Vacuum Pump Design for Enhanced Hydrogen Storage Systems

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Vacuum Pump Evolution and Objectives

Vacuum pump technology has played a crucial role in the evolution of hydrogen storage systems, with its development closely tied to the advancements in hydrogen storage capabilities. The journey of vacuum pumps in this field began in the mid-20th century when hydrogen storage became a focus for energy research. Initially, basic mechanical pumps were used to create low-pressure environments for hydrogen storage, but these proved inadequate for achieving the high vacuum levels required for efficient storage.

The 1970s saw a significant leap forward with the introduction of turbomolecular pumps, which could achieve much higher vacuum levels. This advancement allowed for the development of more sophisticated hydrogen storage systems, particularly in cryogenic applications. As the demand for hydrogen as a clean energy carrier grew in the 1990s and 2000s, the focus shifted towards developing vacuum pumps that could maintain ultra-high vacuum conditions while handling the unique properties of hydrogen gas.

In recent years, the objectives for vacuum pump design in hydrogen storage systems have become increasingly ambitious. The primary goal is to create pumps that can achieve and maintain extreme vacuum levels (10^-9 Torr or lower) while being energy-efficient and resistant to hydrogen embrittlement. This is crucial for enhancing the performance of advanced storage technologies such as metal hydrides and carbon nanostructures.

Another key objective is to develop pumps that can operate reliably in diverse environmental conditions, from cryogenic temperatures to high-pressure systems. This versatility is essential for supporting various hydrogen storage applications, from stationary energy storage to mobile fuel cell systems in vehicles.

Miniaturization and weight reduction have also become important goals, particularly for mobile applications. Engineers are working on compact, lightweight vacuum pump designs that can be integrated into vehicles without significantly impacting their overall weight or space requirements.

Improving the longevity and maintenance intervals of vacuum pumps is another critical objective. Given the corrosive nature of hydrogen and the high-stress operating conditions, developing pumps with enhanced durability and reduced maintenance needs is vital for the widespread adoption of hydrogen storage technologies.

The integration of smart technologies and IoT capabilities into vacuum pump systems is an emerging trend. The aim is to create pumps that can self-monitor, predict maintenance needs, and optimize performance in real-time, thereby enhancing the overall efficiency and reliability of hydrogen storage systems.

As we look to the future, the evolution of vacuum pump technology for hydrogen storage is expected to focus on even more advanced materials and designs. The ultimate goal is to develop pumps that can facilitate the safe, efficient, and cost-effective storage of hydrogen at scale, supporting the transition to a hydrogen-based economy.

The 1970s saw a significant leap forward with the introduction of turbomolecular pumps, which could achieve much higher vacuum levels. This advancement allowed for the development of more sophisticated hydrogen storage systems, particularly in cryogenic applications. As the demand for hydrogen as a clean energy carrier grew in the 1990s and 2000s, the focus shifted towards developing vacuum pumps that could maintain ultra-high vacuum conditions while handling the unique properties of hydrogen gas.

In recent years, the objectives for vacuum pump design in hydrogen storage systems have become increasingly ambitious. The primary goal is to create pumps that can achieve and maintain extreme vacuum levels (10^-9 Torr or lower) while being energy-efficient and resistant to hydrogen embrittlement. This is crucial for enhancing the performance of advanced storage technologies such as metal hydrides and carbon nanostructures.

Another key objective is to develop pumps that can operate reliably in diverse environmental conditions, from cryogenic temperatures to high-pressure systems. This versatility is essential for supporting various hydrogen storage applications, from stationary energy storage to mobile fuel cell systems in vehicles.

Miniaturization and weight reduction have also become important goals, particularly for mobile applications. Engineers are working on compact, lightweight vacuum pump designs that can be integrated into vehicles without significantly impacting their overall weight or space requirements.

Improving the longevity and maintenance intervals of vacuum pumps is another critical objective. Given the corrosive nature of hydrogen and the high-stress operating conditions, developing pumps with enhanced durability and reduced maintenance needs is vital for the widespread adoption of hydrogen storage technologies.

The integration of smart technologies and IoT capabilities into vacuum pump systems is an emerging trend. The aim is to create pumps that can self-monitor, predict maintenance needs, and optimize performance in real-time, thereby enhancing the overall efficiency and reliability of hydrogen storage systems.

As we look to the future, the evolution of vacuum pump technology for hydrogen storage is expected to focus on even more advanced materials and designs. The ultimate goal is to develop pumps that can facilitate the safe, efficient, and cost-effective storage of hydrogen at scale, supporting the transition to a hydrogen-based economy.

Hydrogen Storage Market Demand Analysis

The hydrogen storage market is experiencing significant growth driven by the increasing adoption of hydrogen as a clean energy carrier. As governments worldwide push for decarbonization and sustainable energy solutions, the demand for efficient hydrogen storage systems has surged. The transportation sector, particularly fuel cell electric vehicles (FCEVs), represents a major market segment for hydrogen storage technologies. With major automakers investing heavily in FCEV development, the demand for compact, lightweight, and high-capacity hydrogen storage systems is expected to rise substantially in the coming years.

Industrial applications form another crucial market for hydrogen storage. Industries such as chemical manufacturing, metallurgy, and power generation are exploring hydrogen as a feedstock and energy source to reduce their carbon footprint. This shift is creating a robust demand for large-scale hydrogen storage solutions that can handle high volumes and pressures.

The stationary power sector is emerging as a promising market for hydrogen storage. As renewable energy sources like wind and solar become more prevalent, the need for long-duration energy storage solutions grows. Hydrogen storage systems can play a vital role in grid balancing and seasonal energy storage, addressing the intermittency issues associated with renewable energy generation.

In the aerospace industry, there is a growing interest in hydrogen as a propulsion fuel for aircraft and spacecraft. This sector demands advanced hydrogen storage technologies that can meet stringent weight and safety requirements while providing high energy density.

The market for hydrogen storage is also being shaped by the development of hydrogen infrastructure. As countries invest in hydrogen production facilities and distribution networks, the demand for storage solutions at various points in the supply chain is increasing. This includes storage at production sites, in transportation systems, and at end-use locations.

Geographically, Asia-Pacific is expected to be a key growth region for the hydrogen storage market, with countries like Japan, South Korea, and China leading in hydrogen technology adoption. Europe is also showing strong market potential, driven by ambitious hydrogen strategies and supportive policies in countries such as Germany, the Netherlands, and the UK.

The market demand for hydrogen storage is closely tied to advancements in storage technologies. Innovations in materials science, such as metal hydrides and carbon-based adsorbents, are opening up new possibilities for more efficient and cost-effective storage solutions. This technological progress is expected to further stimulate market growth by enabling new applications and improving the economic viability of hydrogen-based systems.

Industrial applications form another crucial market for hydrogen storage. Industries such as chemical manufacturing, metallurgy, and power generation are exploring hydrogen as a feedstock and energy source to reduce their carbon footprint. This shift is creating a robust demand for large-scale hydrogen storage solutions that can handle high volumes and pressures.

The stationary power sector is emerging as a promising market for hydrogen storage. As renewable energy sources like wind and solar become more prevalent, the need for long-duration energy storage solutions grows. Hydrogen storage systems can play a vital role in grid balancing and seasonal energy storage, addressing the intermittency issues associated with renewable energy generation.

In the aerospace industry, there is a growing interest in hydrogen as a propulsion fuel for aircraft and spacecraft. This sector demands advanced hydrogen storage technologies that can meet stringent weight and safety requirements while providing high energy density.

The market for hydrogen storage is also being shaped by the development of hydrogen infrastructure. As countries invest in hydrogen production facilities and distribution networks, the demand for storage solutions at various points in the supply chain is increasing. This includes storage at production sites, in transportation systems, and at end-use locations.

Geographically, Asia-Pacific is expected to be a key growth region for the hydrogen storage market, with countries like Japan, South Korea, and China leading in hydrogen technology adoption. Europe is also showing strong market potential, driven by ambitious hydrogen strategies and supportive policies in countries such as Germany, the Netherlands, and the UK.

The market demand for hydrogen storage is closely tied to advancements in storage technologies. Innovations in materials science, such as metal hydrides and carbon-based adsorbents, are opening up new possibilities for more efficient and cost-effective storage solutions. This technological progress is expected to further stimulate market growth by enabling new applications and improving the economic viability of hydrogen-based systems.

Vacuum Pump Technology: Current State and Challenges

Vacuum pump technology plays a crucial role in the development of enhanced hydrogen storage systems. The current state of this technology is characterized by significant advancements, yet it also faces several challenges that need to be addressed for optimal performance in hydrogen storage applications.

One of the primary challenges in vacuum pump design for hydrogen storage systems is achieving and maintaining ultra-high vacuum levels. Hydrogen, being the smallest molecule, is particularly difficult to contain and pump effectively. Current vacuum pump technologies struggle to reach the extremely low pressures required for efficient hydrogen storage without compromising the system's overall performance.

Another significant challenge is the development of pumps that can handle high flow rates of hydrogen gas while maintaining low ultimate pressures. This is particularly important in large-scale hydrogen storage applications where rapid filling and emptying of storage tanks are necessary. Existing pump designs often face limitations in balancing these two critical parameters.

Material compatibility is a major concern in vacuum pump technology for hydrogen storage. Hydrogen embrittlement, a process where hydrogen atoms diffuse into the metal structure of pump components, can lead to premature failure and reduced pump lifespan. Developing materials and coatings that are resistant to hydrogen embrittlement while maintaining the necessary mechanical properties is an ongoing challenge.

Energy efficiency is another area where current vacuum pump technology faces limitations. Many existing pump designs consume significant amounts of energy, especially when operating continuously in hydrogen storage systems. Improving the energy efficiency of these pumps is crucial for the overall sustainability and cost-effectiveness of hydrogen storage solutions.

The miniaturization of vacuum pumps for portable or small-scale hydrogen storage applications presents another technological hurdle. Reducing the size and weight of pumps while maintaining their performance characteristics is a complex engineering challenge that requires innovative design approaches and advanced manufacturing techniques.

Contamination control is a critical aspect of vacuum pump technology in hydrogen storage systems. Even minute levels of impurities can significantly affect the purity of stored hydrogen and the overall system performance. Developing pumps with improved sealing mechanisms and materials that minimize outgassing is an ongoing area of research and development.

Lastly, the integration of smart technologies and IoT capabilities into vacuum pumps for hydrogen storage systems is an emerging challenge. The ability to monitor, control, and optimize pump performance in real-time can greatly enhance the efficiency and reliability of hydrogen storage systems. However, implementing these features while maintaining the robustness and simplicity of pump designs presents significant technical challenges.

One of the primary challenges in vacuum pump design for hydrogen storage systems is achieving and maintaining ultra-high vacuum levels. Hydrogen, being the smallest molecule, is particularly difficult to contain and pump effectively. Current vacuum pump technologies struggle to reach the extremely low pressures required for efficient hydrogen storage without compromising the system's overall performance.

Another significant challenge is the development of pumps that can handle high flow rates of hydrogen gas while maintaining low ultimate pressures. This is particularly important in large-scale hydrogen storage applications where rapid filling and emptying of storage tanks are necessary. Existing pump designs often face limitations in balancing these two critical parameters.

Material compatibility is a major concern in vacuum pump technology for hydrogen storage. Hydrogen embrittlement, a process where hydrogen atoms diffuse into the metal structure of pump components, can lead to premature failure and reduced pump lifespan. Developing materials and coatings that are resistant to hydrogen embrittlement while maintaining the necessary mechanical properties is an ongoing challenge.

Energy efficiency is another area where current vacuum pump technology faces limitations. Many existing pump designs consume significant amounts of energy, especially when operating continuously in hydrogen storage systems. Improving the energy efficiency of these pumps is crucial for the overall sustainability and cost-effectiveness of hydrogen storage solutions.

The miniaturization of vacuum pumps for portable or small-scale hydrogen storage applications presents another technological hurdle. Reducing the size and weight of pumps while maintaining their performance characteristics is a complex engineering challenge that requires innovative design approaches and advanced manufacturing techniques.

Contamination control is a critical aspect of vacuum pump technology in hydrogen storage systems. Even minute levels of impurities can significantly affect the purity of stored hydrogen and the overall system performance. Developing pumps with improved sealing mechanisms and materials that minimize outgassing is an ongoing area of research and development.

Lastly, the integration of smart technologies and IoT capabilities into vacuum pumps for hydrogen storage systems is an emerging challenge. The ability to monitor, control, and optimize pump performance in real-time can greatly enhance the efficiency and reliability of hydrogen storage systems. However, implementing these features while maintaining the robustness and simplicity of pump designs presents significant technical challenges.

Existing Vacuum Pump Solutions for Hydrogen Storage

01 Improved pump design for enhanced performance

Vacuum pump performance can be improved through innovative design features. This includes optimizing the shape and configuration of pump components, such as rotors, stators, and seals, to increase efficiency and reduce energy consumption. Advanced materials and manufacturing techniques may also be employed to enhance durability and reduce wear.- Improved rotor design for vacuum pumps: Advancements in rotor design, including optimized blade shapes and materials, can significantly enhance vacuum pump performance. These improvements lead to increased efficiency, reduced power consumption, and better overall pumping capacity.

- Enhanced sealing mechanisms: Innovative sealing technologies, such as advanced gaskets and dynamic sealing systems, contribute to improved vacuum pump performance by minimizing leakage and maintaining consistent pressure levels. These enhancements result in better vacuum quality and increased operational reliability.

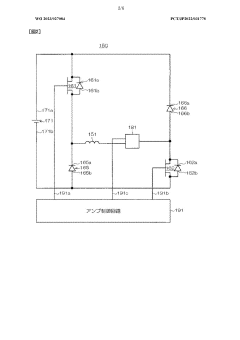

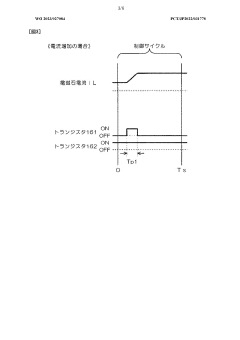

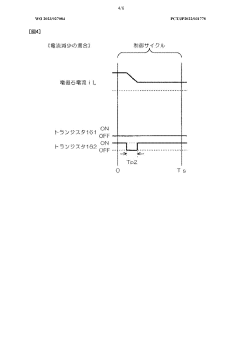

- Intelligent control systems for vacuum pumps: Integration of smart control systems and sensors allows for real-time monitoring and adjustment of vacuum pump operations. This leads to optimized performance, predictive maintenance, and energy efficiency improvements across various operating conditions.

- Multi-stage vacuum pump configurations: Implementing multi-stage vacuum pump designs can significantly enhance overall performance by allowing for more efficient pressure reduction across different stages. This approach enables higher ultimate vacuum levels and improved pumping speeds for various applications.

- Advanced cooling and lubrication systems: Incorporating innovative cooling and lubrication technologies helps maintain optimal operating temperatures and reduces friction in vacuum pumps. These improvements lead to extended equipment lifespan, increased reliability, and enhanced overall performance in demanding applications.

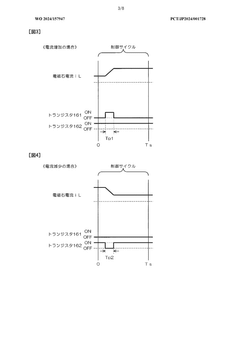

02 Control systems for optimizing vacuum pump operation

Implementing sophisticated control systems can significantly improve vacuum pump performance. These systems may include sensors, microprocessors, and algorithms that monitor and adjust pump parameters in real-time. This allows for adaptive operation based on changing conditions, leading to improved efficiency, reduced power consumption, and extended pump life.Expand Specific Solutions03 Multi-stage vacuum pump configurations

Utilizing multi-stage vacuum pump configurations can enhance overall performance by achieving higher vacuum levels and improved pumping speeds. This approach involves connecting multiple pump stages in series or parallel, each optimized for specific pressure ranges or applications. The result is a more versatile and efficient vacuum pumping system.Expand Specific Solutions04 Thermal management for improved vacuum pump efficiency

Effective thermal management is crucial for maintaining optimal vacuum pump performance. This includes innovative cooling systems, heat dissipation techniques, and temperature monitoring. By managing heat generation and dissipation, pump efficiency can be increased, and the risk of overheating and associated performance degradation can be minimized.Expand Specific Solutions05 Integration of smart technologies for predictive maintenance

Incorporating smart technologies and IoT capabilities into vacuum pumps can significantly enhance their performance and longevity. These features enable real-time monitoring, data analysis, and predictive maintenance, allowing for early detection of potential issues and optimization of maintenance schedules. This proactive approach helps maintain peak performance and reduces downtime.Expand Specific Solutions

Key Players in Hydrogen Storage and Vacuum Pump Industries

The vacuum pump design for enhanced hydrogen storage systems market is in a growth phase, driven by increasing demand for clean energy solutions. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with major players like Air Liquide SA, Linde GmbH, and Toyota Motor Corp. leading innovation. These companies are investing heavily in R&D to improve pump efficiency, storage capacity, and overall system performance. Emerging players such as McPhy Energy SA and GRZ Technologies SA are also contributing to technological advancements, particularly in compact and high-density storage solutions. The competitive landscape is characterized by a mix of established industrial gas companies and specialized hydrogen technology firms, all vying for market share in this promising sector.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced vacuum pump designs for enhanced hydrogen storage systems. Their technology focuses on multi-stage vacuum pumps that can achieve ultra-high vacuum levels necessary for efficient hydrogen storage. The company's pumps utilize a combination of dry screw and roots mechanisms, allowing for oil-free operation and minimizing contamination risks. Air Liquide's vacuum pumps are designed to handle high gas loads and maintain stable performance over extended periods, which is crucial for hydrogen storage applications. The pumps incorporate advanced sealing technologies and corrosion-resistant materials to ensure longevity and reliability when dealing with hydrogen[1][3]. Additionally, Air Liquide has implemented smart control systems that optimize pump performance based on real-time pressure and flow data, enhancing overall system efficiency[5].

Strengths: Expertise in gas handling, advanced multi-stage design, oil-free operation, and smart control systems. Weaknesses: Potentially higher initial costs and complexity compared to simpler pump designs.

McPhy Energy SA

Technical Solution: McPhy Energy has developed innovative vacuum pump solutions for solid-state hydrogen storage systems, particularly focusing on integration with their electrolysis and fuel cell technologies. Their pumps are designed to operate efficiently across a wide range of pressures, accommodating the varying requirements of different solid-state storage materials. McPhy's vacuum pumps incorporate advanced sealing technologies that minimize hydrogen leakage, a critical factor in long-term storage efficiency. The company has implemented smart control systems that optimize pump performance based on real-time storage conditions and hydrogen demand[13]. McPhy's pumps also feature modular designs that allow for easy scaling and integration into various hydrogen infrastructure projects. Additionally, the company has developed specialized vacuum pump configurations that support rapid cycling between storage and release phases, enhancing the responsiveness of hydrogen storage systems in dynamic applications[14][15].

Strengths: Integration with electrolysis and fuel cell systems, scalable designs, and optimization for rapid cycling. Weaknesses: May be less suitable for non-solid-state storage applications.

Core Innovations in Vacuum Pump Technology for H2 Storage

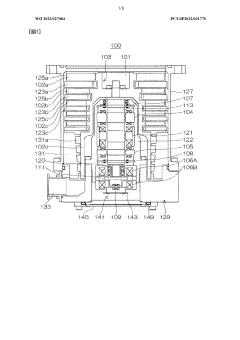

Vacuum pump and fixation component

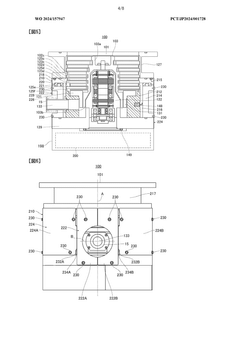

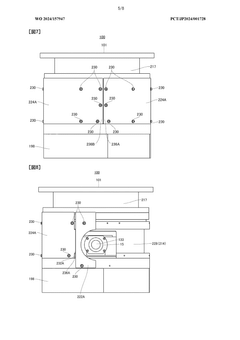

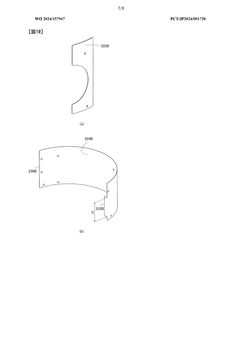

PatentWO2023027084A1

Innovation

- A vacuum pump design with a thermal resistance increasing structure that includes a fixed component with reduced cross-sectional area for heat transfer, supporting the lowermost fixed blade and limiting heat transfer from the pump-side fixed part to the fixed blade support part, combined with a heating component to maintain optimal temperatures and prevent gas molecule accumulation.

Vacuum pump

PatentWO2024157947A1

Innovation

- The vacuum pump design includes a casing with heating means for high-temperature components, an annular side cover, and a removable thin plate-shaped exhaust port cover to manage heat and prevent gas accumulation, featuring a double structure with a heater spacer and outer wall for temperature control and insulation.

Safety and Regulatory Considerations for H2 Storage Systems

Safety and regulatory considerations play a crucial role in the development and implementation of hydrogen storage systems, particularly those utilizing vacuum pump technology for enhanced performance. The inherent properties of hydrogen, including its high flammability and potential for leakage, necessitate stringent safety measures and compliance with established regulations.

One of the primary safety concerns in hydrogen storage systems is the prevention of leaks and unintended releases. Vacuum pump designs must incorporate robust sealing mechanisms and materials that can withstand the corrosive nature of hydrogen. Regular maintenance and inspection protocols are essential to ensure the integrity of these systems over time. Additionally, the use of hydrogen sensors and detection systems is critical for early identification of potential leaks, allowing for prompt intervention and mitigation of risks.

Pressure management is another key safety consideration in hydrogen storage systems. Vacuum pumps must be designed to operate within specified pressure ranges, with appropriate safety valves and pressure relief mechanisms in place to prevent over-pressurization. The integration of redundant safety systems and fail-safe mechanisms is crucial to maintain system integrity under various operating conditions and potential failure scenarios.

From a regulatory perspective, hydrogen storage systems must comply with a range of standards and guidelines set forth by national and international bodies. In the United States, for example, the Department of Energy (DOE) and the National Fire Protection Association (NFPA) provide comprehensive guidelines for the safe handling and storage of hydrogen. These regulations cover aspects such as material selection, system design, installation procedures, and operational protocols.

Internationally, organizations such as the International Organization for Standardization (ISO) have developed standards specifically addressing hydrogen technologies, including ISO/TC 197 for hydrogen technologies. These standards provide a framework for the safe design, construction, and operation of hydrogen storage systems, ensuring consistency and interoperability across different regions and applications.

Environmental considerations also factor into the regulatory landscape for hydrogen storage systems. As part of the broader push towards clean energy solutions, regulations often emphasize the importance of minimizing the environmental impact of these systems throughout their lifecycle. This includes considerations for energy efficiency, materials recycling, and the overall carbon footprint of the storage solution.

Training and certification requirements for personnel involved in the design, installation, and maintenance of hydrogen storage systems are another critical aspect of safety and regulatory compliance. Ensuring that all stakeholders possess the necessary knowledge and skills to handle hydrogen safely is essential for minimizing risks and maintaining operational integrity.

As the field of hydrogen storage continues to evolve, particularly with advancements in vacuum pump technology, it is imperative that safety and regulatory frameworks adapt accordingly. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions is crucial to develop and refine guidelines that address emerging challenges and opportunities in hydrogen storage systems.

One of the primary safety concerns in hydrogen storage systems is the prevention of leaks and unintended releases. Vacuum pump designs must incorporate robust sealing mechanisms and materials that can withstand the corrosive nature of hydrogen. Regular maintenance and inspection protocols are essential to ensure the integrity of these systems over time. Additionally, the use of hydrogen sensors and detection systems is critical for early identification of potential leaks, allowing for prompt intervention and mitigation of risks.

Pressure management is another key safety consideration in hydrogen storage systems. Vacuum pumps must be designed to operate within specified pressure ranges, with appropriate safety valves and pressure relief mechanisms in place to prevent over-pressurization. The integration of redundant safety systems and fail-safe mechanisms is crucial to maintain system integrity under various operating conditions and potential failure scenarios.

From a regulatory perspective, hydrogen storage systems must comply with a range of standards and guidelines set forth by national and international bodies. In the United States, for example, the Department of Energy (DOE) and the National Fire Protection Association (NFPA) provide comprehensive guidelines for the safe handling and storage of hydrogen. These regulations cover aspects such as material selection, system design, installation procedures, and operational protocols.

Internationally, organizations such as the International Organization for Standardization (ISO) have developed standards specifically addressing hydrogen technologies, including ISO/TC 197 for hydrogen technologies. These standards provide a framework for the safe design, construction, and operation of hydrogen storage systems, ensuring consistency and interoperability across different regions and applications.

Environmental considerations also factor into the regulatory landscape for hydrogen storage systems. As part of the broader push towards clean energy solutions, regulations often emphasize the importance of minimizing the environmental impact of these systems throughout their lifecycle. This includes considerations for energy efficiency, materials recycling, and the overall carbon footprint of the storage solution.

Training and certification requirements for personnel involved in the design, installation, and maintenance of hydrogen storage systems are another critical aspect of safety and regulatory compliance. Ensuring that all stakeholders possess the necessary knowledge and skills to handle hydrogen safely is essential for minimizing risks and maintaining operational integrity.

As the field of hydrogen storage continues to evolve, particularly with advancements in vacuum pump technology, it is imperative that safety and regulatory frameworks adapt accordingly. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions is crucial to develop and refine guidelines that address emerging challenges and opportunities in hydrogen storage systems.

Environmental Impact of Advanced Vacuum Pump Technologies

The environmental impact of advanced vacuum pump technologies in hydrogen storage systems is a critical consideration as the world moves towards cleaner energy solutions. These pumps play a crucial role in enhancing the efficiency and effectiveness of hydrogen storage, but their environmental footprint must be carefully evaluated.

Advanced vacuum pumps used in hydrogen storage systems generally consume less energy compared to traditional pumps, resulting in reduced greenhouse gas emissions associated with their operation. This energy efficiency is particularly important in large-scale hydrogen storage facilities, where continuous pump operation is necessary. The improved performance of these pumps also leads to better overall system efficiency, indirectly contributing to reduced energy consumption and environmental impact throughout the hydrogen supply chain.

However, the manufacturing process of advanced vacuum pumps often involves the use of specialized materials and complex production techniques, which may have higher environmental costs compared to simpler pump designs. The extraction and processing of rare earth elements or other advanced materials used in high-performance pump components can have significant environmental implications, including habitat disruption and potential pollution risks.

The longevity and reliability of advanced vacuum pumps contribute positively to their environmental profile. With extended operational lifespans and reduced maintenance requirements, these pumps minimize the need for frequent replacements, thereby reducing waste generation and resource consumption associated with manufacturing and disposal cycles. Additionally, many modern pump designs incorporate recyclable or reusable components, further mitigating their end-of-life environmental impact.

In terms of direct environmental interactions, advanced vacuum pumps typically have improved sealing mechanisms and containment features. This reduces the risk of hydrogen leakage, which is crucial not only for safety but also for preventing the release of this potent greenhouse gas into the atmosphere. The enhanced precision of these pumps also minimizes the potential for contamination of the stored hydrogen, ensuring higher purity levels and reducing the need for energy-intensive purification processes.

The noise pollution associated with vacuum pump operation is another environmental consideration. Advanced pump technologies often incorporate noise reduction features, contributing to a decrease in noise pollution in industrial settings. This is particularly relevant in urban or sensitive environments where hydrogen storage facilities may be located.

As the hydrogen economy expands, the cumulative environmental impact of these pumps becomes increasingly significant. While individual units may have a relatively small footprint, the widespread deployment of hydrogen storage systems could lead to substantial aggregate effects. Therefore, ongoing research and development efforts are focused on further improving the environmental performance of these pumps, exploring novel materials and designs that balance technological advancement with ecological responsibility.

Advanced vacuum pumps used in hydrogen storage systems generally consume less energy compared to traditional pumps, resulting in reduced greenhouse gas emissions associated with their operation. This energy efficiency is particularly important in large-scale hydrogen storage facilities, where continuous pump operation is necessary. The improved performance of these pumps also leads to better overall system efficiency, indirectly contributing to reduced energy consumption and environmental impact throughout the hydrogen supply chain.

However, the manufacturing process of advanced vacuum pumps often involves the use of specialized materials and complex production techniques, which may have higher environmental costs compared to simpler pump designs. The extraction and processing of rare earth elements or other advanced materials used in high-performance pump components can have significant environmental implications, including habitat disruption and potential pollution risks.

The longevity and reliability of advanced vacuum pumps contribute positively to their environmental profile. With extended operational lifespans and reduced maintenance requirements, these pumps minimize the need for frequent replacements, thereby reducing waste generation and resource consumption associated with manufacturing and disposal cycles. Additionally, many modern pump designs incorporate recyclable or reusable components, further mitigating their end-of-life environmental impact.

In terms of direct environmental interactions, advanced vacuum pumps typically have improved sealing mechanisms and containment features. This reduces the risk of hydrogen leakage, which is crucial not only for safety but also for preventing the release of this potent greenhouse gas into the atmosphere. The enhanced precision of these pumps also minimizes the potential for contamination of the stored hydrogen, ensuring higher purity levels and reducing the need for energy-intensive purification processes.

The noise pollution associated with vacuum pump operation is another environmental consideration. Advanced pump technologies often incorporate noise reduction features, contributing to a decrease in noise pollution in industrial settings. This is particularly relevant in urban or sensitive environments where hydrogen storage facilities may be located.

As the hydrogen economy expands, the cumulative environmental impact of these pumps becomes increasingly significant. While individual units may have a relatively small footprint, the widespread deployment of hydrogen storage systems could lead to substantial aggregate effects. Therefore, ongoing research and development efforts are focused on further improving the environmental performance of these pumps, exploring novel materials and designs that balance technological advancement with ecological responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!