Vacuum Pump Optimization for High-Capacity Lithium-Ion Battery Production

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution and Objectives

Vacuum pump technology has played a crucial role in the evolution of lithium-ion battery production, particularly in high-capacity manufacturing processes. The development of this technology can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. As the demand for more efficient and powerful lithium-ion batteries has grown, so too has the need for more sophisticated vacuum pump systems.

The primary objective of vacuum pump optimization in lithium-ion battery production is to enhance the overall efficiency and quality of the manufacturing process. This involves creating a controlled environment with minimal air and moisture content, which is essential for ensuring the purity and performance of battery components. Over time, the focus has shifted from simply achieving a vacuum to maintaining precise pressure levels and reducing energy consumption.

One of the key trends in vacuum pump technology for battery production has been the move towards dry pumps. These pumps offer several advantages over traditional oil-sealed pumps, including reduced contamination risks and lower maintenance requirements. This shift has been driven by the increasing demands of high-capacity battery production, where even minor impurities can significantly impact battery performance and lifespan.

Another important trend has been the integration of smart technologies and Industry 4.0 principles into vacuum pump systems. This has led to the development of pumps with advanced monitoring and control capabilities, allowing for real-time adjustments and predictive maintenance. Such features are particularly valuable in high-capacity production environments, where downtime can be extremely costly.

The evolution of vacuum pump technology has also been influenced by environmental concerns and energy efficiency requirements. Manufacturers have been working to develop pumps that consume less power while maintaining or improving performance. This has resulted in the introduction of variable speed drives and more efficient motor designs, which can significantly reduce energy consumption in large-scale battery production facilities.

Looking ahead, the objectives for vacuum pump technology in high-capacity lithium-ion battery production are likely to focus on further improvements in efficiency, reliability, and integration with other manufacturing processes. This may include the development of more compact and modular pump designs, advanced materials for improved durability, and enhanced automation capabilities to streamline production workflows.

The primary objective of vacuum pump optimization in lithium-ion battery production is to enhance the overall efficiency and quality of the manufacturing process. This involves creating a controlled environment with minimal air and moisture content, which is essential for ensuring the purity and performance of battery components. Over time, the focus has shifted from simply achieving a vacuum to maintaining precise pressure levels and reducing energy consumption.

One of the key trends in vacuum pump technology for battery production has been the move towards dry pumps. These pumps offer several advantages over traditional oil-sealed pumps, including reduced contamination risks and lower maintenance requirements. This shift has been driven by the increasing demands of high-capacity battery production, where even minor impurities can significantly impact battery performance and lifespan.

Another important trend has been the integration of smart technologies and Industry 4.0 principles into vacuum pump systems. This has led to the development of pumps with advanced monitoring and control capabilities, allowing for real-time adjustments and predictive maintenance. Such features are particularly valuable in high-capacity production environments, where downtime can be extremely costly.

The evolution of vacuum pump technology has also been influenced by environmental concerns and energy efficiency requirements. Manufacturers have been working to develop pumps that consume less power while maintaining or improving performance. This has resulted in the introduction of variable speed drives and more efficient motor designs, which can significantly reduce energy consumption in large-scale battery production facilities.

Looking ahead, the objectives for vacuum pump technology in high-capacity lithium-ion battery production are likely to focus on further improvements in efficiency, reliability, and integration with other manufacturing processes. This may include the development of more compact and modular pump designs, advanced materials for improved durability, and enhanced automation capabilities to streamline production workflows.

Li-Ion Battery Market Demand Analysis

The lithium-ion battery market has experienced exponential growth in recent years, driven by the increasing demand for electric vehicles, portable electronics, and renewable energy storage systems. This surge in demand has created a pressing need for high-capacity lithium-ion battery production, which in turn necessitates optimized manufacturing processes, including vacuum pump systems.

The global lithium-ion battery market was valued at approximately $41.1 billion in 2021 and is projected to reach $116.6 billion by 2030, growing at a compound annual growth rate (CAGR) of 12.3% during the forecast period. This remarkable growth is primarily attributed to the rapid adoption of electric vehicles (EVs) worldwide, with major automotive manufacturers committing to electrifying their fleets in the coming decades.

The EV segment alone is expected to dominate the lithium-ion battery market, accounting for over 60% of the total demand by 2030. This is driven by stringent government regulations on vehicle emissions, declining battery costs, and improving charging infrastructure. As a result, the demand for high-capacity lithium-ion batteries for EVs is skyrocketing, necessitating significant advancements in production technologies.

Consumer electronics, another major application area for lithium-ion batteries, continues to show steady growth. The increasing penetration of smartphones, laptops, and wearable devices is fueling the demand for compact, high-capacity batteries. This sector is expected to maintain a CAGR of around 8% through 2030, further contributing to the overall market expansion.

The renewable energy storage sector is emerging as a significant driver for lithium-ion battery demand. As countries worldwide push for greater adoption of renewable energy sources, the need for efficient energy storage solutions is growing. Grid-scale energy storage applications using lithium-ion batteries are projected to grow at a CAGR of over 20% in the coming years, presenting a substantial opportunity for battery manufacturers.

Geographically, Asia-Pacific dominates the lithium-ion battery market, with China leading in both production and consumption. The region is expected to maintain its dominance, accounting for over 50% of the global market share by 2030. North America and Europe are also witnessing rapid growth, driven by EV adoption and renewable energy initiatives.

The increasing demand across these sectors is putting pressure on battery manufacturers to scale up production while maintaining quality and reducing costs. This has led to a growing focus on optimizing manufacturing processes, including the critical step of electrolyte filling, where vacuum pump systems play a crucial role. Efficient vacuum pumps are essential for ensuring proper electrolyte distribution and removing air bubbles, which directly impacts battery performance and longevity.

As the industry moves towards higher capacity batteries, the requirements for vacuum pump performance become more stringent. Manufacturers are seeking solutions that can handle higher throughput, maintain consistent vacuum levels, and operate reliably in continuous production environments. This market demand is driving innovation in vacuum pump technology, with a focus on energy efficiency, precision control, and integration with smart manufacturing systems.

The global lithium-ion battery market was valued at approximately $41.1 billion in 2021 and is projected to reach $116.6 billion by 2030, growing at a compound annual growth rate (CAGR) of 12.3% during the forecast period. This remarkable growth is primarily attributed to the rapid adoption of electric vehicles (EVs) worldwide, with major automotive manufacturers committing to electrifying their fleets in the coming decades.

The EV segment alone is expected to dominate the lithium-ion battery market, accounting for over 60% of the total demand by 2030. This is driven by stringent government regulations on vehicle emissions, declining battery costs, and improving charging infrastructure. As a result, the demand for high-capacity lithium-ion batteries for EVs is skyrocketing, necessitating significant advancements in production technologies.

Consumer electronics, another major application area for lithium-ion batteries, continues to show steady growth. The increasing penetration of smartphones, laptops, and wearable devices is fueling the demand for compact, high-capacity batteries. This sector is expected to maintain a CAGR of around 8% through 2030, further contributing to the overall market expansion.

The renewable energy storage sector is emerging as a significant driver for lithium-ion battery demand. As countries worldwide push for greater adoption of renewable energy sources, the need for efficient energy storage solutions is growing. Grid-scale energy storage applications using lithium-ion batteries are projected to grow at a CAGR of over 20% in the coming years, presenting a substantial opportunity for battery manufacturers.

Geographically, Asia-Pacific dominates the lithium-ion battery market, with China leading in both production and consumption. The region is expected to maintain its dominance, accounting for over 50% of the global market share by 2030. North America and Europe are also witnessing rapid growth, driven by EV adoption and renewable energy initiatives.

The increasing demand across these sectors is putting pressure on battery manufacturers to scale up production while maintaining quality and reducing costs. This has led to a growing focus on optimizing manufacturing processes, including the critical step of electrolyte filling, where vacuum pump systems play a crucial role. Efficient vacuum pumps are essential for ensuring proper electrolyte distribution and removing air bubbles, which directly impacts battery performance and longevity.

As the industry moves towards higher capacity batteries, the requirements for vacuum pump performance become more stringent. Manufacturers are seeking solutions that can handle higher throughput, maintain consistent vacuum levels, and operate reliably in continuous production environments. This market demand is driving innovation in vacuum pump technology, with a focus on energy efficiency, precision control, and integration with smart manufacturing systems.

Vacuum Pump Challenges in Battery Production

Vacuum pumps play a critical role in the production of high-capacity lithium-ion batteries, yet they face several significant challenges in this demanding environment. One of the primary issues is maintaining consistent vacuum levels across large-scale production lines. As battery sizes increase and production volumes grow, vacuum systems must scale accordingly while ensuring uniform pressure distribution throughout the manufacturing process.

The aggressive nature of battery materials poses another substantial challenge. Electrolytes, solvents, and other chemicals used in battery production can be corrosive or reactive, potentially damaging vacuum pump components. This necessitates the use of specialized materials and coatings to protect pump internals, increasing costs and maintenance requirements.

Heat management is a persistent concern in vacuum pump operation for battery production. The continuous operation required in high-volume manufacturing generates significant heat, which can lead to performance degradation and reduced pump lifespan. Efficient cooling systems and heat-resistant materials are essential to address this issue, but they add complexity and cost to pump designs.

Particulate contamination presents a dual challenge for vacuum pumps in battery production. Fine particles generated during manufacturing processes can enter the pump, causing wear and potentially compromising vacuum performance. Conversely, pump oil or other contaminants must be prevented from entering the battery production environment to maintain product quality and safety.

Energy efficiency is an increasingly important consideration as manufacturers seek to reduce production costs and environmental impact. High-capacity battery production requires substantial vacuum capacity, which traditionally translates to high energy consumption. Developing more efficient pump technologies and optimizing vacuum system designs are crucial for addressing this challenge.

Maintenance and reliability are ongoing concerns in the high-stakes environment of battery production. Downtime due to pump failures or maintenance can result in significant production losses. Designing pumps for easy maintenance, implementing predictive maintenance strategies, and improving overall reliability are essential for meeting the demands of continuous, high-volume manufacturing.

Lastly, the rapid evolution of battery technologies and production methods requires vacuum pump manufacturers to continuously innovate and adapt their products. As new battery chemistries and form factors emerge, vacuum systems must be flexible enough to accommodate changing process requirements while maintaining performance and efficiency.

The aggressive nature of battery materials poses another substantial challenge. Electrolytes, solvents, and other chemicals used in battery production can be corrosive or reactive, potentially damaging vacuum pump components. This necessitates the use of specialized materials and coatings to protect pump internals, increasing costs and maintenance requirements.

Heat management is a persistent concern in vacuum pump operation for battery production. The continuous operation required in high-volume manufacturing generates significant heat, which can lead to performance degradation and reduced pump lifespan. Efficient cooling systems and heat-resistant materials are essential to address this issue, but they add complexity and cost to pump designs.

Particulate contamination presents a dual challenge for vacuum pumps in battery production. Fine particles generated during manufacturing processes can enter the pump, causing wear and potentially compromising vacuum performance. Conversely, pump oil or other contaminants must be prevented from entering the battery production environment to maintain product quality and safety.

Energy efficiency is an increasingly important consideration as manufacturers seek to reduce production costs and environmental impact. High-capacity battery production requires substantial vacuum capacity, which traditionally translates to high energy consumption. Developing more efficient pump technologies and optimizing vacuum system designs are crucial for addressing this challenge.

Maintenance and reliability are ongoing concerns in the high-stakes environment of battery production. Downtime due to pump failures or maintenance can result in significant production losses. Designing pumps for easy maintenance, implementing predictive maintenance strategies, and improving overall reliability are essential for meeting the demands of continuous, high-volume manufacturing.

Lastly, the rapid evolution of battery technologies and production methods requires vacuum pump manufacturers to continuously innovate and adapt their products. As new battery chemistries and form factors emerge, vacuum systems must be flexible enough to accommodate changing process requirements while maintaining performance and efficiency.

Current Vacuum Pump Solutions for Li-Ion Batteries

01 Improved pump design and configuration

Optimization of vacuum pump design involves enhancing the overall configuration and structure of the pump. This includes modifications to the rotor, stator, and other internal components to improve efficiency and performance. Advanced materials and manufacturing techniques may be employed to reduce friction, increase durability, and optimize fluid flow within the pump.- Improved pump design and configuration: Optimization of vacuum pump design involves enhancing the overall configuration and structure of the pump. This includes modifications to the rotor, stator, and other internal components to improve efficiency and performance. Advanced materials and manufacturing techniques may be employed to reduce friction, increase durability, and optimize fluid flow within the pump.

- Enhanced control systems and monitoring: Implementation of advanced control systems and monitoring technologies can significantly optimize vacuum pump operation. This includes the use of sensors, data analytics, and intelligent algorithms to adjust pump parameters in real-time, predict maintenance needs, and ensure optimal performance under varying conditions. Integration with IoT and cloud-based systems can further improve remote monitoring and control capabilities.

- Energy efficiency improvements: Focusing on energy efficiency is crucial for vacuum pump optimization. This involves developing more efficient motors, implementing variable speed drives, and optimizing power consumption based on load requirements. Heat recovery systems and innovative cooling methods can also be incorporated to reduce overall energy consumption and improve the pump's ecological footprint.

- Noise and vibration reduction: Minimizing noise and vibration is an important aspect of vacuum pump optimization. This can be achieved through improved balancing techniques, advanced damping systems, and innovative enclosure designs. Acoustic analysis and vibration isolation methods are employed to create quieter and smoother-running pumps, enhancing their suitability for various applications and work environments.

- Maintenance and reliability enhancements: Improving the maintenance aspects and overall reliability of vacuum pumps is crucial for optimization. This includes developing self-diagnostic capabilities, implementing predictive maintenance algorithms, and designing pumps with easily replaceable components. The use of wear-resistant materials and advanced lubrication systems can extend the operational life of the pump and reduce downtime.

02 Enhanced control systems and monitoring

Implementation of sophisticated control systems and monitoring technologies can significantly optimize vacuum pump operation. This includes the use of sensors, data analytics, and intelligent algorithms to adjust pump parameters in real-time, ensuring optimal performance under varying conditions. Advanced monitoring systems can also predict maintenance needs and prevent unexpected failures.Expand Specific Solutions03 Energy efficiency improvements

Focusing on energy efficiency is crucial for vacuum pump optimization. This involves developing pumps with higher energy conversion rates, implementing variable speed drives, and utilizing energy recovery systems. Optimizing the pump's power consumption while maintaining or improving its performance can lead to significant cost savings and reduced environmental impact.Expand Specific Solutions04 Noise and vibration reduction

Minimizing noise and vibration is an important aspect of vacuum pump optimization. This can be achieved through improved balancing techniques, advanced damping systems, and innovative acoustic designs. Reducing noise and vibration not only improves the working environment but also extends the pump's lifespan and maintains its efficiency over time.Expand Specific Solutions05 Multi-stage and hybrid pump systems

Developing multi-stage and hybrid pump systems can lead to significant improvements in vacuum pump performance. These systems combine different pumping technologies or stages to achieve higher vacuum levels, increased pumping speeds, and better overall efficiency. By leveraging the strengths of various pump types, these systems can be optimized for specific applications and operating conditions.Expand Specific Solutions

Key Players in Vacuum Pump Industry

The vacuum pump optimization for high-capacity lithium-ion battery production is in a growth phase, with increasing market size driven by the expanding electric vehicle and energy storage sectors. The technology is maturing rapidly, with major players like Sony Group Corp., Contemporary Amperex Technology Co., Ltd. (CATL), and BYD Co., Ltd. leading innovation. These companies are investing heavily in research and development to improve vacuum pump efficiency and reliability for large-scale battery manufacturing. The competitive landscape is intensifying as both established electronics giants and specialized battery manufacturers vie for market share, pushing technological boundaries to meet the growing demand for high-capacity lithium-ion batteries.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a proprietary vacuum-assisted electrolyte filling process for high-capacity lithium-ion batteries. Their system utilizes custom-designed vacuum pumps that maintain precise negative pressure during the electrolyte injection phase, ensuring uniform distribution and complete wetting of electrode materials[8]. The process incorporates a multi-stage vacuum application, with carefully controlled pressure ramps to optimize electrolyte penetration while minimizing the risk of electrode damage. CATL's vacuum pump system is integrated with their battery management system, allowing for real-time monitoring and adjustment of vacuum levels based on specific battery chemistries and form factors[9].

Strengths: Tailored for battery-specific processes, integrated with battery management systems. Weaknesses: May be less versatile for non-battery applications.

BYD Co., Ltd.

Technical Solution: BYD has developed an innovative vacuum-assisted production line for their high-capacity Blade Battery technology. Their system employs a network of distributed vacuum pumps strategically placed throughout the production process, from electrode preparation to final cell assembly. This approach allows for localized vacuum control, optimizing performance for each specific manufacturing step[10]. BYD's vacuum system incorporates advanced filtration technology to maintain ultra-clean production environments, crucial for the long-term stability and performance of their high-energy-density batteries. The company has also implemented an AI-driven vacuum control system that dynamically adjusts pump parameters based on real-time production data, resulting in a 20% increase in overall equipment effectiveness (OEE)[11].

Strengths: Distributed vacuum control, advanced filtration, and AI-driven optimization. Weaknesses: Potentially complex system architecture requiring specialized maintenance.

Innovative Vacuum Pump Technologies

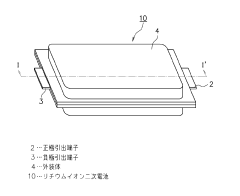

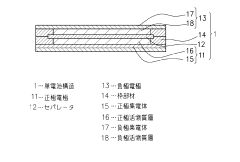

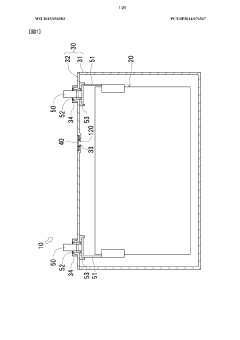

Manufacturing method and manufacturing apparatus of lithium-ion battery

PatentPendingJP2023063055A

Innovation

- A method and apparatus for manufacturing lithium-ion batteries that involves applying pressure to the stacked laminate in the stacking direction while covered with an outer package, followed by heat-sealing the exterior body in a vacuum state to constrain and seal the battery, using a holder and heat-sealing mechanism to ensure uniform sealing and reduce voids and moisture.

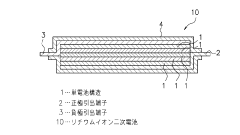

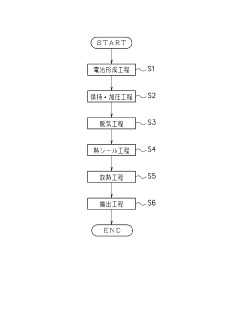

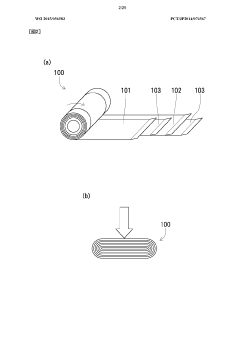

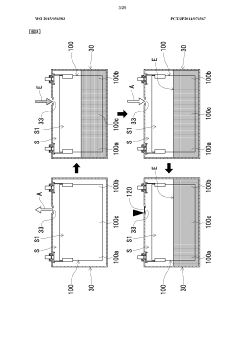

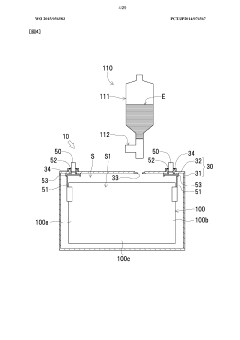

Secondary cell production method

PatentWO2015056583A1

Innovation

- A method involving pressure reduction in the battery case, injecting the electrolytic solution under reduced pressure, and utilizing capillary action to permeate from both ends of the wound body, followed by pressurizing the outer space to equilibrate and enhance permeation, ensuring airtightness and complete impregnation.

Energy Efficiency in Vacuum Pump Systems

Energy efficiency in vacuum pump systems is a critical aspect of optimizing high-capacity lithium-ion battery production. The vacuum process plays a crucial role in various stages of battery manufacturing, including electrode drying, electrolyte filling, and cell sealing. As the demand for lithium-ion batteries continues to grow, particularly in the electric vehicle and renewable energy storage sectors, improving the energy efficiency of vacuum pump systems has become increasingly important.

Vacuum pumps are significant energy consumers in battery production facilities. They operate continuously to maintain the required vacuum levels, often accounting for a substantial portion of the overall energy consumption. Enhancing their efficiency can lead to considerable energy savings and reduced operational costs. Moreover, improved energy efficiency contributes to the overall sustainability of battery production, aligning with global efforts to reduce carbon emissions in manufacturing processes.

Several strategies can be employed to optimize the energy efficiency of vacuum pump systems in lithium-ion battery production. One approach is the implementation of variable speed drives (VSDs) for vacuum pumps. VSDs allow pumps to adjust their speed and power consumption based on the actual vacuum demand, rather than operating at full capacity continuously. This dynamic adjustment can result in significant energy savings, especially during periods of lower production or when maintaining stable vacuum levels.

Another effective method is the use of heat recovery systems. Vacuum pumps generate substantial amounts of heat during operation, which is typically dissipated as waste. By implementing heat recovery technologies, this thermal energy can be captured and repurposed for other processes within the battery production facility, such as preheating materials or maintaining optimal temperatures in certain production areas.

Regular maintenance and monitoring of vacuum pump systems are also crucial for maintaining energy efficiency. This includes routine inspections, timely replacement of worn components, and addressing leaks in the vacuum system. Even small leaks can lead to increased pump workload and energy consumption. Advanced monitoring systems equipped with sensors and data analytics can provide real-time insights into pump performance, enabling proactive maintenance and optimization.

The selection of appropriate pump technology for specific applications within the battery production process is another key factor in energy efficiency. For instance, dry pumps may offer higher efficiency and lower maintenance requirements compared to oil-sealed pumps in certain applications. Additionally, the proper sizing of vacuum pumps to match the specific requirements of each production stage can prevent energy waste from oversized equipment.

In conclusion, optimizing the energy efficiency of vacuum pump systems in high-capacity lithium-ion battery production is a multifaceted approach that combines technological innovations, strategic operational practices, and ongoing monitoring and maintenance. As the battery industry continues to expand, these energy-efficient solutions will play a crucial role in enhancing productivity, reducing costs, and minimizing the environmental impact of battery manufacturing processes.

Vacuum pumps are significant energy consumers in battery production facilities. They operate continuously to maintain the required vacuum levels, often accounting for a substantial portion of the overall energy consumption. Enhancing their efficiency can lead to considerable energy savings and reduced operational costs. Moreover, improved energy efficiency contributes to the overall sustainability of battery production, aligning with global efforts to reduce carbon emissions in manufacturing processes.

Several strategies can be employed to optimize the energy efficiency of vacuum pump systems in lithium-ion battery production. One approach is the implementation of variable speed drives (VSDs) for vacuum pumps. VSDs allow pumps to adjust their speed and power consumption based on the actual vacuum demand, rather than operating at full capacity continuously. This dynamic adjustment can result in significant energy savings, especially during periods of lower production or when maintaining stable vacuum levels.

Another effective method is the use of heat recovery systems. Vacuum pumps generate substantial amounts of heat during operation, which is typically dissipated as waste. By implementing heat recovery technologies, this thermal energy can be captured and repurposed for other processes within the battery production facility, such as preheating materials or maintaining optimal temperatures in certain production areas.

Regular maintenance and monitoring of vacuum pump systems are also crucial for maintaining energy efficiency. This includes routine inspections, timely replacement of worn components, and addressing leaks in the vacuum system. Even small leaks can lead to increased pump workload and energy consumption. Advanced monitoring systems equipped with sensors and data analytics can provide real-time insights into pump performance, enabling proactive maintenance and optimization.

The selection of appropriate pump technology for specific applications within the battery production process is another key factor in energy efficiency. For instance, dry pumps may offer higher efficiency and lower maintenance requirements compared to oil-sealed pumps in certain applications. Additionally, the proper sizing of vacuum pumps to match the specific requirements of each production stage can prevent energy waste from oversized equipment.

In conclusion, optimizing the energy efficiency of vacuum pump systems in high-capacity lithium-ion battery production is a multifaceted approach that combines technological innovations, strategic operational practices, and ongoing monitoring and maintenance. As the battery industry continues to expand, these energy-efficient solutions will play a crucial role in enhancing productivity, reducing costs, and minimizing the environmental impact of battery manufacturing processes.

Environmental Impact of Vacuum Processes

The environmental impact of vacuum processes in high-capacity lithium-ion battery production is a critical consideration for sustainable manufacturing practices. Vacuum pumps, essential for various stages of battery production, contribute significantly to energy consumption and potential environmental hazards. The optimization of these pumps not only improves production efficiency but also plays a crucial role in reducing the overall environmental footprint of battery manufacturing.

Energy consumption is a primary concern in vacuum processes. High-capacity lithium-ion battery production requires extensive use of vacuum pumps, which are energy-intensive components. The continuous operation of these pumps contributes to increased electricity demand, potentially leading to higher carbon emissions if the energy source is not renewable. Optimizing vacuum pump efficiency can substantially reduce energy consumption, thereby decreasing the carbon footprint associated with battery production.

Vacuum processes also involve the use and potential release of various chemicals and gases. In lithium-ion battery manufacturing, these may include electrolytes, solvents, and other volatile organic compounds (VOCs). Inefficient vacuum systems can lead to incomplete removal or containment of these substances, potentially resulting in air and water pollution. Improved vacuum pump technology can enhance the capture and treatment of these emissions, minimizing environmental contamination and health risks to workers and surrounding communities.

Water usage is another environmental aspect affected by vacuum processes. Some vacuum pump systems require water for cooling or as a sealant. Optimizing these systems can lead to reduced water consumption and wastewater generation. Additionally, more efficient vacuum processes can minimize the risk of contaminated water discharge, which is crucial for protecting local water resources and ecosystems.

The lifecycle impact of vacuum pumps themselves is an important consideration. The production, maintenance, and disposal of these pumps involve resource extraction, energy use, and potential waste generation. By optimizing vacuum pump design for longevity and efficiency, manufacturers can reduce the frequency of pump replacements and associated environmental impacts. Furthermore, designing pumps with recyclable or reusable components can contribute to a more circular economy in battery production.

Noise pollution is an often-overlooked environmental impact of vacuum processes. High-capacity battery production facilities can generate significant noise levels, partly due to vacuum pump operations. This noise can affect both the work environment and surrounding communities. Optimizing vacuum pumps for quieter operation can improve the quality of life for workers and neighbors while also complying with environmental noise regulations.

In conclusion, the environmental impact of vacuum processes in lithium-ion battery production is multifaceted, encompassing energy use, emissions, water consumption, resource utilization, and noise pollution. Optimizing vacuum pumps and associated processes is crucial for mitigating these impacts and advancing towards more sustainable battery manufacturing practices. As the demand for high-capacity lithium-ion batteries continues to grow, addressing these environmental concerns becomes increasingly important for the industry's long-term sustainability and social responsibility.

Energy consumption is a primary concern in vacuum processes. High-capacity lithium-ion battery production requires extensive use of vacuum pumps, which are energy-intensive components. The continuous operation of these pumps contributes to increased electricity demand, potentially leading to higher carbon emissions if the energy source is not renewable. Optimizing vacuum pump efficiency can substantially reduce energy consumption, thereby decreasing the carbon footprint associated with battery production.

Vacuum processes also involve the use and potential release of various chemicals and gases. In lithium-ion battery manufacturing, these may include electrolytes, solvents, and other volatile organic compounds (VOCs). Inefficient vacuum systems can lead to incomplete removal or containment of these substances, potentially resulting in air and water pollution. Improved vacuum pump technology can enhance the capture and treatment of these emissions, minimizing environmental contamination and health risks to workers and surrounding communities.

Water usage is another environmental aspect affected by vacuum processes. Some vacuum pump systems require water for cooling or as a sealant. Optimizing these systems can lead to reduced water consumption and wastewater generation. Additionally, more efficient vacuum processes can minimize the risk of contaminated water discharge, which is crucial for protecting local water resources and ecosystems.

The lifecycle impact of vacuum pumps themselves is an important consideration. The production, maintenance, and disposal of these pumps involve resource extraction, energy use, and potential waste generation. By optimizing vacuum pump design for longevity and efficiency, manufacturers can reduce the frequency of pump replacements and associated environmental impacts. Furthermore, designing pumps with recyclable or reusable components can contribute to a more circular economy in battery production.

Noise pollution is an often-overlooked environmental impact of vacuum processes. High-capacity battery production facilities can generate significant noise levels, partly due to vacuum pump operations. This noise can affect both the work environment and surrounding communities. Optimizing vacuum pumps for quieter operation can improve the quality of life for workers and neighbors while also complying with environmental noise regulations.

In conclusion, the environmental impact of vacuum processes in lithium-ion battery production is multifaceted, encompassing energy use, emissions, water consumption, resource utilization, and noise pollution. Optimizing vacuum pumps and associated processes is crucial for mitigating these impacts and advancing towards more sustainable battery manufacturing practices. As the demand for high-capacity lithium-ion batteries continues to grow, addressing these environmental concerns becomes increasingly important for the industry's long-term sustainability and social responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!