Drawing frame with automatic cylinder change device

A drawing frame, automatic technology, applied in textiles and papermaking, etc., can solve the problems of time-consuming and laborious, and the draw frame does not have automatic can changing function, etc., and achieves the effect of broad market prospects and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

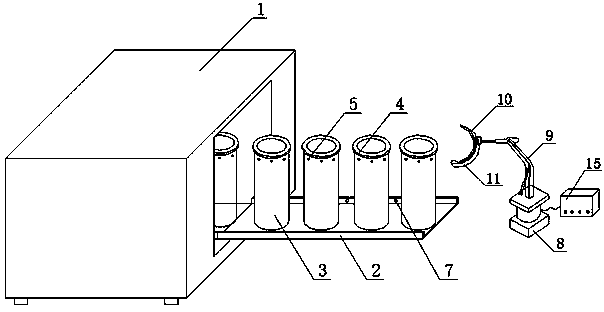

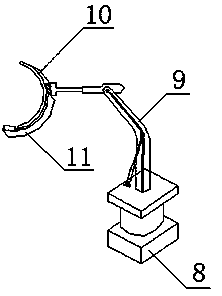

[0025] see Figure 1 to Figure 7 , the draw frame with automatic can changing device of the present invention comprises a draw frame body 1 and a barrel conveyor 2, and more than one cylinder 3 is placed on the barrel conveyor 2, and the upper end surface of the cylinder 3 A cylindrical boss 4 is arranged on the top, and more than one signal transmitter 5 is installed on the outer circumference of the inner side of the cylindrical boss 4. A photoelectric sensor 7 is installed on the inner side of the barrel conveyor 2, and the outer side of the barrel conveyor 2 Base 8 is installed, and the upper end of base 8 is fixed with an end of telescopic arm 9, and the other end of telescopic arm 9 is equipped with arc ring 10, and the outer arc surface of arc ring 10 is provided with gear ring 12, and arc ring 10 is equipped with an arc claw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com