Vacuum Pump Roles in Ultrafast Spectroscopy Experiments

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Spectroscopy Vacuum Requirements

Ultrafast spectroscopy experiments require precise control over environmental conditions to achieve accurate and reproducible results. Vacuum systems play a crucial role in creating and maintaining the necessary experimental conditions. The primary function of vacuum pumps in these experiments is to remove air and other gases from the sample chamber, reducing interference and background noise.

High-quality vacuum conditions are essential for several reasons in ultrafast spectroscopy. Firstly, they minimize molecular collisions and interactions that could affect the sample's behavior or the laser pulse propagation. This is particularly important when studying molecular dynamics or energy transfer processes on ultrafast timescales. Secondly, vacuum environments help prevent sample degradation or contamination, ensuring the integrity of the experimental results.

The vacuum requirements for ultrafast spectroscopy can vary depending on the specific technique and experimental setup. Generally, a high vacuum (10^-6 to 10^-8 torr) or ultra-high vacuum (10^-9 torr and below) is necessary. These levels of vacuum are typically achieved through a combination of different pump types, such as rotary vane pumps, turbomolecular pumps, and ion pumps.

Rotary vane pumps are often used as the first stage to achieve rough vacuum conditions. They can quickly remove the bulk of air from the system, bringing the pressure down to about 10^-3 torr. Turbomolecular pumps are then employed to reach high vacuum levels. These pumps use high-speed rotating blades to impart momentum to gas molecules, effectively "pushing" them out of the chamber.

For ultra-high vacuum conditions, ion pumps may be utilized. These pumps operate by ionizing gas molecules and trapping them on a titanium surface. They are particularly useful for maintaining stable vacuum conditions over extended periods, which is often necessary for long-duration experiments or when frequent pump cycling is undesirable.

In addition to creating and maintaining vacuum conditions, pumps in ultrafast spectroscopy setups must also meet specific performance criteria. Low vibration levels are crucial to prevent interference with sensitive optical components and measurements. Oil-free pumps are often preferred to avoid contamination of the sample or optical surfaces. Furthermore, pumps with high pumping speeds and low ultimate pressures are desirable to quickly establish and maintain the required vacuum levels.

High-quality vacuum conditions are essential for several reasons in ultrafast spectroscopy. Firstly, they minimize molecular collisions and interactions that could affect the sample's behavior or the laser pulse propagation. This is particularly important when studying molecular dynamics or energy transfer processes on ultrafast timescales. Secondly, vacuum environments help prevent sample degradation or contamination, ensuring the integrity of the experimental results.

The vacuum requirements for ultrafast spectroscopy can vary depending on the specific technique and experimental setup. Generally, a high vacuum (10^-6 to 10^-8 torr) or ultra-high vacuum (10^-9 torr and below) is necessary. These levels of vacuum are typically achieved through a combination of different pump types, such as rotary vane pumps, turbomolecular pumps, and ion pumps.

Rotary vane pumps are often used as the first stage to achieve rough vacuum conditions. They can quickly remove the bulk of air from the system, bringing the pressure down to about 10^-3 torr. Turbomolecular pumps are then employed to reach high vacuum levels. These pumps use high-speed rotating blades to impart momentum to gas molecules, effectively "pushing" them out of the chamber.

For ultra-high vacuum conditions, ion pumps may be utilized. These pumps operate by ionizing gas molecules and trapping them on a titanium surface. They are particularly useful for maintaining stable vacuum conditions over extended periods, which is often necessary for long-duration experiments or when frequent pump cycling is undesirable.

In addition to creating and maintaining vacuum conditions, pumps in ultrafast spectroscopy setups must also meet specific performance criteria. Low vibration levels are crucial to prevent interference with sensitive optical components and measurements. Oil-free pumps are often preferred to avoid contamination of the sample or optical surfaces. Furthermore, pumps with high pumping speeds and low ultimate pressures are desirable to quickly establish and maintain the required vacuum levels.

Market Demand Analysis

The market demand for vacuum pumps in ultrafast spectroscopy experiments has been steadily growing, driven by the increasing adoption of advanced spectroscopic techniques in various scientific and industrial applications. Ultrafast spectroscopy, which allows researchers to observe and analyze extremely rapid chemical and physical processes, requires high-performance vacuum systems to maintain the necessary experimental conditions.

In recent years, there has been a significant surge in research activities related to ultrafast phenomena across multiple disciplines, including chemistry, physics, materials science, and biology. This has led to a corresponding increase in the demand for sophisticated vacuum pump systems capable of achieving and maintaining the ultra-high vacuum levels required for these experiments.

The pharmaceutical and biotechnology sectors have emerged as major drivers of market growth for vacuum pumps in ultrafast spectroscopy. These industries rely heavily on spectroscopic techniques for drug discovery, protein analysis, and the study of biomolecular interactions. As the need for more precise and faster analytical methods continues to rise, the demand for advanced vacuum pump systems is expected to grow proportionally.

Additionally, the semiconductor industry has become a significant consumer of vacuum pumps for ultrafast spectroscopy applications. As chip manufacturers strive to develop smaller, faster, and more efficient devices, they increasingly rely on ultrafast spectroscopy to study electron dynamics and material properties at the nanoscale. This trend is likely to continue, further fueling the demand for high-performance vacuum systems.

The academic research sector remains a substantial market for vacuum pumps in ultrafast spectroscopy. Universities and research institutions worldwide are expanding their capabilities in this field, investing in state-of-the-art equipment to stay at the forefront of scientific discovery. This ongoing investment in research infrastructure contributes significantly to the overall market demand.

Geographically, North America and Europe currently dominate the market for vacuum pumps in ultrafast spectroscopy experiments, owing to their well-established research ecosystems and high concentration of pharmaceutical and technology companies. However, the Asia-Pacific region is experiencing the fastest growth in demand, driven by increasing research and development activities in countries like China, Japan, and South Korea.

The market is also seeing a shift towards more energy-efficient and environmentally friendly vacuum pump solutions. This trend is partly driven by regulatory pressures and sustainability initiatives, but also by the need to reduce operational costs in research facilities. As a result, manufacturers are focusing on developing vacuum pumps with lower power consumption and reduced environmental impact, which is likely to shape future market demand.

In recent years, there has been a significant surge in research activities related to ultrafast phenomena across multiple disciplines, including chemistry, physics, materials science, and biology. This has led to a corresponding increase in the demand for sophisticated vacuum pump systems capable of achieving and maintaining the ultra-high vacuum levels required for these experiments.

The pharmaceutical and biotechnology sectors have emerged as major drivers of market growth for vacuum pumps in ultrafast spectroscopy. These industries rely heavily on spectroscopic techniques for drug discovery, protein analysis, and the study of biomolecular interactions. As the need for more precise and faster analytical methods continues to rise, the demand for advanced vacuum pump systems is expected to grow proportionally.

Additionally, the semiconductor industry has become a significant consumer of vacuum pumps for ultrafast spectroscopy applications. As chip manufacturers strive to develop smaller, faster, and more efficient devices, they increasingly rely on ultrafast spectroscopy to study electron dynamics and material properties at the nanoscale. This trend is likely to continue, further fueling the demand for high-performance vacuum systems.

The academic research sector remains a substantial market for vacuum pumps in ultrafast spectroscopy. Universities and research institutions worldwide are expanding their capabilities in this field, investing in state-of-the-art equipment to stay at the forefront of scientific discovery. This ongoing investment in research infrastructure contributes significantly to the overall market demand.

Geographically, North America and Europe currently dominate the market for vacuum pumps in ultrafast spectroscopy experiments, owing to their well-established research ecosystems and high concentration of pharmaceutical and technology companies. However, the Asia-Pacific region is experiencing the fastest growth in demand, driven by increasing research and development activities in countries like China, Japan, and South Korea.

The market is also seeing a shift towards more energy-efficient and environmentally friendly vacuum pump solutions. This trend is partly driven by regulatory pressures and sustainability initiatives, but also by the need to reduce operational costs in research facilities. As a result, manufacturers are focusing on developing vacuum pumps with lower power consumption and reduced environmental impact, which is likely to shape future market demand.

Vacuum Pump Technology Status

Vacuum pump technology plays a crucial role in ultrafast spectroscopy experiments, enabling the creation and maintenance of high-vacuum environments essential for precise measurements. The current status of vacuum pump technology in this field reflects significant advancements and ongoing challenges.

State-of-the-art vacuum pumps used in ultrafast spectroscopy experiments primarily include turbomolecular pumps, ion pumps, and cryogenic pumps. These pumps have evolved to meet the demanding requirements of ultrafast spectroscopy, offering improved pumping speeds, lower ultimate pressures, and enhanced reliability.

Turbomolecular pumps have seen substantial improvements in recent years, with the latest models achieving pumping speeds of up to 3000 liters per second and ultimate pressures in the range of 10^-11 mbar. These pumps are particularly valued for their ability to handle high gas loads and maintain clean vacuum conditions.

Ion pumps, utilizing the principle of ionization and subsequent capture of gas molecules, have also advanced significantly. Modern designs can achieve ultimate pressures below 10^-11 mbar and offer extended operational lifetimes, making them ideal for maintaining ultra-high vacuum conditions in spectroscopy chambers.

Cryogenic pumps, which trap gases by condensation on extremely cold surfaces, have become increasingly popular in ultrafast spectroscopy setups. These pumps can achieve ultimate pressures as low as 10^-13 mbar and are particularly effective at pumping water vapor and other condensable gases.

Despite these advancements, several challenges persist in vacuum pump technology for ultrafast spectroscopy. One major issue is the need for vibration-free operation, as even minute vibrations can interfere with sensitive measurements. Researchers are exploring novel designs and isolation techniques to minimize pump-induced vibrations.

Another challenge is the development of more compact and energy-efficient vacuum systems. As ultrafast spectroscopy experiments become more complex, there is a growing demand for integrated vacuum solutions that can deliver high performance while occupying minimal space and consuming less power.

The integration of smart technologies and remote monitoring capabilities is an emerging trend in vacuum pump development. These features allow for real-time performance optimization and predictive maintenance, enhancing the reliability and efficiency of spectroscopy setups.

Ongoing research is also focused on improving pump materials and coatings to enhance corrosion resistance and reduce outgassing, which is critical for maintaining ultra-clean vacuum environments. Additionally, efforts are being made to develop pumps capable of handling specialized gas mixtures and corrosive substances often encountered in advanced spectroscopy experiments.

In conclusion, while vacuum pump technology for ultrafast spectroscopy has made significant strides, there remains ample room for innovation to address current limitations and meet the evolving needs of this rapidly advancing field.

State-of-the-art vacuum pumps used in ultrafast spectroscopy experiments primarily include turbomolecular pumps, ion pumps, and cryogenic pumps. These pumps have evolved to meet the demanding requirements of ultrafast spectroscopy, offering improved pumping speeds, lower ultimate pressures, and enhanced reliability.

Turbomolecular pumps have seen substantial improvements in recent years, with the latest models achieving pumping speeds of up to 3000 liters per second and ultimate pressures in the range of 10^-11 mbar. These pumps are particularly valued for their ability to handle high gas loads and maintain clean vacuum conditions.

Ion pumps, utilizing the principle of ionization and subsequent capture of gas molecules, have also advanced significantly. Modern designs can achieve ultimate pressures below 10^-11 mbar and offer extended operational lifetimes, making them ideal for maintaining ultra-high vacuum conditions in spectroscopy chambers.

Cryogenic pumps, which trap gases by condensation on extremely cold surfaces, have become increasingly popular in ultrafast spectroscopy setups. These pumps can achieve ultimate pressures as low as 10^-13 mbar and are particularly effective at pumping water vapor and other condensable gases.

Despite these advancements, several challenges persist in vacuum pump technology for ultrafast spectroscopy. One major issue is the need for vibration-free operation, as even minute vibrations can interfere with sensitive measurements. Researchers are exploring novel designs and isolation techniques to minimize pump-induced vibrations.

Another challenge is the development of more compact and energy-efficient vacuum systems. As ultrafast spectroscopy experiments become more complex, there is a growing demand for integrated vacuum solutions that can deliver high performance while occupying minimal space and consuming less power.

The integration of smart technologies and remote monitoring capabilities is an emerging trend in vacuum pump development. These features allow for real-time performance optimization and predictive maintenance, enhancing the reliability and efficiency of spectroscopy setups.

Ongoing research is also focused on improving pump materials and coatings to enhance corrosion resistance and reduce outgassing, which is critical for maintaining ultra-clean vacuum environments. Additionally, efforts are being made to develop pumps capable of handling specialized gas mixtures and corrosive substances often encountered in advanced spectroscopy experiments.

In conclusion, while vacuum pump technology for ultrafast spectroscopy has made significant strides, there remains ample room for innovation to address current limitations and meet the evolving needs of this rapidly advancing field.

Current Vacuum Solutions

01 Rotary vacuum pump designs

Various designs of rotary vacuum pumps have been developed to improve efficiency and performance. These include innovations in rotor configurations, sealing mechanisms, and chamber designs to enhance suction power and reduce friction. Some designs focus on compact arrangements for specific applications, while others aim to optimize flow characteristics and minimize wear.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping capacity, reduced power consumption, and improved reliability in vacuum systems.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps feature high cleanliness standards, precise pressure control, and compatibility with corrosive gases. They play a crucial role in various semiconductor fabrication steps, including etching, deposition, and ion implantation.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to improved performance and functionality. Early designs focused on mechanical displacement principles, while later advancements incorporated new materials, precision engineering, and advanced control systems. These historical developments have laid the foundation for modern vacuum pump capabilities.

- Integration of vacuum pumps in automotive systems: Vacuum pumps have found applications in various automotive systems, enhancing vehicle performance and efficiency. They are used in brake boosters, emissions control systems, and turbocharger regulation. The integration of vacuum pumps in automotive applications has led to improved safety features, reduced emissions, and optimized engine performance.

- Energy-efficient vacuum pump solutions: Recent developments in vacuum pump technology have focused on improving energy efficiency to reduce operational costs and environmental impact. These solutions incorporate advanced motor designs, intelligent control systems, and optimized pump geometries. Energy-efficient vacuum pumps offer significant advantages in industrial processes, scientific research, and environmental applications.

02 Vacuum pump control systems

Advanced control systems for vacuum pumps have been implemented to optimize operation and energy efficiency. These systems may include sensors, electronic controllers, and variable speed drives to adjust pump performance based on demand. Some designs incorporate intelligent algorithms for predictive maintenance and automatic adjustment of operating parameters.Expand Specific Solutions03 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of this industry. These pumps often feature ultra-clean designs, high pumping speeds, and resistance to corrosive gases. Some innovations focus on reducing particle generation and improving pump longevity in harsh environments.Expand Specific Solutions04 Multi-stage vacuum pump systems

Multi-stage vacuum pump systems have been designed to achieve higher vacuum levels and improved overall performance. These systems often combine different types of pumps, such as rotary vane pumps with turbomolecular pumps, to cover a wide range of pressure regimes. Some designs focus on optimizing the interaction between stages and minimizing backstreaming.Expand Specific Solutions05 Vacuum pump sealing and lubrication innovations

Advancements in sealing and lubrication technologies for vacuum pumps have been made to enhance reliability and extend operational life. These innovations include novel seal designs, improved lubricant formulations, and self-lubricating materials. Some developments focus on reducing oil contamination in the pumped gases and minimizing maintenance requirements.Expand Specific Solutions

Key Industry Players

The vacuum pump market in ultrafast spectroscopy experiments is in a mature growth stage, with a significant global market size driven by increasing demand in research and industrial applications. The technology is well-established, with major players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Shimadzu Corp. leading the field. These companies offer advanced vacuum pump solutions, leveraging their extensive experience and R&D capabilities. The competitive landscape is characterized by a mix of established manufacturers and innovative startups, with a focus on improving pump efficiency, reliability, and integration with spectroscopy systems. As the field of ultrafast spectroscopy continues to evolve, vacuum pump technology is expected to advance further, driving market growth and technological innovation.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced turbomolecular pumps specifically designed for ultrafast spectroscopy experiments. Their latest GX series pumps utilize a hybrid bearing system combining ceramic ball bearings and magnetic bearings, allowing for high pumping speeds up to 3000 L/s for N2 [1]. The pumps feature a compact design with integrated controllers, reducing footprint in cramped laboratory spaces. Edwards has also implemented advanced rotor designs with optimized blade geometries to enhance compression ratios, crucial for achieving the ultra-high vacuum levels required in spectroscopy setups [2]. Additionally, their pumps incorporate intelligent control systems that can adjust pumping parameters in real-time based on experimental conditions, ensuring stable vacuum levels throughout long spectroscopy runs [3].

Strengths: High pumping speeds, compact design, and intelligent control systems optimize performance for spectroscopy experiments. Weaknesses: The advanced technology may come with a higher price point, and the hybrid bearing system might require more maintenance compared to simpler designs.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has developed the MAGNUM series of ion getter pumps specifically designed for ultra-high vacuum applications in spectroscopy. These pumps utilize advanced cathode materials and optimized electrode geometries to achieve pumping speeds up to 400 L/s and ultimate pressures below 10^-11 mbar [1]. The company has implemented a unique dual-cathode design that extends pump lifetime and maintains consistent performance over long experimental runs. Thermo Fisher's pumps also feature advanced control systems that can operate in various modes, including pulsed operation for improved pumping efficiency of noble gases often used in spectroscopy [2]. Additionally, the company has developed specialized getter materials that can be integrated into their pumps, enhancing pumping performance for hydrogen and other light gases. Thermo Fisher has also implemented advanced manufacturing techniques to minimize outgassing from pump components, crucial for maintaining ultra-high vacuum levels in sensitive spectroscopy experiments [3].

Strengths: Extremely low ultimate pressures, long operational lifetime, and specialized performance for noble and light gases. Weaknesses: Ion getter pumps may have limited pumping speed compared to turbomolecular pumps, and they require periodic cathode replacement.

Core Vacuum Innovations

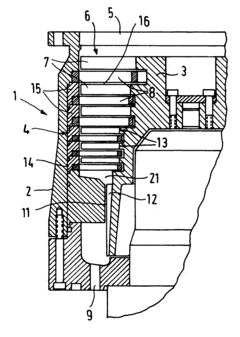

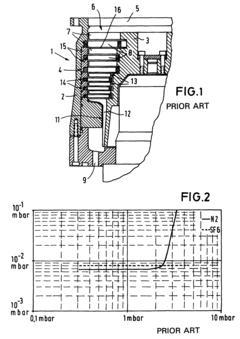

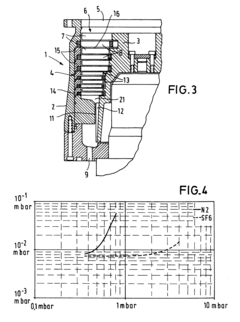

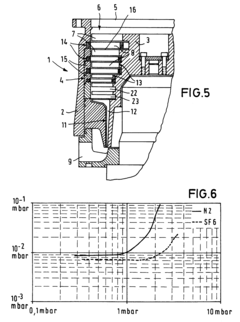

Friction vacuum pump for use in a system for regulating pressure and pressure regulating system comprising a friction vacuum pump of this type

PatentInactiveUS6702544B1

Innovation

- Modifying the Holweck pump stage by creating a partial space without active pumping elements between the last row of stator vanes and the thread, and reducing the number of stator vanes in the turbomolecular pump section, allows for a consistent pressure dependence between high vacuum and fore-vacuum pressures, enabling effective pressure regulation across different gas types.

Mass spectrometry system for determining a measure of a rate of decay

PatentPendingUS20240355608A1

Innovation

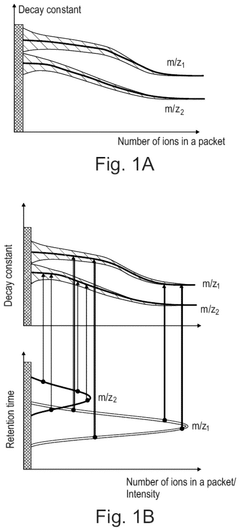

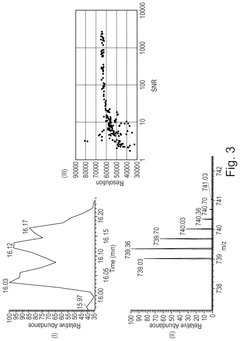

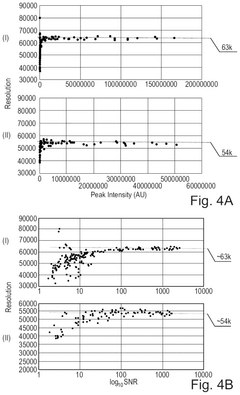

- The system employs signal-to-noise ratio (SNR) and m/z-dependent corrections to improve measurement accuracy, tracks peak widths across the entire elution profile, and uses turbomolecular pump speed control to vary gas pressure, enabling online determination of decay constants and CCS values in Fourier transform mass spectrometry.

Vacuum-Spectroscopy Integration

The integration of vacuum technology with ultrafast spectroscopy experiments represents a critical synergy in advanced scientific research. Vacuum pumps play a pivotal role in creating and maintaining the controlled environments necessary for precise spectroscopic measurements. These pumps are essential for removing atmospheric gases and contaminants that could interfere with the ultrafast laser pulses used in spectroscopy.

In ultrafast spectroscopy setups, vacuum pumps are typically employed to evacuate sample chambers, beam paths, and detection systems. This evacuation process serves multiple purposes. Firstly, it eliminates air molecules that could scatter or absorb the laser light, ensuring that the ultrashort pulses reach the sample and detectors with minimal distortion. Secondly, it prevents unwanted chemical reactions or degradation of sensitive samples that might occur in the presence of oxygen or moisture.

The choice of vacuum pump depends on the specific requirements of the spectroscopy experiment. Turbomolecular pumps are often used for achieving high vacuum levels, typically in the range of 10^-6 to 10^-9 mbar. These pumps are particularly effective for removing lighter gas molecules and can maintain a clean vacuum environment. For initial pump-down stages or backing of turbomolecular pumps, rotary vane or scroll pumps are commonly employed.

In time-resolved spectroscopy experiments, where femtosecond or attosecond pulses are used, the vacuum quality directly impacts the temporal resolution and signal-to-noise ratio of the measurements. Ultra-high vacuum conditions may be necessary for studying surface dynamics or gas-phase molecular processes. In such cases, ion pumps or cryopumps might be integrated into the system to achieve even lower pressures and maintain a contaminant-free environment.

The integration of vacuum technology with spectroscopy also extends to sample handling and preparation. Load-lock systems, often equipped with their dedicated pumping units, allow for the introduction of samples into the vacuum chamber without breaking the main vacuum. This capability is crucial for maintaining experimental conditions and increasing throughput in spectroscopic studies.

Furthermore, vacuum-compatible optical components, such as windows, mirrors, and gratings, are essential elements in the integration process. These components must withstand vacuum conditions while maintaining their optical properties. The design of vacuum chambers for spectroscopy experiments often requires careful consideration of optical access, pump placement, and sample manipulation capabilities.

In ultrafast spectroscopy setups, vacuum pumps are typically employed to evacuate sample chambers, beam paths, and detection systems. This evacuation process serves multiple purposes. Firstly, it eliminates air molecules that could scatter or absorb the laser light, ensuring that the ultrashort pulses reach the sample and detectors with minimal distortion. Secondly, it prevents unwanted chemical reactions or degradation of sensitive samples that might occur in the presence of oxygen or moisture.

The choice of vacuum pump depends on the specific requirements of the spectroscopy experiment. Turbomolecular pumps are often used for achieving high vacuum levels, typically in the range of 10^-6 to 10^-9 mbar. These pumps are particularly effective for removing lighter gas molecules and can maintain a clean vacuum environment. For initial pump-down stages or backing of turbomolecular pumps, rotary vane or scroll pumps are commonly employed.

In time-resolved spectroscopy experiments, where femtosecond or attosecond pulses are used, the vacuum quality directly impacts the temporal resolution and signal-to-noise ratio of the measurements. Ultra-high vacuum conditions may be necessary for studying surface dynamics or gas-phase molecular processes. In such cases, ion pumps or cryopumps might be integrated into the system to achieve even lower pressures and maintain a contaminant-free environment.

The integration of vacuum technology with spectroscopy also extends to sample handling and preparation. Load-lock systems, often equipped with their dedicated pumping units, allow for the introduction of samples into the vacuum chamber without breaking the main vacuum. This capability is crucial for maintaining experimental conditions and increasing throughput in spectroscopic studies.

Furthermore, vacuum-compatible optical components, such as windows, mirrors, and gratings, are essential elements in the integration process. These components must withstand vacuum conditions while maintaining their optical properties. The design of vacuum chambers for spectroscopy experiments often requires careful consideration of optical access, pump placement, and sample manipulation capabilities.

Environmental Considerations

Vacuum pumps play a crucial role in ultrafast spectroscopy experiments, and their environmental impact cannot be overlooked. The operation of these pumps contributes to energy consumption and potential environmental hazards that require careful consideration. High-performance vacuum pumps often consume significant amounts of electricity, particularly during the initial pump-down phase and continuous operation. This energy usage translates to increased carbon emissions, especially in regions where electricity generation relies heavily on fossil fuels.

Furthermore, many vacuum pumps utilize specialized oils and lubricants that can pose environmental risks if not properly managed. These substances may contain harmful chemicals that, if leaked or improperly disposed of, can contaminate soil and water sources. Proper handling, storage, and disposal protocols are essential to mitigate these risks and comply with environmental regulations.

Noise pollution is another environmental concern associated with vacuum pumps in ultrafast spectroscopy setups. The continuous operation of these pumps can generate significant noise levels, potentially affecting the work environment and surrounding areas. Implementing noise reduction strategies, such as acoustic enclosures or vibration isolation systems, can help minimize this impact.

The manufacturing process of vacuum pumps also carries environmental implications. The production of specialized materials and components used in high-performance pumps may involve resource-intensive processes and the use of rare or environmentally sensitive materials. Considering the lifecycle environmental impact of these pumps, from production to disposal, is crucial for a comprehensive environmental assessment.

Water consumption is an often-overlooked aspect of vacuum pump operation in ultrafast spectroscopy. Some pump designs require water cooling systems, which can lead to significant water usage over time. In water-stressed regions, this consumption may contribute to local water scarcity issues, necessitating the implementation of water-efficient cooling solutions or alternative cooling methods.

As environmental concerns continue to gain prominence in scientific research, there is a growing trend towards developing more eco-friendly vacuum pump technologies. This includes the design of energy-efficient pumps, the use of environmentally benign lubricants, and the incorporation of recyclable materials in pump construction. Additionally, the integration of smart control systems that optimize pump operation based on experimental needs can further reduce energy consumption and environmental impact.

Researchers and facility managers involved in ultrafast spectroscopy experiments are increasingly adopting sustainable practices in their vacuum pump usage. This includes regular maintenance to ensure optimal efficiency, implementing pump sharing or centralized vacuum systems to reduce the overall number of pumps required, and exploring alternative technologies such as cryogenic pumps that may offer environmental benefits in certain applications.

Furthermore, many vacuum pumps utilize specialized oils and lubricants that can pose environmental risks if not properly managed. These substances may contain harmful chemicals that, if leaked or improperly disposed of, can contaminate soil and water sources. Proper handling, storage, and disposal protocols are essential to mitigate these risks and comply with environmental regulations.

Noise pollution is another environmental concern associated with vacuum pumps in ultrafast spectroscopy setups. The continuous operation of these pumps can generate significant noise levels, potentially affecting the work environment and surrounding areas. Implementing noise reduction strategies, such as acoustic enclosures or vibration isolation systems, can help minimize this impact.

The manufacturing process of vacuum pumps also carries environmental implications. The production of specialized materials and components used in high-performance pumps may involve resource-intensive processes and the use of rare or environmentally sensitive materials. Considering the lifecycle environmental impact of these pumps, from production to disposal, is crucial for a comprehensive environmental assessment.

Water consumption is an often-overlooked aspect of vacuum pump operation in ultrafast spectroscopy. Some pump designs require water cooling systems, which can lead to significant water usage over time. In water-stressed regions, this consumption may contribute to local water scarcity issues, necessitating the implementation of water-efficient cooling solutions or alternative cooling methods.

As environmental concerns continue to gain prominence in scientific research, there is a growing trend towards developing more eco-friendly vacuum pump technologies. This includes the design of energy-efficient pumps, the use of environmentally benign lubricants, and the incorporation of recyclable materials in pump construction. Additionally, the integration of smart control systems that optimize pump operation based on experimental needs can further reduce energy consumption and environmental impact.

Researchers and facility managers involved in ultrafast spectroscopy experiments are increasingly adopting sustainable practices in their vacuum pump usage. This includes regular maintenance to ensure optimal efficiency, implementing pump sharing or centralized vacuum systems to reduce the overall number of pumps required, and exploring alternative technologies such as cryogenic pumps that may offer environmental benefits in certain applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!