Vacuum Pump Performance in Superconducting Material Synthesis

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pump technology has undergone significant evolution since its inception in the 17th century. The development of vacuum pumps has been closely tied to advancements in scientific research and industrial applications, particularly in the field of superconducting material synthesis. The journey from early mechanical pumps to modern high-performance vacuum systems reflects the growing demands for precise pressure control and contamination-free environments.

In the context of superconducting material synthesis, vacuum pumps play a crucial role in creating and maintaining the ultra-clean, low-pressure environments necessary for high-quality material production. The objectives of vacuum pump technology in this field have consistently focused on achieving lower ultimate pressures, higher pumping speeds, and improved reliability under demanding operating conditions.

Early vacuum pumps used in superconductor research were primarily mechanical, such as rotary vane and piston pumps. These laid the foundation for more advanced technologies but were limited in their ability to achieve the extremely low pressures required for cutting-edge superconductor synthesis. The introduction of diffusion pumps in the mid-20th century marked a significant leap forward, enabling researchers to achieve much lower pressures and cleaner vacuum environments.

The development of turbomolecular pumps in the 1960s revolutionized vacuum technology, offering oil-free operation and the ability to achieve ultra-high vacuum levels. This innovation was particularly important for superconducting material synthesis, as it minimized contamination risks and improved process control. Subsequent advancements in cryogenic pumps and getter pumps further expanded the capabilities of vacuum systems in this field.

Current objectives in vacuum pump technology for superconducting material synthesis focus on several key areas. These include enhancing pumping efficiency to achieve lower ultimate pressures, improving pump durability to withstand the harsh conditions often present in superconductor production processes, and developing more compact and energy-efficient designs to reduce operational costs and environmental impact.

Another critical goal is the integration of smart technologies and advanced control systems. These innovations aim to provide real-time monitoring and adjustment of vacuum conditions, ensuring optimal performance throughout the superconductor synthesis process. Additionally, there is a growing emphasis on developing pumps that can handle specialized gases and materials used in advanced superconductor fabrication techniques.

Looking forward, the evolution of vacuum pump technology is expected to continue in parallel with advancements in superconducting materials research. Objectives for future development include the creation of hybrid pump systems that combine multiple technologies for optimized performance, the exploration of novel materials and designs to push the boundaries of achievable vacuum levels, and the development of more sustainable and environmentally friendly vacuum solutions.

In the context of superconducting material synthesis, vacuum pumps play a crucial role in creating and maintaining the ultra-clean, low-pressure environments necessary for high-quality material production. The objectives of vacuum pump technology in this field have consistently focused on achieving lower ultimate pressures, higher pumping speeds, and improved reliability under demanding operating conditions.

Early vacuum pumps used in superconductor research were primarily mechanical, such as rotary vane and piston pumps. These laid the foundation for more advanced technologies but were limited in their ability to achieve the extremely low pressures required for cutting-edge superconductor synthesis. The introduction of diffusion pumps in the mid-20th century marked a significant leap forward, enabling researchers to achieve much lower pressures and cleaner vacuum environments.

The development of turbomolecular pumps in the 1960s revolutionized vacuum technology, offering oil-free operation and the ability to achieve ultra-high vacuum levels. This innovation was particularly important for superconducting material synthesis, as it minimized contamination risks and improved process control. Subsequent advancements in cryogenic pumps and getter pumps further expanded the capabilities of vacuum systems in this field.

Current objectives in vacuum pump technology for superconducting material synthesis focus on several key areas. These include enhancing pumping efficiency to achieve lower ultimate pressures, improving pump durability to withstand the harsh conditions often present in superconductor production processes, and developing more compact and energy-efficient designs to reduce operational costs and environmental impact.

Another critical goal is the integration of smart technologies and advanced control systems. These innovations aim to provide real-time monitoring and adjustment of vacuum conditions, ensuring optimal performance throughout the superconductor synthesis process. Additionally, there is a growing emphasis on developing pumps that can handle specialized gases and materials used in advanced superconductor fabrication techniques.

Looking forward, the evolution of vacuum pump technology is expected to continue in parallel with advancements in superconducting materials research. Objectives for future development include the creation of hybrid pump systems that combine multiple technologies for optimized performance, the exploration of novel materials and designs to push the boundaries of achievable vacuum levels, and the development of more sustainable and environmentally friendly vacuum solutions.

Market Analysis for Superconducting Material Synthesis

The market for superconducting materials synthesis is experiencing significant growth, driven by advancements in various high-tech industries. The global superconducting materials market is projected to expand at a compound annual growth rate of 17% from 2021 to 2028. This growth is primarily fueled by increasing demand in sectors such as healthcare, energy, and electronics.

In the healthcare sector, superconducting materials are crucial for magnetic resonance imaging (MRI) machines, which require high-performance magnets. The rising prevalence of chronic diseases and the need for advanced diagnostic tools are boosting the demand for MRI machines, consequently driving the market for superconducting materials.

The energy sector presents another substantial market opportunity. Superconducting materials are essential in the development of more efficient power transmission systems and energy storage solutions. As countries worldwide focus on renewable energy and grid modernization, the demand for superconducting cables and fault current limiters is expected to rise significantly.

In the electronics industry, superconducting materials are gaining traction in the development of quantum computers and high-performance computing systems. Major tech companies and research institutions are investing heavily in quantum computing, creating a growing market for superconducting qubits and related materials.

The transportation sector, particularly in the development of maglev trains, represents an emerging market for superconducting materials. Several countries, including Japan and China, are actively pursuing maglev technology, which relies on superconducting magnets for levitation and propulsion.

Geographically, Asia-Pacific is expected to be the fastest-growing market for superconducting materials, driven by rapid industrialization and increasing investments in research and development. North America and Europe remain significant markets, with a focus on advanced applications in healthcare and quantum computing.

However, the market faces challenges, including the high costs associated with superconducting material production and the technical complexities involved in their synthesis. The need for extremely low temperatures for most current superconducting materials also limits their widespread adoption.

Despite these challenges, ongoing research into high-temperature superconductors and more cost-effective production methods is expected to expand market opportunities. The development of room-temperature superconductors, while still in early stages, could potentially revolutionize the market if successful.

In the healthcare sector, superconducting materials are crucial for magnetic resonance imaging (MRI) machines, which require high-performance magnets. The rising prevalence of chronic diseases and the need for advanced diagnostic tools are boosting the demand for MRI machines, consequently driving the market for superconducting materials.

The energy sector presents another substantial market opportunity. Superconducting materials are essential in the development of more efficient power transmission systems and energy storage solutions. As countries worldwide focus on renewable energy and grid modernization, the demand for superconducting cables and fault current limiters is expected to rise significantly.

In the electronics industry, superconducting materials are gaining traction in the development of quantum computers and high-performance computing systems. Major tech companies and research institutions are investing heavily in quantum computing, creating a growing market for superconducting qubits and related materials.

The transportation sector, particularly in the development of maglev trains, represents an emerging market for superconducting materials. Several countries, including Japan and China, are actively pursuing maglev technology, which relies on superconducting magnets for levitation and propulsion.

Geographically, Asia-Pacific is expected to be the fastest-growing market for superconducting materials, driven by rapid industrialization and increasing investments in research and development. North America and Europe remain significant markets, with a focus on advanced applications in healthcare and quantum computing.

However, the market faces challenges, including the high costs associated with superconducting material production and the technical complexities involved in their synthesis. The need for extremely low temperatures for most current superconducting materials also limits their widespread adoption.

Despite these challenges, ongoing research into high-temperature superconductors and more cost-effective production methods is expected to expand market opportunities. The development of room-temperature superconductors, while still in early stages, could potentially revolutionize the market if successful.

Vacuum Technology Challenges in Superconducting Synthesis

The synthesis of superconducting materials requires ultra-high vacuum conditions, presenting significant challenges for vacuum technology. The primary obstacle lies in achieving and maintaining the extremely low pressures necessary for the deposition and growth of high-quality superconducting thin films. Conventional vacuum pumps often struggle to meet these demanding requirements, particularly in terms of ultimate pressure, pumping speed, and contamination control.

One of the key challenges is the need for oil-free pumping systems to prevent hydrocarbon contamination, which can severely degrade the properties of superconducting materials. This has led to the development and refinement of specialized pumps, such as turbomolecular pumps, cryopumps, and ion pumps, each with its own strengths and limitations in superconducting synthesis applications.

Turbomolecular pumps, while effective at achieving high vacuum levels, face limitations in pumping speed for light gases like hydrogen, which are often present in superconducting material precursors. Cryopumps offer excellent pumping capabilities for most gases but require periodic regeneration, potentially interrupting the synthesis process. Ion pumps provide clean, continuous pumping but may struggle with high gas loads during the initial stages of synthesis.

Another critical challenge is the management of outgassing from chamber walls and components, which can introduce impurities and limit the achievable vacuum levels. This necessitates careful material selection, surface treatment, and bakeout procedures to minimize outgassing rates. Additionally, the integration of in-situ characterization tools, essential for monitoring the synthesis process, often introduces additional vacuum interfaces and potential leak sources, further complicating pump performance requirements.

The dynamic nature of the synthesis process itself poses unique challenges. Rapid pressure fluctuations during precursor introduction and reaction stages demand pumps with high throughput and fast response times. Moreover, the pumps must be capable of handling corrosive and reactive gases often used in superconducting material synthesis without degradation or performance loss.

As research pushes towards the discovery and optimization of new superconducting materials, vacuum technology must evolve to meet increasingly stringent requirements. This includes the development of hybrid pumping systems that combine the strengths of different pump types, advanced pressure measurement and control techniques, and innovative chamber designs that minimize volume and maximize pumping efficiency.

One of the key challenges is the need for oil-free pumping systems to prevent hydrocarbon contamination, which can severely degrade the properties of superconducting materials. This has led to the development and refinement of specialized pumps, such as turbomolecular pumps, cryopumps, and ion pumps, each with its own strengths and limitations in superconducting synthesis applications.

Turbomolecular pumps, while effective at achieving high vacuum levels, face limitations in pumping speed for light gases like hydrogen, which are often present in superconducting material precursors. Cryopumps offer excellent pumping capabilities for most gases but require periodic regeneration, potentially interrupting the synthesis process. Ion pumps provide clean, continuous pumping but may struggle with high gas loads during the initial stages of synthesis.

Another critical challenge is the management of outgassing from chamber walls and components, which can introduce impurities and limit the achievable vacuum levels. This necessitates careful material selection, surface treatment, and bakeout procedures to minimize outgassing rates. Additionally, the integration of in-situ characterization tools, essential for monitoring the synthesis process, often introduces additional vacuum interfaces and potential leak sources, further complicating pump performance requirements.

The dynamic nature of the synthesis process itself poses unique challenges. Rapid pressure fluctuations during precursor introduction and reaction stages demand pumps with high throughput and fast response times. Moreover, the pumps must be capable of handling corrosive and reactive gases often used in superconducting material synthesis without degradation or performance loss.

As research pushes towards the discovery and optimization of new superconducting materials, vacuum technology must evolve to meet increasingly stringent requirements. This includes the development of hybrid pumping systems that combine the strengths of different pump types, advanced pressure measurement and control techniques, and innovative chamber designs that minimize volume and maximize pumping efficiency.

Current Vacuum Solutions for Superconductor Synthesis

01 Improved pump design for enhanced performance

Vacuum pump designs are optimized to improve overall performance. This includes modifications to impeller geometry, housing design, and sealing mechanisms to increase efficiency, reduce power consumption, and enhance pumping capacity.- Improved rotor design for vacuum pumps: Advanced rotor designs enhance vacuum pump performance by optimizing fluid dynamics and reducing internal friction. These improvements can include specialized blade geometries, surface treatments, and material selections that contribute to increased efficiency and longevity of the pump.

- Enhanced sealing mechanisms: Innovative sealing technologies are crucial for maintaining optimal vacuum levels. These can include advanced gasket materials, magnetic seals, or dynamic sealing systems that adapt to different operating conditions, resulting in improved vacuum retention and overall pump performance.

- Intelligent control systems for vacuum pumps: Integration of smart control systems allows for real-time monitoring and adjustment of pump parameters. These systems can optimize performance based on varying load conditions, predict maintenance needs, and ensure consistent vacuum levels across different applications.

- Energy-efficient vacuum pump designs: Development of energy-efficient pump designs focuses on reducing power consumption while maintaining high performance. This can involve the use of advanced materials, optimized motor designs, and innovative cooling systems to improve overall efficiency and reduce operating costs.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs can achieve higher ultimate vacuum levels and improved pumping speeds. These configurations often combine different pumping mechanisms or optimize the interaction between stages to enhance overall system performance and versatility across various applications.

02 Advanced control systems for vacuum pumps

Implementation of sophisticated control systems to optimize vacuum pump operation. These systems may include sensors, feedback loops, and intelligent algorithms to adjust pump parameters in real-time, ensuring optimal performance across various operating conditions.Expand Specific Solutions03 Novel materials and coatings for pump components

Utilization of advanced materials and surface coatings to enhance the durability, wear resistance, and overall performance of vacuum pump components. This may include the use of ceramic coatings, composite materials, or specialized alloys to improve pump efficiency and longevity.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Development of multi-stage vacuum pump systems that combine different pump types or stages to achieve higher vacuum levels and improved overall performance. This approach allows for optimized performance across a wide range of pressure conditions.Expand Specific Solutions05 Energy-efficient vacuum pump technologies

Focus on developing energy-efficient vacuum pump technologies to reduce power consumption while maintaining or improving performance. This may include the use of variable speed drives, energy recovery systems, or innovative pump designs that minimize energy losses.Expand Specific Solutions

Key Vacuum Pump Manufacturers and Suppliers

The vacuum pump market for superconducting material synthesis is in a mature growth stage, with a significant global market size driven by increasing demand in semiconductor and advanced materials industries. The technology has reached a high level of maturity, with established players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Shimadzu Corp. leading the field. These companies offer sophisticated vacuum solutions, leveraging decades of experience and continuous innovation. Emerging players such as LOT VACUUM Co., Ltd. and Maiwei Technology are also making strides, particularly in Asian markets. The competitive landscape is characterized by a focus on high-performance, energy-efficient pumps, with ongoing research and development efforts at institutions like Zhejiang University and Shanghai Jiao Tong University contributing to technological advancements in the field.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for superconducting material synthesis. Their GXS dry screw vacuum pumps offer high pumping speeds up to 3400 m³/h and ultimate pressures down to 5x10^-4 mbar[1]. These pumps utilize a unique screw rotor design that enhances compression efficiency and reduces power consumption. For ultra-high vacuum requirements, Edwards integrates their nEXT turbomolecular pumps, capable of reaching pressures as low as 5x10^-11 mbar[2]. The company has also implemented intelligent control systems that optimize pump performance based on process conditions, ensuring stable vacuum levels throughout the synthesis process.

Strengths: High pumping speeds, ultra-low ultimate pressures, and intelligent control systems. Weaknesses: Higher initial cost compared to conventional pumps, and potential complexity in maintenance for advanced models.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed the HiPace turbomolecular pump series, specifically designed for high-performance applications like superconducting material synthesis. These pumps achieve ultimate pressures below 1×10^-10 mbar and offer pumping speeds up to 3000 l/s[3]. The company's patented Holweck stage design improves compression ratios for light gases, crucial in maintaining ultra-high vacuum conditions. Pfeiffer's ATC (Advanced Temperature Control) technology actively regulates pump temperature, ensuring consistent performance during long synthesis processes[4]. Additionally, their vacuum measurement and analysis tools, such as the MPT 200 mass spectrometer, provide real-time monitoring of gas composition, enabling precise control of synthesis environments.

Strengths: Ultra-high vacuum capabilities, advanced temperature control, and integrated process monitoring. Weaknesses: Specialized nature may limit versatility, and high-end models can be cost-prohibitive for smaller research facilities.

Innovative Vacuum Pump Designs for Superconductors

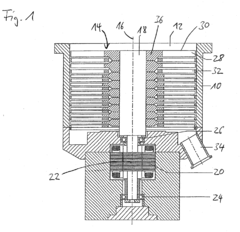

Vacuum pump

PatentActiveEP2740943A3

Innovation

- Incorporating nanoparticles, such as carbon nanotubes, into metal components like rotor disks to enhance mechanical and thermal resistance, maintaining metallic properties while increasing strength and heat resistance, allowing for reliable operation with high gas loads and flow rates.

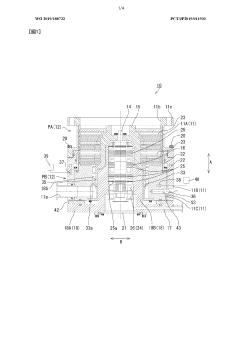

Vacuum pump

PatentWO2019188732A1

Innovation

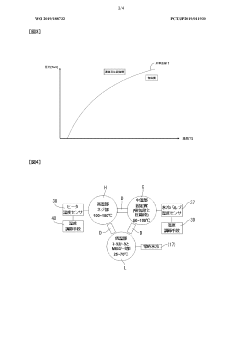

- A vacuum pump design incorporating a turbo-molecular pump mechanism and a screw pump mechanism with independent temperature adjustment means for cooling and heating, along with heat insulation and magnetic bearings, allows precise temperature control to prevent gas solidification and maintain component performance.

Energy Efficiency in Vacuum Pump Systems

Energy efficiency in vacuum pump systems is a critical consideration in the synthesis of superconducting materials. The process of creating these advanced materials often requires prolonged periods of operation under high vacuum conditions, making the energy consumption of vacuum pumps a significant factor in both operational costs and environmental impact.

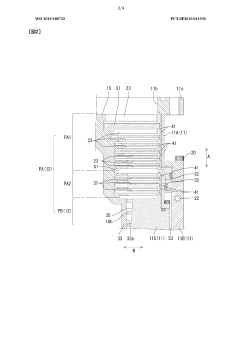

Modern vacuum pump systems have made substantial strides in improving energy efficiency. One key development is the implementation of variable speed drives (VSDs) in pump motors. These drives allow the pump to adjust its speed and power consumption based on the actual vacuum requirements, rather than operating at full capacity continuously. This adaptive approach can lead to energy savings of up to 50% in some applications.

Another area of focus has been the optimization of pump designs to reduce internal friction and improve gas flow dynamics. Advanced rotor designs, low-friction bearings, and precision-engineered clearances have all contributed to higher efficiency ratios. Some manufacturers have reported efficiency improvements of 20-30% through these mechanical enhancements alone.

Heat recovery systems have also been integrated into many high-performance vacuum pumps. These systems capture the waste heat generated during pump operation and repurpose it for other processes or facility heating. This not only reduces the overall energy footprint but also provides a secondary benefit by decreasing the cooling requirements for the pump system itself.

The use of intelligent control systems has further enhanced energy efficiency. These systems monitor vacuum levels, pump performance, and process requirements in real-time, allowing for dynamic adjustments to pump operation. By optimizing the balance between vacuum quality and energy consumption, these smart controls can achieve significant energy savings without compromising process integrity.

Dry pump technologies have gained prominence in superconducting material synthesis due to their lower energy consumption compared to traditional oil-sealed pumps. These pumps eliminate the need for oil, reducing friction and the associated energy losses. Additionally, they offer the benefit of a cleaner vacuum environment, which is crucial for high-purity material synthesis.

Recent advancements in materials science have led to the development of more efficient pump components. Lightweight, high-strength materials reduce the inertial load on pump motors, while advanced coatings minimize wear and maintain efficiency over longer operational periods. Some cutting-edge pumps now incorporate composite materials that offer superior thermal management and reduced energy dissipation.

As the demand for superconducting materials continues to grow, the focus on energy-efficient vacuum pump systems is likely to intensify. Future developments may include the integration of renewable energy sources, such as solar or wind power, to drive pump systems in large-scale production facilities. Additionally, the application of artificial intelligence and machine learning algorithms could further optimize pump performance and energy usage across complex synthesis processes.

Modern vacuum pump systems have made substantial strides in improving energy efficiency. One key development is the implementation of variable speed drives (VSDs) in pump motors. These drives allow the pump to adjust its speed and power consumption based on the actual vacuum requirements, rather than operating at full capacity continuously. This adaptive approach can lead to energy savings of up to 50% in some applications.

Another area of focus has been the optimization of pump designs to reduce internal friction and improve gas flow dynamics. Advanced rotor designs, low-friction bearings, and precision-engineered clearances have all contributed to higher efficiency ratios. Some manufacturers have reported efficiency improvements of 20-30% through these mechanical enhancements alone.

Heat recovery systems have also been integrated into many high-performance vacuum pumps. These systems capture the waste heat generated during pump operation and repurpose it for other processes or facility heating. This not only reduces the overall energy footprint but also provides a secondary benefit by decreasing the cooling requirements for the pump system itself.

The use of intelligent control systems has further enhanced energy efficiency. These systems monitor vacuum levels, pump performance, and process requirements in real-time, allowing for dynamic adjustments to pump operation. By optimizing the balance between vacuum quality and energy consumption, these smart controls can achieve significant energy savings without compromising process integrity.

Dry pump technologies have gained prominence in superconducting material synthesis due to their lower energy consumption compared to traditional oil-sealed pumps. These pumps eliminate the need for oil, reducing friction and the associated energy losses. Additionally, they offer the benefit of a cleaner vacuum environment, which is crucial for high-purity material synthesis.

Recent advancements in materials science have led to the development of more efficient pump components. Lightweight, high-strength materials reduce the inertial load on pump motors, while advanced coatings minimize wear and maintain efficiency over longer operational periods. Some cutting-edge pumps now incorporate composite materials that offer superior thermal management and reduced energy dissipation.

As the demand for superconducting materials continues to grow, the focus on energy-efficient vacuum pump systems is likely to intensify. Future developments may include the integration of renewable energy sources, such as solar or wind power, to drive pump systems in large-scale production facilities. Additionally, the application of artificial intelligence and machine learning algorithms could further optimize pump performance and energy usage across complex synthesis processes.

Cryogenic Compatibility of Vacuum Pumps

The cryogenic compatibility of vacuum pumps is a critical consideration in superconducting material synthesis. As temperatures approach absolute zero, conventional vacuum pumps face significant challenges in maintaining their performance and reliability. The primary issue stems from the extreme cold affecting the mechanical components and seals within the pumps, potentially leading to material contraction, increased brittleness, and seal failures.

Cryogenic-compatible vacuum pumps are specifically designed to operate efficiently in ultra-low temperature environments. These pumps utilize materials and lubricants that can withstand cryogenic conditions without compromising their functionality. Common materials include stainless steel, aluminum alloys, and specialized polymers that maintain their properties at extremely low temperatures.

One key aspect of cryogenic-compatible vacuum pumps is their ability to handle the unique gas dynamics present in low-temperature environments. As gases approach their condensation points, their behavior becomes increasingly non-ideal, affecting pump performance. Cryogenic pumps must be capable of efficiently removing these gases without experiencing internal condensation or freezing.

Turbomolecular pumps, often used in high-vacuum applications, require special modifications for cryogenic compatibility. These modifications may include the use of ceramic bearings, specialized lubricants, and thermal management systems to prevent heat transfer from the pump to the cryogenic environment.

Cryopumps, which operate by condensing gases onto cold surfaces, are inherently well-suited for cryogenic applications. However, they must be carefully designed to handle the specific gas mixtures encountered in superconducting material synthesis without becoming saturated or losing efficiency over time.

The integration of cryogenic-compatible vacuum pumps into superconducting material synthesis systems requires careful consideration of thermal management. Heat generated by the pump must be effectively isolated from the cryogenic environment to prevent unwanted warming of the superconducting materials. This often involves the use of thermal barriers, radiation shields, and strategic placement of pumps within the system.

Maintenance and reliability of cryogenic-compatible vacuum pumps pose unique challenges. Regular inspection and replacement of seals, bearings, and other components subject to wear in extreme cold conditions are essential to ensure consistent performance. Additionally, proper warm-up and cool-down procedures must be followed to prevent thermal shock and extend the lifespan of the pumps.

Cryogenic-compatible vacuum pumps are specifically designed to operate efficiently in ultra-low temperature environments. These pumps utilize materials and lubricants that can withstand cryogenic conditions without compromising their functionality. Common materials include stainless steel, aluminum alloys, and specialized polymers that maintain their properties at extremely low temperatures.

One key aspect of cryogenic-compatible vacuum pumps is their ability to handle the unique gas dynamics present in low-temperature environments. As gases approach their condensation points, their behavior becomes increasingly non-ideal, affecting pump performance. Cryogenic pumps must be capable of efficiently removing these gases without experiencing internal condensation or freezing.

Turbomolecular pumps, often used in high-vacuum applications, require special modifications for cryogenic compatibility. These modifications may include the use of ceramic bearings, specialized lubricants, and thermal management systems to prevent heat transfer from the pump to the cryogenic environment.

Cryopumps, which operate by condensing gases onto cold surfaces, are inherently well-suited for cryogenic applications. However, they must be carefully designed to handle the specific gas mixtures encountered in superconducting material synthesis without becoming saturated or losing efficiency over time.

The integration of cryogenic-compatible vacuum pumps into superconducting material synthesis systems requires careful consideration of thermal management. Heat generated by the pump must be effectively isolated from the cryogenic environment to prevent unwanted warming of the superconducting materials. This often involves the use of thermal barriers, radiation shields, and strategic placement of pumps within the system.

Maintenance and reliability of cryogenic-compatible vacuum pumps pose unique challenges. Regular inspection and replacement of seals, bearings, and other components subject to wear in extreme cold conditions are essential to ensure consistent performance. Additionally, proper warm-up and cool-down procedures must be followed to prevent thermal shock and extend the lifespan of the pumps.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!