Vacuum Pump Applications in Advanced Waveguide Manufacturing

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution

Vacuum pump technology has undergone significant evolution since its inception, particularly in its applications for advanced waveguide manufacturing. The journey began with simple mechanical pumps in the early 20th century, which were primarily used for basic vacuum creation in industrial processes. These pumps, while groundbreaking at the time, had limitations in achieving high vacuum levels and maintaining consistent performance.

The mid-20th century saw a leap forward with the introduction of diffusion pumps. These pumps utilized the principle of gas entrainment by a high-speed jet of vapor, allowing for higher vacuum levels and improved efficiency. This advancement was crucial for early waveguide manufacturing processes, enabling more precise control over the production environment.

The 1960s and 1970s marked the emergence of turbomolecular pumps, a revolutionary development in vacuum technology. These pumps use high-speed rotors to impart momentum to gas molecules, effectively pumping them out of the system. Turbomolecular pumps significantly enhanced the ability to achieve ultra-high vacuum levels, a critical requirement for advanced waveguide manufacturing techniques.

Parallel to these developments, cryogenic pumps were introduced, offering a different approach to vacuum creation. By condensing gases onto extremely cold surfaces, these pumps could achieve and maintain very high vacuum levels. This technology found particular use in specialized waveguide manufacturing processes requiring exceptionally clean environments.

The late 20th century saw the refinement of dry pumps, which operate without oil, eliminating the risk of contamination. This was a game-changer for waveguide manufacturing, where even minute impurities could compromise product quality. Dry pumps, including scroll pumps and diaphragm pumps, became increasingly popular in clean room environments.

Recent years have witnessed the integration of smart technologies into vacuum pump systems. IoT-enabled pumps with advanced sensors and control systems now offer real-time monitoring, predictive maintenance, and automated adjustments. This has greatly enhanced the reliability and efficiency of vacuum systems in waveguide manufacturing facilities.

The latest frontier in vacuum pump technology for waveguide manufacturing involves the development of hybrid systems. These combine different pump technologies to optimize performance across various pressure ranges and process requirements. Such systems offer unprecedented flexibility and efficiency, catering to the increasingly complex demands of advanced waveguide production.

The mid-20th century saw a leap forward with the introduction of diffusion pumps. These pumps utilized the principle of gas entrainment by a high-speed jet of vapor, allowing for higher vacuum levels and improved efficiency. This advancement was crucial for early waveguide manufacturing processes, enabling more precise control over the production environment.

The 1960s and 1970s marked the emergence of turbomolecular pumps, a revolutionary development in vacuum technology. These pumps use high-speed rotors to impart momentum to gas molecules, effectively pumping them out of the system. Turbomolecular pumps significantly enhanced the ability to achieve ultra-high vacuum levels, a critical requirement for advanced waveguide manufacturing techniques.

Parallel to these developments, cryogenic pumps were introduced, offering a different approach to vacuum creation. By condensing gases onto extremely cold surfaces, these pumps could achieve and maintain very high vacuum levels. This technology found particular use in specialized waveguide manufacturing processes requiring exceptionally clean environments.

The late 20th century saw the refinement of dry pumps, which operate without oil, eliminating the risk of contamination. This was a game-changer for waveguide manufacturing, where even minute impurities could compromise product quality. Dry pumps, including scroll pumps and diaphragm pumps, became increasingly popular in clean room environments.

Recent years have witnessed the integration of smart technologies into vacuum pump systems. IoT-enabled pumps with advanced sensors and control systems now offer real-time monitoring, predictive maintenance, and automated adjustments. This has greatly enhanced the reliability and efficiency of vacuum systems in waveguide manufacturing facilities.

The latest frontier in vacuum pump technology for waveguide manufacturing involves the development of hybrid systems. These combine different pump technologies to optimize performance across various pressure ranges and process requirements. Such systems offer unprecedented flexibility and efficiency, catering to the increasingly complex demands of advanced waveguide production.

Waveguide Market Demand

The waveguide market has experienced significant growth in recent years, driven by the increasing demand for high-frequency communication systems and advanced radar technologies. As a critical component in various applications, waveguides play a crucial role in transmitting electromagnetic waves with minimal loss, making them essential in industries such as telecommunications, aerospace, defense, and medical imaging.

In the telecommunications sector, the rapid deployment of 5G networks has created a surge in demand for waveguides. These components are vital for the efficient transmission of high-frequency signals in base stations and other network infrastructure. The global 5G market expansion is expected to continue, further fueling the demand for advanced waveguide solutions.

The aerospace and defense industries represent another significant market for waveguides. With the increasing adoption of phased array radar systems and satellite communications, the need for high-performance waveguides has grown substantially. These sectors require waveguides capable of operating in harsh environments and withstanding extreme conditions, driving innovation in materials and manufacturing processes.

In the medical field, waveguides are finding applications in imaging technologies such as MRI machines and microwave ablation systems. The growing prevalence of chronic diseases and the need for advanced diagnostic tools are contributing to the increased demand for waveguides in medical equipment.

The automotive industry is emerging as a new frontier for waveguide applications, particularly in the development of autonomous vehicles. Advanced driver assistance systems (ADAS) and radar-based safety features rely on waveguides for accurate signal transmission, creating a new market segment with significant growth potential.

As the Internet of Things (IoT) continues to expand, the demand for compact and efficient waveguides in various sensing and communication devices is also on the rise. This trend is driving research into miniaturization techniques and novel materials for waveguide manufacturing.

The market demand for waveguides is not uniform across regions. North America and Europe currently lead in terms of market share, owing to their advanced telecommunications infrastructure and strong presence in the aerospace and defense sectors. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing investments in 5G technology, and the expansion of the electronics manufacturing sector.

The growing emphasis on energy efficiency and environmental sustainability is also influencing the waveguide market. There is an increasing demand for waveguides that offer lower power consumption and reduced electromagnetic interference, aligning with global efforts to minimize energy usage in communication systems.

In the telecommunications sector, the rapid deployment of 5G networks has created a surge in demand for waveguides. These components are vital for the efficient transmission of high-frequency signals in base stations and other network infrastructure. The global 5G market expansion is expected to continue, further fueling the demand for advanced waveguide solutions.

The aerospace and defense industries represent another significant market for waveguides. With the increasing adoption of phased array radar systems and satellite communications, the need for high-performance waveguides has grown substantially. These sectors require waveguides capable of operating in harsh environments and withstanding extreme conditions, driving innovation in materials and manufacturing processes.

In the medical field, waveguides are finding applications in imaging technologies such as MRI machines and microwave ablation systems. The growing prevalence of chronic diseases and the need for advanced diagnostic tools are contributing to the increased demand for waveguides in medical equipment.

The automotive industry is emerging as a new frontier for waveguide applications, particularly in the development of autonomous vehicles. Advanced driver assistance systems (ADAS) and radar-based safety features rely on waveguides for accurate signal transmission, creating a new market segment with significant growth potential.

As the Internet of Things (IoT) continues to expand, the demand for compact and efficient waveguides in various sensing and communication devices is also on the rise. This trend is driving research into miniaturization techniques and novel materials for waveguide manufacturing.

The market demand for waveguides is not uniform across regions. North America and Europe currently lead in terms of market share, owing to their advanced telecommunications infrastructure and strong presence in the aerospace and defense sectors. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing investments in 5G technology, and the expansion of the electronics manufacturing sector.

The growing emphasis on energy efficiency and environmental sustainability is also influencing the waveguide market. There is an increasing demand for waveguides that offer lower power consumption and reduced electromagnetic interference, aligning with global efforts to minimize energy usage in communication systems.

Vacuum Tech Challenges

The application of vacuum pumps in advanced waveguide manufacturing faces several significant challenges that require innovative solutions. One of the primary issues is achieving and maintaining ultra-high vacuum levels necessary for precise waveguide fabrication. The stringent requirements for vacuum quality in this process often exceed the capabilities of conventional pumping systems, necessitating the development of more advanced vacuum technologies.

Contamination control presents another major hurdle in vacuum pump applications for waveguide manufacturing. Even minute particles or molecular contaminants can severely impact the performance and reliability of the final product. This challenge is exacerbated by the need for prolonged vacuum exposure during complex manufacturing processes, increasing the risk of contamination from pump oils or other sources.

The demand for higher throughput in waveguide production introduces additional complications for vacuum systems. Rapid pump-down times and consistent vacuum levels across larger production volumes are essential for meeting industry demands. However, achieving these goals without compromising vacuum quality or system reliability remains a significant technical challenge.

Energy efficiency and heat management in vacuum pumps pose further difficulties, particularly in continuous operation scenarios common in advanced manufacturing. The need to balance power consumption with performance becomes critical, especially as manufacturers seek to reduce overall production costs and environmental impact.

Integrating vacuum pump systems with other advanced manufacturing technologies, such as in-situ monitoring and automated process control, presents its own set of challenges. Ensuring seamless communication and coordination between vacuum systems and other production equipment is crucial for optimizing waveguide manufacturing processes.

The miniaturization trend in waveguide technology also impacts vacuum pump requirements. As waveguides become smaller and more intricate, the demand for localized, high-precision vacuum control increases. This trend pushes the limits of current pump designs and necessitates innovations in compact, yet powerful vacuum solutions.

Lastly, the harsh operating conditions often encountered in advanced manufacturing environments pose reliability and maintenance challenges for vacuum pumps. Developing robust systems capable of withstanding these conditions while maintaining consistent performance over extended periods is a key area of focus for vacuum technology advancement in waveguide production.

Contamination control presents another major hurdle in vacuum pump applications for waveguide manufacturing. Even minute particles or molecular contaminants can severely impact the performance and reliability of the final product. This challenge is exacerbated by the need for prolonged vacuum exposure during complex manufacturing processes, increasing the risk of contamination from pump oils or other sources.

The demand for higher throughput in waveguide production introduces additional complications for vacuum systems. Rapid pump-down times and consistent vacuum levels across larger production volumes are essential for meeting industry demands. However, achieving these goals without compromising vacuum quality or system reliability remains a significant technical challenge.

Energy efficiency and heat management in vacuum pumps pose further difficulties, particularly in continuous operation scenarios common in advanced manufacturing. The need to balance power consumption with performance becomes critical, especially as manufacturers seek to reduce overall production costs and environmental impact.

Integrating vacuum pump systems with other advanced manufacturing technologies, such as in-situ monitoring and automated process control, presents its own set of challenges. Ensuring seamless communication and coordination between vacuum systems and other production equipment is crucial for optimizing waveguide manufacturing processes.

The miniaturization trend in waveguide technology also impacts vacuum pump requirements. As waveguides become smaller and more intricate, the demand for localized, high-precision vacuum control increases. This trend pushes the limits of current pump designs and necessitates innovations in compact, yet powerful vacuum solutions.

Lastly, the harsh operating conditions often encountered in advanced manufacturing environments pose reliability and maintenance challenges for vacuum pumps. Developing robust systems capable of withstanding these conditions while maintaining consistent performance over extended periods is a key area of focus for vacuum technology advancement in waveguide production.

Current Vacuum Solutions

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, innovative sealing mechanisms, and optimized fluid flow paths. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to the field. Early designs focused on mechanical improvements, while later advancements incorporated new materials and manufacturing techniques. These historical developments have laid the foundation for modern vacuum pump systems used in various industries.

- Integration of vacuum pumps in larger systems: Vacuum pumps are often integrated into larger systems for specific applications. This integration involves designing pump systems that can be seamlessly incorporated into manufacturing lines, scientific instruments, or other industrial equipment. Considerations include compact designs, modular components, and compatibility with control systems to ensure optimal performance within the broader operational context.

- Energy-efficient vacuum pump solutions: Efforts to improve the energy efficiency of vacuum pumps have resulted in new designs and operational strategies. These solutions aim to reduce power consumption while maintaining or improving pumping performance. Approaches include the use of variable speed drives, optimized motor designs, and intelligent control systems that adjust pump operation based on demand.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Energy-efficient vacuum pump systems

Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, advanced motor designs, and intelligent control systems. Such features allow for optimized power consumption, reduced operating costs, and minimized environmental impact while maintaining high performance levels.Expand Specific Solutions04 Vacuum pumps for specific industrial applications

Specialized vacuum pumps have been designed to cater to the unique requirements of various industrial applications. These pumps may incorporate features such as explosion-proof designs, high-temperature operation capabilities, or the ability to handle specific types of gases or particulates. Such tailored solutions ensure optimal performance in diverse industrial settings.Expand Specific Solutions05 Integration of vacuum pumps with control and monitoring systems

Advanced vacuum pump systems now incorporate sophisticated control and monitoring capabilities. These features may include real-time performance monitoring, predictive maintenance algorithms, remote operation capabilities, and integration with broader industrial control systems. Such enhancements improve pump reliability, facilitate preventive maintenance, and enable seamless integration into automated manufacturing processes.Expand Specific Solutions

Key Vacuum Pump Makers

The vacuum pump applications in advanced waveguide manufacturing sector is in a growth phase, driven by increasing demand for high-performance communication systems. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is moderately mature but continues to evolve. Key players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Tokyo Electron Ltd. are investing in R&D to improve pump efficiency and precision for waveguide production. Emerging companies such as DigiLens, Inc. are focusing on innovative waveguide technologies, potentially disrupting the market. The competitive landscape is characterized by a mix of established manufacturers and specialized newcomers, indicating a dynamic and evolving industry.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for waveguide manufacturing processes. Their innovative approach includes the use of dry pumping systems that provide contamination-free vacuum environments essential for high-precision waveguide production[1]. The company's GXS dry screw pump series offers high pumping speeds and deep ultimate vacuum levels, crucial for maintaining the purity of waveguide materials during deposition and etching processes[2]. Edwards has also integrated intelligent control systems that allow for real-time monitoring and adjustment of vacuum levels, ensuring consistent quality in waveguide production across various manufacturing stages[3].

Strengths: Specialized dry pumping technology, high pumping speeds, and intelligent control systems. Weaknesses: Potentially higher initial costs compared to traditional vacuum systems, and may require specialized maintenance.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed a comprehensive vacuum solution for advanced waveguide manufacturing, focusing on precision and efficiency. Their HiPace turbomolecular pumps, combined with multi-stage Roots pumps, create an ultra-high vacuum environment essential for the deposition of thin films in waveguide production[1]. The company's ATC (Active Temperature Control) technology ensures stable pumping performance even under varying gas loads, critical for maintaining consistent waveguide quality[2]. Pfeiffer has also introduced the HiLobe series, which offers high pumping speeds at low pressures, ideal for the evacuation of large volumes in waveguide coating chambers[3]. Additionally, their vacuum measurement and analysis tools provide real-time process control, enabling manufacturers to optimize their waveguide production parameters continuously[4].

Strengths: Ultra-high vacuum capabilities, advanced temperature control, and integrated process monitoring. Weaknesses: Complex system integration may require specialized training for operators.

Core Vacuum Innovations

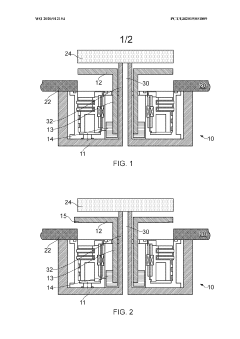

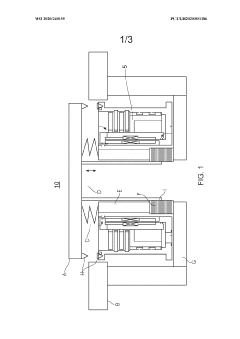

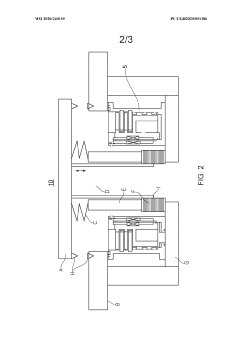

Vacuum pump with through channel and vacuum chamber

PatentWO2020012154A1

Innovation

- A vacuum pump design featuring a rotor, stator, and a controllable valve plate with an axial passage for central substrate mounting and power connections, allowing for uniform gas flow and fast pressure control, along with the option of magnetic levitation for rotor positioning and actuator-controlled axial movement of the valve plate to optimize inlet conductance.

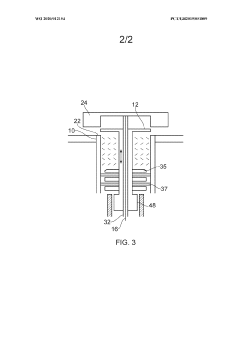

Vacuum assembly and vacuum pump with an axial through passage

PatentWO2020240155A1

Innovation

- A vacuum pump with a hollow shaft defining an axial passage that extends through the pump, allowing the cathode plate to be powered and sealed without disrupting gas flow, eliminating the need for a poppet valve and reducing hardware requirements by using a movable cathode plate for sealing and power supply access.

Vacuum Pump Standards

Vacuum pump standards play a crucial role in ensuring the quality, performance, and safety of vacuum pumps used in advanced waveguide manufacturing. These standards provide guidelines for manufacturers, users, and regulatory bodies to maintain consistency and reliability in vacuum pump applications.

The International Organization for Standardization (ISO) has developed several standards specifically for vacuum technology. ISO 21360 series, for example, focuses on standard methods for measuring the performance characteristics of vacuum pumps. This includes ISO 21360-1, which outlines general measurement methods, and ISO 21360-2, which details specific methods for measuring the ultimate pressure.

In the context of advanced waveguide manufacturing, vacuum pump standards address various aspects such as pumping speed, ultimate pressure, and gas throughput. These parameters are critical for maintaining the required vacuum levels during the waveguide production process. The standards also cover leak detection methods, which are essential for ensuring the integrity of vacuum systems in waveguide manufacturing facilities.

Another important set of standards is the DIN 28400 series, which provides definitions and symbols for vacuum technology. These standards help establish a common language and understanding among professionals working with vacuum pumps in advanced manufacturing settings.

Vacuum pump standards also encompass safety considerations. For instance, the European Standard EN 1012-2 specifies safety requirements for vacuum pumps, including those used in industrial processes like waveguide manufacturing. This standard addresses potential hazards associated with vacuum pump operation and maintenance, ensuring worker safety and equipment longevity.

Environmental considerations are increasingly being incorporated into vacuum pump standards. Energy efficiency ratings and noise level requirements are becoming more stringent, reflecting the industry's move towards more sustainable manufacturing practices. These standards encourage the development of vacuum pumps that consume less power and produce less noise, which is particularly beneficial in clean room environments often used in advanced waveguide production.

Compliance with these standards is often a prerequisite for vacuum pump manufacturers to enter certain markets or industries. In the field of advanced waveguide manufacturing, adherence to these standards ensures that the vacuum pumps meet the high-precision requirements of the production process. This, in turn, contributes to the overall quality and reliability of the manufactured waveguides.

As technology advances, vacuum pump standards continue to evolve. New standards are being developed to address emerging technologies and applications in waveguide manufacturing, such as those related to quantum computing and advanced photonics. These standards will likely focus on ultra-high vacuum capabilities and increased precision in pressure control, reflecting the growing demands of cutting-edge waveguide production techniques.

The International Organization for Standardization (ISO) has developed several standards specifically for vacuum technology. ISO 21360 series, for example, focuses on standard methods for measuring the performance characteristics of vacuum pumps. This includes ISO 21360-1, which outlines general measurement methods, and ISO 21360-2, which details specific methods for measuring the ultimate pressure.

In the context of advanced waveguide manufacturing, vacuum pump standards address various aspects such as pumping speed, ultimate pressure, and gas throughput. These parameters are critical for maintaining the required vacuum levels during the waveguide production process. The standards also cover leak detection methods, which are essential for ensuring the integrity of vacuum systems in waveguide manufacturing facilities.

Another important set of standards is the DIN 28400 series, which provides definitions and symbols for vacuum technology. These standards help establish a common language and understanding among professionals working with vacuum pumps in advanced manufacturing settings.

Vacuum pump standards also encompass safety considerations. For instance, the European Standard EN 1012-2 specifies safety requirements for vacuum pumps, including those used in industrial processes like waveguide manufacturing. This standard addresses potential hazards associated with vacuum pump operation and maintenance, ensuring worker safety and equipment longevity.

Environmental considerations are increasingly being incorporated into vacuum pump standards. Energy efficiency ratings and noise level requirements are becoming more stringent, reflecting the industry's move towards more sustainable manufacturing practices. These standards encourage the development of vacuum pumps that consume less power and produce less noise, which is particularly beneficial in clean room environments often used in advanced waveguide production.

Compliance with these standards is often a prerequisite for vacuum pump manufacturers to enter certain markets or industries. In the field of advanced waveguide manufacturing, adherence to these standards ensures that the vacuum pumps meet the high-precision requirements of the production process. This, in turn, contributes to the overall quality and reliability of the manufactured waveguides.

As technology advances, vacuum pump standards continue to evolve. New standards are being developed to address emerging technologies and applications in waveguide manufacturing, such as those related to quantum computing and advanced photonics. These standards will likely focus on ultra-high vacuum capabilities and increased precision in pressure control, reflecting the growing demands of cutting-edge waveguide production techniques.

Energy Efficiency

Energy efficiency is a critical consideration in the application of vacuum pumps for advanced waveguide manufacturing. The process of creating high-precision waveguides often requires sustained vacuum conditions, which can be energy-intensive. Modern vacuum pump technologies have made significant strides in improving energy efficiency, reducing operational costs, and minimizing environmental impact.

Recent advancements in vacuum pump design have focused on optimizing power consumption without compromising performance. Variable speed drives (VSDs) have been widely adopted, allowing pumps to adjust their speed and power usage based on the specific vacuum requirements of different manufacturing stages. This dynamic adjustment can lead to energy savings of up to 50% compared to traditional fixed-speed pumps.

Another key development is the integration of intelligent control systems. These systems monitor and analyze pump performance in real-time, automatically adjusting operational parameters to maintain optimal efficiency. By preventing unnecessary energy expenditure during idle periods or low-demand phases, these smart controls further enhance overall energy efficiency.

Heat recovery systems have also been implemented in advanced vacuum pump setups. The heat generated during the pumping process, which was previously wasted, is now captured and repurposed for other manufacturing processes or facility heating. This approach not only improves energy efficiency but also contributes to a more sustainable manufacturing ecosystem.

Dry vacuum pumps have gained popularity in waveguide manufacturing due to their lower energy consumption compared to oil-sealed pumps. These pumps eliminate the need for oil changes and reduce the risk of contamination, leading to longer operational lifespans and decreased maintenance requirements. The absence of oil also means less friction, resulting in improved energy efficiency over extended periods.

Manufacturers have also focused on enhancing the mechanical design of vacuum pumps. Improved rotor geometries, advanced bearing systems, and high-efficiency motors all contribute to reduced energy losses. Some cutting-edge pumps now incorporate ceramic components, which offer lower friction and higher temperature resistance, further improving energy efficiency and pump longevity.

The implementation of energy-efficient vacuum pumps in waveguide manufacturing not only reduces operational costs but also aligns with global sustainability goals. As energy regulations become more stringent, the adoption of these technologies positions manufacturers to meet compliance requirements while maintaining competitive advantages in production efficiency and product quality.

Recent advancements in vacuum pump design have focused on optimizing power consumption without compromising performance. Variable speed drives (VSDs) have been widely adopted, allowing pumps to adjust their speed and power usage based on the specific vacuum requirements of different manufacturing stages. This dynamic adjustment can lead to energy savings of up to 50% compared to traditional fixed-speed pumps.

Another key development is the integration of intelligent control systems. These systems monitor and analyze pump performance in real-time, automatically adjusting operational parameters to maintain optimal efficiency. By preventing unnecessary energy expenditure during idle periods or low-demand phases, these smart controls further enhance overall energy efficiency.

Heat recovery systems have also been implemented in advanced vacuum pump setups. The heat generated during the pumping process, which was previously wasted, is now captured and repurposed for other manufacturing processes or facility heating. This approach not only improves energy efficiency but also contributes to a more sustainable manufacturing ecosystem.

Dry vacuum pumps have gained popularity in waveguide manufacturing due to their lower energy consumption compared to oil-sealed pumps. These pumps eliminate the need for oil changes and reduce the risk of contamination, leading to longer operational lifespans and decreased maintenance requirements. The absence of oil also means less friction, resulting in improved energy efficiency over extended periods.

Manufacturers have also focused on enhancing the mechanical design of vacuum pumps. Improved rotor geometries, advanced bearing systems, and high-efficiency motors all contribute to reduced energy losses. Some cutting-edge pumps now incorporate ceramic components, which offer lower friction and higher temperature resistance, further improving energy efficiency and pump longevity.

The implementation of energy-efficient vacuum pumps in waveguide manufacturing not only reduces operational costs but also aligns with global sustainability goals. As energy regulations become more stringent, the adoption of these technologies positions manufacturers to meet compliance requirements while maintaining competitive advantages in production efficiency and product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!