Vacuum Pump Usage in Fusion Reactor Development

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fusion Reactor Vacuum Challenges

Vacuum systems play a critical role in fusion reactor development, presenting unique challenges that demand innovative solutions. The extreme conditions within fusion reactors, including high temperatures and intense magnetic fields, necessitate advanced vacuum technologies to maintain the required low-pressure environment for plasma confinement and fusion reactions.

One of the primary challenges in fusion reactor vacuum systems is the need for ultra-high vacuum conditions. Achieving and maintaining pressures as low as 10^-8 to 10^-10 torr is essential for minimizing impurities and optimizing plasma performance. This requires highly efficient pumping systems capable of handling large gas loads and operating continuously for extended periods.

The presence of high-energy neutrons and other radiation in fusion reactors poses significant challenges for vacuum components. Materials used in pumps, valves, and seals must withstand radiation damage and maintain their integrity over long operational lifetimes. This necessitates the development of radiation-resistant materials and novel pump designs that can function reliably in these harsh environments.

Another major challenge is the management of tritium, a radioactive isotope of hydrogen used as fuel in fusion reactions. Vacuum systems must be capable of efficiently pumping and containing tritium while preventing its release into the environment. This requires specialized pumping technologies and stringent safety measures to handle this hazardous material.

The large size of fusion reactors presents additional challenges for vacuum systems. Pumping enormous volumes quickly and efficiently requires high-capacity pumps and carefully designed vacuum vessel geometries. The integration of multiple pumping stages and the strategic placement of pumps throughout the reactor system are crucial for maintaining uniform vacuum conditions.

Heat management is another significant concern in fusion reactor vacuum systems. The high heat loads generated during plasma operations can affect vacuum component performance and longevity. Developing cooling systems and heat-resistant materials for vacuum pumps and associated equipment is essential for ensuring reliable operation under these extreme conditions.

The dynamic nature of fusion plasmas also poses challenges for vacuum systems. Rapid changes in gas loads during plasma startup, shutdown, and disruptions require vacuum pumps with fast response times and the ability to handle sudden pressure spikes. This necessitates the development of advanced control systems and pump designs capable of adapting to rapidly changing conditions.

Addressing these challenges requires a multidisciplinary approach, combining expertise in vacuum technology, materials science, nuclear engineering, and plasma physics. Ongoing research and development efforts focus on improving pump efficiency, developing novel materials, and optimizing vacuum system designs to meet the demanding requirements of fusion reactors.

One of the primary challenges in fusion reactor vacuum systems is the need for ultra-high vacuum conditions. Achieving and maintaining pressures as low as 10^-8 to 10^-10 torr is essential for minimizing impurities and optimizing plasma performance. This requires highly efficient pumping systems capable of handling large gas loads and operating continuously for extended periods.

The presence of high-energy neutrons and other radiation in fusion reactors poses significant challenges for vacuum components. Materials used in pumps, valves, and seals must withstand radiation damage and maintain their integrity over long operational lifetimes. This necessitates the development of radiation-resistant materials and novel pump designs that can function reliably in these harsh environments.

Another major challenge is the management of tritium, a radioactive isotope of hydrogen used as fuel in fusion reactions. Vacuum systems must be capable of efficiently pumping and containing tritium while preventing its release into the environment. This requires specialized pumping technologies and stringent safety measures to handle this hazardous material.

The large size of fusion reactors presents additional challenges for vacuum systems. Pumping enormous volumes quickly and efficiently requires high-capacity pumps and carefully designed vacuum vessel geometries. The integration of multiple pumping stages and the strategic placement of pumps throughout the reactor system are crucial for maintaining uniform vacuum conditions.

Heat management is another significant concern in fusion reactor vacuum systems. The high heat loads generated during plasma operations can affect vacuum component performance and longevity. Developing cooling systems and heat-resistant materials for vacuum pumps and associated equipment is essential for ensuring reliable operation under these extreme conditions.

The dynamic nature of fusion plasmas also poses challenges for vacuum systems. Rapid changes in gas loads during plasma startup, shutdown, and disruptions require vacuum pumps with fast response times and the ability to handle sudden pressure spikes. This necessitates the development of advanced control systems and pump designs capable of adapting to rapidly changing conditions.

Addressing these challenges requires a multidisciplinary approach, combining expertise in vacuum technology, materials science, nuclear engineering, and plasma physics. Ongoing research and development efforts focus on improving pump efficiency, developing novel materials, and optimizing vacuum system designs to meet the demanding requirements of fusion reactors.

Market Analysis for Fusion Energy

The fusion energy market is experiencing significant growth and attracting substantial investments as the world seeks sustainable and clean energy solutions. The global fusion energy market is projected to reach a value of several billion dollars by 2030, with a compound annual growth rate (CAGR) exceeding 20% during the forecast period. This rapid expansion is driven by increasing energy demands, environmental concerns, and advancements in fusion technology.

Key market drivers include government initiatives and funding for fusion research, growing private sector investments, and the potential for fusion to provide a virtually limitless source of clean energy. Several countries, including the United States, China, and members of the European Union, have allocated substantial budgets for fusion research and development programs. Private companies, such as Commonwealth Fusion Systems, TAE Technologies, and General Fusion, have also secured significant funding from venture capital firms and strategic investors.

The market for fusion energy technologies encompasses various segments, including tokamak reactors, stellarators, inertial confinement fusion systems, and alternative concepts like magnetic target fusion. Each of these approaches presents unique opportunities and challenges, with tokamak reactors currently leading in terms of research progress and investment.

Vacuum pump technology plays a crucial role in fusion reactor development, as maintaining ultra-high vacuum conditions is essential for plasma confinement and fusion reactions. The demand for advanced vacuum pumps in fusion research is expected to grow significantly, creating opportunities for specialized equipment manufacturers and suppliers.

Despite the promising outlook, the fusion energy market faces several challenges. These include the high costs associated with research and development, technical hurdles in achieving sustained fusion reactions, and competition from other renewable energy sources. Additionally, the long timeline for commercialization of fusion energy presents uncertainties for investors and policymakers.

Geographically, North America and Europe are currently the leading regions in fusion energy research and market potential, with Asia-Pacific showing rapid growth. China, in particular, has made significant strides in fusion technology development and is expected to be a major player in the future market.

As fusion technology progresses, ancillary markets are likely to emerge, including specialized materials, advanced diagnostics, and control systems. The successful development of commercial fusion reactors could also have far-reaching impacts on the broader energy sector, potentially disrupting traditional power generation methods and reshaping global energy policies.

Key market drivers include government initiatives and funding for fusion research, growing private sector investments, and the potential for fusion to provide a virtually limitless source of clean energy. Several countries, including the United States, China, and members of the European Union, have allocated substantial budgets for fusion research and development programs. Private companies, such as Commonwealth Fusion Systems, TAE Technologies, and General Fusion, have also secured significant funding from venture capital firms and strategic investors.

The market for fusion energy technologies encompasses various segments, including tokamak reactors, stellarators, inertial confinement fusion systems, and alternative concepts like magnetic target fusion. Each of these approaches presents unique opportunities and challenges, with tokamak reactors currently leading in terms of research progress and investment.

Vacuum pump technology plays a crucial role in fusion reactor development, as maintaining ultra-high vacuum conditions is essential for plasma confinement and fusion reactions. The demand for advanced vacuum pumps in fusion research is expected to grow significantly, creating opportunities for specialized equipment manufacturers and suppliers.

Despite the promising outlook, the fusion energy market faces several challenges. These include the high costs associated with research and development, technical hurdles in achieving sustained fusion reactions, and competition from other renewable energy sources. Additionally, the long timeline for commercialization of fusion energy presents uncertainties for investors and policymakers.

Geographically, North America and Europe are currently the leading regions in fusion energy research and market potential, with Asia-Pacific showing rapid growth. China, in particular, has made significant strides in fusion technology development and is expected to be a major player in the future market.

As fusion technology progresses, ancillary markets are likely to emerge, including specialized materials, advanced diagnostics, and control systems. The successful development of commercial fusion reactors could also have far-reaching impacts on the broader energy sector, potentially disrupting traditional power generation methods and reshaping global energy policies.

Vacuum Pump Tech Status

Vacuum pump technology plays a crucial role in fusion reactor development, serving as a cornerstone for maintaining the ultra-high vacuum environment essential for plasma confinement and fusion reactions. The current state of vacuum pump technology in this field is characterized by significant advancements, yet faces ongoing challenges in meeting the demanding requirements of fusion reactors.

High-vacuum and ultra-high-vacuum pumps are the primary focus in fusion reactor applications. Turbomolecular pumps, cryopumps, and getter pumps are among the most widely used technologies. Turbomolecular pumps, known for their high pumping speeds and clean operation, have seen improvements in rotor design and magnetic bearings, enhancing their reliability and efficiency. Cryopumps, utilizing extremely low temperatures to condense gases, have advanced in terms of regeneration cycles and helium management, crucial for fusion reactor operations.

The development of large-scale vacuum systems capable of handling high gas loads and maintaining ultra-low pressures remains a significant challenge. Current systems often employ a combination of pump types to achieve the required vacuum levels and pumping speeds. For instance, roughing pumps are used in conjunction with high-vacuum pumps to create a staged pumping process, efficiently evacuating large volumes.

One of the primary technical hurdles is the management of tritium, a radioactive isotope of hydrogen used in fusion reactions. Specialized vacuum pumps and systems are being developed to handle tritium safely and efficiently, incorporating materials resistant to tritium permeation and advanced sealing technologies.

The integration of smart control systems and predictive maintenance capabilities is an emerging trend in vacuum pump technology for fusion reactors. These systems aim to optimize pump performance, reduce downtime, and enhance overall system reliability. Advanced sensors and data analytics are being employed to monitor pump health and predict potential failures before they occur.

Vacuum pump manufacturers are also focusing on improving energy efficiency and reducing the environmental impact of their products. This includes the development of oil-free pump technologies and the use of more sustainable materials in pump construction. Such advancements are particularly relevant for large-scale fusion reactor projects, where energy consumption and environmental considerations are significant factors.

Collaboration between research institutions and industry leaders has accelerated the pace of innovation in vacuum pump technology. Projects like ITER (International Thermonuclear Experimental Reactor) have driven the development of specialized vacuum solutions, pushing the boundaries of what is technically feasible. These collaborations have resulted in novel pump designs and materials that can withstand the extreme conditions present in fusion reactors.

High-vacuum and ultra-high-vacuum pumps are the primary focus in fusion reactor applications. Turbomolecular pumps, cryopumps, and getter pumps are among the most widely used technologies. Turbomolecular pumps, known for their high pumping speeds and clean operation, have seen improvements in rotor design and magnetic bearings, enhancing their reliability and efficiency. Cryopumps, utilizing extremely low temperatures to condense gases, have advanced in terms of regeneration cycles and helium management, crucial for fusion reactor operations.

The development of large-scale vacuum systems capable of handling high gas loads and maintaining ultra-low pressures remains a significant challenge. Current systems often employ a combination of pump types to achieve the required vacuum levels and pumping speeds. For instance, roughing pumps are used in conjunction with high-vacuum pumps to create a staged pumping process, efficiently evacuating large volumes.

One of the primary technical hurdles is the management of tritium, a radioactive isotope of hydrogen used in fusion reactions. Specialized vacuum pumps and systems are being developed to handle tritium safely and efficiently, incorporating materials resistant to tritium permeation and advanced sealing technologies.

The integration of smart control systems and predictive maintenance capabilities is an emerging trend in vacuum pump technology for fusion reactors. These systems aim to optimize pump performance, reduce downtime, and enhance overall system reliability. Advanced sensors and data analytics are being employed to monitor pump health and predict potential failures before they occur.

Vacuum pump manufacturers are also focusing on improving energy efficiency and reducing the environmental impact of their products. This includes the development of oil-free pump technologies and the use of more sustainable materials in pump construction. Such advancements are particularly relevant for large-scale fusion reactor projects, where energy consumption and environmental considerations are significant factors.

Collaboration between research institutions and industry leaders has accelerated the pace of innovation in vacuum pump technology. Projects like ITER (International Thermonuclear Experimental Reactor) have driven the development of specialized vacuum solutions, pushing the boundaries of what is technically feasible. These collaborations have resulted in novel pump designs and materials that can withstand the extreme conditions present in fusion reactors.

Current Vacuum Solutions

01 Improved pump design for enhanced efficiency

Vacuum pumps with innovative designs to increase efficiency and performance. These improvements may include optimized rotor configurations, advanced sealing mechanisms, or novel compression techniques to achieve better vacuum levels with reduced energy consumption.- Improved pump design for enhanced efficiency: Vacuum pumps with innovative designs to increase efficiency and performance. These improvements may include optimized rotor configurations, advanced sealing mechanisms, or novel compression techniques to achieve better vacuum levels with reduced energy consumption.

- Multi-stage vacuum pump systems: Development of multi-stage vacuum pump systems that combine different pump types or stages to achieve higher vacuum levels and improved pumping speeds. These systems may integrate various technologies such as rotary vane, scroll, or turbomolecular pumps to optimize performance across different pressure ranges.

- Vacuum pump control and monitoring systems: Integration of advanced control and monitoring systems in vacuum pumps to optimize operation, detect faults, and improve overall reliability. These systems may include sensors, microprocessors, and software algorithms for real-time performance analysis and adjustment.

- Specialized vacuum pumps for specific applications: Development of vacuum pumps tailored for specific industrial or scientific applications, such as semiconductor manufacturing, food packaging, or scientific research. These pumps may have unique features or materials to meet the requirements of particular processes or environments.

- Energy-efficient and environmentally friendly vacuum pumps: Design of vacuum pumps with a focus on energy efficiency and environmental sustainability. These pumps may incorporate features such as variable speed drives, heat recovery systems, or eco-friendly materials and lubricants to reduce energy consumption and environmental impact.

02 Multi-stage vacuum pump systems

Development of multi-stage vacuum pump systems that combine different pump types or stages to achieve higher vacuum levels and improved pumping speeds. These systems may integrate various technologies such as rotary vane, scroll, or turbomolecular pumps to optimize performance across different pressure ranges.Expand Specific Solutions03 Vacuum pump control and monitoring systems

Integration of advanced control and monitoring systems in vacuum pumps to optimize operation, detect faults, and improve overall reliability. These systems may include sensors, microprocessors, and software algorithms for real-time performance analysis and adjustment.Expand Specific Solutions04 Specialized vacuum pumps for specific applications

Development of vacuum pumps tailored for specific industrial or scientific applications, such as semiconductor manufacturing, food processing, or medical equipment. These pumps may have unique features or materials to meet the requirements of their intended use.Expand Specific Solutions05 Energy-efficient and environmentally friendly vacuum pumps

Design of vacuum pumps with a focus on energy efficiency and environmental sustainability. These pumps may incorporate features such as variable speed drives, heat recovery systems, or eco-friendly materials and lubricants to reduce energy consumption and environmental impact.Expand Specific Solutions

Key Fusion Reactor Players

The development of vacuum pumps for fusion reactors is in a nascent stage, with the market still emerging and characterized by significant technological challenges. The industry is primarily driven by research institutions and specialized companies, with key players including Edwards Ltd., Pfeiffer Vacuum GmbH, and LEYBOLD AG. These firms are leveraging their expertise in vacuum technology to address the unique demands of fusion reactor environments. The market size remains limited, primarily fueled by government-funded research projects and private sector initiatives. As the technology matures, we can expect increased competition and market expansion, potentially attracting more established industrial players to enter this specialized field.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pumps specifically designed for fusion reactor environments. Their latest GXS dry screw pump series offers high pumping speeds up to 3400 m³/h and ultimate pressures down to 5x10^-4 mbar[1]. These pumps utilize a unique screw mechanism that provides excellent performance in harsh fusion environments, handling high gas loads and potentially corrosive process gases. Edwards has also implemented intelligent control systems in their pumps, allowing for real-time monitoring and adjustment of pump parameters to optimize performance and efficiency during different stages of fusion reactor operation[2]. Additionally, their pumps incorporate advanced cooling systems to maintain stability under high heat loads typically encountered in fusion reactors.

Strengths: High pumping speeds, excellent performance in harsh environments, intelligent control systems. Weaknesses: May require frequent maintenance due to exposure to extreme conditions in fusion reactors.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has developed the HiPace turbomolecular pump series specifically tailored for fusion reactor applications. These pumps achieve extremely high compression ratios for light gases, crucial for maintaining the ultra-high vacuum conditions required in fusion reactors[3]. The HiPace series incorporates advanced magnetic bearings, eliminating the need for lubricants and ensuring contamination-free operation. Pfeiffer's pumps also feature a unique rotor design that allows for pumping speeds up to 3000 l/s and ultimate pressures below 10^-10 mbar[4]. Additionally, Pfeiffer has implemented advanced control systems in their pumps, enabling precise pressure regulation and remote operation, which is essential for the complex vacuum systems in fusion reactors.

Strengths: Ultra-high vacuum capabilities, contamination-free operation, advanced control systems. Weaknesses: Higher initial cost compared to conventional vacuum pumps, may require specialized maintenance.

Core Vacuum Innovations

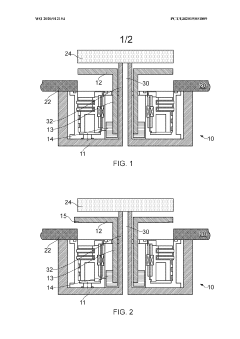

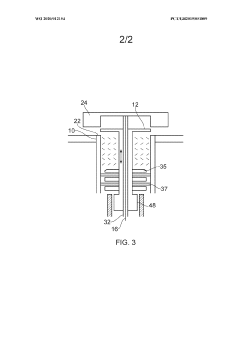

Vacuum pump with through channel and vacuum chamber

PatentWO2020012154A1

Innovation

- A vacuum pump design featuring a rotor, stator, and a controllable valve plate with an axial passage for central substrate mounting and power connections, allowing for uniform gas flow and fast pressure control, along with the option of magnetic levitation for rotor positioning and actuator-controlled axial movement of the valve plate to optimize inlet conductance.

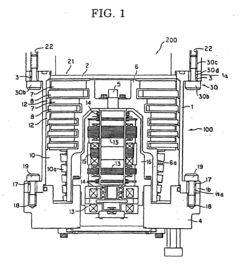

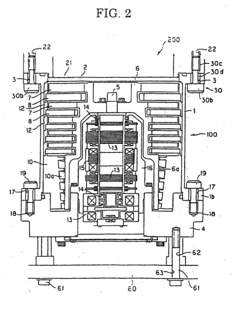

Vacuum pump

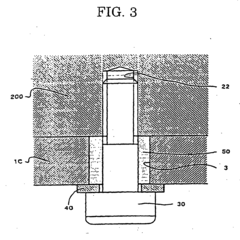

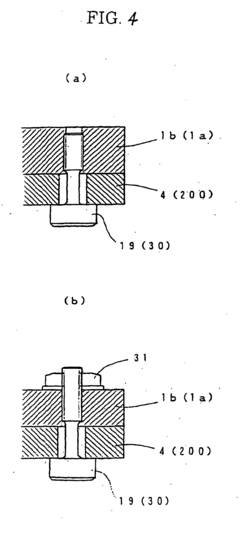

PatentInactiveEP1314892B2

Innovation

- The use of reduced-diameter bolts with buffer members inserted into the gaps between the bolts and bolt-holes to absorb and reduce the damaging torque, allowing the flange and base fastening portions to slip and deform, thereby preventing torque transfer to the vacuum chamber and base member.

Safety and Radiation Issues

Safety and radiation issues are paramount concerns in the development and operation of fusion reactors, particularly in relation to vacuum pump usage. The high-energy neutrons produced during fusion reactions pose significant challenges to the structural integrity of reactor components and the safety of personnel. Vacuum pumps, being critical for maintaining the necessary low-pressure environment, are exposed to intense radiation fields and must be designed to withstand these harsh conditions.

Radiation damage to vacuum pump materials can lead to embrittlement, swelling, and degradation of mechanical properties. This necessitates the use of radiation-resistant materials and regular maintenance schedules to ensure pump reliability. Additionally, the activation of pump components by neutron bombardment creates radioactive waste, requiring careful handling and disposal procedures.

The potential for tritium contamination is another major safety concern. Tritium, a radioactive isotope of hydrogen used as fuel in fusion reactions, can permeate through materials and potentially leak into the environment. Vacuum pumps must be designed with robust sealing systems and tritium-compatible materials to minimize the risk of tritium escape.

Electromagnetic fields generated during reactor operation can interfere with vacuum pump performance and control systems. Shielding and electromagnetic compatibility measures are essential to ensure pump functionality and prevent safety-critical failures.

The placement of vacuum pumps within the reactor system must be carefully considered to balance accessibility for maintenance with radiation protection. Remote handling systems and robotic technologies are often employed to minimize human exposure during pump servicing and replacement.

Safety protocols for vacuum pump operation in fusion reactors include comprehensive monitoring systems for radiation levels, tritium detection, and pump performance. Emergency shutdown procedures must be in place to rapidly isolate pumps in case of system failures or unexpected radiation events.

Research into advanced materials and pump designs continues to address these safety and radiation challenges. Innovations such as ceramic composites, advanced coatings, and novel pump architectures aim to enhance radiation resistance and reduce activation. Furthermore, the development of integrated safety systems that combine real-time monitoring with predictive maintenance algorithms is crucial for ensuring long-term operational safety and reliability of vacuum pumps in fusion reactor environments.

Radiation damage to vacuum pump materials can lead to embrittlement, swelling, and degradation of mechanical properties. This necessitates the use of radiation-resistant materials and regular maintenance schedules to ensure pump reliability. Additionally, the activation of pump components by neutron bombardment creates radioactive waste, requiring careful handling and disposal procedures.

The potential for tritium contamination is another major safety concern. Tritium, a radioactive isotope of hydrogen used as fuel in fusion reactions, can permeate through materials and potentially leak into the environment. Vacuum pumps must be designed with robust sealing systems and tritium-compatible materials to minimize the risk of tritium escape.

Electromagnetic fields generated during reactor operation can interfere with vacuum pump performance and control systems. Shielding and electromagnetic compatibility measures are essential to ensure pump functionality and prevent safety-critical failures.

The placement of vacuum pumps within the reactor system must be carefully considered to balance accessibility for maintenance with radiation protection. Remote handling systems and robotic technologies are often employed to minimize human exposure during pump servicing and replacement.

Safety protocols for vacuum pump operation in fusion reactors include comprehensive monitoring systems for radiation levels, tritium detection, and pump performance. Emergency shutdown procedures must be in place to rapidly isolate pumps in case of system failures or unexpected radiation events.

Research into advanced materials and pump designs continues to address these safety and radiation challenges. Innovations such as ceramic composites, advanced coatings, and novel pump architectures aim to enhance radiation resistance and reduce activation. Furthermore, the development of integrated safety systems that combine real-time monitoring with predictive maintenance algorithms is crucial for ensuring long-term operational safety and reliability of vacuum pumps in fusion reactor environments.

Environmental Impact

The environmental impact of vacuum pump usage in fusion reactor development is a critical consideration that extends beyond the immediate technological benefits. As fusion reactors progress towards commercial viability, the environmental footprint of their components, including vacuum pumps, becomes increasingly significant.

Vacuum pumps play a crucial role in maintaining the ultra-low pressure environment necessary for fusion reactions. However, their operation can have several environmental implications. The primary concern is energy consumption. High-performance vacuum pumps required for fusion reactors consume substantial amounts of electricity, potentially offsetting some of the clean energy benefits of fusion power if not managed efficiently.

Manufacturing processes for advanced vacuum pumps often involve rare earth elements and specialized materials. The extraction and processing of these resources can lead to environmental degradation, including habitat destruction and water pollution, particularly in regions where mining regulations are less stringent. Additionally, the production of these pumps may result in greenhouse gas emissions and other industrial pollutants.

The operational lifespan of vacuum pumps in fusion reactors is another environmental factor to consider. Regular maintenance and replacement of pump components generate waste, some of which may be radioactive or contaminated with tritium, requiring specialized disposal methods. This creates challenges for waste management and potential long-term environmental risks if not handled properly.

On the positive side, advancements in vacuum pump technology for fusion reactors often lead to improvements in energy efficiency and durability. These innovations can have spillover effects in other industries, potentially reducing overall environmental impact across various sectors. For instance, more efficient pumps developed for fusion applications could be adapted for use in semiconductor manufacturing or aerospace industries, leading to broader energy savings.

The development of fusion reactors, including their vacuum systems, also drives research into new materials and manufacturing processes. This research often focuses on creating more sustainable and environmentally friendly alternatives, which could have far-reaching benefits beyond the fusion industry. For example, innovations in low-friction coatings or advanced ceramics for vacuum pumps could lead to more durable and efficient products in other fields.

As the fusion industry progresses, there is an increasing emphasis on lifecycle assessment of all components, including vacuum pumps. This holistic approach considers environmental impacts from raw material extraction through manufacturing, operation, and eventual decommissioning. Such assessments are crucial for identifying areas for improvement and ensuring that the environmental benefits of fusion energy are not undermined by the impacts of its enabling technologies.

Vacuum pumps play a crucial role in maintaining the ultra-low pressure environment necessary for fusion reactions. However, their operation can have several environmental implications. The primary concern is energy consumption. High-performance vacuum pumps required for fusion reactors consume substantial amounts of electricity, potentially offsetting some of the clean energy benefits of fusion power if not managed efficiently.

Manufacturing processes for advanced vacuum pumps often involve rare earth elements and specialized materials. The extraction and processing of these resources can lead to environmental degradation, including habitat destruction and water pollution, particularly in regions where mining regulations are less stringent. Additionally, the production of these pumps may result in greenhouse gas emissions and other industrial pollutants.

The operational lifespan of vacuum pumps in fusion reactors is another environmental factor to consider. Regular maintenance and replacement of pump components generate waste, some of which may be radioactive or contaminated with tritium, requiring specialized disposal methods. This creates challenges for waste management and potential long-term environmental risks if not handled properly.

On the positive side, advancements in vacuum pump technology for fusion reactors often lead to improvements in energy efficiency and durability. These innovations can have spillover effects in other industries, potentially reducing overall environmental impact across various sectors. For instance, more efficient pumps developed for fusion applications could be adapted for use in semiconductor manufacturing or aerospace industries, leading to broader energy savings.

The development of fusion reactors, including their vacuum systems, also drives research into new materials and manufacturing processes. This research often focuses on creating more sustainable and environmentally friendly alternatives, which could have far-reaching benefits beyond the fusion industry. For example, innovations in low-friction coatings or advanced ceramics for vacuum pumps could lead to more durable and efficient products in other fields.

As the fusion industry progresses, there is an increasing emphasis on lifecycle assessment of all components, including vacuum pumps. This holistic approach considers environmental impacts from raw material extraction through manufacturing, operation, and eventual decommissioning. Such assessments are crucial for identifying areas for improvement and ensuring that the environmental benefits of fusion energy are not undermined by the impacts of its enabling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!