Continuous roll wipe material dispenser

A technology of material rolls and dispensers, applied in the direction of home appliances, etc., can solve problems such as discomfort, mechanism failure, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

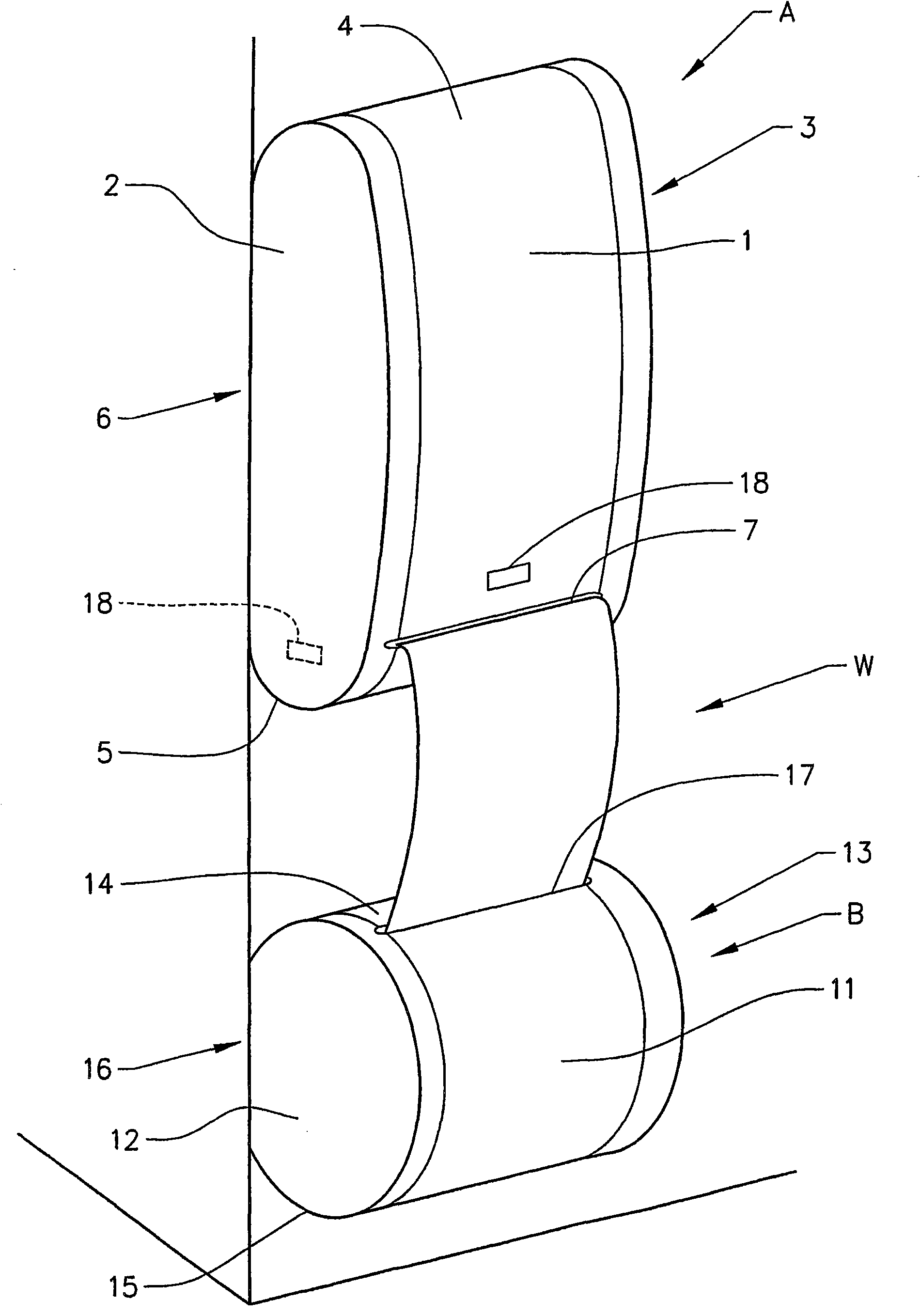

[0030] figure 1 A schematic diagram of a dispenser according to one embodiment of the invention is shown. The dispenser shown in this figure comprises a combination of an upper module A with means for mounting a rotatable roll of wipe material within the upper module A and a lower module B with means for containing the used wipe material s installation. The upper module A comprises a front cover 1, a pair of side walls 2, 3, an upper part 4, a lower part 5 and a rear part 6 (see figure 1 ), the rear portion 6 is suitable for mounting on a wall or similar surface. A dispensing opening 7 shaped as a slit is provided along the lower front part of the upper module A in an area where the front cover 1 is joined to the lower part 5 .

[0031] Similarly, the lower module B includes a front cover 11, a pair of side walls 12, 13, an upper portion 14, a lower portion 15 and a rear portion 16 (see figure 1 ), the rear portion 16 is adapted to be mounted below the upper module A to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com