Zirconia in Solid Oxide Fuel Cells: Innovations and Challenges

SOFC Zirconia Background

Solid Oxide Fuel Cells (SOFCs) have emerged as a promising technology for clean and efficient energy conversion. At the heart of this technology lies zirconia, a ceramic material that plays a crucial role in the performance and durability of SOFCs. The journey of zirconia in SOFCs began in the mid-20th century when researchers discovered its unique properties as an oxygen ion conductor at high temperatures.

Zirconia's application in SOFCs is primarily due to its excellent ionic conductivity, mechanical strength, and chemical stability at elevated temperatures. The material's ability to conduct oxygen ions while remaining electrically insulating makes it an ideal electrolyte for SOFCs. This property allows for the separation of fuel and oxidant, enabling the electrochemical reactions that generate electricity.

The development of zirconia-based SOFCs has seen significant progress over the years. Initially, pure zirconia was used, but researchers soon discovered that doping it with other elements could enhance its performance. Yttria-stabilized zirconia (YSZ) became the standard material for SOFC electrolytes, offering improved ionic conductivity and mechanical stability.

As SOFC technology advanced, the focus shifted towards reducing operating temperatures to improve long-term stability and reduce material costs. This led to the exploration of alternative zirconia-based compositions and structures. Scandia-stabilized zirconia (ScSZ) and ceria-doped zirconia emerged as promising candidates for intermediate-temperature SOFCs, offering higher ionic conductivity at lower temperatures compared to traditional YSZ.

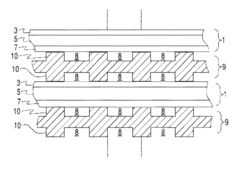

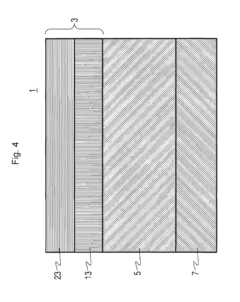

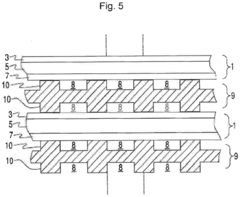

The evolution of zirconia in SOFCs has also been closely tied to advancements in manufacturing techniques. From traditional ceramic processing methods to more advanced techniques like tape casting and screen printing, the ability to produce thin, dense, and defect-free zirconia electrolytes has significantly improved SOFC performance and reliability.

Despite the progress, challenges remain in optimizing zirconia-based materials for SOFCs. These include further enhancing ionic conductivity, improving mechanical strength to prevent cracking during thermal cycling, and addressing degradation issues that occur over long-term operation. Researchers are exploring nanostructured zirconia composites and novel doping strategies to overcome these limitations.

The ongoing research in zirconia for SOFCs aims to achieve higher power densities, longer lifetimes, and lower operating temperatures. These advancements are crucial for the widespread commercialization of SOFC technology and its integration into various applications, from stationary power generation to transportation.

Market Analysis for SOFC

The Solid Oxide Fuel Cell (SOFC) market has been experiencing significant growth in recent years, driven by the increasing demand for clean and efficient energy solutions. The global SOFC market size was valued at approximately $772 million in 2020 and is projected to reach $2.8 billion by 2027, growing at a CAGR of 20.1% during the forecast period.

The market for SOFCs is primarily segmented into stationary, portable, and transport applications. Stationary applications currently dominate the market, accounting for over 60% of the total market share. This segment includes power generation for residential, commercial, and industrial sectors. The portable segment is expected to witness the highest growth rate due to the increasing demand for off-grid power solutions in remote areas and emergency situations.

Geographically, Asia Pacific leads the SOFC market, followed by North America and Europe. Japan and South Korea are the major contributors to the Asia Pacific market, with significant investments in research and development. The North American market is driven by the growing adoption of clean energy technologies and supportive government policies.

Key factors driving the SOFC market growth include increasing focus on renewable energy sources, rising demand for distributed power generation, and growing awareness about environmental sustainability. The high efficiency of SOFCs compared to conventional power generation technologies, coupled with their ability to operate on various fuels, makes them an attractive option for diverse applications.

However, the SOFC market faces challenges such as high initial costs, durability issues, and competition from other fuel cell technologies. The cost of SOFC systems remains a significant barrier to widespread adoption, particularly in price-sensitive markets. Ongoing research and development efforts are focused on addressing these challenges and improving the overall performance and cost-effectiveness of SOFC systems.

The competitive landscape of the SOFC market is characterized by the presence of several key players, including Bloom Energy, Mitsubishi Power, FuelCell Energy, and Ceres Power. These companies are investing heavily in research and development to enhance their product offerings and gain a competitive edge in the market.

Looking ahead, the SOFC market is expected to witness substantial growth opportunities, driven by increasing investments in clean energy technologies and the growing need for reliable and efficient power generation solutions. The integration of SOFCs with renewable energy systems and the development of hybrid power solutions are likely to create new avenues for market expansion in the coming years.

Zirconia Challenges in SOFC

Zirconia, a key material in Solid Oxide Fuel Cells (SOFCs), faces several significant challenges that hinder the widespread adoption and performance optimization of these energy conversion devices. One of the primary issues is the mechanical stability of zirconia-based electrolytes, particularly at high operating temperatures. The thermal cycling and prolonged exposure to extreme heat can lead to microstructural changes, resulting in decreased ionic conductivity and potential mechanical failure.

Another critical challenge is the chemical reactivity of zirconia with other SOFC components, especially at the electrode-electrolyte interfaces. This reactivity can lead to the formation of insulating phases, which impede ion transport and reduce overall cell efficiency. The degradation of zirconia-based electrolytes over time, known as aging, is also a significant concern, as it affects the long-term performance and durability of SOFCs.

The high sintering temperatures required for zirconia-based electrolytes pose manufacturing challenges, limiting the choice of electrode materials and increasing production costs. This constraint also impacts the ability to create thin electrolyte layers, which are desirable for reducing ohmic losses and improving cell performance.

Dopant segregation in zirconia electrolytes is another issue that researchers are grappling with. The migration of dopant cations to grain boundaries or surfaces can lead to the formation of resistive phases, reducing the overall ionic conductivity of the electrolyte. This phenomenon is particularly problematic in long-term SOFC operation and can significantly impact the cell's electrochemical performance.

The development of alternative zirconia-based materials, such as scandia-stabilized zirconia (ScSZ), has shown promise in addressing some of these challenges. However, the high cost of scandium and the limited understanding of its long-term stability present new obstacles to overcome. Researchers are also exploring composite electrolytes and novel fabrication techniques to mitigate some of the inherent limitations of zirconia-based materials.

Addressing these challenges requires a multidisciplinary approach, combining materials science, electrochemistry, and advanced manufacturing techniques. Innovations in nanostructured zirconia electrolytes, surface modification strategies, and the development of protective coatings are some of the avenues being explored to enhance the performance and durability of zirconia in SOFCs. The successful resolution of these challenges will be crucial for the advancement of SOFC technology and its wider implementation in clean energy systems.

Current Zirconia Solutions

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.- Zirconia synthesis and processing: Various methods for synthesizing and processing zirconia materials, including techniques for controlling particle size, crystalline structure, and purity. This encompasses sol-gel methods, hydrothermal synthesis, and other advanced processing techniques to produce zirconia with specific properties for different applications.

- Zirconia-based composites and coatings: Development of composite materials and coatings incorporating zirconia, often combined with other ceramics or metals. These composites and coatings are designed to enhance properties such as wear resistance, thermal insulation, and chemical stability for use in various industrial and technological applications.

- Dental and biomedical applications of zirconia: Utilization of zirconia in dental and biomedical fields, particularly for prosthetics, implants, and other medical devices. This includes the development of specialized zirconia formulations with improved biocompatibility, strength, and aesthetic properties suitable for oral and orthopedic applications.

- Zirconia in catalysis and fuel cells: Application of zirconia materials in catalytic processes and solid oxide fuel cells. This involves the development of zirconia-based catalysts, supports, and electrolytes with enhanced performance characteristics such as improved ionic conductivity, thermal stability, and catalytic activity.

- Stabilization and phase control of zirconia: Techniques for stabilizing specific crystalline phases of zirconia, particularly the tetragonal and cubic phases, through doping with other elements or controlling processing conditions. This is crucial for tailoring the mechanical, thermal, and electrical properties of zirconia for various high-performance applications.

02 Zirconia-based composites and coatings

Development of zirconia-based composites and coatings for enhanced mechanical, thermal, and chemical properties. These materials often combine zirconia with other ceramics, metals, or polymers to create advanced materials with improved performance in various industrial and technological applications.Expand Specific Solutions03 Dental and biomedical applications of zirconia

Utilization of zirconia in dental and biomedical fields, including dental implants, crowns, and orthopedic implants. The material's biocompatibility, strength, and aesthetic properties make it suitable for these applications, with ongoing research focusing on improving its performance and integration with biological tissues.Expand Specific Solutions04 Zirconia in fuel cells and energy applications

Application of zirconia in solid oxide fuel cells and other energy-related technologies. The material's unique properties, such as high ionic conductivity at elevated temperatures, make it valuable for these applications. Research in this area focuses on optimizing zirconia's performance and durability in energy conversion and storage systems.Expand Specific Solutions05 Stabilization and phase transformation of zirconia

Techniques for stabilizing zirconia in its various crystalline phases and controlling phase transformations. This includes the use of dopants and specific processing conditions to achieve desired crystal structures and properties, which are crucial for many applications of zirconia in advanced ceramics and materials science.Expand Specific Solutions

Key SOFC Manufacturers

The field of zirconia in solid oxide fuel cells (SOFCs) is in a growth phase, with increasing market size and technological advancements. The global SOFC market is expanding rapidly, driven by the demand for clean energy solutions. Technologically, zirconia-based SOFCs are progressing from early commercial stages to more mature implementations. Companies like Bloom Energy Corp. and NGK Insulators, Ltd. are at the forefront of commercialization, while research institutions such as the University of Science & Technology of China and Korea Institute of Energy Research are pushing the boundaries of zirconia SOFC technology. The competitive landscape is diverse, with both established players and innovative startups contributing to the field's development.

Bloom Energy Corp.

NGK Insulators, Ltd.

Zirconia SOFC Innovations

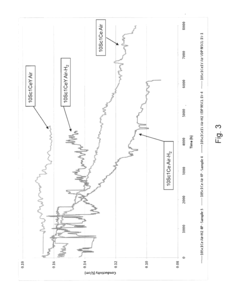

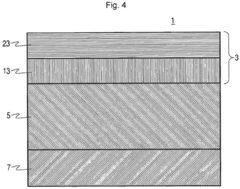

- Incorporating ceria and at least one of yttria and ytterbia into the SSZ composition to stabilize the cubic phase and prevent the phase transformation, thereby maintaining high ionic conductivity and reducing degradation, with specific formulations such as (ZrO2)1-w-x-z(Sc2O3)w(CeO2)x(Y2O3)a(Yb2O3)b, where w, x, and z are within defined ranges to optimize thermal expansion and stability.

- Incorporating ceria and at least one of yttria and ytterbia into the SSZ composition to stabilize the cubic phase, preventing the phase transformation and maintaining high ionic conductivity over extended operation periods, with specific formulations such as (ZrO2)1-w-x-z(Sc2O3)w(CeO2)x(Y2O3)a(Yb2O3)b, where w, x, and z are within defined ranges, to enhance stability and thermal expansion matching fuel cell interconnects.

Environmental Impact of SOFC

The environmental impact of Solid Oxide Fuel Cells (SOFCs) is a critical consideration in the broader context of sustainable energy solutions. SOFCs, which utilize zirconia as a key component, offer several environmental advantages over traditional power generation methods. Primarily, SOFCs demonstrate high electrical efficiency, typically ranging from 50% to 60%, with potential to reach up to 70% in combined heat and power systems. This high efficiency translates to reduced fuel consumption and, consequently, lower greenhouse gas emissions per unit of energy produced.

One of the most significant environmental benefits of SOFCs is their fuel flexibility. Unlike many other energy technologies, SOFCs can operate on a variety of fuels, including hydrogen, natural gas, biogas, and even liquid hydrocarbons. This versatility allows for the use of renewable fuels, further reducing the carbon footprint of energy production. Additionally, when operated on hydrogen produced from renewable sources, SOFCs can achieve near-zero emissions, contributing to the decarbonization of the energy sector.

The durability and long operational life of zirconia-based SOFCs also contribute to their positive environmental profile. With lifespans potentially exceeding 40,000 hours, these fuel cells require less frequent replacement, reducing the environmental impact associated with manufacturing and disposal of energy production equipment. Furthermore, the absence of moving parts in SOFCs results in quieter operation, reducing noise pollution in urban environments.

However, the environmental impact of SOFCs is not without challenges. The production of zirconia and other materials used in SOFCs can be energy-intensive, potentially offsetting some of the environmental gains during operation. The mining and processing of rare earth elements, sometimes used as dopants in zirconia electrolytes, also raise environmental concerns related to resource extraction and waste management.

End-of-life considerations for SOFCs present both challenges and opportunities. While the ceramic nature of zirconia components makes recycling complex, research is ongoing to develop effective recycling methods for SOFC materials. Successful implementation of these recycling strategies could significantly reduce the life-cycle environmental impact of SOFC technology.

In the context of air quality, SOFCs offer substantial benefits. Unlike combustion-based power generation, SOFCs produce minimal pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter. This characteristic makes them particularly attractive for urban and sensitive environmental areas where air quality is a primary concern.

As the technology continues to evolve, ongoing research focuses on improving the environmental performance of SOFCs. This includes developing more efficient manufacturing processes, exploring alternative materials to reduce reliance on rare earth elements, and enhancing the overall system efficiency to further decrease fuel consumption and emissions.

SOFC Cost-Benefit Analysis

The cost-benefit analysis of Solid Oxide Fuel Cells (SOFCs) is crucial for assessing their economic viability and potential for widespread adoption. Initial capital costs for SOFC systems are typically high due to the use of expensive materials like zirconia and the complex manufacturing processes involved. However, these costs are offset by the long-term benefits of high efficiency and fuel flexibility.

In terms of efficiency, SOFCs can achieve electrical efficiencies of up to 60% when operating on hydrogen, and even higher when used in combined heat and power systems. This high efficiency translates to lower fuel costs over the lifetime of the system, particularly in regions with high electricity prices. The fuel flexibility of SOFCs allows them to operate on a variety of fuels, including natural gas, biogas, and hydrogen, providing a hedge against fuel price volatility.

Maintenance costs for SOFCs are generally lower than those for conventional power generation systems due to the absence of moving parts. However, the high operating temperatures can lead to degradation of components over time, necessitating periodic replacement. The lifespan of SOFC systems has been steadily increasing, with some systems now capable of operating for 40,000 to 80,000 hours, further improving their long-term economic viability.

Environmental benefits must also be factored into the cost-benefit analysis. SOFCs produce significantly lower emissions compared to conventional power generation methods, potentially leading to savings in carbon taxes or credits in regions with stringent environmental regulations. Additionally, the quiet operation of SOFCs makes them suitable for residential and commercial applications, potentially increasing their market value.

The scalability of SOFC technology is another important consideration. While large-scale systems benefit from economies of scale, smaller systems for distributed power generation can offer benefits in terms of reduced transmission losses and increased grid resilience. This flexibility in scale allows for diverse applications, from portable power units to large-scale power plants, each with its own cost-benefit profile.

As the technology matures and production volumes increase, the cost of SOFC systems is expected to decrease. Innovations in materials science, particularly in the development of more durable and cost-effective alternatives to traditional zirconia-based electrolytes, are likely to play a significant role in improving the economic competitiveness of SOFCs. Government incentives and supportive policies for clean energy technologies can also significantly impact the cost-benefit analysis, potentially accelerating the adoption of SOFC technology in various markets.