Vacuum Pump Utilization in Next-Generation Display Technologies

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Tech Evolution

The evolution of display technologies has been a remarkable journey, spanning several decades and revolutionizing the way we interact with visual information. From the early cathode ray tubes (CRTs) to the latest advancements in organic light-emitting diodes (OLEDs) and beyond, each iteration has brought significant improvements in image quality, energy efficiency, and form factor.

The 1960s and 1970s saw the dominance of CRT displays, which relied on electron beams to illuminate phosphor-coated screens. While bulky and energy-intensive, CRTs provided the foundation for color television and early computer monitors. The 1980s marked the emergence of liquid crystal displays (LCDs), offering a flatter profile and lower power consumption. This technology paved the way for portable electronic devices and laptops.

The late 1990s and early 2000s witnessed the rise of plasma display panels (PDPs), which excelled in producing large-screen televisions with superior contrast ratios and viewing angles. However, their high manufacturing costs and power consumption ultimately limited their market penetration. Concurrently, LCD technology continued to evolve, with the introduction of LED backlighting in the mid-2000s, enhancing brightness and energy efficiency.

A significant leap forward came with the commercialization of OLED displays in the late 2000s. OLEDs offer self-emissive pixels, eliminating the need for backlighting and enabling true blacks, infinite contrast ratios, and flexible form factors. This technology has become prevalent in smartphones, high-end televisions, and wearable devices.

Recent years have seen the emergence of quantum dot displays, which enhance color accuracy and brightness in LCD panels. Additionally, microLED technology is gaining traction, promising even higher contrast ratios, brightness, and energy efficiency than OLEDs. The ongoing development of flexible and foldable displays is pushing the boundaries of form factor innovation.

In the context of vacuum pump utilization, the evolution of display technologies has consistently demanded higher levels of precision in manufacturing processes. As pixel densities increase and display components become more intricate, the need for ultra-clean, controlled environments during production has intensified. Vacuum pumps play a crucial role in creating and maintaining these environments, enabling the deposition of thin films, removal of contaminants, and precise control of gas compositions during various stages of display manufacturing.

The progression towards larger substrate sizes, particularly in the production of televisions and monitors, has necessitated more powerful and efficient vacuum systems. Furthermore, the shift towards flexible and organic materials in next-generation displays has introduced new challenges in maintaining stable vacuum conditions while handling temperature-sensitive components.

The 1960s and 1970s saw the dominance of CRT displays, which relied on electron beams to illuminate phosphor-coated screens. While bulky and energy-intensive, CRTs provided the foundation for color television and early computer monitors. The 1980s marked the emergence of liquid crystal displays (LCDs), offering a flatter profile and lower power consumption. This technology paved the way for portable electronic devices and laptops.

The late 1990s and early 2000s witnessed the rise of plasma display panels (PDPs), which excelled in producing large-screen televisions with superior contrast ratios and viewing angles. However, their high manufacturing costs and power consumption ultimately limited their market penetration. Concurrently, LCD technology continued to evolve, with the introduction of LED backlighting in the mid-2000s, enhancing brightness and energy efficiency.

A significant leap forward came with the commercialization of OLED displays in the late 2000s. OLEDs offer self-emissive pixels, eliminating the need for backlighting and enabling true blacks, infinite contrast ratios, and flexible form factors. This technology has become prevalent in smartphones, high-end televisions, and wearable devices.

Recent years have seen the emergence of quantum dot displays, which enhance color accuracy and brightness in LCD panels. Additionally, microLED technology is gaining traction, promising even higher contrast ratios, brightness, and energy efficiency than OLEDs. The ongoing development of flexible and foldable displays is pushing the boundaries of form factor innovation.

In the context of vacuum pump utilization, the evolution of display technologies has consistently demanded higher levels of precision in manufacturing processes. As pixel densities increase and display components become more intricate, the need for ultra-clean, controlled environments during production has intensified. Vacuum pumps play a crucial role in creating and maintaining these environments, enabling the deposition of thin films, removal of contaminants, and precise control of gas compositions during various stages of display manufacturing.

The progression towards larger substrate sizes, particularly in the production of televisions and monitors, has necessitated more powerful and efficient vacuum systems. Furthermore, the shift towards flexible and organic materials in next-generation displays has introduced new challenges in maintaining stable vacuum conditions while handling temperature-sensitive components.

Vacuum Pump Market Trends

The vacuum pump market for next-generation display technologies is experiencing significant growth, driven by the increasing demand for high-quality displays in various applications. This market segment is closely tied to the development of advanced display technologies, such as OLED, QLED, and MicroLED, which require precise vacuum environments during manufacturing processes.

The global vacuum pump market for display technologies is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily attributed to the rising adoption of OLED displays in smartphones, televisions, and other consumer electronics. As OLED technology continues to mature and production costs decrease, the demand for vacuum pumps in this sector is expected to surge.

In the Asia-Pacific region, particularly in countries like South Korea, China, and Japan, the market for vacuum pumps in display manufacturing is witnessing robust growth. These countries are home to major display manufacturers and are investing heavily in next-generation display technologies. The region is expected to dominate the market share due to the presence of key players and the increasing number of display production facilities.

The market is also seeing a shift towards dry vacuum pumps, which offer advantages such as lower maintenance requirements and reduced environmental impact compared to traditional oil-sealed pumps. This trend is driven by the industry's focus on sustainability and the need for cleaner manufacturing processes in display production.

Another notable trend is the increasing demand for high-vacuum and ultra-high-vacuum pumps in the production of advanced displays. These pumps are essential for creating the extremely low-pressure environments required for depositing thin films and other critical processes in next-generation display manufacturing.

The vacuum pump market for display technologies is characterized by intense competition among key players, including Edwards Vacuum, Pfeiffer Vacuum, and Atlas Copco. These companies are investing in research and development to improve pump efficiency, reduce energy consumption, and develop pumps tailored specifically for next-generation display production processes.

As the display industry continues to evolve, with emerging technologies like flexible and foldable displays gaining traction, the vacuum pump market is expected to adapt and innovate. Manufacturers are focusing on developing pumps that can meet the unique requirements of these new display types, potentially opening up new growth opportunities in the coming years.

The global vacuum pump market for display technologies is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily attributed to the rising adoption of OLED displays in smartphones, televisions, and other consumer electronics. As OLED technology continues to mature and production costs decrease, the demand for vacuum pumps in this sector is expected to surge.

In the Asia-Pacific region, particularly in countries like South Korea, China, and Japan, the market for vacuum pumps in display manufacturing is witnessing robust growth. These countries are home to major display manufacturers and are investing heavily in next-generation display technologies. The region is expected to dominate the market share due to the presence of key players and the increasing number of display production facilities.

The market is also seeing a shift towards dry vacuum pumps, which offer advantages such as lower maintenance requirements and reduced environmental impact compared to traditional oil-sealed pumps. This trend is driven by the industry's focus on sustainability and the need for cleaner manufacturing processes in display production.

Another notable trend is the increasing demand for high-vacuum and ultra-high-vacuum pumps in the production of advanced displays. These pumps are essential for creating the extremely low-pressure environments required for depositing thin films and other critical processes in next-generation display manufacturing.

The vacuum pump market for display technologies is characterized by intense competition among key players, including Edwards Vacuum, Pfeiffer Vacuum, and Atlas Copco. These companies are investing in research and development to improve pump efficiency, reduce energy consumption, and develop pumps tailored specifically for next-generation display production processes.

As the display industry continues to evolve, with emerging technologies like flexible and foldable displays gaining traction, the vacuum pump market is expected to adapt and innovate. Manufacturers are focusing on developing pumps that can meet the unique requirements of these new display types, potentially opening up new growth opportunities in the coming years.

Vacuum Tech Challenges

The utilization of vacuum pumps in next-generation display technologies faces several significant challenges that require innovative solutions. One of the primary obstacles is achieving and maintaining ultra-high vacuum levels necessary for advanced manufacturing processes. As display technologies evolve towards higher resolutions and more complex structures, the demand for precise vacuum control intensifies.

Contamination control presents another major hurdle. Even minute particles or residual gases can severely impact the quality and performance of display components. This necessitates the development of more efficient filtration systems and cleaner pump technologies to minimize the risk of contamination during the manufacturing process.

Energy efficiency is a growing concern in vacuum pump applications for display production. Traditional vacuum pumps often consume substantial amounts of energy, leading to increased operational costs and environmental impact. The industry is actively seeking more energy-efficient pump designs that can deliver the required vacuum levels while reducing power consumption.

Noise reduction is another critical challenge, particularly in cleanroom environments where multiple vacuum pumps operate simultaneously. Excessive noise can affect worker comfort and potentially impact the precision of manufacturing processes. Developing quieter pump technologies without compromising performance is a key focus area for researchers and engineers.

Scalability and flexibility pose additional challenges as display manufacturers strive to increase production capacity and adapt to evolving product designs. Vacuum systems must be capable of scaling up to meet higher throughput demands while maintaining consistent performance across various production scenarios.

Maintenance and reliability issues also present ongoing challenges. The continuous operation of vacuum pumps in high-precision manufacturing environments requires robust designs that can withstand prolonged use with minimal downtime. Improving pump longevity and developing more efficient maintenance protocols are crucial for optimizing production efficiency.

Furthermore, the integration of vacuum pump systems with other manufacturing equipment and control systems presents complex engineering challenges. Ensuring seamless communication and coordination between vacuum systems and other production components is essential for achieving optimal manufacturing outcomes.

As display technologies continue to advance, addressing these vacuum technology challenges will be critical for enabling the production of next-generation displays with enhanced performance, efficiency, and quality.

Contamination control presents another major hurdle. Even minute particles or residual gases can severely impact the quality and performance of display components. This necessitates the development of more efficient filtration systems and cleaner pump technologies to minimize the risk of contamination during the manufacturing process.

Energy efficiency is a growing concern in vacuum pump applications for display production. Traditional vacuum pumps often consume substantial amounts of energy, leading to increased operational costs and environmental impact. The industry is actively seeking more energy-efficient pump designs that can deliver the required vacuum levels while reducing power consumption.

Noise reduction is another critical challenge, particularly in cleanroom environments where multiple vacuum pumps operate simultaneously. Excessive noise can affect worker comfort and potentially impact the precision of manufacturing processes. Developing quieter pump technologies without compromising performance is a key focus area for researchers and engineers.

Scalability and flexibility pose additional challenges as display manufacturers strive to increase production capacity and adapt to evolving product designs. Vacuum systems must be capable of scaling up to meet higher throughput demands while maintaining consistent performance across various production scenarios.

Maintenance and reliability issues also present ongoing challenges. The continuous operation of vacuum pumps in high-precision manufacturing environments requires robust designs that can withstand prolonged use with minimal downtime. Improving pump longevity and developing more efficient maintenance protocols are crucial for optimizing production efficiency.

Furthermore, the integration of vacuum pump systems with other manufacturing equipment and control systems presents complex engineering challenges. Ensuring seamless communication and coordination between vacuum systems and other production components is essential for achieving optimal manufacturing outcomes.

As display technologies continue to advance, addressing these vacuum technology challenges will be critical for enabling the production of next-generation displays with enhanced performance, efficiency, and quality.

Current Vacuum Solutions

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include novel rotor configurations, advanced sealing mechanisms, or optimized flow paths to achieve better vacuum levels and energy efficiency.

- Vacuum pump control systems: Advanced control systems for vacuum pumps focus on optimizing operation, monitoring performance, and automating processes. These systems may incorporate sensors, microprocessors, and software algorithms to adjust pump parameters in real-time, ensuring optimal vacuum levels and energy consumption.

- Specialized vacuum pumps for specific applications: Vacuum pumps designed for specific industries or applications, such as semiconductor manufacturing, medical devices, or food processing. These pumps may have unique features tailored to the requirements of their intended use, including corrosion resistance, contamination prevention, or ultra-high vacuum capabilities.

- Energy-efficient vacuum pump technologies: Innovations focused on reducing energy consumption in vacuum pumps, including the use of variable speed drives, regenerative technologies, and heat recovery systems. These advancements aim to minimize operating costs and environmental impact while maintaining high performance levels.

- Maintenance and reliability improvements: Developments in vacuum pump design and materials aimed at enhancing durability, reducing maintenance requirements, and extending operational lifespans. These may include self-lubricating components, wear-resistant materials, or modular designs for easier servicing and part replacement.

02 Energy-efficient vacuum pump systems

Development of energy-efficient vacuum pump systems focuses on reducing power consumption while maintaining high performance. These systems may incorporate advanced control algorithms, variable speed drives, or heat recovery mechanisms to optimize energy usage.Expand Specific Solutions03 Vacuum pump cooling and lubrication

Innovations in cooling and lubrication systems for vacuum pumps aim to improve reliability and extend operational life. These may include advanced cooling techniques, self-lubricating materials, or intelligent lubrication systems that adapt to pump conditions.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Multi-stage vacuum pump designs combine different pump types or stages to achieve higher vacuum levels or improved pumping speeds. These configurations may integrate various pump technologies to optimize performance across a wide range of pressure conditions.Expand Specific Solutions05 Smart vacuum pump control systems

Integration of smart control systems in vacuum pumps enables advanced monitoring, diagnostics, and optimization. These systems may incorporate sensors, IoT connectivity, and machine learning algorithms to enhance pump performance, predict maintenance needs, and optimize energy consumption.Expand Specific Solutions

Key Vacuum Pump Players

The vacuum pump utilization in next-generation display technologies market is in a growth phase, driven by increasing demand for advanced displays in consumer electronics and industrial applications. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like Canon, Edwards, and Tokyo Electron leading innovation. These firms are developing more efficient and specialized vacuum pumps tailored for display manufacturing processes. The competition is intense, with established players like Toshiba and LG Display investing heavily in R&D to maintain their market positions. Emerging players such as BOE Technology are also making strides, particularly in flexible display technologies, further intensifying the competitive landscape.

Canon, Inc.

Technical Solution: Canon has leveraged its expertise in precision engineering to develop vacuum pump technologies for next-generation display manufacturing. Their ANOVA series of vacuum deposition systems incorporates high-capacity vacuum pumps optimized for large-area OLED and quantum dot display production[13]. Canon's vacuum systems feature advanced gas flow simulation and chamber design to ensure uniform deposition across large substrates. They have developed proprietary vacuum sealing technologies that minimize leakage and contamination risks in production environments. Canon has also invested in research on vacuum-based inkjet printing technologies for OLED displays, which could potentially reduce material waste and improve production efficiency[14]. Their vacuum systems are integrated with sophisticated control software that enables real-time adjustments to maintain optimal process conditions throughout the manufacturing cycle[15].

Strengths: Precision engineering expertise, focus on large-area display production, innovative deposition techniques. Weaknesses: Relatively new entrant in display-specific vacuum technologies, may face competition from established players.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for next-generation display manufacturing. Their iXL dry pump series incorporates a unique tapered screw design, enabling high pumping speeds and ultimate pressures suitable for OLED and flexible display production[1]. The company has also introduced the nEXT turbomolecular pump range, which offers improved pumping performance for light gases, critical in the thin film deposition processes used in advanced display fabrication[2]. Edwards' vacuum systems are designed to maintain ultra-clean environments, crucial for preventing defects in high-resolution displays. They have implemented advanced control systems that optimize pump performance and energy efficiency, reducing overall production costs for display manufacturers[3].

Strengths: Specialized pumps for display manufacturing, high pumping efficiency, ultra-clean operation. Weaknesses: Potentially higher initial costs, may require specialized maintenance.

Vacuum Pump Innovations

An integrated high vacuum pumping system

PatentActiveEP1781946A1

Innovation

- An integrated high-vacuum pumping system is developed, where a housing incorporates a turbo-molecular pump, inlet valve, bypass line, and exhaust valve as a single unit, maintaining components at similar temperatures and reducing the number of seals and components, thereby minimizing thermal differentials and simplifying maintenance.

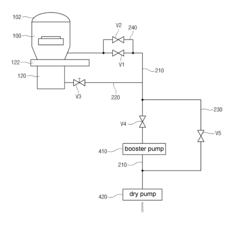

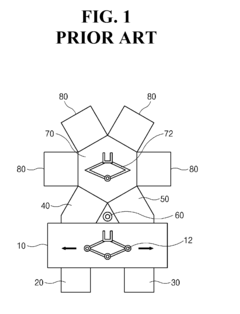

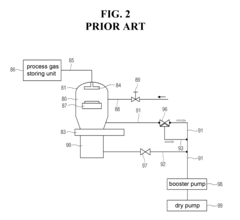

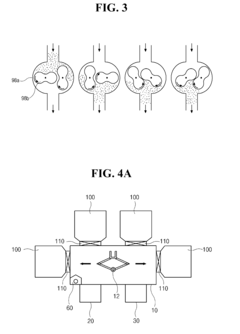

Vacuum pumping system, driving method thereof, apparatus having the same, and method of transferring substrate using the same

PatentInactiveUS7866341B2

Innovation

- A vacuum pumping system with a transfer unit under atmospheric conditions, connected to process chambers via a booster pump and dry pump with a bypass line, and a venting system using preheated gases to minimize temperature variations, eliminating the need for a separate transfer chamber and load-lock chambers.

Environmental Impact

The utilization of vacuum pumps in next-generation display technologies has significant environmental implications that warrant careful consideration. These advanced display manufacturing processes, while offering improved performance and efficiency, also present potential environmental challenges that need to be addressed.

One of the primary environmental concerns associated with vacuum pump usage in display production is energy consumption. The high-vacuum environments required for processes such as thin-film deposition and etching demand substantial power input. This increased energy demand contributes to higher carbon emissions if the energy source is not renewable, potentially exacerbating climate change issues.

Additionally, the production and disposal of vacuum pumps used in display manufacturing raise sustainability concerns. These pumps often contain materials that can be harmful to the environment if not properly managed at the end of their lifecycle. Proper recycling and disposal protocols are essential to mitigate the environmental impact of these components.

The use of certain process gases in vacuum-based manufacturing techniques also poses environmental risks. Some of these gases, such as sulfur hexafluoride (SF6) used in plasma etching, are potent greenhouse gases with high global warming potential. Stringent control measures and alternative gas options are being explored to reduce the environmental footprint of these processes.

Water consumption is another critical environmental factor to consider. Many vacuum-based processes in display manufacturing require significant amounts of ultra-pure water for cleaning and cooling purposes. The production and treatment of this water can strain local water resources and contribute to water scarcity issues in manufacturing regions.

On a positive note, the adoption of more efficient vacuum pump technologies in next-generation display production can lead to reduced resource consumption and waste generation. Advanced pump designs with improved energy efficiency and longer operational lifespans can help minimize the overall environmental impact of display manufacturing processes.

Furthermore, the transition to vacuum-based technologies in display production may enable the creation of more energy-efficient and longer-lasting display products. This could potentially offset some of the environmental costs associated with manufacturing by reducing the frequency of device replacement and lowering energy consumption during product use.

As the display industry continues to evolve, there is a growing emphasis on developing more sustainable manufacturing practices. This includes research into eco-friendly materials, closed-loop production systems, and improved waste management strategies specifically tailored to vacuum-based processes. These efforts aim to balance technological advancement with environmental stewardship in the production of next-generation displays.

One of the primary environmental concerns associated with vacuum pump usage in display production is energy consumption. The high-vacuum environments required for processes such as thin-film deposition and etching demand substantial power input. This increased energy demand contributes to higher carbon emissions if the energy source is not renewable, potentially exacerbating climate change issues.

Additionally, the production and disposal of vacuum pumps used in display manufacturing raise sustainability concerns. These pumps often contain materials that can be harmful to the environment if not properly managed at the end of their lifecycle. Proper recycling and disposal protocols are essential to mitigate the environmental impact of these components.

The use of certain process gases in vacuum-based manufacturing techniques also poses environmental risks. Some of these gases, such as sulfur hexafluoride (SF6) used in plasma etching, are potent greenhouse gases with high global warming potential. Stringent control measures and alternative gas options are being explored to reduce the environmental footprint of these processes.

Water consumption is another critical environmental factor to consider. Many vacuum-based processes in display manufacturing require significant amounts of ultra-pure water for cleaning and cooling purposes. The production and treatment of this water can strain local water resources and contribute to water scarcity issues in manufacturing regions.

On a positive note, the adoption of more efficient vacuum pump technologies in next-generation display production can lead to reduced resource consumption and waste generation. Advanced pump designs with improved energy efficiency and longer operational lifespans can help minimize the overall environmental impact of display manufacturing processes.

Furthermore, the transition to vacuum-based technologies in display production may enable the creation of more energy-efficient and longer-lasting display products. This could potentially offset some of the environmental costs associated with manufacturing by reducing the frequency of device replacement and lowering energy consumption during product use.

As the display industry continues to evolve, there is a growing emphasis on developing more sustainable manufacturing practices. This includes research into eco-friendly materials, closed-loop production systems, and improved waste management strategies specifically tailored to vacuum-based processes. These efforts aim to balance technological advancement with environmental stewardship in the production of next-generation displays.

Vacuum Pump Standards

Vacuum pump standards play a crucial role in ensuring the quality, performance, and safety of vacuum systems used in next-generation display technologies. These standards provide guidelines for manufacturers, users, and regulatory bodies to maintain consistency and reliability in vacuum pump operations.

The International Organization for Standardization (ISO) has developed several standards specifically for vacuum technology. ISO 21360 is a key standard that outlines the measurement methods for evaluating the performance characteristics of vacuum pumps. This standard is particularly relevant for the display industry, as it helps in selecting the most suitable pumps for specific applications.

Another important standard is ISO 3529, which defines the terms and definitions used in vacuum technology. This standard ensures clear communication between manufacturers, suppliers, and end-users, reducing the risk of misunderstandings in technical specifications and requirements.

For safety considerations, the IEC 60034 series of standards is applicable to vacuum pumps used in display manufacturing. These standards cover the safety and performance aspects of rotating electrical machines, including those used in vacuum pump systems.

In the context of clean room environments, which are essential for display manufacturing, ISO 14644 provides guidelines for air cleanliness classification and monitoring. This standard is crucial for maintaining the required level of cleanliness in vacuum systems used in display production processes.

The American Vacuum Society (AVS) has also developed standards specific to vacuum technology. The AVS Technical Standard on Procedure for Calibrating Vacuum Gauges of the Ionization Type provides guidelines for accurate pressure measurements, which is critical for maintaining precise vacuum levels in display manufacturing.

Compliance with these standards ensures that vacuum pumps used in next-generation display technologies meet the required performance criteria, operate safely, and maintain the necessary cleanliness levels. Manufacturers of display technologies must carefully consider these standards when selecting and implementing vacuum pump systems in their production processes.

As the display industry continues to evolve, these standards are regularly reviewed and updated to keep pace with technological advancements. Industry stakeholders should stay informed about any changes or new standards that may impact vacuum pump utilization in display manufacturing.

The International Organization for Standardization (ISO) has developed several standards specifically for vacuum technology. ISO 21360 is a key standard that outlines the measurement methods for evaluating the performance characteristics of vacuum pumps. This standard is particularly relevant for the display industry, as it helps in selecting the most suitable pumps for specific applications.

Another important standard is ISO 3529, which defines the terms and definitions used in vacuum technology. This standard ensures clear communication between manufacturers, suppliers, and end-users, reducing the risk of misunderstandings in technical specifications and requirements.

For safety considerations, the IEC 60034 series of standards is applicable to vacuum pumps used in display manufacturing. These standards cover the safety and performance aspects of rotating electrical machines, including those used in vacuum pump systems.

In the context of clean room environments, which are essential for display manufacturing, ISO 14644 provides guidelines for air cleanliness classification and monitoring. This standard is crucial for maintaining the required level of cleanliness in vacuum systems used in display production processes.

The American Vacuum Society (AVS) has also developed standards specific to vacuum technology. The AVS Technical Standard on Procedure for Calibrating Vacuum Gauges of the Ionization Type provides guidelines for accurate pressure measurements, which is critical for maintaining precise vacuum levels in display manufacturing.

Compliance with these standards ensures that vacuum pumps used in next-generation display technologies meet the required performance criteria, operate safely, and maintain the necessary cleanliness levels. Manufacturers of display technologies must carefully consider these standards when selecting and implementing vacuum pump systems in their production processes.

As the display industry continues to evolve, these standards are regularly reviewed and updated to keep pace with technological advancements. Industry stakeholders should stay informed about any changes or new standards that may impact vacuum pump utilization in display manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!