 samples per hour while maintaining high precision. This efficiency is further enhanced by automated switching between modes based on predefined element-specific parameters, eliminating the need for manual intervention during analysis sequences.

Despite these advancements, several limitations persist in current dual mode ICP-MS technology. Matrix effects remain a significant challenge, particularly when analyzing samples with high dissolved solid content (>0.2%), which can lead to signal suppression or enhancement. This necessitates careful matrix matching or internal standardization to maintain accuracy.

Instrument stability presents another challenge, with signal drift occurring over extended analytical sessions, particularly for volatile elements. Modern systems incorporate internal standardization and drift correction algorithms, but these solutions are not universally effective across all sample types and analytical conditions.

The collision/reaction cell technology, while powerful, introduces complexity in method development. Optimization of cell parameters (gas type, flow rate, cell voltage) requires significant expertise and can be element-specific, complicating multi-element analysis protocols. Additionally, the use of reaction gases can create new interferences that must be carefully managed.

Cost considerations remain a barrier to widespread adoption, with dual mode ICP-MS systems typically commanding premium prices compared to single-mode alternatives. Operational expenses are also higher due to the consumption of specialized gases and increased maintenance requirements for the collision/reaction cell components.

Future development efforts are focused on enhancing cell technology to provide more universal interference removal solutions, improving software algorithms for automated optimization, and developing more robust sample introduction systems to minimize matrix effects and extend instrument uptime in challenging sample environments.

The integration of collision/reaction cell technology with traditional quadrupole mass spectrometry has effectively addressed one of the most persistent challenges in ICP-MS analysis: polyatomic interferences. Modern dual mode systems can switch seamlessly between standard mode for interference-free elements and collision/reaction mode for problematic elements affected by spectral overlaps, all within a single analytical run.

Sample throughput capabilities have improved dramatically, with current systems capable of analyzing up to 60-80 samples per hour while maintaining high precision. This efficiency is further enhanced by automated switching between modes based on predefined element-specific parameters, eliminating the need for manual intervention during analysis sequences.

Despite these advancements, several limitations persist in current dual mode ICP-MS technology. Matrix effects remain a significant challenge, particularly when analyzing samples with high dissolved solid content (>0.2%), which can lead to signal suppression or enhancement. This necessitates careful matrix matching or internal standardization to maintain accuracy.

Instrument stability presents another challenge, with signal drift occurring over extended analytical sessions, particularly for volatile elements. Modern systems incorporate internal standardization and drift correction algorithms, but these solutions are not universally effective across all sample types and analytical conditions.

The collision/reaction cell technology, while powerful, introduces complexity in method development. Optimization of cell parameters (gas type, flow rate, cell voltage) requires significant expertise and can be element-specific, complicating multi-element analysis protocols. Additionally, the use of reaction gases can create new interferences that must be carefully managed.

Cost considerations remain a barrier to widespread adoption, with dual mode ICP-MS systems typically commanding premium prices compared to single-mode alternatives. Operational expenses are also higher due to the consumption of specialized gases and increased maintenance requirements for the collision/reaction cell components.

Future development efforts are focused on enhancing cell technology to provide more universal interference removal solutions, improving software algorithms for automated optimization, and developing more robust sample introduction systems to minimize matrix effects and extend instrument uptime in challenging sample environments.

Existing Dual Mode ICP-MS Methodologies

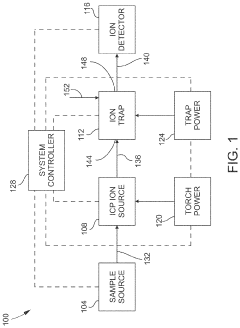

01 Dual mode ICP-MS system design

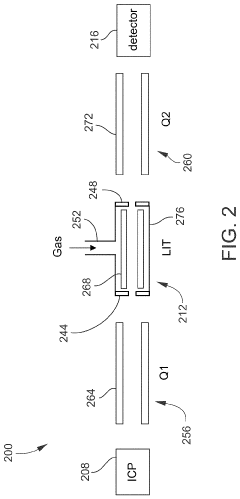

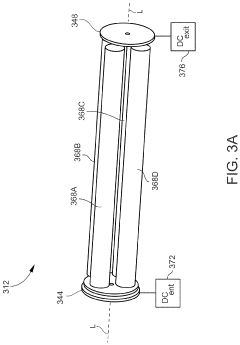

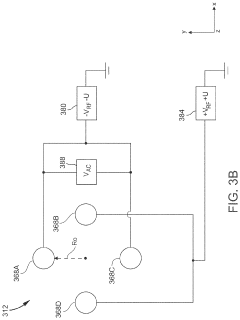

Dual mode Inductively Coupled Plasma Mass Spectrometry (ICP-MS) systems incorporate innovative hardware configurations that allow switching between different operational modes for comprehensive elemental analysis. These systems typically feature specialized ion optics, dual detectors, and advanced plasma interface designs that enable seamless transition between high-sensitivity and high-throughput modes. The dual functionality allows analysts to optimize performance for different sample types and concentration ranges without hardware modifications.- Dual mode ICP-MS system design: Dual mode ICP-MS systems are designed to operate in multiple analytical modes, allowing for comprehensive elemental analysis with enhanced sensitivity and flexibility. These systems can switch between different operational modes such as standard mode and collision/reaction cell mode to address various analytical challenges including polyatomic interferences. The dual mode capability enables analysis of both high and low concentration elements in a single run, improving laboratory efficiency and analytical capabilities.

- Collision/reaction cell technology: Collision/reaction cell technology is a critical component in dual mode ICP-MS systems that helps eliminate or reduce polyatomic interferences. By introducing specific gases into the collision/reaction cell, interfering species can be removed through chemical reactions or kinetic energy discrimination, allowing for more accurate measurement of problematic elements. This technology significantly improves detection limits and analytical precision for elements that traditionally suffer from spectral interferences.

- Sample introduction and preparation methods: Advanced sample introduction and preparation methods are essential for comprehensive elemental analysis using dual mode ICP-MS. These include specialized nebulizers, spray chambers, and sample preparation techniques designed to handle diverse sample matrices ranging from environmental samples to biological tissues. Automated sample preparation systems can be integrated with dual mode ICP-MS to improve throughput and reduce contamination risks, ensuring reliable and reproducible analytical results.

- Data acquisition and processing systems: Sophisticated data acquisition and processing systems are developed specifically for dual mode ICP-MS to handle the complex data generated during comprehensive elemental analysis. These systems feature advanced software algorithms for spectral interpretation, interference correction, and quantitative analysis. Real-time data processing capabilities allow for simultaneous monitoring of multiple elements across a wide concentration range, while intelligent calibration methods ensure accuracy across different operational modes.

- Applications in multi-element analysis: Dual mode ICP-MS enables comprehensive multi-element analysis across various fields including environmental monitoring, food safety, pharmaceutical analysis, and materials science. The ability to analyze trace and ultra-trace elements alongside major constituents makes these systems particularly valuable for complex sample analysis. Applications include toxic element screening in environmental samples, nutritional element profiling in food products, impurity analysis in pharmaceuticals, and composition analysis of advanced materials.

02 Integration of collision/reaction cell technology

Advanced dual mode ICP-MS systems incorporate collision/reaction cell technology to address polyatomic interferences that can compromise analytical accuracy. These cells can operate in different modes - either as collision cells using inert gases to reduce kinetic energy of interfering ions, or as reaction cells using reactive gases to chemically transform interfering species. This technology significantly improves detection limits for challenging elements in complex matrices and enables comprehensive multi-elemental analysis across the periodic table.Expand Specific Solutions03 Sample introduction and preparation techniques

Specialized sample introduction systems enhance the capabilities of dual mode ICP-MS for comprehensive elemental analysis. These include laser ablation systems for direct solid sampling, desolvation nebulizers for improved sensitivity, and automated sample preparation platforms. Advanced sample introduction techniques reduce matrix effects, minimize contamination, and enable analysis of challenging sample types including high-salt matrices, organic solvents, and limited volume samples, thereby expanding the application range of dual mode ICP-MS.Expand Specific Solutions04 Data acquisition and processing methods

Sophisticated data acquisition and processing methods are essential for dual mode ICP-MS systems to handle the complex datasets generated during comprehensive elemental analysis. These include time-resolved analysis capabilities, advanced calibration algorithms, and automated interference correction. Modern systems employ machine learning approaches for spectral deconvolution, intelligent peak identification, and automated quality control. These computational methods enable simultaneous quantification of multiple elements across wide concentration ranges with improved accuracy and precision.Expand Specific Solutions05 Application-specific analytical protocols

Specialized analytical protocols have been developed for dual mode ICP-MS to address specific application requirements in fields such as environmental monitoring, pharmaceutical analysis, semiconductor manufacturing, and clinical diagnostics. These protocols optimize instrument parameters, calibration strategies, and data processing workflows for particular sample types and analytical challenges. Application-specific methods include speciation analysis using hyphenated techniques, isotope ratio measurements, and ultra-trace analysis protocols that leverage the dual mode capabilities to achieve comprehensive elemental characterization.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The dual mode ICP-MS market is in a growth phase, characterized by increasing adoption across environmental, pharmaceutical, and research sectors. The global market size is estimated to exceed $1 billion, with projected annual growth of 6-8%. Technologically, the field is maturing rapidly with major players like Thermo Fisher Scientific and PerkinElmer leading innovation through advanced spectrometry solutions. Shimadzu, SPECTRO Analytical, and LECO are expanding capabilities with hybrid systems, while emerging competitors like Bioyong Technology and Skyray Instrument are gaining market share through cost-effective alternatives. Research institutions including Forschungszentrum Jülich and Korea Research Institute of Standards & Science are driving technological advancements through collaborative development with commercial partners.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has developed advanced dual mode ICP-MS systems, particularly their iCAP TQ ICP-MS platform, which integrates both single quadrupole and triple quadrupole capabilities in one instrument. This technology allows seamless switching between standard mode for routine analysis and triple quadrupole mode for handling complex matrices with spectral interferences. Their patented collision/reaction cell technology employs multiple reaction gases (including oxygen, hydrogen, and ammonia) to eliminate polyatomic interferences while maintaining high sensitivity. The system incorporates intelligent auto-tuning features that optimize performance based on sample types and analytical requirements, significantly reducing method development time. Their latest innovations include enhanced plasma stability control systems that maintain consistent performance across varying sample matrices, and improved interface designs that minimize signal drift during long analytical runs[1][3]. The company has also developed specialized software solutions that integrate calibration, quality control, and data processing specifically for dual mode applications.

Strengths: Industry-leading sensitivity and interference removal capabilities; comprehensive application support across multiple industries; robust hardware design with proven reliability in high-throughput environments. Weaknesses: Higher initial investment cost compared to single-mode systems; requires more specialized training for operators to fully utilize dual-mode capabilities; higher operating costs due to multiple reaction gas requirements.

Shimadzu Corp.

Technical Solution: Shimadzu has pioneered dual mode ICP-MS technology with their ICPMS-2030 platform featuring patented "Dual Mode" capability that combines traditional quadrupole ICP-MS with their proprietary collision/reaction cell technology. Their approach utilizes a unique octopole collision cell design that can operate in both kinetic energy discrimination (KED) mode and dynamic reaction cell (DRC) mode within the same analytical run. This system incorporates their "MiniTorch" technology, which reduces argon consumption by up to 30% while maintaining plasma stability. Shimadzu's dual mode systems feature their proprietary "Development Assistant" software that automatically suggests optimal measurement parameters based on target elements and expected matrix composition. Their latest innovations include an eco-mode that reduces power consumption during standby periods and intelligent auto-dilution systems that extend the dynamic range of measurements without manual intervention[2]. The company has also developed specialized interface cones that improve ion transmission efficiency while reducing maintenance requirements in challenging sample matrices.

Strengths: Excellent cost-performance ratio; lower operating costs through reduced gas consumption; intuitive software that simplifies method development for non-specialist users. Weaknesses: Slightly lower sensitivity for some ultra-trace elements compared to market leaders; more limited reaction gas options; fewer specialized accessories for niche applications.

Key Innovations in Interference Reduction

Inductively coupled plasma mass spectrometry (ICP-MS) with ion trapping

PatentActiveUS11443933B1

Innovation

- Incorporating an ion trap, such as a linear ion trap, into the ICP-MS system to confine and mass-selectively eject ions, allowing for the simultaneous analysis of multiple elements from transient signals by preventing ion exit and entry during a confinement period and transmitting selected ions to a detector for measurement.

Environmental and Safety Considerations

The implementation of Dual Mode ICP-MS technology necessitates careful consideration of environmental impacts and safety protocols throughout its lifecycle. Laboratory operations utilizing this analytical technique generate various waste streams including acidic solutions, organic solvents, and samples containing potentially toxic elements. Proper waste management systems must be established to segregate, neutralize, and dispose of these materials according to local regulations and international standards such as ISO 14001.

Energy consumption represents another significant environmental concern, as ICP-MS instruments typically operate at high temperatures and require substantial power for plasma generation and cooling systems. Modern dual mode systems incorporate energy-efficient components and standby modes that can reduce power consumption by up to 40% compared to older generation instruments, thereby minimizing carbon footprint while maintaining analytical capabilities.

Regarding laboratory safety, ICP-MS operations present several hazards that require mitigation. The high-temperature plasma (6,000-10,000K) poses thermal risks, while the generation of UV radiation and radio frequency fields necessitates appropriate shielding and personal protective equipment. Additionally, the handling of compressed gases (argon, helium) demands proper cylinder storage, secure connections, and leak detection systems to prevent asphyxiation hazards or explosive risks.

Chemical exposure represents another critical safety consideration. Sample preparation often involves concentrated acids and organic solvents that require fume hoods, appropriate ventilation systems, and strict handling protocols. Automated sample introduction systems in modern dual mode ICP-MS significantly reduce operator exposure to hazardous materials while improving analytical reproducibility.

Regulatory compliance frameworks vary globally but typically include adherence to OSHA standards (US), REACH regulations (EU), and similar protocols in other regions. Manufacturers of dual mode ICP-MS systems increasingly design instruments with built-in safety features such as interlocks, automated shutdown procedures, and real-time monitoring of critical parameters to ensure operational safety and regulatory compliance.

Training and standard operating procedures form the foundation of safe laboratory practices. Comprehensive training programs covering instrument operation, waste handling, emergency response, and maintenance procedures are essential for minimizing risks associated with dual mode ICP-MS technology. Regular safety audits and refresher training sessions help maintain awareness and compliance with evolving safety standards.

Energy consumption represents another significant environmental concern, as ICP-MS instruments typically operate at high temperatures and require substantial power for plasma generation and cooling systems. Modern dual mode systems incorporate energy-efficient components and standby modes that can reduce power consumption by up to 40% compared to older generation instruments, thereby minimizing carbon footprint while maintaining analytical capabilities.

Regarding laboratory safety, ICP-MS operations present several hazards that require mitigation. The high-temperature plasma (6,000-10,000K) poses thermal risks, while the generation of UV radiation and radio frequency fields necessitates appropriate shielding and personal protective equipment. Additionally, the handling of compressed gases (argon, helium) demands proper cylinder storage, secure connections, and leak detection systems to prevent asphyxiation hazards or explosive risks.

Chemical exposure represents another critical safety consideration. Sample preparation often involves concentrated acids and organic solvents that require fume hoods, appropriate ventilation systems, and strict handling protocols. Automated sample introduction systems in modern dual mode ICP-MS significantly reduce operator exposure to hazardous materials while improving analytical reproducibility.

Regulatory compliance frameworks vary globally but typically include adherence to OSHA standards (US), REACH regulations (EU), and similar protocols in other regions. Manufacturers of dual mode ICP-MS systems increasingly design instruments with built-in safety features such as interlocks, automated shutdown procedures, and real-time monitoring of critical parameters to ensure operational safety and regulatory compliance.

Training and standard operating procedures form the foundation of safe laboratory practices. Comprehensive training programs covering instrument operation, waste handling, emergency response, and maintenance procedures are essential for minimizing risks associated with dual mode ICP-MS technology. Regular safety audits and refresher training sessions help maintain awareness and compliance with evolving safety standards.

Validation and Quality Control Protocols

Validation and quality control protocols are essential components for ensuring the reliability and accuracy of dual mode ICP-MS analytical methods. These protocols must be rigorously designed and implemented to maintain data integrity across both standard and collision/reaction cell modes of operation.

Method validation for dual mode ICP-MS should follow internationally recognized guidelines such as those established by ICH, FDA, or ISO 17025. The validation process must encompass key performance parameters including specificity, linearity, range, accuracy, precision, detection limit, quantitation limit, and robustness. For comprehensive elemental analysis, these parameters should be validated for each element of interest in both operational modes.

Quality control measures must be integrated throughout the analytical workflow. Daily system suitability tests are crucial to verify instrument performance before sample analysis begins. These tests typically include mass calibration verification, resolution checks, and sensitivity assessments for representative elements across the mass range. Oxide and doubly-charged ion ratios should be monitored to ensure optimal plasma conditions.

Internal standardization represents a critical quality control strategy for dual mode ICP-MS. Selection of appropriate internal standards that match the ionization and chemical behavior of target analytes is essential for compensating for matrix effects and instrument drift. For comprehensive elemental analysis, multiple internal standards covering different mass ranges are typically required.

Regular analysis of certified reference materials (CRMs) provides objective evidence of method accuracy and precision. CRMs should be matrix-matched to the samples being analyzed and should contain certified values for the elements of interest. Control charts tracking CRM recoveries over time enable detection of systematic errors or instrumental drift.

Blank monitoring constitutes another fundamental quality control measure. Various types of blanks including calibration blanks, method blanks, and field blanks should be analyzed to identify potential sources of contamination. Particularly for trace element analysis, rigorous blank control is essential for achieving low detection limits.

Proficiency testing participation offers external validation of laboratory performance. Regular participation in interlaboratory comparison programs specific to elemental analysis provides objective assessment of analytical capabilities and helps identify systematic biases that may not be apparent through internal quality control measures.

Documentation of all validation and quality control activities must be comprehensive and traceable. Standard operating procedures should clearly define acceptance criteria for quality control samples, corrective actions for out-of-specification results, and revalidation requirements when significant changes are made to the analytical system or methodology.

Method validation for dual mode ICP-MS should follow internationally recognized guidelines such as those established by ICH, FDA, or ISO 17025. The validation process must encompass key performance parameters including specificity, linearity, range, accuracy, precision, detection limit, quantitation limit, and robustness. For comprehensive elemental analysis, these parameters should be validated for each element of interest in both operational modes.

Quality control measures must be integrated throughout the analytical workflow. Daily system suitability tests are crucial to verify instrument performance before sample analysis begins. These tests typically include mass calibration verification, resolution checks, and sensitivity assessments for representative elements across the mass range. Oxide and doubly-charged ion ratios should be monitored to ensure optimal plasma conditions.

Internal standardization represents a critical quality control strategy for dual mode ICP-MS. Selection of appropriate internal standards that match the ionization and chemical behavior of target analytes is essential for compensating for matrix effects and instrument drift. For comprehensive elemental analysis, multiple internal standards covering different mass ranges are typically required.

Regular analysis of certified reference materials (CRMs) provides objective evidence of method accuracy and precision. CRMs should be matrix-matched to the samples being analyzed and should contain certified values for the elements of interest. Control charts tracking CRM recoveries over time enable detection of systematic errors or instrumental drift.

Blank monitoring constitutes another fundamental quality control measure. Various types of blanks including calibration blanks, method blanks, and field blanks should be analyzed to identify potential sources of contamination. Particularly for trace element analysis, rigorous blank control is essential for achieving low detection limits.

Proficiency testing participation offers external validation of laboratory performance. Regular participation in interlaboratory comparison programs specific to elemental analysis provides objective assessment of analytical capabilities and helps identify systematic biases that may not be apparent through internal quality control measures.

Documentation of all validation and quality control activities must be comprehensive and traceable. Standard operating procedures should clearly define acceptance criteria for quality control samples, corrective actions for out-of-specification results, and revalidation requirements when significant changes are made to the analytical system or methodology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!