Vacuum Pump Roles in Additive Manufacturing of Metals

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM Vacuum Pump Tech Evolution and Objectives

Vacuum pumps have played a crucial role in the evolution of additive manufacturing (AM) for metals, particularly in powder bed fusion processes. The technology's development can be traced back to the 1980s when selective laser sintering (SLS) was first introduced. Initially, vacuum systems were rudimentary, primarily used to create an inert atmosphere for metal powder processing.

As AM technologies advanced, the importance of vacuum systems became increasingly apparent. In the 1990s and early 2000s, the focus shifted towards improving build chamber environments to enhance part quality and reduce defects. This led to the integration of more sophisticated vacuum pump systems capable of achieving lower pressures and maintaining stable atmospheres during the build process.

The evolution of vacuum pump technology in metal AM has been driven by several key objectives. Firstly, there has been a continuous push to achieve higher vacuum levels to minimize oxygen content and other contaminants in the build chamber. This is crucial for preventing oxidation and ensuring the purity of the final metal parts.

Another significant objective has been to improve the efficiency and reliability of vacuum systems. As AM machines became larger and more complex, the demand for vacuum pumps that could operate continuously for extended periods increased. This led to the development of more robust pump designs and improved cooling systems to handle the heat generated during long build cycles.

In recent years, the focus has shifted towards developing vacuum systems that can handle a wider range of materials and process parameters. This includes the ability to manage reactive metal powders and deal with the byproducts of the AM process, such as metal vapors and spatter. Advanced filtration systems and specialized pump designs have been introduced to address these challenges.

The integration of smart technologies and Industry 4.0 principles has also become a key objective in vacuum pump development for AM. Modern systems now incorporate sensors and monitoring capabilities that allow for real-time adjustments and predictive maintenance, enhancing overall process control and reliability.

Looking ahead, the objectives for vacuum pump technology in metal AM are likely to focus on further miniaturization, energy efficiency, and the ability to create more precise and controllable atmospheres. There is also a growing interest in developing vacuum systems that can support new AM processes, such as multi-material printing and in-situ alloying, which may require even more sophisticated atmospheric control.

As AM technologies advanced, the importance of vacuum systems became increasingly apparent. In the 1990s and early 2000s, the focus shifted towards improving build chamber environments to enhance part quality and reduce defects. This led to the integration of more sophisticated vacuum pump systems capable of achieving lower pressures and maintaining stable atmospheres during the build process.

The evolution of vacuum pump technology in metal AM has been driven by several key objectives. Firstly, there has been a continuous push to achieve higher vacuum levels to minimize oxygen content and other contaminants in the build chamber. This is crucial for preventing oxidation and ensuring the purity of the final metal parts.

Another significant objective has been to improve the efficiency and reliability of vacuum systems. As AM machines became larger and more complex, the demand for vacuum pumps that could operate continuously for extended periods increased. This led to the development of more robust pump designs and improved cooling systems to handle the heat generated during long build cycles.

In recent years, the focus has shifted towards developing vacuum systems that can handle a wider range of materials and process parameters. This includes the ability to manage reactive metal powders and deal with the byproducts of the AM process, such as metal vapors and spatter. Advanced filtration systems and specialized pump designs have been introduced to address these challenges.

The integration of smart technologies and Industry 4.0 principles has also become a key objective in vacuum pump development for AM. Modern systems now incorporate sensors and monitoring capabilities that allow for real-time adjustments and predictive maintenance, enhancing overall process control and reliability.

Looking ahead, the objectives for vacuum pump technology in metal AM are likely to focus on further miniaturization, energy efficiency, and the ability to create more precise and controllable atmospheres. There is also a growing interest in developing vacuum systems that can support new AM processes, such as multi-material printing and in-situ alloying, which may require even more sophisticated atmospheric control.

Metal AM Market Demand Analysis

The metal additive manufacturing (AM) market has experienced significant growth in recent years, driven by increasing demand for complex, lightweight, and customized metal components across various industries. The global metal AM market was valued at approximately $2.3 billion in 2020 and is projected to reach $10.6 billion by 2025, growing at a CAGR of 35.8% during the forecast period.

Aerospace and defense industries are the primary drivers of metal AM market demand, accounting for nearly 40% of the total market share. These sectors utilize metal AM for producing lightweight components, reducing fuel consumption, and enhancing overall performance of aircraft and spacecraft. The automotive industry is another significant contributor, with a growing interest in metal AM for prototyping, tooling, and production of complex parts for high-performance vehicles.

The healthcare sector, particularly orthopedics and dental implants, has also emerged as a key market for metal AM. The ability to create patient-specific implants and prosthetics has revolutionized the medical field, leading to improved patient outcomes and reduced surgical times. This sector is expected to witness the highest growth rate in the coming years, with a CAGR of over 40%.

Industrial machinery and tooling applications are gaining traction in the metal AM market, driven by the need for rapid prototyping, on-demand spare parts production, and the creation of complex tooling components. This segment is projected to grow at a CAGR of 32% over the next five years.

Geographically, North America dominates the metal AM market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate, fueled by increasing adoption in countries like China, Japan, and South Korea.

The demand for metal powders used in AM processes is also on the rise, with titanium, aluminum, and nickel-based alloys being the most sought-after materials. The metal powder market for AM is expected to grow at a CAGR of 22% from 2020 to 2025.

As the technology matures and becomes more cost-effective, new applications and industries are expected to adopt metal AM, further driving market growth. The energy sector, particularly oil and gas, is showing increased interest in metal AM for producing complex components used in harsh environments. Additionally, the jewelry and luxury goods industries are exploring metal AM for creating intricate designs and customized products.

Aerospace and defense industries are the primary drivers of metal AM market demand, accounting for nearly 40% of the total market share. These sectors utilize metal AM for producing lightweight components, reducing fuel consumption, and enhancing overall performance of aircraft and spacecraft. The automotive industry is another significant contributor, with a growing interest in metal AM for prototyping, tooling, and production of complex parts for high-performance vehicles.

The healthcare sector, particularly orthopedics and dental implants, has also emerged as a key market for metal AM. The ability to create patient-specific implants and prosthetics has revolutionized the medical field, leading to improved patient outcomes and reduced surgical times. This sector is expected to witness the highest growth rate in the coming years, with a CAGR of over 40%.

Industrial machinery and tooling applications are gaining traction in the metal AM market, driven by the need for rapid prototyping, on-demand spare parts production, and the creation of complex tooling components. This segment is projected to grow at a CAGR of 32% over the next five years.

Geographically, North America dominates the metal AM market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate, fueled by increasing adoption in countries like China, Japan, and South Korea.

The demand for metal powders used in AM processes is also on the rise, with titanium, aluminum, and nickel-based alloys being the most sought-after materials. The metal powder market for AM is expected to grow at a CAGR of 22% from 2020 to 2025.

As the technology matures and becomes more cost-effective, new applications and industries are expected to adopt metal AM, further driving market growth. The energy sector, particularly oil and gas, is showing increased interest in metal AM for producing complex components used in harsh environments. Additionally, the jewelry and luxury goods industries are exploring metal AM for creating intricate designs and customized products.

Vacuum Pump Challenges in Metal AM

Vacuum pumps play a critical role in metal additive manufacturing (AM) processes, yet they face several significant challenges that impact the overall efficiency and quality of production. One of the primary issues is maintaining consistent vacuum levels throughout the build process. As metal powders are melted and solidified, they release gases and contaminants that can compromise the vacuum environment. This requires vacuum pumps to operate continuously and efficiently, often for extended periods, which puts considerable strain on the equipment.

The high temperatures involved in metal AM processes also pose a challenge for vacuum pumps. The heat generated during the melting and solidification of metal powders can affect the performance and longevity of vacuum components. This necessitates the development of heat-resistant materials and cooling systems for vacuum pumps, adding complexity and cost to their design and maintenance.

Contamination is another significant concern in metal AM vacuum systems. Fine metal particles and condensed vapors can enter the vacuum pump, potentially causing damage or reducing its efficiency. This requires the implementation of advanced filtration systems and regular maintenance procedures to prevent pump failure and ensure consistent performance.

The size and capacity of vacuum pumps present another challenge in metal AM applications. As the industry moves towards larger build volumes and higher throughput, vacuum pumps must scale accordingly while maintaining performance. This scaling often leads to increased power consumption and heat generation, further complicating system design and operation.

Vacuum pump noise and vibration are additional factors that need to be addressed in metal AM environments. These issues can affect the precision of the printing process and create workplace discomfort. Developing quieter, low-vibration pump technologies is essential for improving overall system performance and operator well-being.

The corrosive nature of some metal powders used in AM processes also presents a challenge for vacuum pump durability. Pumps must be constructed with materials resistant to chemical attack, which can increase costs and limit material choices. This corrosion resistance must be balanced with other performance requirements, such as thermal management and efficiency.

Lastly, the integration of vacuum pumps with other AM system components and control software poses a significant challenge. Ensuring seamless communication and coordination between the vacuum system and other process parameters is crucial for achieving optimal print quality and consistency. This requires sophisticated control algorithms and robust integration protocols, adding another layer of complexity to metal AM system design and operation.

The high temperatures involved in metal AM processes also pose a challenge for vacuum pumps. The heat generated during the melting and solidification of metal powders can affect the performance and longevity of vacuum components. This necessitates the development of heat-resistant materials and cooling systems for vacuum pumps, adding complexity and cost to their design and maintenance.

Contamination is another significant concern in metal AM vacuum systems. Fine metal particles and condensed vapors can enter the vacuum pump, potentially causing damage or reducing its efficiency. This requires the implementation of advanced filtration systems and regular maintenance procedures to prevent pump failure and ensure consistent performance.

The size and capacity of vacuum pumps present another challenge in metal AM applications. As the industry moves towards larger build volumes and higher throughput, vacuum pumps must scale accordingly while maintaining performance. This scaling often leads to increased power consumption and heat generation, further complicating system design and operation.

Vacuum pump noise and vibration are additional factors that need to be addressed in metal AM environments. These issues can affect the precision of the printing process and create workplace discomfort. Developing quieter, low-vibration pump technologies is essential for improving overall system performance and operator well-being.

The corrosive nature of some metal powders used in AM processes also presents a challenge for vacuum pump durability. Pumps must be constructed with materials resistant to chemical attack, which can increase costs and limit material choices. This corrosion resistance must be balanced with other performance requirements, such as thermal management and efficiency.

Lastly, the integration of vacuum pumps with other AM system components and control software poses a significant challenge. Ensuring seamless communication and coordination between the vacuum system and other process parameters is crucial for achieving optimal print quality and consistency. This requires sophisticated control algorithms and robust integration protocols, adding another layer of complexity to metal AM system design and operation.

Current Vacuum Solutions for Metal AM

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include novel rotor configurations, advanced sealing mechanisms, or optimized flow paths to achieve better vacuum levels and energy efficiency.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.

- Vacuum pump control systems: Advanced control systems for vacuum pumps focus on optimizing operation, energy efficiency, and performance. These systems may incorporate sensors, microprocessors, and adaptive algorithms to regulate pump speed, pressure, and other parameters based on real-time conditions.

- Specialized vacuum pumps for specific applications: Vacuum pumps designed for particular industries or applications, such as semiconductor manufacturing, medical devices, or aerospace, feature tailored characteristics to meet specific requirements. These pumps may have unique features like contamination control, ultra-high vacuum capabilities, or compact designs.

- Energy-efficient vacuum pump technologies: Innovations focused on improving the energy efficiency of vacuum pumps, including the use of variable speed drives, regenerative technologies, and optimized motor designs. These advancements aim to reduce power consumption while maintaining or improving pump performance.

- Vacuum pump maintenance and monitoring systems: Technologies for enhancing the reliability and longevity of vacuum pumps through improved maintenance practices and monitoring systems. These may include predictive maintenance algorithms, remote monitoring capabilities, and self-diagnostic features to detect and prevent potential issues.

02 Vacuum pump control systems

Advanced control systems for vacuum pumps focus on optimizing operation, monitoring performance, and automating processes. These systems may incorporate sensors, microprocessors, and software algorithms to adjust pump parameters in real-time, ensuring optimal vacuum levels and energy consumption.Expand Specific Solutions03 Specialized vacuum pumps for specific applications

Vacuum pumps designed for specific industries or applications, such as semiconductor manufacturing, medical devices, or food packaging. These pumps may have unique features tailored to the requirements of their intended use, including contamination control, high throughput, or compatibility with certain gases or materials.Expand Specific Solutions04 Energy-efficient vacuum pump technologies

Innovations focused on reducing energy consumption in vacuum pumps, including the use of variable speed drives, regenerative technologies, and heat recovery systems. These advancements aim to minimize operational costs and environmental impact while maintaining high performance levels.Expand Specific Solutions05 Vacuum pump maintenance and reliability improvements

Technologies and methods to enhance the longevity and reliability of vacuum pumps, including self-diagnostic systems, predictive maintenance algorithms, and innovative materials for wear-resistant components. These improvements aim to reduce downtime, extend service intervals, and lower overall maintenance costs.Expand Specific Solutions

Key Players in AM Vacuum Systems

The vacuum pump market in additive manufacturing of metals is in a growth phase, driven by increasing adoption of metal 3D printing across industries. The market size is expanding, with projections indicating significant growth potential. Technologically, vacuum pumps for metal additive manufacturing are evolving, with companies like Edwards Japan Ltd., Pfeiffer Vacuum GmbH, and Kashiyama Industries, Ltd. leading innovation. These firms are developing more efficient and specialized pumps to meet the demanding requirements of metal 3D printing processes. The competitive landscape is diverse, with established industrial players like Hitachi Ltd. and General Electric Company also entering the market, leveraging their extensive manufacturing expertise to develop advanced vacuum solutions for additive manufacturing applications.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed a range of vacuum solutions tailored for additive manufacturing of metals. Their HiPace turbomolecular pumps, combined with backing pumps, are designed to achieve the high vacuum levels required for metal AM processes. These pumps can reach ultimate pressures as low as 10^-10 mbar[3], far exceeding the requirements of most metal AM systems. Pfeiffer's vacuum solutions incorporate advanced features such as integrated drive electronics and adaptive pumping speed control, which optimize performance and energy efficiency during the varying pressure conditions of the AM process[4]. Additionally, their pumps are designed with corrosion-resistant materials to handle the potentially reactive metal powders used in AM.

Strengths: Wide range of vacuum solutions, extremely low ultimate pressure capabilities, adaptive control systems. Weaknesses: May be over-specified for some AM applications, potentially higher initial investment.

Arcam AB

Technical Solution: Arcam AB, a pioneer in Electron Beam Melting (EBM) technology, has developed advanced vacuum pump systems specifically for metal additive manufacturing. Their EBM process operates in a high vacuum environment, typically at pressures below 1×10^-4 mbar[1]. The vacuum pumps play a crucial role in maintaining this low-pressure environment, which is essential for the electron beam's stability and the overall print quality. Arcam's vacuum systems are designed to rapidly evacuate the build chamber, achieving the required vacuum levels in minutes rather than hours[2]. This efficiency is critical for reducing cycle times and increasing productivity in industrial-scale metal 3D printing operations.

Strengths: Specialized vacuum technology for EBM, fast chamber evacuation, high vacuum quality. Weaknesses: Limited to EBM technology, potentially higher cost compared to general-purpose vacuum systems.

Innovative Vacuum Pump Designs for AM

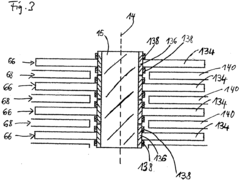

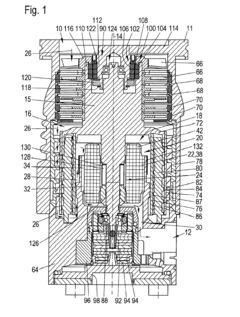

Production of a vacuum pump part by metallic additive manufacturing

PatentActiveEP3085964A1

Innovation

- The use of additive manufacturing processes, such as 3D printing, to produce components like rotor and stator disks from materials like aluminum and titanium, allowing for complex geometries to be created quickly, cost-effectively, and with reduced material waste, using layer-by-layer construction and lamination techniques.

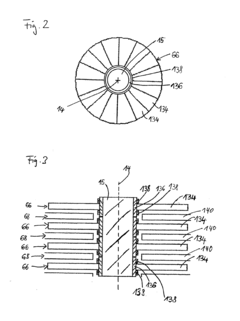

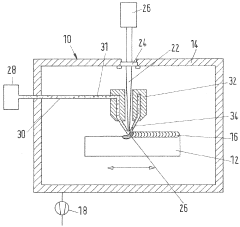

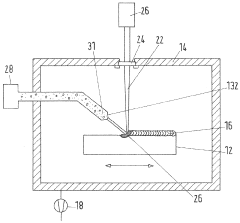

Vacuum sls method for the additive manufacture of metallic components

PatentInactiveUS20180178326A1

Innovation

- The method involves mixing metal powder with a gas stream and directing it specifically to the laser processing location, eliminating the need for spreading powder over the entire surface, using either inert or doped gases to ensure efficient material application and minimize powder loss.

Material Compatibility and Vacuum Performance

In the context of additive manufacturing of metals, vacuum pumps play a crucial role in maintaining material compatibility and ensuring optimal vacuum performance. The selection of appropriate vacuum pump systems is essential for achieving high-quality metal parts and efficient manufacturing processes.

Material compatibility is a primary concern when choosing vacuum pumps for metal additive manufacturing. Different metal powders and alloys may react with certain pump components or lubricants, potentially leading to contamination or degradation of the manufacturing environment. Vacuum pumps used in these applications must be constructed with materials that are resistant to corrosion and chemical reactions with metal powders. Stainless steel, for instance, is commonly used in pump components due to its excellent resistance to corrosion and compatibility with a wide range of metal materials.

The vacuum performance of pumps in metal additive manufacturing directly impacts the quality of the final product. High-performance vacuum pumps are required to achieve and maintain the low pressures necessary for optimal metal powder behavior and laser-material interactions. Typically, pressures in the range of 10^-3 to 10^-5 mbar are desired for most metal additive manufacturing processes. To achieve these levels, a combination of different pump types may be employed, such as rotary vane pumps for initial roughing and turbomolecular pumps for achieving high vacuum.

The choice of vacuum pump also affects the overall efficiency and reliability of the manufacturing process. Oil-sealed pumps, while effective, may introduce the risk of oil contamination in the build chamber. Dry pumps, on the other hand, eliminate this risk but may have different pumping speeds and ultimate vacuum levels. The trade-offs between these pump types must be carefully considered based on the specific requirements of the metal additive manufacturing process.

Vacuum pump performance in metal additive manufacturing is not solely about achieving low pressures; it also involves maintaining stable vacuum conditions throughout the build process. Fluctuations in vacuum levels can lead to inconsistencies in part quality and process repeatability. Therefore, pumps with precise control systems and stable performance characteristics are preferred in these applications.

The size and capacity of vacuum pumps must be appropriately matched to the volume of the build chamber and the expected gas load during the manufacturing process. Undersized pumps may struggle to maintain the required vacuum levels, while oversized pumps can lead to unnecessary energy consumption and increased costs. Proper sizing ensures optimal performance and energy efficiency throughout the additive manufacturing process.

Material compatibility is a primary concern when choosing vacuum pumps for metal additive manufacturing. Different metal powders and alloys may react with certain pump components or lubricants, potentially leading to contamination or degradation of the manufacturing environment. Vacuum pumps used in these applications must be constructed with materials that are resistant to corrosion and chemical reactions with metal powders. Stainless steel, for instance, is commonly used in pump components due to its excellent resistance to corrosion and compatibility with a wide range of metal materials.

The vacuum performance of pumps in metal additive manufacturing directly impacts the quality of the final product. High-performance vacuum pumps are required to achieve and maintain the low pressures necessary for optimal metal powder behavior and laser-material interactions. Typically, pressures in the range of 10^-3 to 10^-5 mbar are desired for most metal additive manufacturing processes. To achieve these levels, a combination of different pump types may be employed, such as rotary vane pumps for initial roughing and turbomolecular pumps for achieving high vacuum.

The choice of vacuum pump also affects the overall efficiency and reliability of the manufacturing process. Oil-sealed pumps, while effective, may introduce the risk of oil contamination in the build chamber. Dry pumps, on the other hand, eliminate this risk but may have different pumping speeds and ultimate vacuum levels. The trade-offs between these pump types must be carefully considered based on the specific requirements of the metal additive manufacturing process.

Vacuum pump performance in metal additive manufacturing is not solely about achieving low pressures; it also involves maintaining stable vacuum conditions throughout the build process. Fluctuations in vacuum levels can lead to inconsistencies in part quality and process repeatability. Therefore, pumps with precise control systems and stable performance characteristics are preferred in these applications.

The size and capacity of vacuum pumps must be appropriately matched to the volume of the build chamber and the expected gas load during the manufacturing process. Undersized pumps may struggle to maintain the required vacuum levels, while oversized pumps can lead to unnecessary energy consumption and increased costs. Proper sizing ensures optimal performance and energy efficiency throughout the additive manufacturing process.

Energy Efficiency in AM Vacuum Systems

Energy efficiency in additive manufacturing (AM) vacuum systems is a critical aspect of the overall process optimization in metal 3D printing. The vacuum environment plays a crucial role in ensuring the quality and integrity of printed parts, but it also represents a significant energy consumption point in the manufacturing process. As the AM industry continues to grow and scale, improving the energy efficiency of vacuum systems has become a key focus for both economic and environmental reasons.

Vacuum pumps in AM systems are typically required to maintain a low-pressure environment throughout the build process, which can last for several hours or even days. This continuous operation demands substantial energy input, contributing significantly to the overall energy footprint of the AM process. Recent advancements in vacuum pump technology have led to the development of more energy-efficient models specifically designed for AM applications.

One of the primary approaches to enhancing energy efficiency in AM vacuum systems is the implementation of variable speed drives (VSDs) in vacuum pumps. VSDs allow the pump to adjust its speed and power consumption based on the actual vacuum requirements at different stages of the printing process. This dynamic adjustment can lead to energy savings of up to 50% compared to conventional fixed-speed pumps, particularly during periods of lower vacuum demand.

Another innovative solution is the integration of intelligent control systems that optimize the vacuum pump's operation based on real-time process data. These systems can predict vacuum requirements based on the geometry of the part being printed and adjust the pump's performance accordingly. By minimizing unnecessary power consumption during idle periods or when full vacuum capacity is not required, these smart controls further contribute to energy efficiency.

Heat recovery systems are also being explored as a means to improve overall energy efficiency in AM vacuum systems. The heat generated by vacuum pumps during operation can be captured and repurposed for other processes within the AM facility, such as preheating metal powders or maintaining optimal ambient temperatures in the printing chamber. This approach not only reduces energy waste but also contributes to a more sustainable manufacturing ecosystem.

Furthermore, advancements in vacuum chamber design and sealing technologies have led to improved vacuum retention, reducing the workload on pumps and consequently lowering energy consumption. The use of high-performance materials and precision engineering in chamber construction minimizes leakage and allows for faster pump-down times, resulting in shorter overall process durations and reduced energy requirements.

As the AM industry continues to mature, the focus on energy efficiency in vacuum systems is likely to intensify. Future developments may include the integration of renewable energy sources to power vacuum pumps, further reducing the carbon footprint of metal AM processes. Additionally, ongoing research into alternative vacuum technologies, such as cryogenic pumps or getter materials, may lead to even more energy-efficient solutions for maintaining the necessary low-pressure environments in metal 3D printing.

Vacuum pumps in AM systems are typically required to maintain a low-pressure environment throughout the build process, which can last for several hours or even days. This continuous operation demands substantial energy input, contributing significantly to the overall energy footprint of the AM process. Recent advancements in vacuum pump technology have led to the development of more energy-efficient models specifically designed for AM applications.

One of the primary approaches to enhancing energy efficiency in AM vacuum systems is the implementation of variable speed drives (VSDs) in vacuum pumps. VSDs allow the pump to adjust its speed and power consumption based on the actual vacuum requirements at different stages of the printing process. This dynamic adjustment can lead to energy savings of up to 50% compared to conventional fixed-speed pumps, particularly during periods of lower vacuum demand.

Another innovative solution is the integration of intelligent control systems that optimize the vacuum pump's operation based on real-time process data. These systems can predict vacuum requirements based on the geometry of the part being printed and adjust the pump's performance accordingly. By minimizing unnecessary power consumption during idle periods or when full vacuum capacity is not required, these smart controls further contribute to energy efficiency.

Heat recovery systems are also being explored as a means to improve overall energy efficiency in AM vacuum systems. The heat generated by vacuum pumps during operation can be captured and repurposed for other processes within the AM facility, such as preheating metal powders or maintaining optimal ambient temperatures in the printing chamber. This approach not only reduces energy waste but also contributes to a more sustainable manufacturing ecosystem.

Furthermore, advancements in vacuum chamber design and sealing technologies have led to improved vacuum retention, reducing the workload on pumps and consequently lowering energy consumption. The use of high-performance materials and precision engineering in chamber construction minimizes leakage and allows for faster pump-down times, resulting in shorter overall process durations and reduced energy requirements.

As the AM industry continues to mature, the focus on energy efficiency in vacuum systems is likely to intensify. Future developments may include the integration of renewable energy sources to power vacuum pumps, further reducing the carbon footprint of metal AM processes. Additionally, ongoing research into alternative vacuum technologies, such as cryogenic pumps or getter materials, may lead to even more energy-efficient solutions for maintaining the necessary low-pressure environments in metal 3D printing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!