Zirconia's Future in the High-Tech Sector

Zirconia Tech Evolution

Zirconia, a versatile ceramic material, has undergone significant technological evolution since its discovery in the late 18th century. Initially used in jewelry and dental applications, zirconia's potential in high-tech sectors has expanded dramatically over the past few decades.

The 1960s marked a turning point for zirconia technology with the development of partially stabilized zirconia (PSZ). This breakthrough enhanced the material's mechanical properties, opening doors to new industrial applications. The 1970s saw the introduction of tetragonal zirconia polycrystals (TZP), further improving its strength and toughness.

In the 1980s and 1990s, zirconia found its way into advanced ceramics for electronic components, particularly in solid oxide fuel cells (SOFCs) and oxygen sensors. The material's high ionic conductivity at elevated temperatures made it an ideal candidate for these applications.

The early 2000s witnessed a surge in zirconia's use in the medical field, particularly in orthopedic implants and dental prosthetics. The development of yttria-stabilized zirconia (YSZ) provided enhanced biocompatibility and wear resistance, revolutionizing the field of biomaterials.

The past decade has seen zirconia's integration into cutting-edge technologies. In the semiconductor industry, zirconia-based thin films have shown promise in next-generation memory devices and high-k dielectrics. The material's exceptional thermal and chemical stability has also led to its adoption in advanced coatings for aerospace and energy applications.

Recent advancements in nanotechnology have opened new avenues for zirconia. Zirconia nanoparticles and nanocomposites are being explored for applications in catalysis, energy storage, and environmental remediation. The ability to manipulate zirconia at the nanoscale has unlocked unprecedented material properties and functionalities.

Looking ahead, the future of zirconia in high-tech sectors appears promising. Ongoing research focuses on enhancing its electrical properties for advanced electronics, improving its performance in extreme environments for space exploration, and developing novel zirconia-based materials for quantum computing and photonics. As manufacturing techniques continue to evolve, particularly in the realm of additive manufacturing, the potential for creating complex zirconia structures with tailored properties is expanding rapidly.

The trajectory of zirconia's technological evolution demonstrates its adaptability and enduring relevance in the face of changing industrial needs. From its humble beginnings as a gemstone substitute to its current status as a critical material in advanced technologies, zirconia continues to push the boundaries of material science and engineering.

High-Tech Market Demand

The high-tech sector's demand for zirconia is experiencing significant growth, driven by its unique properties and versatile applications. Zirconia's exceptional hardness, thermal stability, and chemical resistance make it an attractive material for various advanced technologies.

In the electronics industry, zirconia is increasingly used in the production of semiconductor components and substrates. As the demand for smaller, more powerful, and energy-efficient electronic devices continues to rise, zirconia's role in manufacturing processes becomes more critical. Its high dielectric constant and thermal insulation properties make it ideal for use in capacitors, sensors, and other electronic components.

The aerospace and automotive sectors are also driving the demand for zirconia-based materials. In aerospace applications, zirconia is utilized in thermal barrier coatings for jet engine components, enhancing their durability and performance under extreme conditions. The automotive industry is incorporating zirconia in oxygen sensors, fuel cells, and catalytic converters, contributing to improved fuel efficiency and reduced emissions.

The medical technology field represents another significant market for zirconia. Its biocompatibility and aesthetic properties have led to increased adoption in dental implants and prosthetics. As the global population ages and dental care advances, the demand for zirconia-based dental products is expected to grow substantially.

In the energy sector, zirconia plays a crucial role in solid oxide fuel cells (SOFCs) and other clean energy technologies. The push for sustainable energy solutions is likely to boost the demand for zirconia in this area, as governments and industries worldwide invest in alternative energy sources.

The optical industry is another emerging market for zirconia. Its high refractive index and durability make it suitable for use in optical fibers, lenses, and other photonic devices. As the demand for high-performance optical components in telecommunications and imaging systems grows, so does the market for zirconia-based materials.

While the exact market size for zirconia in the high-tech sector is difficult to quantify due to its diverse applications, industry reports suggest a compound annual growth rate (CAGR) in the range of 5-7% for the overall zirconia market. The high-tech applications are expected to be a significant driver of this growth, potentially outpacing other segments.

Zirconia Challenges

Despite its promising properties, zirconia faces several challenges that hinder its widespread adoption in high-tech applications. One of the primary obstacles is the material's inherent brittleness, which limits its use in applications requiring high impact resistance or flexibility. This characteristic makes zirconia susceptible to sudden failure under certain stress conditions, potentially compromising the reliability of devices or components.

Another significant challenge is the high cost associated with zirconia production and processing. The complex manufacturing processes required to achieve the desired properties and shapes of zirconia components contribute to increased production expenses. This cost factor often makes zirconia less competitive compared to alternative materials in price-sensitive markets.

The limited thermal shock resistance of zirconia poses challenges in applications involving rapid temperature changes. This limitation restricts its use in certain high-temperature environments where thermal cycling is common, such as in some aerospace or industrial applications.

Zirconia's relatively low thermal conductivity, while beneficial in some applications, can be a drawback in others where heat dissipation is crucial. This property limits its use in electronic components or other applications where efficient heat transfer is essential for optimal performance.

The material's susceptibility to low-temperature degradation, also known as aging, is another significant challenge. This phenomenon can lead to a gradual decrease in mechanical properties over time, particularly in moist environments, potentially affecting the long-term reliability of zirconia-based components.

Machining and processing zirconia can be challenging due to its hardness and wear resistance. Traditional machining techniques often prove inefficient or costly when working with zirconia, necessitating specialized equipment and expertise.

The limited electrical conductivity of zirconia restricts its application in certain electronic or electrical components where conductivity is required. This property narrows the range of potential applications in the electronics industry.

Lastly, the variability in properties depending on the specific composition and processing methods of zirconia can lead to inconsistencies in performance across different batches or suppliers. This variability poses challenges in maintaining consistent quality and performance in high-tech applications where precision and reliability are paramount.

Current Zirconia Apps

01 Zirconia synthesis and processing

Various methods for synthesizing and processing zirconia materials, including techniques for controlling particle size, crystalline structure, and purity. This encompasses sol-gel methods, hydrothermal synthesis, and other advanced processing techniques to produce zirconia with specific properties for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are explored, including novel techniques for producing zirconia powders, ceramics, and composites. These methods aim to improve the material's properties, such as strength, durability, and thermal stability, for diverse applications in industries like electronics, aerospace, and medical devices.

- Zirconia-based dental materials: Zirconia is widely used in dental applications due to its biocompatibility, aesthetics, and mechanical properties. Research focuses on developing improved zirconia-based materials for dental implants, crowns, and bridges, with emphasis on enhancing translucency, strength, and long-term stability in the oral environment.

- Zirconia coatings and thin films: Zirconia coatings and thin films are developed for various applications, including thermal barrier coatings, wear-resistant surfaces, and optical coatings. Research in this area focuses on improving deposition techniques, enhancing coating adhesion, and optimizing the microstructure for specific performance requirements.

- Zirconia-based composites and nanocomposites: The development of zirconia-based composites and nanocomposites aims to combine the properties of zirconia with other materials to create advanced materials with enhanced mechanical, thermal, and electrical properties. These composites find applications in areas such as cutting tools, structural components, and energy storage devices.

- Stabilized zirconia and phase transformation: Research on stabilized zirconia focuses on controlling its crystal structure and phase transformations to optimize its properties for specific applications. This includes the development of new stabilizers, understanding the mechanisms of phase transformation, and exploiting the transformation toughening effect to enhance the material's mechanical properties.

02 Zirconia-based dental materials

Development of zirconia-based materials for dental applications, including dental implants, crowns, and bridges. These materials are designed to have high strength, biocompatibility, and aesthetic properties suitable for use in oral environments.Expand Specific Solutions03 Zirconia in catalysis and fuel cells

Applications of zirconia in catalysis and fuel cell technology, focusing on its use as a catalyst support or as a component in solid oxide fuel cells. This includes modifications to enhance catalytic activity, stability, and ionic conductivity.Expand Specific Solutions04 Zirconia coatings and thin films

Methods for depositing zirconia coatings and thin films on various substrates, including techniques such as physical vapor deposition, chemical vapor deposition, and sol-gel processes. These coatings are used for thermal barrier, wear resistance, and optical applications.Expand Specific Solutions05 Zirconia composites and nanocomposites

Development of zirconia-based composite and nanocomposite materials, combining zirconia with other ceramics, metals, or polymers to enhance mechanical, thermal, or electrical properties. This includes techniques for uniform dispersion of zirconia nanoparticles in various matrices.Expand Specific Solutions

Key Industry Players

The zirconia market in the high-tech sector is in a growth phase, driven by increasing demand in various applications. The market size is expanding, with projections indicating significant growth potential. Technologically, zirconia is reaching maturity, with ongoing advancements in its properties and applications. Key players like 3M Innovative Properties Co., Saint-Gobain Ceramics & Plastics, Inc., and Tosoh Corp. are leading innovation efforts. Research institutions such as the University of Connecticut and Harbin Institute of Technology are contributing to technological progress. Emerging companies like BYD Co., Ltd. and Aidite Technology Co., Ltd. are also making strides in zirconia applications, particularly in the automotive and dental sectors. The competitive landscape is diverse, with a mix of established corporations, specialized manufacturers, and research-driven entities collaborating and competing to advance zirconia technology.

Tosoh Corp.

Saint-Gobain Ceramics & Plastics, Inc.

Zirconia Innovations

- Zirconia-based particles with 0.02 to 20 mole percent lanthanide element oxide and 0 to 15 mole percent yttrium oxide are synthesized using a hydrothermal treatment method, resulting in crystalline particles with an average primary size of no greater than 100 nanometers, which are then used in sols, composites, and sintered bodies to enhance mechanical properties and refractive index.

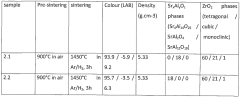

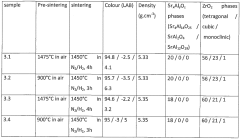

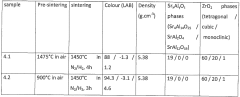

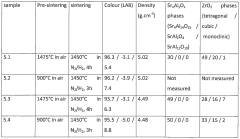

- A ceramic composite material is developed using yttria-doped zirconia as the primary phase for mechanical stability and strontium aluminate doped with Eu and Dy as the phosphorescent phase, with a densification process involving sintering under oxidizing and reducing conditions to achieve a dense body with persistent phosphorescence. A shielding layer can be applied to create specific patterns of phosphorescent and non-phosphorescent areas on the surface.

Zirconia Supply Chain

The zirconia supply chain plays a crucial role in the high-tech sector, encompassing various stages from raw material extraction to end-product manufacturing. The primary source of zirconium is zircon sand, which is mined predominantly in Australia, South Africa, and Indonesia. These countries account for over 70% of global zircon production, creating a geographically concentrated supply base.

The extraction process involves heavy mineral sand mining, followed by separation and refining to produce zirconium compounds. Key players in this stage include major mining companies like Iluka Resources, Rio Tinto, and Tronox. These companies have significant influence over the supply and pricing of zircon in the global market.

Once extracted, zircon undergoes further processing to produce zirconia powder, which is the primary form used in high-tech applications. This stage involves chemical processing and advanced manufacturing techniques. Companies like Tosoh Corporation, Saint-Gobain, and Daiichi Kigenso Kagaku Kogyo are major producers of high-purity zirconia powders.

The supply chain then branches into various high-tech sectors, including electronics, aerospace, and medical devices. In the electronics industry, zirconia is used in the production of ceramic capacitors and other components. The aerospace sector utilizes zirconia in thermal barrier coatings and structural ceramics. Medical applications include dental implants and prosthetics.

A significant challenge in the zirconia supply chain is the potential for supply disruptions due to the concentrated nature of raw material sources. Geopolitical tensions or natural disasters in key producing regions could have substantial impacts on global supply. Additionally, the energy-intensive nature of zirconia production raises concerns about environmental sustainability and cost fluctuations tied to energy prices.

To mitigate these risks, there is a growing trend towards diversifying supply sources and developing more efficient production methods. Research into alternative zirconium sources and recycling technologies is ongoing. Some companies are also exploring vertical integration strategies to gain more control over their supply chains.

The future of the zirconia supply chain in the high-tech sector will likely be shaped by advancements in materials science, evolving regulatory landscapes, and shifts in global manufacturing patterns. As demand for high-performance materials in technology applications continues to grow, ensuring a stable and sustainable zirconia supply chain will be critical for the continued development of various high-tech industries.

Environmental Impact

The environmental impact of zirconia in the high-tech sector is a critical consideration as its usage continues to expand. Zirconia production and processing involve energy-intensive processes, contributing to greenhouse gas emissions. The mining of zircon, the primary source of zirconia, can lead to land degradation and habitat disruption if not managed responsibly. However, the industry is making strides towards more sustainable practices.

Advancements in zirconia production techniques are focusing on reducing energy consumption and minimizing waste. Some manufacturers are implementing closed-loop systems to recycle water and chemicals used in the production process, significantly reducing environmental footprint. Additionally, research is ongoing to develop more efficient sintering methods, which could potentially lower the energy requirements for zirconia production.

The durability and longevity of zirconia-based products contribute positively to sustainability efforts. In applications such as cutting tools and wear-resistant components, zirconia's extended lifespan reduces the frequency of replacements, thereby decreasing overall material consumption and waste generation. This aspect is particularly relevant in industries like aerospace and automotive, where component longevity is crucial for both economic and environmental reasons.

Recycling of zirconia presents both challenges and opportunities. While pure zirconia can be recycled, many high-tech applications involve composite materials or coatings that complicate the recycling process. Developing effective separation and recycling technologies for zirconia-containing products is an area of active research, with potential to significantly reduce the environmental impact of zirconia use in the high-tech sector.

The use of zirconia in clean energy technologies also offers environmental benefits. Its application in solid oxide fuel cells and as a coating in solar panels contributes to the advancement of renewable energy sources. These applications indirectly offset the environmental impact of zirconia production by facilitating cleaner energy generation.

As environmental regulations become more stringent globally, the zirconia industry is likely to face increased pressure to adopt cleaner production methods and improve material efficiency. This may drive innovation in production processes and recycling technologies, potentially leading to a more environmentally sustainable lifecycle for zirconia in high-tech applications.