Vacuum Pump Applications in Next-Gen Electronic Build Platforms

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution

Vacuum pump technology has undergone significant evolution since its inception, particularly in the context of electronic build platforms. The journey began with simple mechanical pumps in the early 20th century, progressing through various stages of innovation to meet the increasing demands of precision manufacturing and advanced electronics production.

In the 1950s and 1960s, the development of rotary vane pumps marked a significant milestone. These pumps offered improved vacuum levels and reliability, becoming a staple in early electronic manufacturing processes. The 1970s saw the introduction of turbomolecular pumps, which revolutionized high-vacuum applications by achieving much lower pressures than their predecessors.

The 1980s and 1990s brought about the refinement of dry pumps, addressing the contamination issues associated with oil-sealed pumps. This innovation was crucial for the semiconductor industry, where even minute impurities could compromise product quality. Scroll pumps and diaphragm pumps also gained prominence during this period, offering oil-free operation for sensitive applications.

The turn of the millennium heralded a new era of vacuum pump technology, with a focus on energy efficiency and miniaturization. Multi-stage pumps combining different technologies emerged, providing a balance between high vacuum levels and operational efficiency. The integration of smart controls and IoT capabilities in the 2010s allowed for real-time monitoring and predictive maintenance, enhancing reliability in critical manufacturing processes.

Recent years have seen a surge in the development of specialized vacuum pumps for next-generation electronic build platforms. These pumps are designed to handle the unique challenges posed by advanced manufacturing techniques such as 3D printing of electronics and nanoscale fabrication. Innovations include ultra-clean pumps with near-zero particle emissions, rapid cycling pumps for processes requiring frequent pressure changes, and highly compact designs for integration into increasingly dense manufacturing environments.

The latest frontier in vacuum pump technology focuses on sustainability and adaptability. Manufacturers are developing pumps with reduced environmental impact, incorporating materials and designs that minimize resource consumption and emissions. Additionally, modular pump systems are gaining traction, allowing for easy upgrades and customization to meet evolving manufacturing requirements.

As we look to the future, the evolution of vacuum pump technology in electronic build platforms is likely to continue its trajectory towards higher precision, greater efficiency, and enhanced integration with smart manufacturing systems. The ongoing miniaturization of electronic components and the advent of quantum computing technologies will undoubtedly drive further innovations in vacuum pump design and capabilities.

In the 1950s and 1960s, the development of rotary vane pumps marked a significant milestone. These pumps offered improved vacuum levels and reliability, becoming a staple in early electronic manufacturing processes. The 1970s saw the introduction of turbomolecular pumps, which revolutionized high-vacuum applications by achieving much lower pressures than their predecessors.

The 1980s and 1990s brought about the refinement of dry pumps, addressing the contamination issues associated with oil-sealed pumps. This innovation was crucial for the semiconductor industry, where even minute impurities could compromise product quality. Scroll pumps and diaphragm pumps also gained prominence during this period, offering oil-free operation for sensitive applications.

The turn of the millennium heralded a new era of vacuum pump technology, with a focus on energy efficiency and miniaturization. Multi-stage pumps combining different technologies emerged, providing a balance between high vacuum levels and operational efficiency. The integration of smart controls and IoT capabilities in the 2010s allowed for real-time monitoring and predictive maintenance, enhancing reliability in critical manufacturing processes.

Recent years have seen a surge in the development of specialized vacuum pumps for next-generation electronic build platforms. These pumps are designed to handle the unique challenges posed by advanced manufacturing techniques such as 3D printing of electronics and nanoscale fabrication. Innovations include ultra-clean pumps with near-zero particle emissions, rapid cycling pumps for processes requiring frequent pressure changes, and highly compact designs for integration into increasingly dense manufacturing environments.

The latest frontier in vacuum pump technology focuses on sustainability and adaptability. Manufacturers are developing pumps with reduced environmental impact, incorporating materials and designs that minimize resource consumption and emissions. Additionally, modular pump systems are gaining traction, allowing for easy upgrades and customization to meet evolving manufacturing requirements.

As we look to the future, the evolution of vacuum pump technology in electronic build platforms is likely to continue its trajectory towards higher precision, greater efficiency, and enhanced integration with smart manufacturing systems. The ongoing miniaturization of electronic components and the advent of quantum computing technologies will undoubtedly drive further innovations in vacuum pump design and capabilities.

Market Demand Analysis

The market demand for vacuum pump applications in next-generation electronic build platforms is experiencing significant growth, driven by the rapid advancement of semiconductor manufacturing and electronic device production. As the electronics industry continues to push the boundaries of miniaturization and performance, the need for precise and efficient vacuum systems in manufacturing processes has become increasingly critical.

In the semiconductor sector, vacuum pumps play a crucial role in creating the ultra-clean environments required for wafer fabrication. The ongoing trend towards smaller transistor sizes and more complex chip designs has intensified the demand for high-performance vacuum solutions. This is particularly evident in the production of advanced logic and memory chips, where even minute contamination can significantly impact yield and device performance.

The emerging field of advanced packaging technologies, such as 3D IC integration and fan-out wafer-level packaging, has also contributed to the growing market for specialized vacuum pump applications. These packaging methods require precise control of pressure and atmosphere during various stages of the manufacturing process, further driving the need for innovative vacuum solutions.

In the display industry, the shift towards OLED and microLED technologies has created new opportunities for vacuum pump applications. The production of these advanced display panels involves several vacuum-dependent processes, including thin-film deposition and encapsulation. As consumer demand for high-quality, energy-efficient displays continues to rise, so does the market for vacuum systems tailored to these manufacturing requirements.

The expansion of the electric vehicle (EV) market has introduced another significant driver for vacuum pump applications in electronic build platforms. The production of EV batteries and power electronics components often requires stringent environmental control, including vacuum-based processes for coating and sealing. As global EV adoption accelerates, the demand for specialized vacuum solutions in this sector is expected to grow substantially.

Furthermore, the increasing focus on sustainability and energy efficiency in manufacturing has led to a growing interest in more advanced, energy-efficient vacuum pump technologies. This trend is pushing manufacturers to develop and adopt next-generation vacuum systems that offer improved performance while reducing energy consumption and environmental impact.

The market for vacuum pump applications in electronic build platforms is also being shaped by the global push for technological sovereignty and supply chain resilience. Many countries and regions are investing heavily in domestic semiconductor and electronics manufacturing capabilities, leading to the establishment of new fabrication facilities and the upgrading of existing ones. This expansion and modernization of manufacturing infrastructure is creating additional demand for cutting-edge vacuum pump solutions.

In the semiconductor sector, vacuum pumps play a crucial role in creating the ultra-clean environments required for wafer fabrication. The ongoing trend towards smaller transistor sizes and more complex chip designs has intensified the demand for high-performance vacuum solutions. This is particularly evident in the production of advanced logic and memory chips, where even minute contamination can significantly impact yield and device performance.

The emerging field of advanced packaging technologies, such as 3D IC integration and fan-out wafer-level packaging, has also contributed to the growing market for specialized vacuum pump applications. These packaging methods require precise control of pressure and atmosphere during various stages of the manufacturing process, further driving the need for innovative vacuum solutions.

In the display industry, the shift towards OLED and microLED technologies has created new opportunities for vacuum pump applications. The production of these advanced display panels involves several vacuum-dependent processes, including thin-film deposition and encapsulation. As consumer demand for high-quality, energy-efficient displays continues to rise, so does the market for vacuum systems tailored to these manufacturing requirements.

The expansion of the electric vehicle (EV) market has introduced another significant driver for vacuum pump applications in electronic build platforms. The production of EV batteries and power electronics components often requires stringent environmental control, including vacuum-based processes for coating and sealing. As global EV adoption accelerates, the demand for specialized vacuum solutions in this sector is expected to grow substantially.

Furthermore, the increasing focus on sustainability and energy efficiency in manufacturing has led to a growing interest in more advanced, energy-efficient vacuum pump technologies. This trend is pushing manufacturers to develop and adopt next-generation vacuum systems that offer improved performance while reducing energy consumption and environmental impact.

The market for vacuum pump applications in electronic build platforms is also being shaped by the global push for technological sovereignty and supply chain resilience. Many countries and regions are investing heavily in domestic semiconductor and electronics manufacturing capabilities, leading to the establishment of new fabrication facilities and the upgrading of existing ones. This expansion and modernization of manufacturing infrastructure is creating additional demand for cutting-edge vacuum pump solutions.

Current Tech Challenges

The application of vacuum pumps in next-generation electronic build platforms faces several significant challenges. One of the primary issues is achieving and maintaining ultra-high vacuum levels required for advanced manufacturing processes. As electronic components continue to shrink and become more complex, the need for cleaner and more controlled environments becomes paramount. Current vacuum pump technologies struggle to consistently reach and sustain the extreme low pressures needed for cutting-edge fabrication techniques.

Another major challenge lies in the energy efficiency of vacuum systems. Traditional vacuum pumps consume substantial amounts of power, which not only increases operational costs but also contradicts the industry's push towards more sustainable manufacturing practices. The development of energy-efficient vacuum solutions that can meet the demanding requirements of next-gen electronic build platforms remains a significant hurdle.

Contamination control presents yet another obstacle. As electronic components become increasingly sensitive to impurities, even minute particles or vapors can cause critical defects. Current vacuum pump designs often struggle to prevent backstreaming of pump oils or other contaminants into the process chamber, potentially compromising product quality and yield rates.

The integration of vacuum systems with advanced process control and monitoring capabilities is also a pressing challenge. Industry 4.0 and smart manufacturing trends demand real-time data collection and analysis, but many existing vacuum pump solutions lack sophisticated sensors and communication interfaces necessary for seamless integration with factory automation systems.

Scalability and flexibility pose additional difficulties. As electronic manufacturers seek to adapt quickly to changing market demands, vacuum systems must be able to scale up or down efficiently and reconfigure for different processes. However, current vacuum pump designs often lack the modularity and adaptability required for rapid production line changes.

Noise and vibration reduction represent another area of concern, particularly in cleanroom environments. Traditional vacuum pumps can generate significant noise and vibration, which may interfere with sensitive manufacturing processes or compromise worker comfort and safety. Developing quieter and low-vibration vacuum solutions without sacrificing performance is a complex engineering challenge.

Lastly, the reliability and maintenance requirements of vacuum pumps in continuous operation scenarios remain problematic. Electronic manufacturing often involves 24/7 production cycles, and any downtime for pump maintenance or replacement can result in significant productivity losses. Improving the longevity and reducing the maintenance frequency of vacuum pumps while maintaining their performance is a critical challenge for next-generation build platforms.

Another major challenge lies in the energy efficiency of vacuum systems. Traditional vacuum pumps consume substantial amounts of power, which not only increases operational costs but also contradicts the industry's push towards more sustainable manufacturing practices. The development of energy-efficient vacuum solutions that can meet the demanding requirements of next-gen electronic build platforms remains a significant hurdle.

Contamination control presents yet another obstacle. As electronic components become increasingly sensitive to impurities, even minute particles or vapors can cause critical defects. Current vacuum pump designs often struggle to prevent backstreaming of pump oils or other contaminants into the process chamber, potentially compromising product quality and yield rates.

The integration of vacuum systems with advanced process control and monitoring capabilities is also a pressing challenge. Industry 4.0 and smart manufacturing trends demand real-time data collection and analysis, but many existing vacuum pump solutions lack sophisticated sensors and communication interfaces necessary for seamless integration with factory automation systems.

Scalability and flexibility pose additional difficulties. As electronic manufacturers seek to adapt quickly to changing market demands, vacuum systems must be able to scale up or down efficiently and reconfigure for different processes. However, current vacuum pump designs often lack the modularity and adaptability required for rapid production line changes.

Noise and vibration reduction represent another area of concern, particularly in cleanroom environments. Traditional vacuum pumps can generate significant noise and vibration, which may interfere with sensitive manufacturing processes or compromise worker comfort and safety. Developing quieter and low-vibration vacuum solutions without sacrificing performance is a complex engineering challenge.

Lastly, the reliability and maintenance requirements of vacuum pumps in continuous operation scenarios remain problematic. Electronic manufacturing often involves 24/7 production cycles, and any downtime for pump maintenance or replacement can result in significant productivity losses. Improving the longevity and reducing the maintenance frequency of vacuum pumps while maintaining their performance is a critical challenge for next-generation build platforms.

Existing Vacuum Solutions

01 Rotary vacuum pump designs

Various designs of rotary vacuum pumps have been developed to improve efficiency and performance. These designs may include specific rotor configurations, sealing mechanisms, and lubrication systems to enhance vacuum generation and maintain consistent operation.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.

- Vacuum pump applications in semiconductor manufacturing: Vacuum pumps play a crucial role in semiconductor manufacturing processes. Specialized pumps have been developed to meet the stringent requirements of this industry, including high cleanliness, precise pressure control, and compatibility with various process gases. These pumps are designed to maintain ultra-high vacuum levels and minimize contamination risks in semiconductor fabrication.

- Energy-efficient vacuum pump technologies: Efforts have been made to develop energy-efficient vacuum pump technologies. These innovations focus on reducing power consumption while maintaining or improving pump performance. Techniques such as variable speed drives, advanced motor designs, and optimized compression stages have been implemented to enhance the energy efficiency of vacuum pumps across various applications.

- Vacuum pump noise reduction methods: Noise reduction in vacuum pumps has been a focus of development to improve working environments and meet regulatory requirements. Various approaches have been implemented, including acoustic enclosures, vibration isolation systems, and redesigned pump components. These methods aim to minimize noise emissions without compromising pump performance or efficiency.

- Integration of vacuum pumps in automotive systems: Vacuum pumps have found applications in automotive systems, particularly in brake boosters and engine management. Specialized pumps have been developed to meet the specific requirements of automotive applications, including compact design, durability under harsh conditions, and integration with vehicle control systems. These pumps contribute to improved vehicle performance and safety features.

02 Improvements in reciprocating vacuum pumps

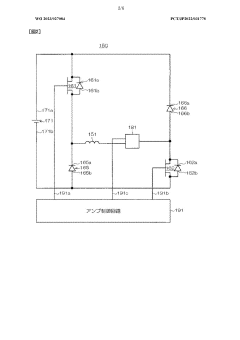

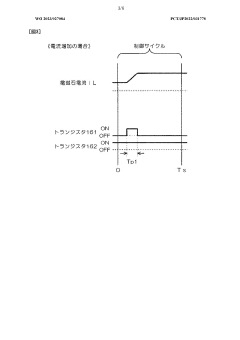

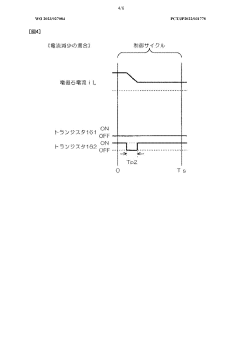

Advancements in reciprocating vacuum pump technology focus on enhancing piston designs, valve systems, and cylinder arrangements. These improvements aim to increase pumping capacity, reduce wear, and improve overall efficiency in creating and maintaining vacuum conditions.Expand Specific Solutions03 Vacuum pump control systems

Modern vacuum pumps incorporate sophisticated control systems to optimize performance and energy efficiency. These systems may include sensors, variable speed drives, and intelligent algorithms to adjust pump operation based on demand and environmental conditions.Expand Specific Solutions04 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps designed specifically for semiconductor manufacturing processes have been developed to meet the stringent cleanliness and performance requirements of the industry. These pumps often incorporate advanced materials and contamination control features.Expand Specific Solutions05 Historical developments in vacuum pump technology

The evolution of vacuum pump technology can be traced through various historical patents, showcasing early innovations and fundamental designs that have shaped modern vacuum pumping systems. These developments have led to more efficient and versatile vacuum generation methods.Expand Specific Solutions

Key Industry Players

The vacuum pump applications in next-generation electronic build platforms are in a growth phase, with increasing market size driven by advancements in semiconductor manufacturing and electronic device production. The technology is maturing rapidly, with key players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Leybold AG leading innovation. These companies are developing more efficient and specialized vacuum pumps tailored for advanced electronic manufacturing processes. The market is characterized by intense competition and continuous R&D efforts to improve pump performance, energy efficiency, and integration with smart manufacturing systems. As the demand for more sophisticated electronic devices grows, the vacuum pump technology is expected to evolve further, with a focus on miniaturization, precision control, and compatibility with emerging materials and processes.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for next-generation electronic build platforms. Their innovative approach includes the implementation of dry pumping technology, which eliminates the need for oil in the pumping mechanism. This results in a cleaner vacuum environment, crucial for sensitive electronic manufacturing processes. Edwards' pumps incorporate intelligent control systems that optimize performance based on real-time process demands, ensuring energy efficiency and consistent vacuum levels[1]. The company has also introduced turbomolecular pumps with magnetic bearings, reducing maintenance requirements and extending operational lifespan in high-throughput electronic manufacturing environments[2].

Strengths: Clean, oil-free operation; intelligent control for optimized performance; low maintenance requirements. Weaknesses: Higher initial cost compared to traditional pumps; may require specialized training for operators.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed a range of vacuum solutions specifically designed for next-generation electronic build platforms. Their HiPace turbopumps feature advanced rotor designs that achieve high compression ratios for light gases, crucial in electronic manufacturing processes[3]. Pfeiffer's pumps incorporate hybrid bearing technology, combining ceramic ball bearings with permanent magnetic bearings, resulting in reduced friction and extended maintenance intervals. The company has also introduced smart vacuum gauges that integrate seamlessly with their pumps, providing real-time pressure monitoring and control in electronic build platforms[4]. Additionally, Pfeiffer's ACP multi-stage roots pumps offer high pumping speeds at low pressures, making them ideal for large volume chambers in advanced electronic manufacturing facilities.

Strengths: High performance in light gas applications; long maintenance intervals; integrated smart monitoring systems. Weaknesses: Potentially higher cost for fully integrated systems; may require specialized infrastructure for optimal performance.

Core Vacuum Innovations

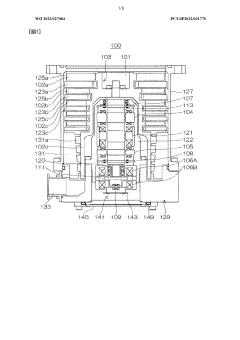

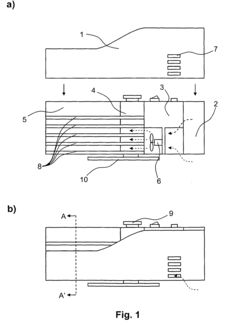

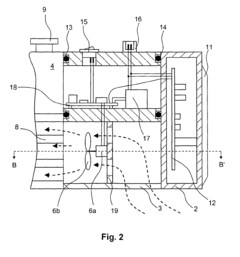

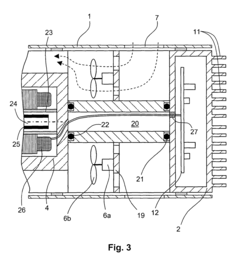

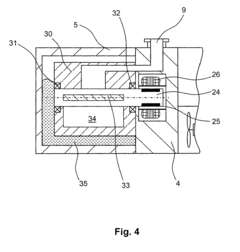

Vacuum pump and fixation component

PatentWO2023027084A1

Innovation

- A vacuum pump design with a thermal resistance increasing structure that includes a fixed component with reduced cross-sectional area for heat transfer, supporting the lowermost fixed blade and limiting heat transfer from the pump-side fixed part to the fixed blade support part, combined with a heating component to maintain optimal temperatures and prevent gas molecule accumulation.

Vacuum pump

PatentInactiveEP1936198A2

Innovation

- The vacuum pump is designed with a housing divided into separate sections for control electronics and the pump system, along with a peripheral section for gas connections and intermediate section for cooling, allowing for thermal separation and independent cooling air flow, which improves heat balance and reduces production costs by enabling reuse of sections across different models.

Environmental Impact

The environmental impact of vacuum pump applications in next-generation electronic build platforms is a critical consideration in the development and implementation of these technologies. As the electronics industry continues to advance, the demand for more efficient and precise manufacturing processes has led to increased use of vacuum pumps in various applications. However, this increased usage also raises concerns about potential environmental consequences.

Vacuum pumps in electronic build platforms consume significant amounts of energy, contributing to overall power consumption and associated carbon emissions. The energy-intensive nature of these systems necessitates careful evaluation of their environmental footprint. Manufacturers are increasingly focusing on developing more energy-efficient vacuum pump technologies to mitigate this impact, such as variable speed drives and advanced control systems that optimize pump operation based on demand.

Another environmental consideration is the use of working fluids in certain types of vacuum pumps. Some pumps require oil or other lubricants, which can potentially lead to contamination if not properly managed. Leaks or improper disposal of these fluids can have adverse effects on soil and water resources. To address this issue, manufacturers are exploring oil-free vacuum pump designs and developing more environmentally friendly lubricants.

The production and disposal of vacuum pump components also contribute to the overall environmental impact. Many pumps contain materials that require energy-intensive manufacturing processes or may be challenging to recycle. As a result, there is a growing emphasis on designing pumps with more sustainable materials and improving their recyclability at the end of their lifecycle.

Noise pollution is another environmental concern associated with vacuum pump operations. In industrial settings, the continuous operation of multiple pumps can create significant noise levels, potentially affecting both workers and surrounding communities. Efforts are being made to develop quieter pump designs and implement noise reduction technologies to minimize this impact.

Water consumption is an often-overlooked aspect of vacuum pump environmental impact. Some pump cooling systems require substantial amounts of water, which can strain local water resources in areas where water scarcity is a concern. Manufacturers are exploring alternative cooling methods, such as air-cooled systems or closed-loop water recycling, to reduce water consumption and minimize environmental impact.

As the electronics industry continues to evolve, addressing these environmental concerns will be crucial for the sustainable development of next-generation electronic build platforms. Balancing the need for high-performance vacuum pump applications with environmental responsibility will require ongoing innovation and collaboration between manufacturers, researchers, and environmental experts.

Vacuum pumps in electronic build platforms consume significant amounts of energy, contributing to overall power consumption and associated carbon emissions. The energy-intensive nature of these systems necessitates careful evaluation of their environmental footprint. Manufacturers are increasingly focusing on developing more energy-efficient vacuum pump technologies to mitigate this impact, such as variable speed drives and advanced control systems that optimize pump operation based on demand.

Another environmental consideration is the use of working fluids in certain types of vacuum pumps. Some pumps require oil or other lubricants, which can potentially lead to contamination if not properly managed. Leaks or improper disposal of these fluids can have adverse effects on soil and water resources. To address this issue, manufacturers are exploring oil-free vacuum pump designs and developing more environmentally friendly lubricants.

The production and disposal of vacuum pump components also contribute to the overall environmental impact. Many pumps contain materials that require energy-intensive manufacturing processes or may be challenging to recycle. As a result, there is a growing emphasis on designing pumps with more sustainable materials and improving their recyclability at the end of their lifecycle.

Noise pollution is another environmental concern associated with vacuum pump operations. In industrial settings, the continuous operation of multiple pumps can create significant noise levels, potentially affecting both workers and surrounding communities. Efforts are being made to develop quieter pump designs and implement noise reduction technologies to minimize this impact.

Water consumption is an often-overlooked aspect of vacuum pump environmental impact. Some pump cooling systems require substantial amounts of water, which can strain local water resources in areas where water scarcity is a concern. Manufacturers are exploring alternative cooling methods, such as air-cooled systems or closed-loop water recycling, to reduce water consumption and minimize environmental impact.

As the electronics industry continues to evolve, addressing these environmental concerns will be crucial for the sustainable development of next-generation electronic build platforms. Balancing the need for high-performance vacuum pump applications with environmental responsibility will require ongoing innovation and collaboration between manufacturers, researchers, and environmental experts.

Miniaturization Trends

The miniaturization trend in vacuum pump applications for next-generation electronic build platforms is driven by the increasing demand for compact and efficient manufacturing processes in the electronics industry. As devices become smaller and more complex, the need for precise control over the build environment becomes paramount.

Vacuum pumps play a crucial role in maintaining the required atmospheric conditions during the fabrication of electronic components. The trend towards miniaturization in this field is characterized by the development of smaller, more powerful pumps that can achieve higher vacuum levels while occupying less space on the production floor.

One of the key advancements in this area is the integration of micro-electromechanical systems (MEMS) technology into vacuum pump design. MEMS-based pumps offer significant size reduction compared to traditional mechanical pumps, while still maintaining high performance levels. These miniaturized pumps are particularly well-suited for use in portable electronic manufacturing equipment and cleanroom environments where space is at a premium.

Another aspect of the miniaturization trend is the development of multi-stage pump systems that combine different pump technologies in a compact package. For example, a combination of a turbomolecular pump and a diaphragm pump can achieve high vacuum levels in a smaller footprint than traditional pump configurations.

The use of advanced materials and manufacturing techniques has also contributed to the miniaturization of vacuum pumps. High-strength, lightweight alloys and composite materials allow for the creation of smaller pump components without sacrificing durability or performance. Additionally, 3D printing and other additive manufacturing techniques enable the production of complex pump geometries that were previously impossible to manufacture using traditional methods.

Miniaturization efforts have also focused on reducing the power consumption of vacuum pumps. This is achieved through the use of more efficient motors, improved pump designs that minimize friction and heat generation, and intelligent control systems that optimize pump operation based on real-time process requirements.

The trend towards miniaturization in vacuum pump technology is expected to continue as the electronics industry pushes for even smaller and more advanced devices. Future developments may include the integration of nanotechnology-based pumping mechanisms and the use of smart materials that can adapt to changing vacuum requirements in real-time.

As vacuum pumps become smaller and more efficient, they enable the development of more compact and versatile electronic build platforms. This, in turn, facilitates the production of increasingly sophisticated electronic devices while reducing manufacturing costs and improving overall process efficiency.

Vacuum pumps play a crucial role in maintaining the required atmospheric conditions during the fabrication of electronic components. The trend towards miniaturization in this field is characterized by the development of smaller, more powerful pumps that can achieve higher vacuum levels while occupying less space on the production floor.

One of the key advancements in this area is the integration of micro-electromechanical systems (MEMS) technology into vacuum pump design. MEMS-based pumps offer significant size reduction compared to traditional mechanical pumps, while still maintaining high performance levels. These miniaturized pumps are particularly well-suited for use in portable electronic manufacturing equipment and cleanroom environments where space is at a premium.

Another aspect of the miniaturization trend is the development of multi-stage pump systems that combine different pump technologies in a compact package. For example, a combination of a turbomolecular pump and a diaphragm pump can achieve high vacuum levels in a smaller footprint than traditional pump configurations.

The use of advanced materials and manufacturing techniques has also contributed to the miniaturization of vacuum pumps. High-strength, lightweight alloys and composite materials allow for the creation of smaller pump components without sacrificing durability or performance. Additionally, 3D printing and other additive manufacturing techniques enable the production of complex pump geometries that were previously impossible to manufacture using traditional methods.

Miniaturization efforts have also focused on reducing the power consumption of vacuum pumps. This is achieved through the use of more efficient motors, improved pump designs that minimize friction and heat generation, and intelligent control systems that optimize pump operation based on real-time process requirements.

The trend towards miniaturization in vacuum pump technology is expected to continue as the electronics industry pushes for even smaller and more advanced devices. Future developments may include the integration of nanotechnology-based pumping mechanisms and the use of smart materials that can adapt to changing vacuum requirements in real-time.

As vacuum pumps become smaller and more efficient, they enable the development of more compact and versatile electronic build platforms. This, in turn, facilitates the production of increasingly sophisticated electronic devices while reducing manufacturing costs and improving overall process efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!