Vision for PLA in Environmental Regulations and Standards

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Environmental Regulations Background

Polylactic acid (PLA) has emerged as a prominent biodegradable plastic in recent years, gaining attention for its potential to address environmental concerns associated with conventional plastics. The growing focus on sustainable materials has led to increased scrutiny of PLA's environmental impact and the development of regulations and standards to govern its use and disposal.

The environmental regulations surrounding PLA are rooted in broader efforts to combat plastic pollution and promote circular economy principles. These regulations aim to ensure that PLA products are truly biodegradable and compostable, minimizing their environmental footprint throughout their lifecycle. The regulatory landscape for PLA has evolved significantly over the past decade, with various countries and regions implementing their own standards and certification processes.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard has become a benchmark for PLA products, requiring them to biodegrade by at least 90% within six months under industrial composting conditions. Similarly, the United States has established the ASTM D6400 standard, which specifies requirements for plastics and products made from plastics to be labeled as "compostable in municipal and industrial composting facilities."

The development of these standards has been driven by the need to differentiate truly biodegradable plastics from those that merely fragment into smaller pieces, potentially exacerbating microplastic pollution. As a result, certification schemes such as the "Seedling" logo in Europe and the "BPI Compostable" logo in North America have been introduced to help consumers identify products that meet these stringent biodegradability standards.

Regulatory bodies have also begun to address the end-of-life management of PLA products. In some jurisdictions, PLA is now included in organic waste collection programs, recognizing its potential to be processed in industrial composting facilities. However, the implementation of such programs varies widely, highlighting the need for harmonized approaches to PLA waste management across different regions.

The regulatory landscape for PLA continues to evolve, with ongoing discussions about the material's performance in different environmental conditions and its potential impact on existing recycling streams. As the use of PLA expands into new applications, from packaging to textiles and 3D printing, regulators are faced with the challenge of developing comprehensive frameworks that address the full spectrum of PLA products and their environmental implications.

The environmental regulations surrounding PLA are rooted in broader efforts to combat plastic pollution and promote circular economy principles. These regulations aim to ensure that PLA products are truly biodegradable and compostable, minimizing their environmental footprint throughout their lifecycle. The regulatory landscape for PLA has evolved significantly over the past decade, with various countries and regions implementing their own standards and certification processes.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard has become a benchmark for PLA products, requiring them to biodegrade by at least 90% within six months under industrial composting conditions. Similarly, the United States has established the ASTM D6400 standard, which specifies requirements for plastics and products made from plastics to be labeled as "compostable in municipal and industrial composting facilities."

The development of these standards has been driven by the need to differentiate truly biodegradable plastics from those that merely fragment into smaller pieces, potentially exacerbating microplastic pollution. As a result, certification schemes such as the "Seedling" logo in Europe and the "BPI Compostable" logo in North America have been introduced to help consumers identify products that meet these stringent biodegradability standards.

Regulatory bodies have also begun to address the end-of-life management of PLA products. In some jurisdictions, PLA is now included in organic waste collection programs, recognizing its potential to be processed in industrial composting facilities. However, the implementation of such programs varies widely, highlighting the need for harmonized approaches to PLA waste management across different regions.

The regulatory landscape for PLA continues to evolve, with ongoing discussions about the material's performance in different environmental conditions and its potential impact on existing recycling streams. As the use of PLA expands into new applications, from packaging to textiles and 3D printing, regulators are faced with the challenge of developing comprehensive frameworks that address the full spectrum of PLA products and their environmental implications.

Market Demand for Sustainable Packaging

The market demand for sustainable packaging has been growing rapidly in recent years, driven by increasing environmental awareness and regulatory pressures. Consumers are becoming more conscious of the environmental impact of their purchasing decisions, leading to a shift in preferences towards eco-friendly packaging solutions. This trend is particularly evident in the food and beverage industry, where single-use plastics have been a major concern.

Polylactic acid (PLA), a biodegradable and compostable bioplastic derived from renewable resources, has emerged as a promising alternative to conventional plastics in the packaging sector. The global PLA market is expected to experience significant growth, with projections indicating a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is largely attributed to the increasing adoption of PLA in various packaging applications, including food containers, beverage bottles, and disposable cutlery.

The demand for PLA-based packaging is particularly strong in regions with stringent environmental regulations, such as Europe and North America. These markets have implemented policies to reduce plastic waste and promote the use of sustainable materials, creating a favorable environment for PLA adoption. In addition, developing economies in Asia-Pacific are also showing increased interest in sustainable packaging solutions, driven by growing environmental concerns and government initiatives.

Key industries driving the demand for PLA packaging include food and beverage, personal care, and healthcare. The food and beverage sector, in particular, has been at the forefront of adopting PLA-based packaging due to its compatibility with food products and its ability to extend shelf life. Major food and beverage companies have announced commitments to increase their use of sustainable packaging materials, including PLA, in response to consumer demands and regulatory pressures.

Despite the growing demand, challenges remain in the widespread adoption of PLA packaging. These include higher production costs compared to conventional plastics, limited availability of industrial composting facilities, and the need for consumer education on proper disposal methods. However, ongoing research and development efforts are focused on addressing these challenges, with innovations in PLA production techniques and the development of more efficient composting infrastructure.

As environmental regulations continue to evolve and consumer awareness grows, the market demand for sustainable packaging solutions like PLA is expected to strengthen further. This presents significant opportunities for companies operating in the PLA value chain, from raw material suppliers to packaging manufacturers and end-users. The future of PLA in packaging looks promising, with potential for continued innovation and market expansion in the coming years.

Polylactic acid (PLA), a biodegradable and compostable bioplastic derived from renewable resources, has emerged as a promising alternative to conventional plastics in the packaging sector. The global PLA market is expected to experience significant growth, with projections indicating a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is largely attributed to the increasing adoption of PLA in various packaging applications, including food containers, beverage bottles, and disposable cutlery.

The demand for PLA-based packaging is particularly strong in regions with stringent environmental regulations, such as Europe and North America. These markets have implemented policies to reduce plastic waste and promote the use of sustainable materials, creating a favorable environment for PLA adoption. In addition, developing economies in Asia-Pacific are also showing increased interest in sustainable packaging solutions, driven by growing environmental concerns and government initiatives.

Key industries driving the demand for PLA packaging include food and beverage, personal care, and healthcare. The food and beverage sector, in particular, has been at the forefront of adopting PLA-based packaging due to its compatibility with food products and its ability to extend shelf life. Major food and beverage companies have announced commitments to increase their use of sustainable packaging materials, including PLA, in response to consumer demands and regulatory pressures.

Despite the growing demand, challenges remain in the widespread adoption of PLA packaging. These include higher production costs compared to conventional plastics, limited availability of industrial composting facilities, and the need for consumer education on proper disposal methods. However, ongoing research and development efforts are focused on addressing these challenges, with innovations in PLA production techniques and the development of more efficient composting infrastructure.

As environmental regulations continue to evolve and consumer awareness grows, the market demand for sustainable packaging solutions like PLA is expected to strengthen further. This presents significant opportunities for companies operating in the PLA value chain, from raw material suppliers to packaging manufacturers and end-users. The future of PLA in packaging looks promising, with potential for continued innovation and market expansion in the coming years.

Current PLA Environmental Standards

Polylactic acid (PLA) has gained significant attention in recent years due to its biodegradable properties and potential to reduce environmental impact. As a result, various environmental standards and regulations have been developed to govern the production, use, and disposal of PLA-based products. These standards aim to ensure the material's sustainability and minimize its ecological footprint throughout its lifecycle.

One of the primary environmental standards for PLA is the ASTM D6400, which sets the specifications for compostable plastics. This standard requires that PLA products completely biodegrade in industrial composting facilities within a specified timeframe, typically 180 days. Additionally, the European Standard EN 13432 provides similar guidelines for biodegradable packaging materials, including PLA, ensuring their compatibility with organic recycling processes.

The ISO 17088 standard is another crucial benchmark for PLA, defining the specifications for compostable plastics. This international standard ensures that PLA products meet specific requirements for biodegradation, disintegration, and ecotoxicity when composted under controlled conditions. Compliance with these standards is often indicated through certification labels, such as the "Seedling" logo in Europe or the BPI (Biodegradable Products Institute) logo in North America.

In terms of production, the Global Recycle Standard (GRS) and the Recycled Claim Standard (RCS) have been adapted to include PLA. These standards verify the recycled content in products and track the chain of custody from the recycler to the final product. While primarily focused on traditional recycled materials, they now accommodate bio-based materials like PLA, reflecting the growing importance of sustainable alternatives in the circular economy.

Environmental Product Declarations (EPDs) have also become increasingly relevant for PLA products. These standardized documents provide transparent and comparable information about the environmental impact of products throughout their lifecycle. For PLA, EPDs typically highlight its lower carbon footprint compared to conventional plastics, as well as its potential for composting or recycling at end-of-life.

The U.S. Department of Agriculture's BioPreferred program includes standards for bio-based content, which are applicable to PLA products. This program promotes the purchase and use of bio-based products, including those made from PLA, by federal agencies and their contractors. Products meeting these standards can display the USDA Certified Biobased Product label, indicating their renewable content and potential environmental benefits.

As the adoption of PLA continues to grow, regulatory bodies are developing more specific standards to address its unique properties and applications. For instance, food contact regulations such as EU Regulation No. 10/2011 and FDA 21 CFR 177.1630 now include provisions for PLA used in food packaging, ensuring its safety for consumers while considering its biodegradable nature.

One of the primary environmental standards for PLA is the ASTM D6400, which sets the specifications for compostable plastics. This standard requires that PLA products completely biodegrade in industrial composting facilities within a specified timeframe, typically 180 days. Additionally, the European Standard EN 13432 provides similar guidelines for biodegradable packaging materials, including PLA, ensuring their compatibility with organic recycling processes.

The ISO 17088 standard is another crucial benchmark for PLA, defining the specifications for compostable plastics. This international standard ensures that PLA products meet specific requirements for biodegradation, disintegration, and ecotoxicity when composted under controlled conditions. Compliance with these standards is often indicated through certification labels, such as the "Seedling" logo in Europe or the BPI (Biodegradable Products Institute) logo in North America.

In terms of production, the Global Recycle Standard (GRS) and the Recycled Claim Standard (RCS) have been adapted to include PLA. These standards verify the recycled content in products and track the chain of custody from the recycler to the final product. While primarily focused on traditional recycled materials, they now accommodate bio-based materials like PLA, reflecting the growing importance of sustainable alternatives in the circular economy.

Environmental Product Declarations (EPDs) have also become increasingly relevant for PLA products. These standardized documents provide transparent and comparable information about the environmental impact of products throughout their lifecycle. For PLA, EPDs typically highlight its lower carbon footprint compared to conventional plastics, as well as its potential for composting or recycling at end-of-life.

The U.S. Department of Agriculture's BioPreferred program includes standards for bio-based content, which are applicable to PLA products. This program promotes the purchase and use of bio-based products, including those made from PLA, by federal agencies and their contractors. Products meeting these standards can display the USDA Certified Biobased Product label, indicating their renewable content and potential environmental benefits.

As the adoption of PLA continues to grow, regulatory bodies are developing more specific standards to address its unique properties and applications. For instance, food contact regulations such as EU Regulation No. 10/2011 and FDA 21 CFR 177.1630 now include provisions for PLA used in food packaging, ensuring its safety for consumers while considering its biodegradable nature.

Existing PLA Compliance Solutions

01 PLA-based composite materials

Polylactic acid (PLA) is used as a base material in various composite formulations. These composites often incorporate other materials to enhance specific properties such as strength, flexibility, or biodegradability. The development of PLA-based composites aims to expand the application range of this biodegradable polymer in different industries.- PLA-based composite materials: Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.

- PLA processing techniques: Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.

- PLA modification for improved properties: Chemical or physical modification of PLA to enhance its properties such as thermal stability, mechanical strength, or barrier properties. This includes techniques like blending with other polymers, crosslinking, or surface treatments to overcome limitations of pure PLA.

- Biodegradable PLA applications: Development of biodegradable products using PLA, focusing on environmentally friendly alternatives to traditional plastics. Applications include packaging materials, disposable items, and agricultural films that can decompose naturally in the environment.

- PLA in medical and pharmaceutical applications: Utilization of PLA in biomedical and pharmaceutical fields, including drug delivery systems, tissue engineering scaffolds, and implantable medical devices. The focus is on exploiting PLA's biocompatibility and biodegradability for these specialized applications.

02 PLA processing techniques

Various processing techniques are employed to manufacture PLA products. These may include extrusion, injection molding, 3D printing, and other forming methods. The choice of processing technique can significantly affect the final properties of the PLA product, such as crystallinity, mechanical strength, and thermal stability.Expand Specific Solutions03 PLA modifications and blends

PLA is often modified or blended with other materials to overcome its inherent limitations. This can involve chemical modifications, physical blending with other polymers, or the addition of plasticizers. These modifications aim to improve properties such as impact resistance, heat resistance, or processability of PLA.Expand Specific Solutions04 PLA in packaging applications

PLA is widely used in packaging applications due to its biodegradability and renewability. Research in this area focuses on developing PLA-based packaging materials with improved barrier properties, mechanical strength, and compatibility with various food products. This includes the development of films, containers, and other packaging formats.Expand Specific Solutions05 PLA in biomedical applications

PLA finds significant use in biomedical applications due to its biocompatibility and biodegradability. Research in this area includes the development of PLA-based materials for tissue engineering scaffolds, drug delivery systems, and medical implants. The focus is on tailoring PLA properties to meet specific biomedical requirements.Expand Specific Solutions

Key Players in PLA Industry

The vision for PLA in environmental regulations and standards is evolving within a rapidly growing market, driven by increasing environmental concerns and regulatory pressures. The industry is in a transitional phase, moving from early adoption to mainstream acceptance. Market size is expanding significantly, with projections indicating substantial growth in the coming years. Technologically, PLA is maturing, with companies like NatureWorks LLC, LG Chem Ltd., and Total Research Corp leading innovation. These firms, along with others like Covestro Deutschland AG and Stora Enso Oyj, are advancing PLA applications across various sectors. The competitive landscape is diverse, featuring established chemical companies, specialized bioplastics manufacturers, and research institutions collaborating to improve PLA's performance and sustainability profile.

NatureWorks LLC

Technical Solution: NatureWorks is a pioneer in the development of polylactic acid (PLA), a biodegradable polymer derived from renewable resources. Their Ingeo brand of PLA is used in various applications, including packaging, fibers, and 3D printing. In the context of environmental regulations and standards, NatureWorks has developed a comprehensive life cycle assessment (LCA) for their PLA products, demonstrating reduced greenhouse gas emissions and fossil fuel usage compared to traditional plastics. They have also implemented a closed-loop recycling system for PLA, addressing end-of-life concerns and promoting circular economy principles.

Strengths: Renewable feedstock, biodegradability, and lower carbon footprint. Weaknesses: Higher production costs and limited high-temperature applications compared to conventional plastics.

LG Chem Ltd.

Technical Solution: LG Chem has developed a range of bio-based materials, including their CLAREN bio-based polycarbonate and bio-based ABS. These materials are designed to meet stringent environmental regulations while maintaining performance characteristics similar to their petroleum-based counterparts. LG Chem has also invested in the development of biodegradable plastics and recycling technologies. Their approach includes the use of renewable raw materials, such as biomass and CO2, to produce eco-friendly plastics. Additionally, they have implemented a chemical recycling process for ABS plastics, contributing to the circular economy and reducing plastic waste.

Strengths: Diverse portfolio of bio-based and recyclable materials, strong R&D capabilities. Weaknesses: Dependency on agricultural feedstocks may raise sustainability concerns, and higher production costs compared to conventional plastics.

Innovations in PLA Environmental Testing

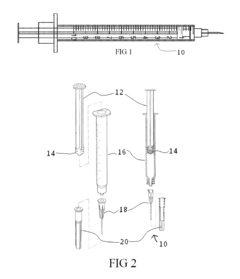

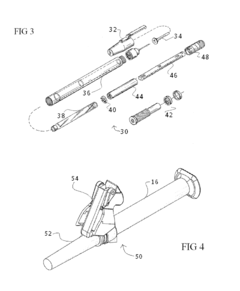

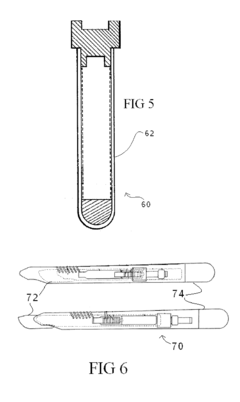

Disposable items made from bioplastic resins

PatentActiveUS20120315688A1

Innovation

- Development of disposable devices using biodegradable resins like polylactic acid (PLA), polyhydroxyalkonate (PHA), and poly 3-hydroxybutrate co 3-hydroxyhexanote (PHBH) intermixed with plasticizers, which can be sterilized and composted, overcoming biodegradability challenges and providing sustainable disposal through the Bio medical and printing waste Sterilization and Composting Process (BSCP).

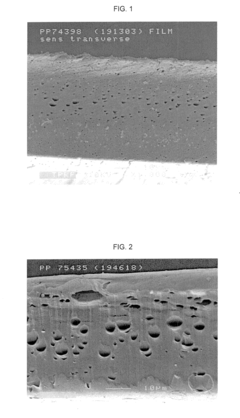

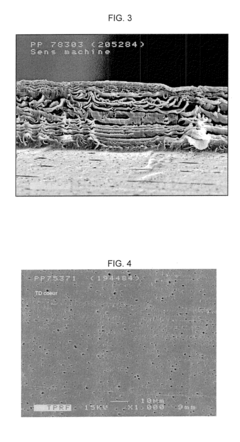

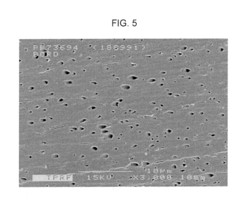

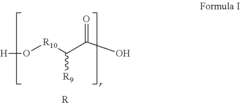

Polypropylene Prepared with a Single-Site Catalyst and Poly(hydroxyl carboxylic acid) Blends

PatentInactiveUS20110251333A1

Innovation

- A resin composition comprising at least 0.1% to 50% by weight of poly(hydroxy carboxylic acid) blended with polypropylene prepared using single-site metallocene catalysts, achieving homogeneous blends without compatibilizers, suitable for various applications including films, fibers, and molded objects.

Global PLA Policy Harmonization

The harmonization of global PLA (Polylactic Acid) policies is a critical step towards establishing a unified approach to environmental regulations and standards for this biodegradable polymer. As PLA gains prominence in various industries due to its eco-friendly properties, the need for consistent policies across different regions becomes increasingly apparent.

Currently, PLA regulations vary significantly between countries and regions, leading to challenges in international trade and product development. Some nations have embraced PLA as a sustainable alternative to traditional plastics, implementing favorable policies to encourage its use. Others remain cautious, citing concerns about its long-term environmental impact and end-of-life management.

To achieve global policy harmonization, international collaboration and dialogue are essential. Organizations such as the United Nations Environment Programme (UNEP) and the International Organization for Standardization (ISO) can play pivotal roles in facilitating discussions and developing universal guidelines for PLA production, use, and disposal.

Key areas for policy alignment include standardized testing methods for biodegradability and compostability, consistent labeling requirements, and agreed-upon definitions of terms like "bio-based" and "biodegradable." These standards would ensure that PLA products meet uniform quality and environmental criteria across different markets.

Another crucial aspect of harmonization is the development of a global framework for PLA waste management. This would involve coordinating efforts to establish widespread composting infrastructure and educating consumers about proper disposal methods. Such a framework would address concerns about PLA's environmental impact and promote its circular economy potential.

Harmonized policies could also drive innovation in PLA technology by creating a more predictable regulatory landscape for manufacturers and researchers. This stability would encourage investment in research and development, potentially leading to improvements in PLA's performance characteristics and cost-effectiveness.

However, achieving global consensus presents significant challenges. Differing economic priorities, existing regulatory frameworks, and varying levels of environmental awareness among nations can impede progress towards harmonization. Overcoming these obstacles will require sustained diplomatic efforts and a willingness to compromise on certain policy details while maintaining core environmental principles.

In conclusion, the vision for global PLA policy harmonization is ambitious but necessary for realizing the full potential of this sustainable material. By aligning regulations and standards worldwide, we can create a more cohesive approach to addressing environmental challenges while fostering innovation and economic growth in the bioplastics sector.

Currently, PLA regulations vary significantly between countries and regions, leading to challenges in international trade and product development. Some nations have embraced PLA as a sustainable alternative to traditional plastics, implementing favorable policies to encourage its use. Others remain cautious, citing concerns about its long-term environmental impact and end-of-life management.

To achieve global policy harmonization, international collaboration and dialogue are essential. Organizations such as the United Nations Environment Programme (UNEP) and the International Organization for Standardization (ISO) can play pivotal roles in facilitating discussions and developing universal guidelines for PLA production, use, and disposal.

Key areas for policy alignment include standardized testing methods for biodegradability and compostability, consistent labeling requirements, and agreed-upon definitions of terms like "bio-based" and "biodegradable." These standards would ensure that PLA products meet uniform quality and environmental criteria across different markets.

Another crucial aspect of harmonization is the development of a global framework for PLA waste management. This would involve coordinating efforts to establish widespread composting infrastructure and educating consumers about proper disposal methods. Such a framework would address concerns about PLA's environmental impact and promote its circular economy potential.

Harmonized policies could also drive innovation in PLA technology by creating a more predictable regulatory landscape for manufacturers and researchers. This stability would encourage investment in research and development, potentially leading to improvements in PLA's performance characteristics and cost-effectiveness.

However, achieving global consensus presents significant challenges. Differing economic priorities, existing regulatory frameworks, and varying levels of environmental awareness among nations can impede progress towards harmonization. Overcoming these obstacles will require sustained diplomatic efforts and a willingness to compromise on certain policy details while maintaining core environmental principles.

In conclusion, the vision for global PLA policy harmonization is ambitious but necessary for realizing the full potential of this sustainable material. By aligning regulations and standards worldwide, we can create a more cohesive approach to addressing environmental challenges while fostering innovation and economic growth in the bioplastics sector.

PLA Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of Polylactic Acid (PLA) throughout its entire lifecycle. This comprehensive analysis encompasses raw material extraction, production, use, and end-of-life stages, providing valuable insights into PLA's sustainability profile.

The production phase of PLA involves the fermentation of renewable resources, typically corn or sugarcane. This process consumes less energy compared to conventional petroleum-based plastics, resulting in lower greenhouse gas emissions. However, the agricultural practices used to grow these feedstocks can have significant environmental implications, including land use changes, water consumption, and potential biodiversity loss.

During the use phase, PLA demonstrates favorable characteristics in terms of carbon footprint and energy efficiency. Its biodegradability offers advantages in certain applications, particularly in packaging and disposable products. However, the actual environmental benefits depend on proper waste management and disposal practices.

End-of-life considerations for PLA are complex and context-dependent. In industrial composting facilities, PLA can biodegrade within months, returning nutrients to the soil. However, these facilities are not universally available, and PLA may end up in landfills where degradation is significantly slower. Recycling PLA presents challenges due to contamination issues and the need for specialized recycling streams.

LCA studies have shown that PLA generally outperforms conventional plastics in terms of fossil fuel consumption and greenhouse gas emissions. However, its performance in other impact categories, such as eutrophication and acidification, can vary depending on production methods and regional factors.

The environmental regulations and standards governing PLA are evolving. Policymakers are increasingly recognizing the importance of considering the full lifecycle impacts of materials. This has led to the development of more comprehensive eco-labeling schemes and certification programs that take into account LCA results.

As the PLA industry matures, there is a growing emphasis on improving production efficiencies, developing more sustainable feedstock sources, and enhancing end-of-life management strategies. These efforts aim to further reduce PLA's environmental footprint and strengthen its position as a viable alternative to traditional plastics in various applications.

The production phase of PLA involves the fermentation of renewable resources, typically corn or sugarcane. This process consumes less energy compared to conventional petroleum-based plastics, resulting in lower greenhouse gas emissions. However, the agricultural practices used to grow these feedstocks can have significant environmental implications, including land use changes, water consumption, and potential biodiversity loss.

During the use phase, PLA demonstrates favorable characteristics in terms of carbon footprint and energy efficiency. Its biodegradability offers advantages in certain applications, particularly in packaging and disposable products. However, the actual environmental benefits depend on proper waste management and disposal practices.

End-of-life considerations for PLA are complex and context-dependent. In industrial composting facilities, PLA can biodegrade within months, returning nutrients to the soil. However, these facilities are not universally available, and PLA may end up in landfills where degradation is significantly slower. Recycling PLA presents challenges due to contamination issues and the need for specialized recycling streams.

LCA studies have shown that PLA generally outperforms conventional plastics in terms of fossil fuel consumption and greenhouse gas emissions. However, its performance in other impact categories, such as eutrophication and acidification, can vary depending on production methods and regional factors.

The environmental regulations and standards governing PLA are evolving. Policymakers are increasingly recognizing the importance of considering the full lifecycle impacts of materials. This has led to the development of more comprehensive eco-labeling schemes and certification programs that take into account LCA results.

As the PLA industry matures, there is a growing emphasis on improving production efficiencies, developing more sustainable feedstock sources, and enhancing end-of-life management strategies. These efforts aim to further reduce PLA's environmental footprint and strengthen its position as a viable alternative to traditional plastics in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!