Zirconia-Based Ion Conductors: Applications in Electronics

Zirconia Ion Conductors: Evolution and Objectives

Zirconia-based ion conductors have emerged as a pivotal technology in the field of electronics, with a rich history of development spanning several decades. The evolution of these materials has been driven by the increasing demand for more efficient and reliable energy storage and conversion devices.

The journey of zirconia-based ion conductors began in the 1960s when researchers first discovered the unique ionic conductivity properties of yttria-stabilized zirconia (YSZ). This breakthrough laid the foundation for extensive research and development in the field of solid electrolytes. As the potential applications in fuel cells and sensors became apparent, the scientific community intensified its efforts to enhance the performance and stability of these materials.

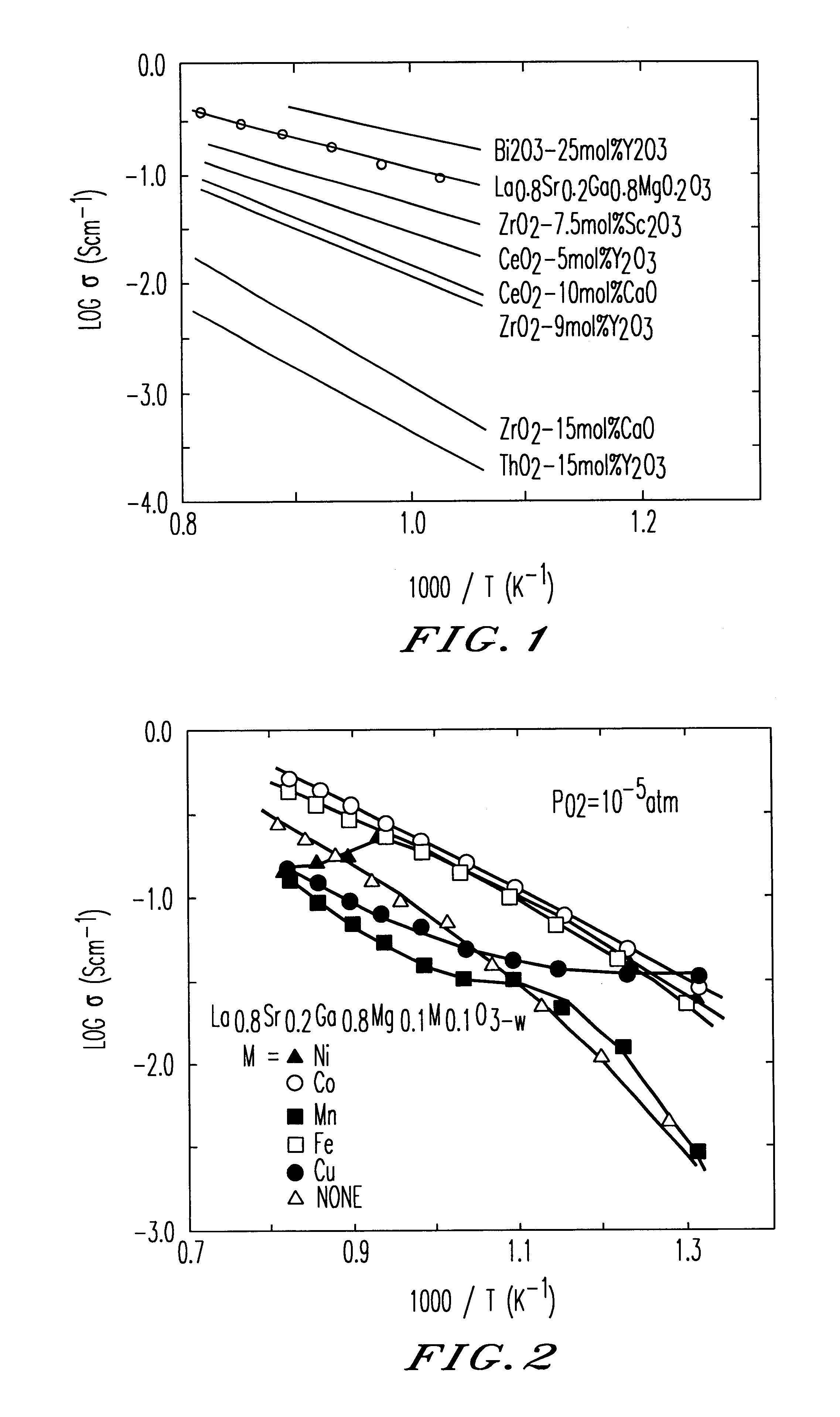

Throughout the 1980s and 1990s, significant advancements were made in understanding the fundamental mechanisms of ion conduction in zirconia-based materials. Researchers explored various dopants and compositional modifications to optimize the ionic conductivity and mechanical properties. This period saw the emergence of new zirconia-based compositions, such as scandia-stabilized zirconia (ScSZ) and ceria-doped zirconia, which exhibited improved conductivity at lower temperatures.

The turn of the millennium marked a new era for zirconia-based ion conductors, with a shift towards miniaturization and integration in electronic devices. The development of thin-film deposition techniques enabled the fabrication of zirconia-based electrolytes on a microscale, opening up possibilities for their use in microelectronic devices and solid-state batteries.

In recent years, the focus has shifted towards addressing the challenges of low-temperature performance and long-term stability. Researchers are exploring novel synthesis methods, nanostructuring approaches, and composite materials to overcome these limitations. The advent of advanced characterization techniques and computational modeling has accelerated the discovery and optimization of new zirconia-based ion conductors.

Looking ahead, the objectives for zirconia-based ion conductors in electronics are multifaceted. There is a strong drive to develop materials with higher ionic conductivity at lower operating temperatures, which would significantly enhance the efficiency and applicability of solid oxide fuel cells and sensors. Improving the mechanical strength and durability of these materials under various operating conditions remains a critical goal to ensure their long-term reliability in electronic devices.

Another key objective is to achieve better integration of zirconia-based ion conductors with other components in electronic systems. This includes developing compatible electrode materials and optimizing interfaces to minimize resistance and enhance overall device performance. Additionally, there is a growing interest in exploring the potential of zirconia-based materials for emerging applications, such as memristors and neuromorphic computing devices.

Market Analysis for Zirconia-Based Electronic Components

The market for zirconia-based electronic components has been experiencing significant growth in recent years, driven by the increasing demand for high-performance, miniaturized electronic devices across various industries. Zirconia-based ion conductors, in particular, have garnered substantial attention due to their unique properties and potential applications in advanced electronics.

The global market for zirconia-based electronic components is projected to expand at a compound annual growth rate (CAGR) of over 8% during the forecast period of 2021-2026. This growth is primarily attributed to the rising adoption of zirconia-based materials in solid-state batteries, sensors, and other electronic applications. The automotive sector, in particular, has emerged as a key driver for market growth, with the increasing production of electric vehicles and the integration of advanced sensor technologies.

In terms of regional distribution, Asia-Pacific currently dominates the market, accounting for the largest share of global revenue. This can be attributed to the presence of major electronics manufacturing hubs in countries like China, Japan, and South Korea. North America and Europe follow closely, with significant investments in research and development of advanced electronic materials.

The market landscape is characterized by intense competition among key players, including established multinational corporations and emerging startups. Major companies are focusing on strategic collaborations and partnerships to enhance their product portfolios and expand their market presence. Additionally, there is a growing trend towards vertical integration, with some companies investing in the entire value chain from raw material production to end-product manufacturing.

One of the key factors driving market growth is the increasing demand for energy-efficient and high-performance electronic devices. Zirconia-based ion conductors offer superior ionic conductivity, thermal stability, and mechanical strength compared to traditional materials, making them ideal for use in various electronic applications. The growing emphasis on sustainability and environmental concerns has also contributed to the adoption of zirconia-based materials, as they are considered more eco-friendly alternatives to conventional electronic components.

However, the market faces certain challenges, including high production costs and technical complexities associated with the integration of zirconia-based materials into existing electronic systems. These factors may hinder widespread adoption, particularly in price-sensitive markets. Nevertheless, ongoing research and development efforts are expected to address these challenges and further expand the application scope of zirconia-based electronic components in the coming years.

Current Challenges in Zirconia Ion Conductor Technology

Despite significant advancements in zirconia-based ion conductor technology, several challenges persist in their development and application in electronics. One of the primary obstacles is the relatively low ionic conductivity at room temperature, which limits their efficiency in various electronic devices. While zirconia-based materials exhibit excellent conductivity at high temperatures, achieving comparable performance at ambient conditions remains a significant hurdle.

Another challenge lies in the mechanical stability of zirconia-based ion conductors. These materials often suffer from degradation and cracking under prolonged use or thermal cycling, compromising their long-term reliability in electronic applications. Addressing this issue requires innovative approaches to enhance the structural integrity of the materials without sacrificing their ionic conductivity.

The interface between the zirconia-based ion conductor and electrodes presents another critical challenge. Poor interfacial contact can lead to increased resistance and reduced overall performance of the electronic devices. Developing strategies to improve the electrode-electrolyte interface and minimize interfacial resistance is crucial for enhancing the efficiency of zirconia-based ion conductors in electronic applications.

Scalability and cost-effectiveness pose additional challenges in the widespread adoption of zirconia-based ion conductors. Current manufacturing processes for high-quality zirconia-based materials are often complex and expensive, hindering their commercial viability. Developing more efficient and economical production methods is essential to make these materials competitive in the electronics market.

Furthermore, the integration of zirconia-based ion conductors into existing electronic manufacturing processes presents technical difficulties. Compatibility issues with other materials and components in electronic devices, as well as the need for specialized fabrication techniques, complicate their incorporation into mainstream electronics production.

Lastly, there is a need for more comprehensive understanding of the fundamental mechanisms governing ion conduction in zirconia-based materials. While significant progress has been made in this area, gaps in knowledge still exist, particularly regarding the influence of dopants, defects, and grain boundaries on ionic conductivity. Addressing these knowledge gaps through advanced characterization techniques and theoretical modeling is crucial for optimizing the performance of zirconia-based ion conductors in electronic applications.

State-of-the-Art Zirconia Ion Conductor Solutions

01 Composition of zirconia-based ion conductors

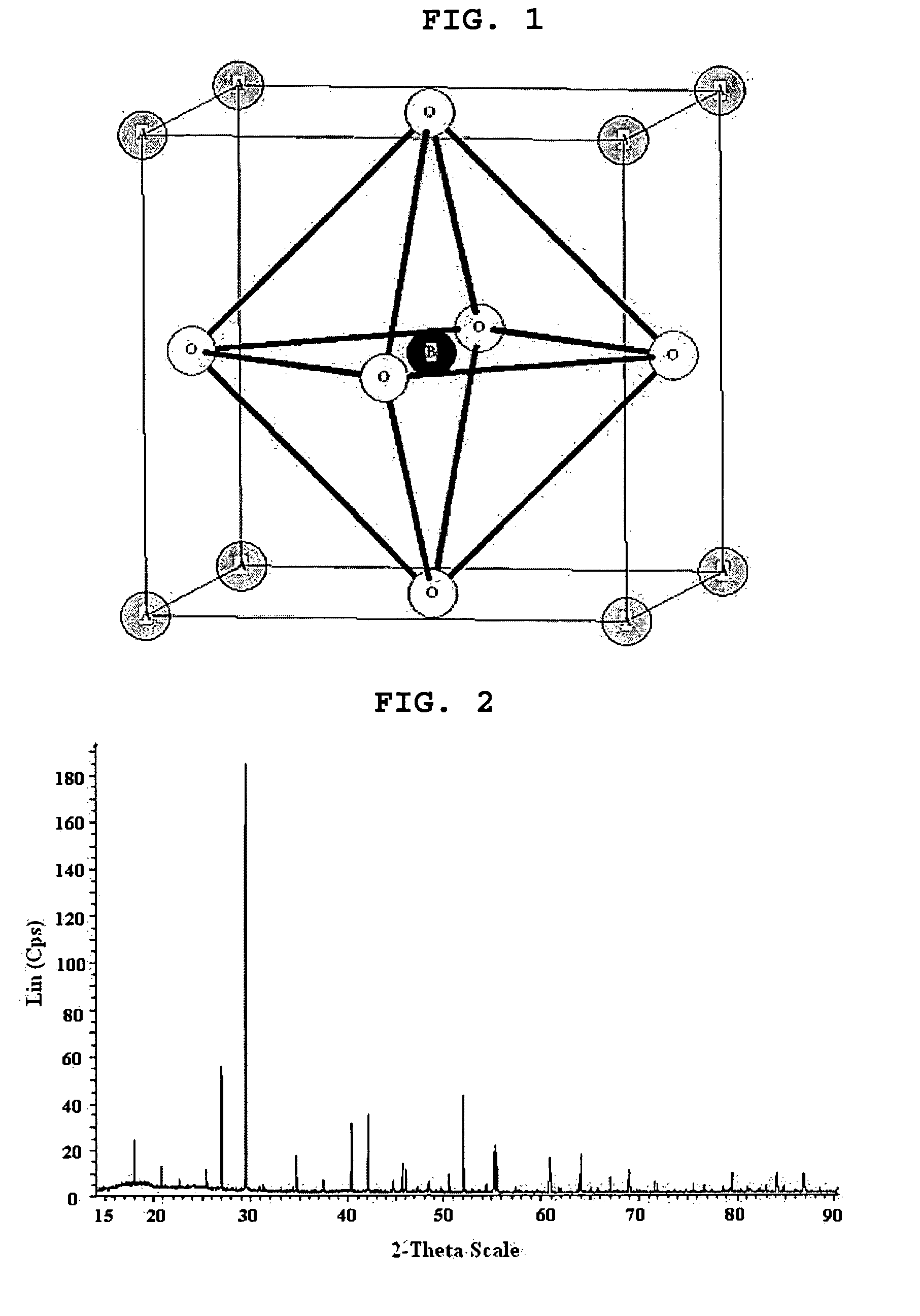

Zirconia-based ion conductors are typically composed of zirconium oxide (ZrO2) stabilized with various dopants such as yttria, scandia, or ceria. These dopants create oxygen vacancies in the crystal structure, enabling ionic conduction. The specific composition and dopant concentration can be optimized to enhance conductivity and stability at different operating temperatures.- Composition of zirconia-based ion conductors: Zirconia-based ion conductors are typically composed of zirconium oxide (ZrO2) stabilized with various dopants such as yttria, scandia, or ceria. These materials exhibit high ionic conductivity at elevated temperatures, making them suitable for applications in solid oxide fuel cells and oxygen sensors. The specific composition and dopant concentration can be tailored to optimize the ionic conductivity and stability of the material.

- Fabrication methods for zirconia-based ion conductors: Various fabrication methods are employed to produce zirconia-based ion conductors, including sol-gel processes, solid-state reactions, and chemical vapor deposition. These techniques allow for the precise control of the material's microstructure, grain size, and dopant distribution, which are crucial factors in determining the ionic conductivity and mechanical properties of the final product.

- Applications in solid oxide fuel cells: Zirconia-based ion conductors are widely used as electrolytes in solid oxide fuel cells (SOFCs) due to their high oxygen ion conductivity at elevated temperatures. These materials enable efficient electrochemical conversion of fuel to electricity, making SOFCs a promising technology for clean energy generation. Ongoing research focuses on improving the performance and durability of zirconia-based electrolytes for SOFC applications.

- Thin film and coating applications: Zirconia-based ion conductors can be deposited as thin films or coatings on various substrates, enabling their use in miniaturized devices and protective layers. These thin film applications include gas sensors, electrochromic devices, and protective coatings for high-temperature environments. Advanced deposition techniques are employed to achieve uniform and dense films with optimal ionic conductivity.

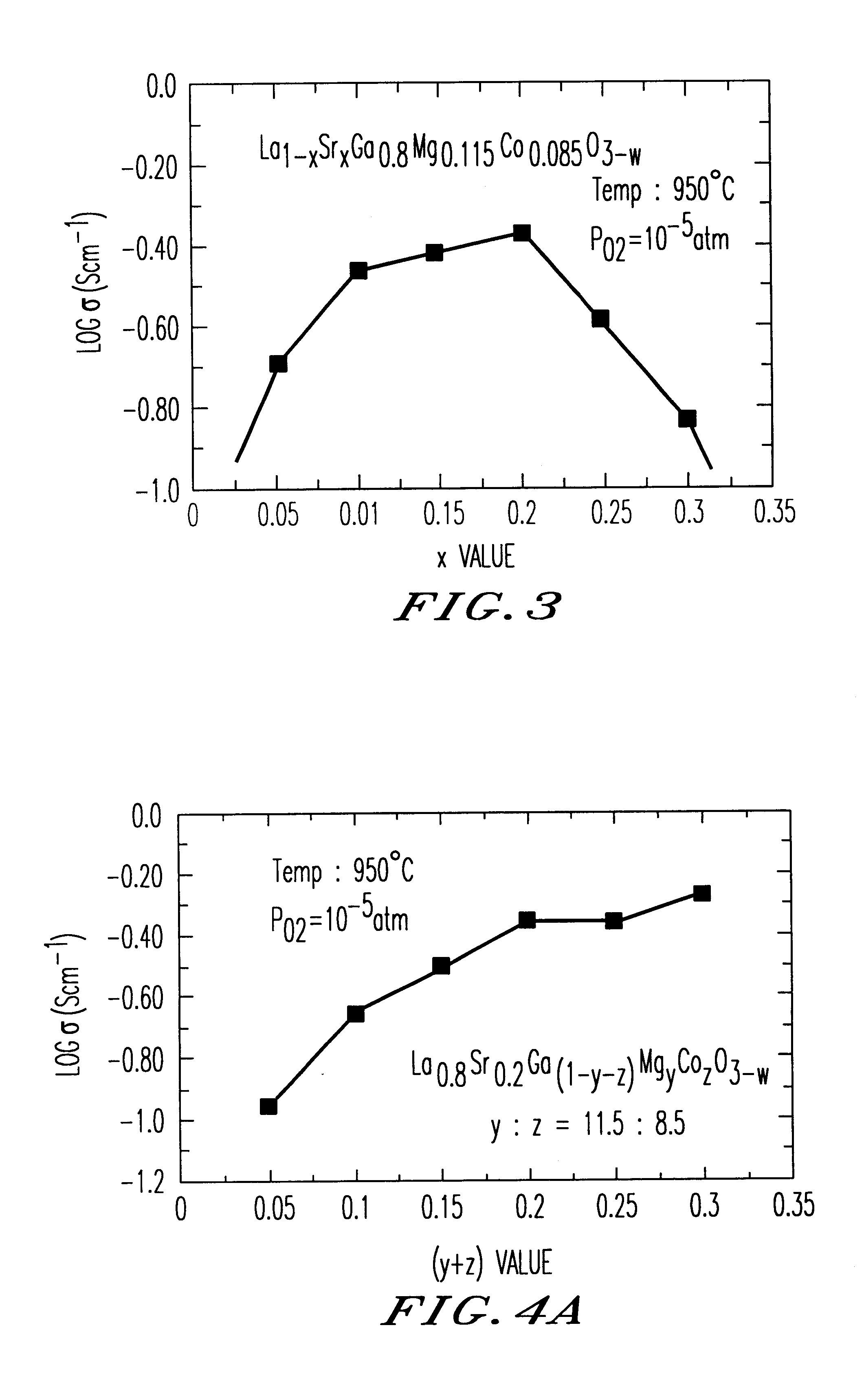

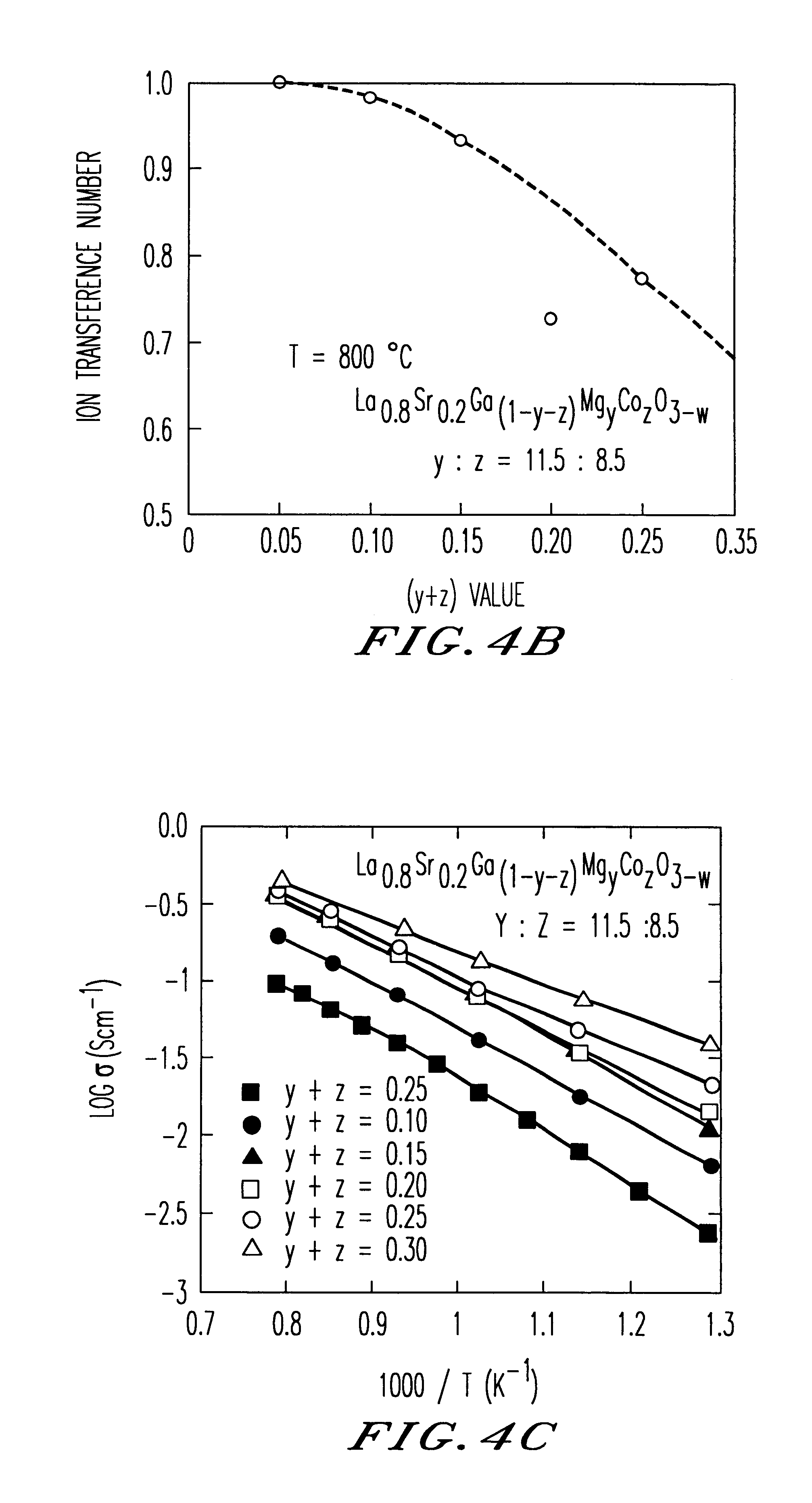

- Doping strategies for enhanced performance: Researchers are exploring various doping strategies to enhance the performance of zirconia-based ion conductors. This includes co-doping with multiple elements, gradient doping, and nanostructuring approaches. These strategies aim to improve ionic conductivity, reduce operating temperatures, and enhance the long-term stability of the materials for diverse applications in energy conversion and storage devices.

02 Fabrication methods for zirconia-based ion conductors

Various fabrication methods are employed to produce zirconia-based ion conductors, including sol-gel processes, solid-state reactions, and chemical vapor deposition. These methods aim to control the microstructure, grain size, and density of the material, which significantly influence its ionic conductivity and mechanical properties. Post-processing techniques such as sintering and annealing are often used to further enhance performance.Expand Specific Solutions03 Applications in solid oxide fuel cells

Zirconia-based ion conductors are widely used as electrolytes in solid oxide fuel cells (SOFCs) due to their high oxygen ion conductivity at elevated temperatures. These materials enable efficient electrochemical conversion of fuel to electricity, with ongoing research focused on lowering operating temperatures and improving long-term stability for practical SOFC applications.Expand Specific Solutions04 Thin film and nanostructured zirconia-based ion conductors

Research is ongoing in developing thin film and nanostructured zirconia-based ion conductors to enhance performance and reduce operating temperatures. These approaches include creating multilayer structures, nanocomposites, and engineered interfaces to improve ionic conductivity and reduce resistance. Thin film techniques allow for precise control of composition and microstructure, potentially leading to more efficient and compact devices.Expand Specific Solutions05 Doping strategies for improved conductivity

Various doping strategies are employed to enhance the ionic conductivity of zirconia-based materials. This includes co-doping with multiple elements, graded doping profiles, and the use of novel dopants to optimize the crystal structure and vacancy concentration. Research is focused on understanding the complex relationships between dopant type, concentration, and distribution to achieve higher conductivity at lower temperatures.Expand Specific Solutions

Key Industry Players in Zirconia-Based Electronics

The field of Zirconia-Based Ion Conductors in electronics is in a growth phase, with increasing market size and technological advancements. The market is driven by the demand for efficient energy storage and conversion devices. Companies like LG Chem Ltd., Toyota Motor Corp., and Panasonic Holdings Corp. are leading the technological development, focusing on improving ionic conductivity and stability. Research institutions such as the Chinese Academy of Sciences and the University of Warwick are contributing to fundamental advancements. The technology's maturity varies across applications, with some areas like solid oxide fuel cells being more established, while others, such as all-solid-state batteries, are still evolving. This diverse landscape indicates significant potential for further innovation and market expansion in the coming years.

Advanced Industrial Science & Technology

LG Chem Ltd.

Breakthrough Patents in Zirconia Ion Conduction

- A rare earth gallate oxide-ion conductor with a perovskite structure, specifically formulated as Ln1−xAxGa1−y−zB1yB2zO3−w, where Ln is a lanthanoid, A is an alkaline earth metal, B1 is a non-transition metal, and B2 is a transition metal, is developed to maintain high oxide-ion conductivity and ion transference number across varying temperatures and oxygen partial pressures.

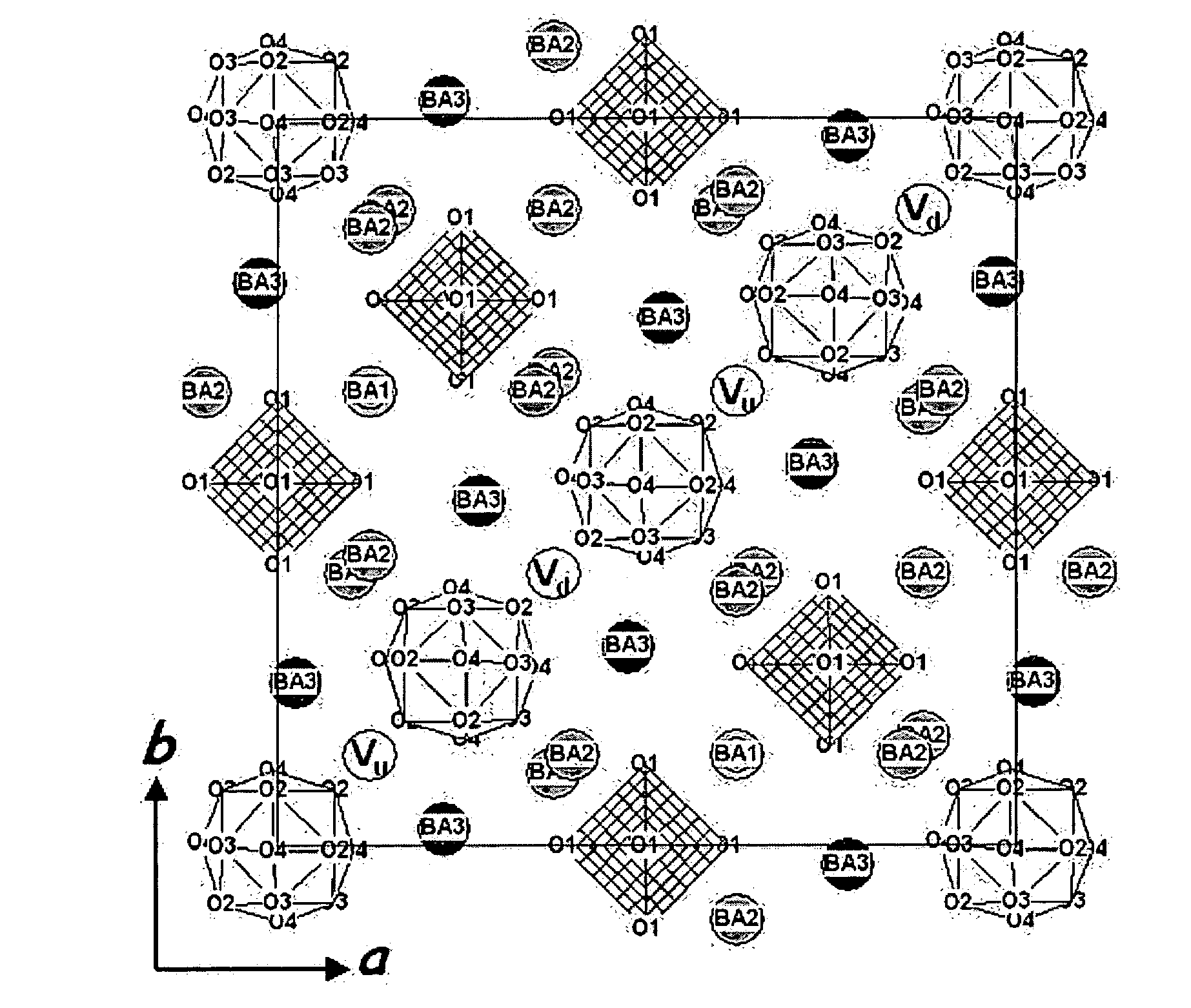

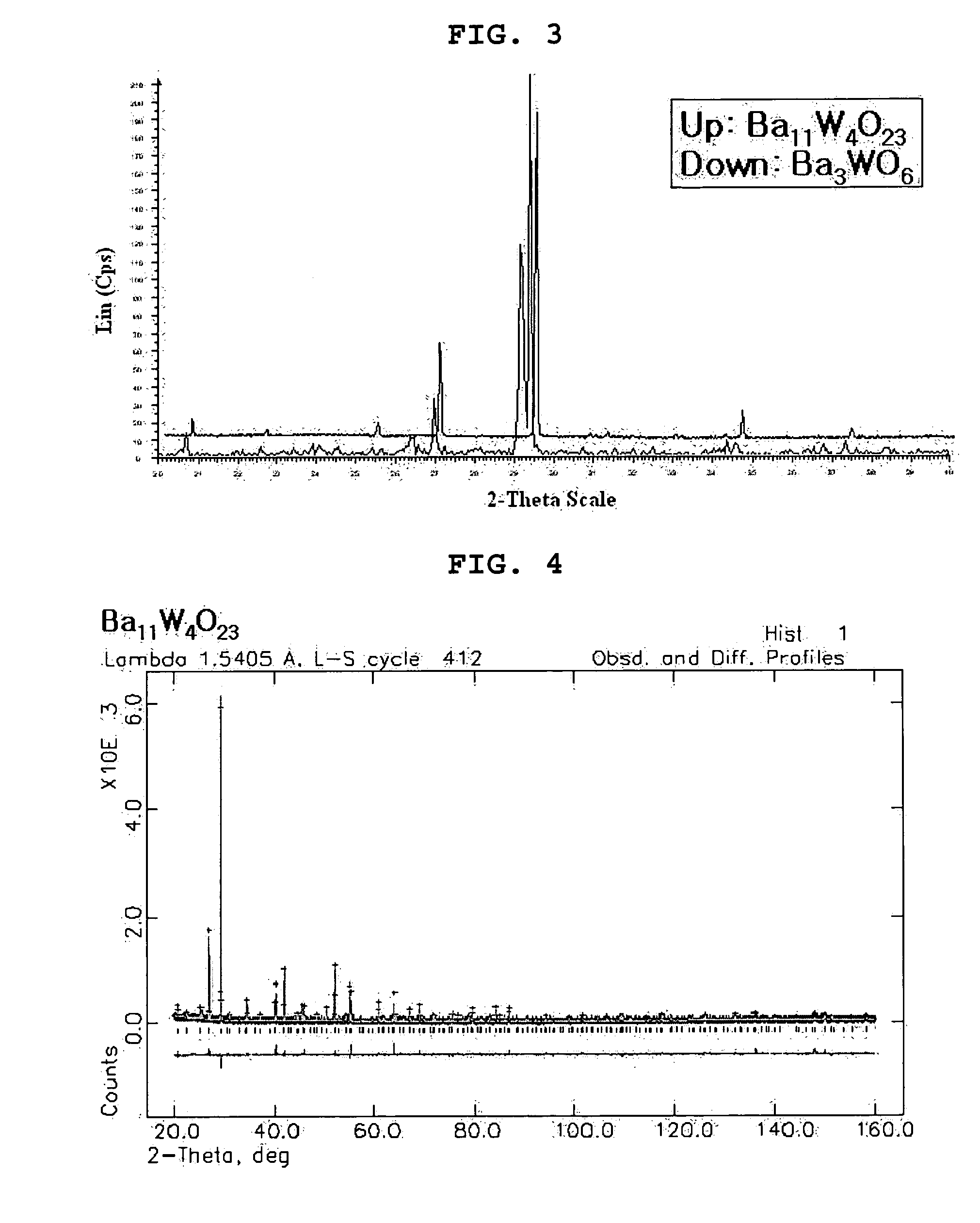

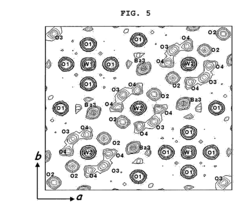

- Development of metal composite oxides with a specific crystal structure characterized by a space group of Fd-3m and unit cell parameter of 17.0±1.0 Å, featuring ordered metal sites and defects that form an ion channel for enhanced ionic conductivity, allowing for both oxygen and hydrogen ion conduction.

Environmental Impact of Zirconia-Based Electronics

The environmental impact of zirconia-based electronics is a critical consideration as these materials gain prominence in various electronic applications. Zirconia-based ion conductors offer several advantages in terms of performance and efficiency, but their production, use, and disposal also have environmental implications that must be carefully evaluated.

The manufacturing process of zirconia-based materials involves energy-intensive steps, including high-temperature sintering and precision machining. These processes contribute to greenhouse gas emissions and energy consumption. However, compared to traditional electronic materials, zirconia-based components often have longer lifespans and higher durability, potentially reducing the frequency of replacement and associated waste generation.

In terms of resource utilization, zirconium is relatively abundant in the Earth's crust, making it a more sustainable option compared to rare earth elements used in some electronic components. The mining and extraction of zirconium, however, can lead to habitat disruption and soil erosion if not managed responsibly. It is crucial for manufacturers to implement sustainable mining practices and optimize resource efficiency in production.

During the use phase, zirconia-based ion conductors in electronics can contribute to improved energy efficiency. Their superior ionic conductivity allows for better performance in applications such as solid-state batteries and fuel cells, potentially reducing overall energy consumption and associated environmental impacts. This efficiency gain could offset some of the environmental costs incurred during production.

End-of-life considerations for zirconia-based electronics present both challenges and opportunities. While these materials are generally chemically stable and non-toxic, proper recycling infrastructure needs to be developed to recover and reuse zirconia components. The development of efficient recycling processes could significantly reduce the environmental footprint of these materials and promote a circular economy approach in the electronics industry.

It is important to note that the environmental impact of zirconia-based electronics extends beyond the material itself. The entire lifecycle, including the production of associated components and the energy consumed during device operation, must be considered for a comprehensive environmental assessment. As the technology evolves, ongoing research into more environmentally friendly production methods and improved recycling techniques will be crucial in minimizing the ecological footprint of zirconia-based electronic devices.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for zirconia-based ion conductors in electronic applications are crucial factors that determine their widespread adoption and commercial viability. As these materials transition from laboratory-scale research to industrial production, several key challenges must be addressed.

One of the primary concerns is the development of cost-effective and reliable manufacturing processes for large-scale production of zirconia-based ion conductors. Current synthesis methods, such as solid-state reactions and sol-gel processes, often require high temperatures and precise control of reaction conditions. Scaling up these processes while maintaining consistent quality and performance of the final product is a significant challenge.

The selection and sourcing of raw materials also play a critical role in scalability. Ensuring a stable supply chain for high-purity zirconia and dopant materials is essential for consistent production. Additionally, the development of standardized quality control measures and characterization techniques is necessary to maintain the desired ionic conductivity and mechanical properties across large production batches.

Another important aspect is the integration of zirconia-based ion conductors into existing electronic manufacturing processes. This includes developing compatible deposition techniques for thin-film applications and optimizing sintering processes for bulk materials. The ability to produce these materials in various forms, such as thin films, pellets, or powders, is crucial for their versatility in different electronic applications.

Environmental considerations and energy efficiency in the manufacturing process are becoming increasingly important. Developing greener synthesis routes and reducing the energy consumption during high-temperature processing steps are areas that require further research and innovation.

The scalability of zirconia-based ion conductors also depends on their long-term stability and reliability in electronic devices. Addressing issues such as degradation under operating conditions and improving the interface properties with other device components are critical for ensuring the longevity and performance of the final products.

Lastly, the economic viability of large-scale production needs to be carefully evaluated. This includes assessing the capital investment required for manufacturing facilities, operational costs, and potential market demand. Developing strategies to reduce production costs while maintaining high performance will be key to the successful commercialization of zirconia-based ion conductors in electronic applications.