Zirconia in Advanced Optics: New Developments

Zirconia Optics Evolution

Zirconia's journey in advanced optics has been marked by significant milestones and continuous innovation. The evolution of zirconia in optical applications can be traced back to the mid-20th century when its potential as a high-refractive-index material was first recognized. Initially, zirconia's use in optics was limited due to its complex manufacturing process and the challenges in achieving optical-grade purity.

The 1970s saw a breakthrough in zirconia production techniques, particularly with the development of chemical vapor deposition (CVD) methods. This advancement allowed for the creation of thin zirconia films with improved optical properties, paving the way for its use in anti-reflection coatings and optical filters. The 1980s brought further refinement in zirconia synthesis, including sol-gel processes, which enabled better control over the material's nanostructure and optical characteristics.

A significant leap forward occurred in the 1990s with the introduction of yttria-stabilized zirconia (YSZ). This innovation addressed the phase stability issues of pure zirconia, making it more suitable for a wider range of optical applications. YSZ quickly found its way into high-power laser systems as thermal barrier coatings and in optical waveguides due to its excellent thermal and mechanical properties.

The turn of the millennium marked the beginning of zirconia's integration into advanced photonics. Researchers began exploring zirconia's potential in photonic crystals and metamaterials, leveraging its high refractive index and low optical loss. This period also saw the development of zirconia-based optical ceramics, offering a viable alternative to traditional optical glasses in certain applications.

In recent years, the focus has shifted towards nanostructured zirconia for optical applications. The ability to manipulate zirconia at the nanoscale has opened up new possibilities in areas such as nonlinear optics and quantum photonics. Advances in 3D printing technologies have also enabled the fabrication of complex zirconia optical components with unprecedented precision and customization.

The latest developments in zirconia optics include its application in ultrafast laser systems, where its high damage threshold and thermal stability are particularly advantageous. Additionally, zirconia is being explored for use in next-generation optical computing and communication systems, potentially playing a crucial role in the development of integrated photonic circuits.

Looking ahead, the evolution of zirconia in advanced optics is likely to continue with a focus on enhancing its optical properties through novel synthesis methods and composite materials. The integration of zirconia with other advanced materials, such as 2D materials and quantum dots, presents exciting opportunities for creating hybrid optical systems with unique capabilities. As research in this field progresses, zirconia is poised to play an increasingly important role in shaping the future of optical technologies.

Advanced Optics Market

The advanced optics market has experienced significant growth in recent years, driven by increasing demand for high-performance optical components across various industries. This market encompasses a wide range of applications, including telecommunications, healthcare, aerospace, defense, and consumer electronics. The global advanced optics market was valued at approximately $20 billion in 2020 and is projected to reach $30 billion by 2025, with a compound annual growth rate (CAGR) of around 8%.

One of the key factors driving market growth is the rapid advancement in optical technologies, particularly in the field of zirconia-based materials. Zirconia has emerged as a promising material for advanced optical applications due to its exceptional properties, such as high refractive index, excellent mechanical strength, and superior thermal stability. These characteristics make zirconia-based optics ideal for use in demanding environments and high-precision applications.

The telecommunications sector represents a significant portion of the advanced optics market, with the increasing adoption of fiber-optic networks and the rollout of 5G technology driving demand for high-performance optical components. Zirconia-based optical fibers and connectors are gaining traction in this sector due to their ability to transmit signals over longer distances with minimal loss and improved durability.

In the healthcare industry, advanced optics play a crucial role in medical imaging, diagnostics, and surgical procedures. Zirconia-based optical components are being increasingly utilized in endoscopes, microscopes, and other medical devices, offering improved image quality and durability compared to traditional materials. The growing emphasis on minimally invasive procedures and precision medicine is expected to further boost demand for advanced optical components in this sector.

The aerospace and defense industries are also significant contributors to the advanced optics market. Zirconia-based optics are being employed in various applications, including high-power laser systems, infrared sensors, and optical windows for aircraft and satellites. The material's ability to withstand extreme temperatures and harsh environments makes it particularly suitable for these applications.

Consumer electronics represent another rapidly growing segment of the advanced optics market. Zirconia-based optical components are finding applications in smartphone cameras, augmented reality (AR) and virtual reality (VR) devices, and wearable technology. The demand for higher-quality imaging and display technologies in consumer devices is driving innovation in this sector.

As the advanced optics market continues to evolve, manufacturers are investing heavily in research and development to explore new applications for zirconia-based materials and improve their performance characteristics. This ongoing innovation is expected to create new opportunities for market growth and drive further advancements in optical technologies across various industries.

Zirconia Challenges

Despite its promising properties, zirconia faces several challenges in advanced optical applications. One of the primary issues is its relatively high refractive index compared to other optical materials, which can lead to increased reflection and scattering of light. This characteristic limits its use in certain optical systems where minimal light loss is crucial.

Another significant challenge is the material's inherent birefringence, particularly in its tetragonal and monoclinic phases. This property causes the refractive index to vary depending on the polarization and direction of light propagation, potentially leading to image distortion and reduced optical performance in precision applications.

The thermal expansion coefficient of zirconia is also a concern, especially in high-power laser systems or applications involving rapid temperature changes. The material's thermal expansion can cause stress and potential deformation in optical components, affecting their long-term stability and performance.

Zirconia's hardness, while beneficial for durability, presents manufacturing challenges. Precision polishing and shaping of zirconia optical components can be time-consuming and costly, requiring specialized equipment and techniques. This difficulty in processing can limit its widespread adoption in some optical applications where complex geometries are needed.

The phase transformation of zirconia under certain conditions is another critical issue. The transition between its crystalline phases, particularly from tetragonal to monoclinic, can be accompanied by volume changes. This transformation can induce stress and potentially lead to cracking or surface degradation in optical components, affecting their long-term reliability.

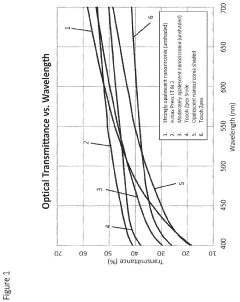

Optical absorption is also a challenge, especially in the ultraviolet and infrared regions of the spectrum. While zirconia exhibits good transparency in the visible range, its performance in UV and IR applications may be limited compared to other specialized optical materials.

Lastly, the consistency in optical properties across different production batches remains a challenge. Ensuring uniform optical quality, particularly for large-scale or high-precision applications, requires stringent control over the manufacturing process, which can increase production costs and complexity.

Current Zirconia Solutions

01 Zirconia synthesis and processing

Various methods for synthesizing and processing zirconia materials, including sol-gel techniques, hydrothermal processes, and sintering. These processes aim to control the crystalline structure, particle size, and purity of zirconia for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are explored, including novel techniques for producing zirconia powders, ceramics, and composites. These methods aim to improve the material's properties, such as strength, durability, and thermal stability, for diverse applications in industries like electronics, aerospace, and medical devices.

- Zirconia-based dental materials: Zirconia is widely used in dental applications due to its biocompatibility, aesthetics, and mechanical properties. Innovations in this field include improved formulations for dental prosthetics, crowns, and implants, as well as novel manufacturing techniques to enhance the material's performance and longevity in oral environments.

- Zirconia in fuel cell technology: Zirconia plays a crucial role in solid oxide fuel cell (SOFC) technology, particularly as an electrolyte material. Research focuses on improving the ionic conductivity, stability, and performance of zirconia-based electrolytes, as well as developing novel electrode materials and cell designs for more efficient and durable fuel cells.

- Zirconia coatings and thin films: Advanced techniques for depositing zirconia coatings and thin films are developed for various applications, including thermal barrier coatings, wear-resistant surfaces, and optical coatings. These methods aim to enhance the material's adhesion, uniformity, and functional properties while optimizing the deposition process for industrial scalability.

- Zirconia-based composites and nanostructures: Research into zirconia-based composites and nanostructures focuses on combining zirconia with other materials or manipulating its structure at the nanoscale to achieve enhanced properties. This includes developing zirconia-reinforced ceramics, nanocomposites, and hierarchical structures for applications in catalysis, sensors, and advanced structural materials.

02 Zirconia-based composites and coatings

Development of zirconia-based composites and coatings for enhanced mechanical, thermal, and chemical properties. These materials often combine zirconia with other ceramics, metals, or polymers to achieve specific performance characteristics.Expand Specific Solutions03 Dental and biomedical applications of zirconia

Use of zirconia in dental and biomedical applications, such as dental implants, crowns, and orthopedic implants. The focus is on biocompatibility, aesthetics, and mechanical strength for these medical devices.Expand Specific Solutions04 Zirconia in fuel cells and sensors

Application of zirconia in solid oxide fuel cells and various types of sensors, particularly oxygen sensors. The material's unique ionic conductivity properties are utilized in these electrochemical devices.Expand Specific Solutions05 Stabilization and phase transformation of zirconia

Techniques for stabilizing zirconia in specific crystalline phases and controlling phase transformations. This includes the use of dopants and heat treatments to achieve desired properties for different applications.Expand Specific Solutions

Optics Industry Leaders

The field of zirconia in advanced optics is experiencing rapid growth, driven by increasing demand for high-performance optical components. The market is in a mature growth stage, with a projected global market size reaching billions of dollars by 2025. Technologically, zirconia-based optics are advancing quickly, with companies like Tosoh Corp., 3M Innovative Properties Co., and EssilorLuxottica SA leading innovation. These firms are developing new zirconia formulations and manufacturing processes to enhance optical properties, durability, and cost-effectiveness. Research institutions such as Shanghai University and Xidian University are also contributing significantly to the field, pushing the boundaries of zirconia's applications in cutting-edge optical technologies.

Tosoh Corp.

Kuraray Noritake Dental, Inc.

Key Zirconia Innovations

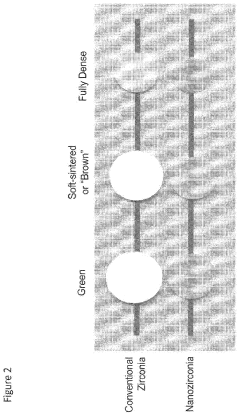

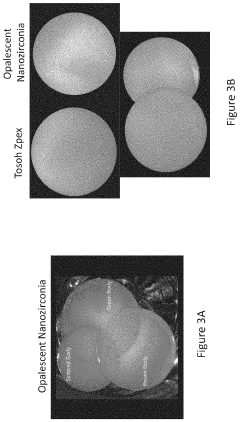

- Nanozirconia bodies with specific processing conditions that result in fully dense, opalescent, and highly translucent tetragonal zirconia materials with high strength, achieving light transmittance above 45% at 560 nm and flexural strength of at least 800 MPa, sinterable at temperatures below 1200°C using conventional dental furnaces.

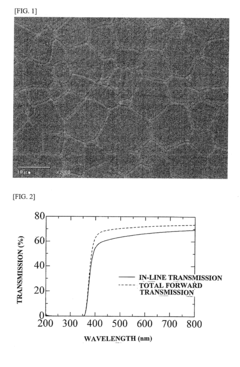

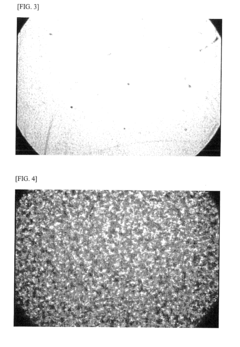

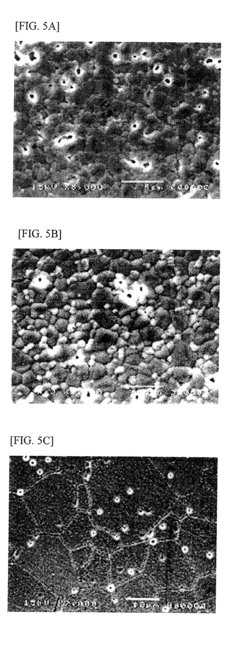

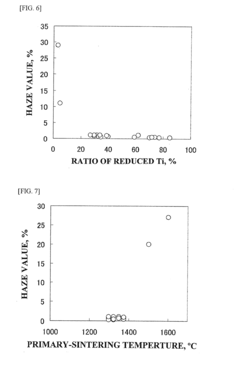

- A zirconia sintered body with a composition of 6-15 mol% yttria and 3-20 mol% titania, processed through primary sintering at ordinary pressure followed by hot isostatic pressing (HIP) and annealing, achieving an in-line transmission of 50% or higher and a bending strength of 250 MPa or higher.

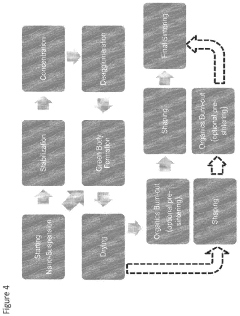

Manufacturing Processes

The manufacturing processes for zirconia in advanced optics have undergone significant advancements in recent years. These developments have been driven by the increasing demand for high-performance optical components in various industries, including aerospace, defense, and telecommunications.

One of the key manufacturing processes for zirconia optics is precision grinding and polishing. This technique involves the use of specialized equipment and abrasives to shape and refine the zirconia surface to achieve the desired optical properties. Advanced computer-controlled grinding machines are now employed to ensure high precision and repeatability in the manufacturing process.

Another important manufacturing method is hot isostatic pressing (HIP). This process involves subjecting zirconia powder to high pressure and temperature simultaneously, resulting in a fully dense and homogeneous material. HIP has proven to be particularly effective in producing large-scale zirconia optical components with minimal defects and superior mechanical properties.

Chemical vapor deposition (CVD) has emerged as a promising technique for manufacturing thin-film zirconia coatings on optical substrates. This process allows for precise control of film thickness and composition, enabling the production of high-quality optical coatings with tailored properties.

Additive manufacturing, or 3D printing, is gaining traction in the production of complex zirconia optical components. This technology offers the ability to create intricate geometries and internal structures that are difficult or impossible to achieve through traditional manufacturing methods. However, challenges remain in achieving the required optical quality and surface finish.

Post-processing techniques play a crucial role in enhancing the performance of zirconia optics. These include ion beam figuring, which uses a focused ion beam to remove material at the atomic level, allowing for ultra-precise surface shaping. Additionally, magnetorheological finishing has proven effective in achieving nanometer-level surface smoothness on zirconia optics.

Recent developments in manufacturing processes have also focused on improving the environmental sustainability of zirconia optics production. This includes the implementation of more efficient material utilization strategies and the development of eco-friendly polishing compounds.

As the demand for advanced zirconia optics continues to grow, ongoing research is being conducted to further refine and optimize these manufacturing processes. This includes exploring new sintering techniques, developing novel polishing methods, and investigating the potential of hybrid manufacturing approaches that combine multiple processes to achieve superior optical performance and cost-effectiveness.

Environmental Impact

The environmental impact of zirconia in advanced optics is a crucial consideration as the material gains prominence in various applications. Zirconia's production process involves mining and refining, which can lead to habitat disruption and energy-intensive manufacturing. However, its durability and longevity in optical applications may offset some of these initial environmental costs over time.

One of the primary environmental concerns is the energy consumption during the production of high-purity zirconia for optical applications. The process requires high temperatures and precise control, resulting in significant carbon emissions. Manufacturers are increasingly exploring more energy-efficient methods and cleaner energy sources to mitigate this impact.

Water usage and potential contamination are also important factors to consider. The refining process of zirconia can involve substantial water consumption and may produce wastewater containing trace amounts of chemicals and heavy metals. Implementing advanced water treatment and recycling systems is becoming a priority for environmentally conscious producers.

The extraction of zirconium, the primary source of zirconia, can have localized environmental impacts on mining sites. These include soil erosion, alteration of local ecosystems, and potential groundwater contamination. Responsible mining practices and site rehabilitation efforts are essential to minimize these effects.

On the positive side, zirconia's exceptional durability in optical applications can lead to reduced waste and replacement frequency. This longevity translates to fewer resources needed for replacement parts and less frequent disposal of optical components, potentially offsetting some of the environmental costs associated with its production.

Recycling and end-of-life management of zirconia-based optical components present both challenges and opportunities. While zirconia itself is not toxic, the complex nature of advanced optical systems can make recycling difficult. Developing efficient recycling processes for these components is an area of ongoing research and development.

As the demand for high-performance optical materials grows, there is an increasing focus on developing more sustainable production methods for zirconia. This includes exploring alternative precursors, optimizing manufacturing processes for energy efficiency, and investigating bio-inspired synthesis routes that could potentially reduce environmental impact.

The optical industry is also considering the broader lifecycle assessment of zirconia-based components, from raw material extraction to end-of-life disposal. This holistic approach aims to identify areas for improvement and guide the development of more environmentally friendly practices throughout the supply chain.