Zirconia’s Role in Carbon Capture Technologies

Zirconia in Carbon Capture: Background and Objectives

Carbon capture technologies have emerged as a critical solution in the global effort to mitigate climate change. Among the various materials and methods employed in this field, zirconia has gained significant attention due to its unique properties and potential applications. The development of zirconia-based carbon capture technologies represents a convergence of materials science, chemical engineering, and environmental studies.

Zirconia, a crystalline oxide of zirconium, has been known for its exceptional thermal and chemical stability. Its journey in carbon capture technologies began in the early 2000s when researchers started exploring its potential as a support material for amine-based sorbents. The initial focus was on leveraging zirconia's high surface area and porous structure to enhance the efficiency of carbon dioxide adsorption.

As research progressed, the role of zirconia in carbon capture expanded beyond being a mere support material. Scientists discovered that certain forms of zirconia, particularly those doped with other elements, exhibited intrinsic CO2 capture capabilities. This revelation opened up new avenues for developing more efficient and cost-effective carbon capture solutions.

The evolution of zirconia in carbon capture technologies has been marked by several key milestones. These include the development of zirconia-based mixed oxide sorbents, the creation of zirconia-supported membranes for gas separation, and the synthesis of zirconia-based metal-organic frameworks (MOFs) for selective CO2 adsorption. Each of these advancements has contributed to pushing the boundaries of what is possible in carbon capture efficiency and selectivity.

The primary objective of incorporating zirconia in carbon capture technologies is to enhance the overall performance of CO2 capture systems. This encompasses improving adsorption capacity, increasing selectivity for CO2 over other gases, enhancing the stability and durability of capture materials, and reducing the energy requirements for sorbent regeneration. Additionally, researchers aim to develop zirconia-based materials that can operate effectively under a wide range of conditions, including high temperatures and pressures typically found in industrial settings.

Looking ahead, the future of zirconia in carbon capture technologies appears promising. Ongoing research is focused on optimizing the structure and composition of zirconia-based materials to further improve their CO2 capture properties. There is also a growing interest in exploring the potential of zirconia in novel carbon capture approaches, such as direct air capture and integrated capture-conversion systems.

As global efforts to reduce greenhouse gas emissions intensify, the role of zirconia in carbon capture technologies is expected to become increasingly significant. The continued development and refinement of zirconia-based materials and systems will be crucial in addressing the technical and economic challenges associated with large-scale carbon capture implementation.

Market Analysis for Zirconia-based Carbon Capture Solutions

The market for zirconia-based carbon capture solutions is experiencing significant growth, driven by increasing global efforts to reduce greenhouse gas emissions and combat climate change. As governments worldwide implement stricter environmental regulations and set ambitious carbon reduction targets, industries are seeking innovative and efficient carbon capture technologies. Zirconia-based solutions have emerged as a promising option due to their unique properties and potential advantages over traditional carbon capture methods.

The global carbon capture and storage (CCS) market is projected to expand rapidly in the coming years, with zirconia-based technologies poised to capture a substantial share. This growth is fueled by the rising demand for clean energy solutions across various sectors, including power generation, oil and gas, cement production, and chemical manufacturing. The versatility of zirconia-based materials allows for their application in both pre-combustion and post-combustion carbon capture processes, further expanding their market potential.

One of the key drivers for the adoption of zirconia-based carbon capture solutions is their superior performance in high-temperature environments. This characteristic makes them particularly attractive for industrial applications where conventional amine-based sorbents may degrade or become less effective. Additionally, zirconia-based materials offer improved energy efficiency and reduced operational costs compared to some existing carbon capture technologies, making them an economically viable option for large-scale implementation.

The market for zirconia-based carbon capture solutions is also benefiting from increased investment in research and development. Both private companies and government institutions are allocating substantial resources to advance these technologies, aiming to enhance their efficiency, durability, and scalability. This ongoing innovation is expected to further improve the cost-effectiveness of zirconia-based solutions, potentially accelerating their market adoption.

Geographically, North America and Europe are currently leading the market for zirconia-based carbon capture technologies, owing to their stringent environmental regulations and well-established industrial infrastructure. However, rapid industrialization and growing environmental concerns in Asia-Pacific regions, particularly in countries like China and India, are creating new opportunities for market expansion. These emerging economies are increasingly recognizing the importance of carbon capture technologies in achieving their sustainability goals while maintaining economic growth.

Despite the promising outlook, the market for zirconia-based carbon capture solutions faces some challenges. The high initial investment required for implementing these technologies and the need for specialized infrastructure can be barriers to adoption, especially for smaller industries. Additionally, the market is still in its early stages, with ongoing research needed to optimize the performance and long-term stability of zirconia-based materials in various industrial settings.

Current Challenges in Zirconia-enabled Carbon Capture

Despite the promising potential of zirconia in carbon capture technologies, several significant challenges currently hinder its widespread adoption and effectiveness. One of the primary obstacles is the high cost associated with zirconia-based materials and their integration into existing carbon capture systems. The production of high-quality zirconia compounds often involves complex processes and expensive precursors, making large-scale implementation economically challenging for many industries.

Another critical issue is the long-term stability and durability of zirconia-based sorbents under real-world operating conditions. While zirconia exhibits excellent thermal and chemical resistance, prolonged exposure to harsh environments in carbon capture processes can lead to degradation of its performance over time. This degradation may manifest as reduced CO2 adsorption capacity, decreased selectivity, or structural changes that impact the material's effectiveness.

The optimization of zirconia's surface properties and pore structure for enhanced CO2 capture remains a significant challenge. Although zirconia has shown promising CO2 adsorption capabilities, further improvements in surface area, pore size distribution, and functionalization are necessary to maximize its carbon capture efficiency. Achieving the ideal balance between high adsorption capacity and rapid adsorption-desorption kinetics is crucial for practical applications.

Furthermore, the integration of zirconia-based materials into existing carbon capture technologies poses engineering challenges. Adapting current systems to accommodate zirconia sorbents may require significant modifications to process designs, equipment, and operational parameters. This integration complexity can be a barrier to the adoption of zirconia-enabled carbon capture solutions, particularly in retrofitting scenarios.

The scalability of zirconia production and its incorporation into large-scale carbon capture systems is another hurdle that needs to be addressed. Current manufacturing processes may not be suitable for the massive quantities required for industrial-scale carbon capture applications. Developing cost-effective and scalable production methods for zirconia-based materials is essential for their widespread implementation.

Additionally, the regeneration of zirconia sorbents after CO2 capture presents challenges in terms of energy consumption and efficiency. The desorption process often requires significant energy input, which can offset the environmental benefits of carbon capture. Optimizing the regeneration cycle to minimize energy requirements while maintaining high CO2 release efficiency is a critical area for improvement.

Lastly, there is a need for more comprehensive life cycle assessments and long-term performance studies of zirconia-based carbon capture systems. Understanding the environmental impact, resource requirements, and overall sustainability of these technologies is crucial for their acceptance and implementation on a global scale.

Existing Zirconia-based Carbon Capture Technologies

01 Zirconia synthesis and processing

Various methods for synthesizing and processing zirconia materials, including techniques for controlling particle size, crystalline structure, and purity. This encompasses sol-gel processes, hydrothermal synthesis, and other advanced manufacturing techniques to produce zirconia with specific properties for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are explored, including sol-gel techniques, hydrothermal processes, and chemical vapor deposition. These methods aim to control the crystalline structure, particle size, and purity of zirconia for different applications.

- Zirconia-based dental materials: Zirconia is widely used in dental applications due to its biocompatibility and mechanical properties. Innovations in this field include zirconia-based ceramics for crowns, bridges, and implants, as well as coloring techniques to match natural tooth appearance.

- Zirconia in electronic and optical applications: Zirconia finds applications in electronic and optical devices due to its unique properties. This includes use in solid oxide fuel cells, oxygen sensors, and as a high-refractive-index material in optical coatings and components.

- Zirconia composites and reinforced materials: Research focuses on developing zirconia-based composites and reinforced materials to enhance mechanical properties and thermal stability. This includes zirconia-toughened alumina, zirconia-reinforced polymers, and ceramic matrix composites for high-temperature applications.

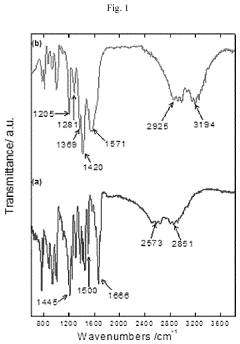

- Surface modification and functionalization of zirconia: Techniques for modifying and functionalizing zirconia surfaces are developed to improve its properties and expand its applications. This includes surface treatments, coatings, and the incorporation of dopants to enhance specific characteristics such as catalytic activity or biocompatibility.

02 Zirconia-based composites and coatings

Development of zirconia-based composite materials and coatings, often combining zirconia with other ceramics or metals to enhance properties such as strength, toughness, and wear resistance. These composites find applications in various industries, including aerospace, automotive, and medical fields.Expand Specific Solutions03 Dental and biomedical applications of zirconia

Utilization of zirconia in dental and biomedical applications, particularly for dental implants, crowns, and other prosthetic devices. This includes research on biocompatibility, mechanical properties, and aesthetic characteristics of zirconia-based materials for medical use.Expand Specific Solutions04 Zirconia in fuel cells and energy applications

Application of zirconia materials in fuel cells, particularly as solid electrolytes in solid oxide fuel cells (SOFCs). This involves research on ionic conductivity, stability at high temperatures, and integration with other fuel cell components to improve energy conversion efficiency.Expand Specific Solutions05 Stabilization and phase transformation of zirconia

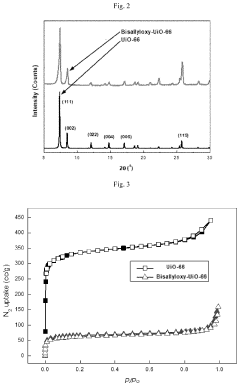

Techniques for stabilizing zirconia in its various crystalline phases, particularly the tetragonal and cubic phases, through doping with other elements or controlling processing conditions. This research aims to tailor the properties of zirconia for specific applications and improve its performance under different environmental conditions.Expand Specific Solutions

Key Players in Zirconia-based Carbon Capture Industry

The carbon capture technology market utilizing zirconia is in a growth phase, with increasing global focus on reducing greenhouse gas emissions. The market size is expanding, driven by stringent environmental regulations and corporate sustainability goals. Technologically, zirconia-based carbon capture solutions are advancing, but still evolving. Companies like Toyota Motor Corp., BASF SE, and China Petroleum & Chemical Corp. are at the forefront, investing in research and development. Academic institutions such as the University of Connecticut and King Fahd University of Petroleum & Minerals are contributing to technological advancements. The involvement of diverse players, from automotive to energy sectors, indicates the technology's broad potential applications and ongoing maturation process.

Toyota Motor Corp.

China Petroleum & Chemical Corp.

Core Innovations in Zirconia for Carbon Capture

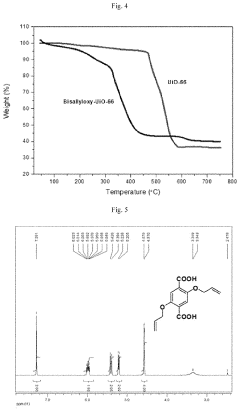

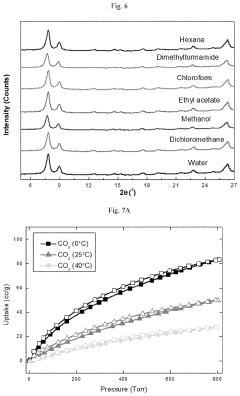

- A zirconium metal-organic framework (Zr-MOF) is synthesized using zirconium ion clusters and a specific linker, providing a coordination product with enhanced surface properties for selective CO2 adsorption, including a BET surface area of 300 to 600 m2/g and CO2 uptake capacity of 75 to 90 cm3/g at 273 K.

- A carbon dioxide absorbent composition comprising an active ingredient, a support, and a regeneration enhancer, specifically titania, zirconia, α-alumina, vanadium sulfate, and manganese oxide, is developed, which is spray-dried and calcined to produce spherical particles with excellent absorbency and regeneration properties, allowing for continuous reuse and reduced energy consumption.

Environmental Impact of Zirconia-based Carbon Capture

The environmental impact of zirconia-based carbon capture technologies is a critical consideration in the development and implementation of these systems. Zirconia, a ceramic material with unique properties, has shown promising potential in carbon capture applications due to its high thermal stability and chemical resistance.

One of the primary environmental benefits of zirconia-based carbon capture is its potential to significantly reduce greenhouse gas emissions from industrial processes and power plants. By efficiently capturing CO2 from flue gases, these technologies can help mitigate the effects of climate change and contribute to global efforts to reduce carbon footprints.

However, the production and use of zirconia in carbon capture systems also have environmental implications that must be carefully evaluated. The mining and processing of zirconium ores, primarily zircon, can lead to habitat disruption and potential soil and water contamination if not managed properly. Additionally, the energy-intensive nature of zirconia production may offset some of the environmental gains achieved through carbon capture.

The durability and long lifespan of zirconia-based materials in carbon capture applications can contribute to reduced waste and resource consumption over time. This longevity may result in fewer replacements and less frequent maintenance, potentially lowering the overall environmental impact of the technology throughout its lifecycle.

Water usage is another important environmental factor to consider. While zirconia-based systems may require less water compared to some alternative carbon capture technologies, the exact water footprint can vary depending on the specific implementation and process design. Optimizing water consumption in these systems remains an area of ongoing research and development.

The disposal or recycling of spent zirconia materials at the end of their useful life in carbon capture systems is an environmental concern that requires attention. Developing effective recycling processes for zirconia components could significantly reduce the environmental footprint of these technologies and promote a more circular economy approach.

Furthermore, the potential for zirconia-based carbon capture to enable carbon utilization technologies may have additional environmental implications. By providing a source of captured CO2 for use in various industrial processes or for conversion into valuable products, these systems could contribute to the development of a more sustainable carbon economy.

In conclusion, while zirconia-based carbon capture technologies offer significant potential for reducing greenhouse gas emissions, a comprehensive life cycle assessment is necessary to fully understand and optimize their environmental impact. Balancing the benefits of carbon capture against the environmental costs of material production and system operation remains a key challenge in the ongoing development of these technologies.

Economic Viability of Zirconia in Carbon Capture Systems

The economic viability of zirconia in carbon capture systems is a critical factor in determining its widespread adoption and implementation. Zirconia-based materials have shown promising potential in carbon capture technologies, particularly in high-temperature applications. However, the economic feasibility of these systems depends on various factors, including material costs, energy requirements, and overall system efficiency.

One of the primary advantages of zirconia-based carbon capture systems is their high thermal stability and resistance to corrosion. This durability translates to longer operational lifetimes and reduced maintenance costs, potentially offsetting the initial higher material costs. Additionally, zirconia's ability to operate at elevated temperatures allows for more efficient integration with existing industrial processes, particularly in power plants and cement factories.

The production costs of zirconia-based materials have been steadily decreasing due to advancements in manufacturing processes and increased demand in various industries. This trend is expected to continue, making zirconia more competitive with traditional carbon capture materials such as zeolites and amine-based sorbents. However, the current production scale may need to be significantly expanded to meet the potential demand for large-scale carbon capture applications.

Energy consumption is a crucial factor in the economic viability of any carbon capture technology. Zirconia-based systems, particularly those utilizing mixed ionic-electronic conducting (MIEC) membranes, have shown promising results in reducing the energy penalty associated with carbon capture. These systems can operate at high temperatures without the need for additional heating or cooling steps, potentially leading to substantial energy savings compared to conventional amine-based capture methods.

The efficiency of zirconia-based carbon capture systems is another key economic consideration. Recent studies have demonstrated CO2 capture rates of up to 90% with certain zirconia-based materials, comparable to or exceeding the performance of established technologies. This high efficiency can lead to reduced operational costs and improved overall economics of the capture process.

However, challenges remain in scaling up zirconia-based carbon capture technologies from laboratory demonstrations to industrial-scale applications. The capital costs associated with retrofitting existing facilities or constructing new plants with zirconia-based capture systems are significant. These costs must be weighed against the long-term benefits of reduced operational expenses and potential carbon pricing mechanisms.

In conclusion, while zirconia shows promise in carbon capture technologies, its economic viability depends on a complex interplay of factors including material costs, energy efficiency, and system performance. Continued research and development efforts, coupled with supportive policy frameworks and carbon pricing mechanisms, will be crucial in determining the widespread adoption of zirconia-based carbon capture systems in the coming years.