Vacuum Pumps in the Development of High-Precision Optoelectronic Devices

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution and Objectives

Vacuum pumps have played a pivotal role in the evolution of high-precision optoelectronic devices, serving as a cornerstone technology for creating the controlled environments necessary for advanced manufacturing processes. The journey of vacuum pump technology in this field spans several decades, with significant advancements paralleling the increasing demands of the optoelectronics industry.

In the early stages of optoelectronic device development, basic mechanical pumps were sufficient for creating low-vacuum environments. However, as the precision requirements for devices such as lasers, photodetectors, and integrated optical circuits increased, the need for higher vacuum levels and cleaner environments became paramount.

The 1960s and 1970s saw the introduction of turbomolecular pumps, which marked a significant leap forward in vacuum technology. These pumps allowed for the achievement of high and ultra-high vacuum levels, critical for the deposition of thin films and the manipulation of materials at the atomic level. This advancement enabled the production of more sophisticated optoelectronic components with enhanced performance characteristics.

As the industry progressed into the 1980s and 1990s, the focus shifted towards developing pumps that could maintain cleaner vacuum environments. The introduction of oil-free and dry pumps addressed the contamination issues associated with earlier oil-sealed pumps, paving the way for even more precise and reliable manufacturing processes.

The turn of the millennium brought about further refinements in vacuum pump technology, with an emphasis on energy efficiency, reduced footprint, and improved process control. These advancements were crucial in supporting the miniaturization trend in optoelectronic devices and the increasing complexity of integrated photonic systems.

Today, the objectives of vacuum pump technology in high-precision optoelectronic device development are multifaceted. There is a continuous push for pumps that can achieve and maintain even higher vacuum levels, with some applications requiring pressures as low as 10^-12 mbar. Simultaneously, there is a drive to develop pumps with enhanced particulate control and reduced vibration, critical for nanoscale fabrication processes.

Looking forward, the goals for vacuum pump technology include the development of smart pumping systems that can integrate with Industry 4.0 practices, offering real-time monitoring and predictive maintenance capabilities. There is also a focus on creating more sustainable vacuum solutions, with reduced energy consumption and environmental impact, aligning with global initiatives for greener manufacturing processes.

The ongoing evolution of vacuum pump technology aims to support the next generation of optoelectronic devices, including quantum photonic systems, advanced LiDAR technologies, and ultra-high-bandwidth optical communication components. As these devices become more sophisticated, the demands on vacuum technology will continue to grow, driving innovation in pump design, materials, and control systems.

In the early stages of optoelectronic device development, basic mechanical pumps were sufficient for creating low-vacuum environments. However, as the precision requirements for devices such as lasers, photodetectors, and integrated optical circuits increased, the need for higher vacuum levels and cleaner environments became paramount.

The 1960s and 1970s saw the introduction of turbomolecular pumps, which marked a significant leap forward in vacuum technology. These pumps allowed for the achievement of high and ultra-high vacuum levels, critical for the deposition of thin films and the manipulation of materials at the atomic level. This advancement enabled the production of more sophisticated optoelectronic components with enhanced performance characteristics.

As the industry progressed into the 1980s and 1990s, the focus shifted towards developing pumps that could maintain cleaner vacuum environments. The introduction of oil-free and dry pumps addressed the contamination issues associated with earlier oil-sealed pumps, paving the way for even more precise and reliable manufacturing processes.

The turn of the millennium brought about further refinements in vacuum pump technology, with an emphasis on energy efficiency, reduced footprint, and improved process control. These advancements were crucial in supporting the miniaturization trend in optoelectronic devices and the increasing complexity of integrated photonic systems.

Today, the objectives of vacuum pump technology in high-precision optoelectronic device development are multifaceted. There is a continuous push for pumps that can achieve and maintain even higher vacuum levels, with some applications requiring pressures as low as 10^-12 mbar. Simultaneously, there is a drive to develop pumps with enhanced particulate control and reduced vibration, critical for nanoscale fabrication processes.

Looking forward, the goals for vacuum pump technology include the development of smart pumping systems that can integrate with Industry 4.0 practices, offering real-time monitoring and predictive maintenance capabilities. There is also a focus on creating more sustainable vacuum solutions, with reduced energy consumption and environmental impact, aligning with global initiatives for greener manufacturing processes.

The ongoing evolution of vacuum pump technology aims to support the next generation of optoelectronic devices, including quantum photonic systems, advanced LiDAR technologies, and ultra-high-bandwidth optical communication components. As these devices become more sophisticated, the demands on vacuum technology will continue to grow, driving innovation in pump design, materials, and control systems.

Market Demand Analysis for High-Precision Optoelectronics

The market demand for high-precision optoelectronic devices has been experiencing significant growth, driven by advancements in various industries such as telecommunications, healthcare, aerospace, and consumer electronics. This surge in demand has directly impacted the requirement for vacuum pumps, which play a crucial role in the manufacturing and operation of these sophisticated devices.

In the telecommunications sector, the ongoing rollout of 5G networks and the increasing demand for high-speed data transmission have led to a growing need for advanced optical components. These components, including lasers, photodetectors, and optical modulators, require precise manufacturing processes that often involve vacuum environments. As a result, the demand for high-performance vacuum pumps has risen substantially.

The healthcare industry has also contributed to the market growth, with the increasing adoption of advanced medical imaging technologies such as endoscopy, laser surgery, and spectroscopy. These applications rely heavily on high-precision optoelectronic devices, which in turn necessitate the use of vacuum pumps during their production and operation.

In the aerospace and defense sectors, the development of cutting-edge technologies like laser-based communication systems, remote sensing equipment, and guidance systems has further fueled the demand for high-precision optoelectronic devices. The stringent requirements for reliability and performance in these applications have led to an increased focus on vacuum-based manufacturing processes, driving the need for advanced vacuum pump technologies.

The consumer electronics market has also played a significant role in boosting the demand for high-precision optoelectronic devices. The growing popularity of smartphones, tablets, and wearable devices with advanced display technologies and camera systems has created a substantial market for components that require vacuum-based manufacturing processes.

As the demand for miniaturization and improved performance continues to grow across various industries, the market for high-precision optoelectronic devices is expected to expand further. This trend is likely to sustain the demand for vacuum pumps in the foreseeable future, as manufacturers strive to meet the increasingly stringent requirements for precision and quality in device production.

The global market for vacuum pumps used in the production of high-precision optoelectronic devices is projected to grow steadily over the next few years. This growth is attributed to the increasing adoption of advanced manufacturing techniques, the expansion of production capacities, and the emergence of new applications for optoelectronic devices in various industries.

In the telecommunications sector, the ongoing rollout of 5G networks and the increasing demand for high-speed data transmission have led to a growing need for advanced optical components. These components, including lasers, photodetectors, and optical modulators, require precise manufacturing processes that often involve vacuum environments. As a result, the demand for high-performance vacuum pumps has risen substantially.

The healthcare industry has also contributed to the market growth, with the increasing adoption of advanced medical imaging technologies such as endoscopy, laser surgery, and spectroscopy. These applications rely heavily on high-precision optoelectronic devices, which in turn necessitate the use of vacuum pumps during their production and operation.

In the aerospace and defense sectors, the development of cutting-edge technologies like laser-based communication systems, remote sensing equipment, and guidance systems has further fueled the demand for high-precision optoelectronic devices. The stringent requirements for reliability and performance in these applications have led to an increased focus on vacuum-based manufacturing processes, driving the need for advanced vacuum pump technologies.

The consumer electronics market has also played a significant role in boosting the demand for high-precision optoelectronic devices. The growing popularity of smartphones, tablets, and wearable devices with advanced display technologies and camera systems has created a substantial market for components that require vacuum-based manufacturing processes.

As the demand for miniaturization and improved performance continues to grow across various industries, the market for high-precision optoelectronic devices is expected to expand further. This trend is likely to sustain the demand for vacuum pumps in the foreseeable future, as manufacturers strive to meet the increasingly stringent requirements for precision and quality in device production.

The global market for vacuum pumps used in the production of high-precision optoelectronic devices is projected to grow steadily over the next few years. This growth is attributed to the increasing adoption of advanced manufacturing techniques, the expansion of production capacities, and the emergence of new applications for optoelectronic devices in various industries.

Current Vacuum Pump Challenges in Optoelectronics

The development of high-precision optoelectronic devices has been significantly impacted by the advancements in vacuum pump technology. However, several challenges persist in the application of vacuum pumps within the optoelectronics industry. One of the primary issues is achieving and maintaining ultra-high vacuum levels required for the fabrication of sensitive optoelectronic components.

Current vacuum pump systems often struggle to reach the extreme low pressures needed for processes such as thin film deposition and electron beam lithography. These processes demand pressures as low as 10^-10 Torr, which pushes the limits of conventional pump technologies. The inability to consistently achieve these vacuum levels can lead to contamination and defects in the final optoelectronic devices, compromising their performance and reliability.

Another significant challenge is the management of particulate contamination. As optoelectronic devices become increasingly miniaturized and sensitive, even nanoscale particles can cause critical failures. Vacuum pumps must not only create a high vacuum but also prevent the backstreaming of pump oil or other contaminants into the process chamber. This requirement has led to the development of oil-free pump technologies, but these often face limitations in pumping speed and ultimate vacuum levels.

The need for cleaner vacuum environments has also highlighted the issue of outgassing from pump components and chamber materials. Materials used in vacuum systems can release gases over time, degrading the vacuum quality and potentially introducing contaminants. This necessitates the use of specialized materials and surface treatments, which can significantly increase the cost and complexity of vacuum systems.

Energy efficiency and heat management present additional challenges in vacuum pump design for optoelectronics applications. High-performance pumps often consume substantial amounts of energy and generate considerable heat, which can affect the stability of sensitive optoelectronic manufacturing processes. Balancing the need for powerful pumping capabilities with energy efficiency and thermal management remains a significant engineering challenge.

Furthermore, the integration of vacuum pumps into increasingly automated and miniaturized production lines poses design and operational challenges. There is a growing demand for compact, low-vibration pump systems that can be seamlessly incorporated into complex manufacturing equipment without compromising performance or cleanroom integrity.

Lastly, the reliability and maintenance requirements of vacuum pumps in continuous operation environments are critical concerns. Optoelectronic device manufacturing often involves long production cycles where any downtime can result in significant losses. Developing pump technologies that offer extended service intervals and predictable maintenance schedules while maintaining consistent performance is an ongoing challenge for the industry.

Current vacuum pump systems often struggle to reach the extreme low pressures needed for processes such as thin film deposition and electron beam lithography. These processes demand pressures as low as 10^-10 Torr, which pushes the limits of conventional pump technologies. The inability to consistently achieve these vacuum levels can lead to contamination and defects in the final optoelectronic devices, compromising their performance and reliability.

Another significant challenge is the management of particulate contamination. As optoelectronic devices become increasingly miniaturized and sensitive, even nanoscale particles can cause critical failures. Vacuum pumps must not only create a high vacuum but also prevent the backstreaming of pump oil or other contaminants into the process chamber. This requirement has led to the development of oil-free pump technologies, but these often face limitations in pumping speed and ultimate vacuum levels.

The need for cleaner vacuum environments has also highlighted the issue of outgassing from pump components and chamber materials. Materials used in vacuum systems can release gases over time, degrading the vacuum quality and potentially introducing contaminants. This necessitates the use of specialized materials and surface treatments, which can significantly increase the cost and complexity of vacuum systems.

Energy efficiency and heat management present additional challenges in vacuum pump design for optoelectronics applications. High-performance pumps often consume substantial amounts of energy and generate considerable heat, which can affect the stability of sensitive optoelectronic manufacturing processes. Balancing the need for powerful pumping capabilities with energy efficiency and thermal management remains a significant engineering challenge.

Furthermore, the integration of vacuum pumps into increasingly automated and miniaturized production lines poses design and operational challenges. There is a growing demand for compact, low-vibration pump systems that can be seamlessly incorporated into complex manufacturing equipment without compromising performance or cleanroom integrity.

Lastly, the reliability and maintenance requirements of vacuum pumps in continuous operation environments are critical concerns. Optoelectronic device manufacturing often involves long production cycles where any downtime can result in significant losses. Developing pump technologies that offer extended service intervals and predictable maintenance schedules while maintaining consistent performance is an ongoing challenge for the industry.

Existing Vacuum Solutions for Optoelectronic Fabrication

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping capacity, reduced energy consumption, and improved reliability in vacuum systems.

- Specialized vacuum pumps for specific applications: Vacuum pumps have been developed for specific industrial and scientific applications. These specialized pumps are designed to meet unique requirements such as high vacuum levels, corrosive gas handling, or clean room compatibility. Custom features and materials are incorporated to ensure optimal performance in diverse operating conditions.

- Integration of vacuum pumps in semiconductor manufacturing: Vacuum pumps play a crucial role in semiconductor manufacturing processes. Innovations in this field focus on integrating vacuum pumps into semiconductor production equipment, enhancing process control, and minimizing contamination risks. These advancements contribute to improved yield and quality in semiconductor fabrication.

- Energy-efficient vacuum pump systems: Efforts have been made to develop energy-efficient vacuum pump systems. These innovations include the use of advanced motor technologies, intelligent control systems, and heat recovery mechanisms. Such improvements result in reduced power consumption, lower operating costs, and decreased environmental impact of vacuum pump operations.

- Vacuum pump maintenance and monitoring solutions: Advancements in vacuum pump maintenance and monitoring solutions have been introduced to enhance pump longevity and performance. These innovations include predictive maintenance systems, remote monitoring capabilities, and automated diagnostics. Such solutions help minimize downtime, optimize pump operation, and reduce maintenance costs in industrial and research settings.

02 Vacuum pump applications in semiconductor manufacturing

Vacuum pumps play a crucial role in semiconductor manufacturing processes. Specialized pumps have been developed to meet the stringent requirements of clean room environments and ultra-high vacuum conditions. These pumps are designed to handle corrosive gases, minimize particle generation, and maintain stable vacuum levels essential for various semiconductor fabrication steps.Expand Specific Solutions03 Historical developments in vacuum pump technology

The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to their advancement. Early designs focused on mechanical improvements, while later developments incorporated new materials and manufacturing techniques. These historical advancements have laid the foundation for modern vacuum pump systems used across various industries.Expand Specific Solutions04 Vacuum pump control and monitoring systems

Advanced control and monitoring systems have been developed to optimize vacuum pump operation. These systems incorporate sensors, microprocessors, and software algorithms to regulate pump speed, monitor performance parameters, and detect potential issues. Such intelligent control systems enhance energy efficiency, extend pump lifespan, and enable predictive maintenance strategies.Expand Specific Solutions05 Specialized vacuum pumps for specific applications

Various industries require vacuum pumps tailored to their specific needs. Customized pump designs have been developed for applications such as food packaging, medical devices, and scientific research. These specialized pumps incorporate features like oil-free operation, compact size, or the ability to handle specific gases or particulates, addressing the unique requirements of different sectors.Expand Specific Solutions

Key Players in Vacuum Pump and Optoelectronics

The vacuum pump market for high-precision optoelectronic devices is in a mature growth stage, with a global market size expected to reach several billion dollars by 2025. The industry is characterized by intense competition among established players like Edwards Ltd., ASML Netherlands BV, and Pfeiffer Vacuum GmbH, who are continuously innovating to meet the increasing demands of semiconductor and display manufacturers. The technology has reached a high level of maturity, with companies like Edwards Vacuum LLC and MKS, Inc. focusing on developing more efficient and precise pumps for critical applications. Asian players such as BYD Co., Ltd. and Tokyo Electron Ltd. are also making significant strides in this field, leveraging their strong presence in the electronics manufacturing sector.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for high-precision optoelectronic device manufacturing. Their innovative dry pumping solutions, such as the iXH series, offer contamination-free vacuum environments crucial for sensitive optoelectronic processes. These pumps utilize a unique screw mechanism that provides high pumping speeds and ultimate pressures down to 10^-3 mbar[1]. Edwards has also introduced intelligent pump management systems that optimize performance and energy efficiency, reducing operational costs in optoelectronic manufacturing facilities[2]. Their pumps incorporate advanced materials and coatings to resist corrosion from aggressive process gases, ensuring long-term reliability in demanding optoelectronic applications[3].

Strengths: High pumping efficiency, contamination-free operation, and intelligent control systems. Weaknesses: Higher initial cost compared to traditional pumps, may require specialized maintenance.

ASML Netherlands BV

Technical Solution: ASML, a leader in photolithography systems for the semiconductor industry, has integrated cutting-edge vacuum technologies into their EUV (Extreme Ultraviolet) lithography machines. These systems require ultra-high vacuum conditions to operate effectively. ASML's vacuum solutions include multi-stage pump systems that can achieve and maintain pressures as low as 10^-9 mbar in the EUV source and projection optics[4]. They have developed specialized vacuum chambers with advanced sealing technologies to prevent contamination and maintain the pristine environment needed for EUV lithography. ASML's vacuum systems also incorporate real-time monitoring and control, allowing for rapid adjustments to maintain optimal conditions during the lithography process[5].

Strengths: Ultra-high vacuum capabilities, integrated system approach, and real-time control. Weaknesses: Extremely high cost and complexity, limited to very specialized applications.

Core Innovations in Vacuum Pump Technology

An integrated high vacuum pumping system

PatentActiveEP1781946A1

Innovation

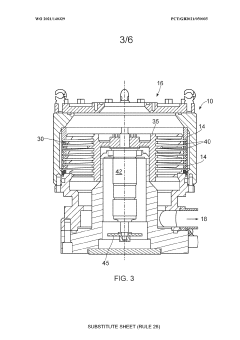

- An integrated high-vacuum pumping system is developed, where a housing incorporates a turbo-molecular pump, inlet valve, bypass line, and exhaust valve as a single unit, maintaining components at similar temperatures and reducing the number of seals and components, thereby minimizing thermal differentials and simplifying maintenance.

Vacuum pump, vacuum pump set for evacuating a semiconductor processing chamber and method of evacuating a semiconductor processing chamber

PatentWO2021140329A1

Innovation

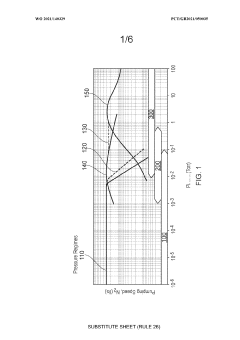

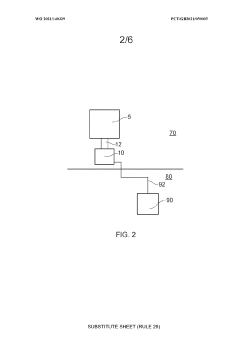

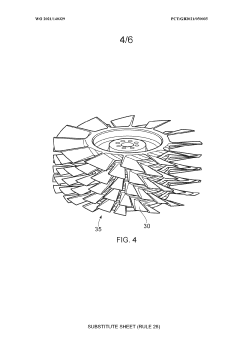

- A vacuum pump with a rotor and stator design featuring angled blades on a helical path, magnetically levitated bearings, and high transparency perforated elements, allowing effective pumping between 1 mbar and 5 × 10^2 mbar, backed by a roots blower for enhanced performance across the transitional flow regime.

Environmental Impact of Vacuum Processes

The environmental impact of vacuum processes in the development of high-precision optoelectronic devices is a critical consideration for sustainable manufacturing practices. Vacuum pumps, essential for creating the controlled environments necessary for these devices, contribute significantly to energy consumption and potential environmental hazards.

Energy consumption is a primary concern in vacuum processes. High-performance vacuum pumps often require substantial electrical power to operate, particularly during the initial pump-down phase. This energy demand can lead to increased carbon emissions if the power source is not from renewable energy. Manufacturers are increasingly focusing on developing energy-efficient pump designs and implementing smart control systems to optimize power usage without compromising performance.

Vacuum processes may involve the use of various gases and chemicals, some of which can have detrimental effects on the environment if not properly managed. For instance, certain cleaning and etching processes in optoelectronic device fabrication may utilize greenhouse gases or ozone-depleting substances. Strict protocols for gas handling, recycling, and disposal are crucial to minimize environmental impact.

The production of vacuum equipment itself has environmental implications. The manufacturing of specialized materials and components for high-performance vacuum pumps can involve resource-intensive processes. Additionally, the disposal of used vacuum equipment, particularly oil-sealed pumps, requires careful consideration due to potential contamination from pump fluids and accumulated process byproducts.

Water usage is another environmental factor in vacuum processes. Some vacuum systems, especially those used in larger industrial settings, may employ water for cooling or as a working fluid in certain pump types. Efficient water management and recycling systems are essential to reduce water consumption and minimize wastewater generation.

Noise pollution is an often-overlooked environmental impact of vacuum pumps. High-capacity pumps can generate significant noise levels, potentially affecting the work environment and surrounding areas. Acoustic engineering solutions and proper pump enclosures are being developed to address this issue, improving both environmental and occupational health aspects.

As the demand for high-precision optoelectronic devices continues to grow, the industry is increasingly adopting eco-friendly vacuum technologies. This includes the development of dry pumps that eliminate the need for oil, reducing the risk of contamination and simplifying maintenance. Additionally, advancements in pump design are focusing on materials that are more easily recyclable and have a lower overall environmental footprint.

Energy consumption is a primary concern in vacuum processes. High-performance vacuum pumps often require substantial electrical power to operate, particularly during the initial pump-down phase. This energy demand can lead to increased carbon emissions if the power source is not from renewable energy. Manufacturers are increasingly focusing on developing energy-efficient pump designs and implementing smart control systems to optimize power usage without compromising performance.

Vacuum processes may involve the use of various gases and chemicals, some of which can have detrimental effects on the environment if not properly managed. For instance, certain cleaning and etching processes in optoelectronic device fabrication may utilize greenhouse gases or ozone-depleting substances. Strict protocols for gas handling, recycling, and disposal are crucial to minimize environmental impact.

The production of vacuum equipment itself has environmental implications. The manufacturing of specialized materials and components for high-performance vacuum pumps can involve resource-intensive processes. Additionally, the disposal of used vacuum equipment, particularly oil-sealed pumps, requires careful consideration due to potential contamination from pump fluids and accumulated process byproducts.

Water usage is another environmental factor in vacuum processes. Some vacuum systems, especially those used in larger industrial settings, may employ water for cooling or as a working fluid in certain pump types. Efficient water management and recycling systems are essential to reduce water consumption and minimize wastewater generation.

Noise pollution is an often-overlooked environmental impact of vacuum pumps. High-capacity pumps can generate significant noise levels, potentially affecting the work environment and surrounding areas. Acoustic engineering solutions and proper pump enclosures are being developed to address this issue, improving both environmental and occupational health aspects.

As the demand for high-precision optoelectronic devices continues to grow, the industry is increasingly adopting eco-friendly vacuum technologies. This includes the development of dry pumps that eliminate the need for oil, reducing the risk of contamination and simplifying maintenance. Additionally, advancements in pump design are focusing on materials that are more easily recyclable and have a lower overall environmental footprint.

Vacuum Standards and Certifications

In the development of high-precision optoelectronic devices, adherence to vacuum standards and certifications is crucial for ensuring product quality, reliability, and performance. These standards provide a framework for consistent measurement, testing, and evaluation of vacuum systems and components used in the manufacturing process.

The International Organization for Standardization (ISO) has established several key standards relevant to vacuum technology in optoelectronic device production. ISO 3529 defines terminology and symbols for vacuum technology, ensuring clear communication across the industry. ISO 21360 specifies methods for evaluating the performance of vacuum pumps, which is essential for maintaining precise vacuum levels during device fabrication.

For high-precision optoelectronic devices, cleanliness is paramount. The SEMI standards, particularly SEMI E14 for measurement and reporting of particle contamination levels in gas distribution systems, are widely adopted in the semiconductor and optoelectronics industries. These standards help manufacturers maintain ultra-clean environments necessary for producing sensitive optical components.

The American Vacuum Society (AVS) also plays a significant role in establishing guidelines for vacuum technology. Their recommended practices cover various aspects of vacuum system design, operation, and maintenance, which are invaluable for ensuring consistent performance in optoelectronic device production.

Certification programs, such as those offered by the Institute of Environmental Sciences and Technology (IEST), provide validation of cleanroom and contamination control practices. These certifications are often required by optoelectronic device manufacturers to ensure their production environments meet stringent cleanliness standards.

In Europe, the CE marking is mandatory for vacuum equipment sold within the European Economic Area. This certification ensures that products meet safety, health, and environmental protection requirements. For optoelectronic device manufacturers, using CE-marked vacuum pumps and related equipment is essential for compliance with European regulations.

The National Institute of Standards and Technology (NIST) in the United States provides traceability for vacuum measurements, which is critical for calibrating instruments used in high-precision optoelectronic device production. NIST-traceable calibrations ensure that vacuum gauges and other measurement devices maintain accuracy over time, contributing to consistent product quality.

As the demand for higher precision in optoelectronic devices grows, vacuum standards and certifications continue to evolve. Industry collaborations and research initiatives are driving the development of new standards to address emerging challenges in vacuum technology, such as those related to extreme ultraviolet (EUV) lithography and advanced packaging techniques for optoelectronic components.

The International Organization for Standardization (ISO) has established several key standards relevant to vacuum technology in optoelectronic device production. ISO 3529 defines terminology and symbols for vacuum technology, ensuring clear communication across the industry. ISO 21360 specifies methods for evaluating the performance of vacuum pumps, which is essential for maintaining precise vacuum levels during device fabrication.

For high-precision optoelectronic devices, cleanliness is paramount. The SEMI standards, particularly SEMI E14 for measurement and reporting of particle contamination levels in gas distribution systems, are widely adopted in the semiconductor and optoelectronics industries. These standards help manufacturers maintain ultra-clean environments necessary for producing sensitive optical components.

The American Vacuum Society (AVS) also plays a significant role in establishing guidelines for vacuum technology. Their recommended practices cover various aspects of vacuum system design, operation, and maintenance, which are invaluable for ensuring consistent performance in optoelectronic device production.

Certification programs, such as those offered by the Institute of Environmental Sciences and Technology (IEST), provide validation of cleanroom and contamination control practices. These certifications are often required by optoelectronic device manufacturers to ensure their production environments meet stringent cleanliness standards.

In Europe, the CE marking is mandatory for vacuum equipment sold within the European Economic Area. This certification ensures that products meet safety, health, and environmental protection requirements. For optoelectronic device manufacturers, using CE-marked vacuum pumps and related equipment is essential for compliance with European regulations.

The National Institute of Standards and Technology (NIST) in the United States provides traceability for vacuum measurements, which is critical for calibrating instruments used in high-precision optoelectronic device production. NIST-traceable calibrations ensure that vacuum gauges and other measurement devices maintain accuracy over time, contributing to consistent product quality.

As the demand for higher precision in optoelectronic devices grows, vacuum standards and certifications continue to evolve. Industry collaborations and research initiatives are driving the development of new standards to address emerging challenges in vacuum technology, such as those related to extreme ultraviolet (EUV) lithography and advanced packaging techniques for optoelectronic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!