Adaptive Ultrafiltration System Designs: Maximizing Adaptability and Efficiency

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Evolution and Objectives

Ultrafiltration technology has evolved significantly since its inception in the mid-20th century. Initially developed for laboratory applications, ultrafiltration emerged as an industrial separation process in the 1960s with the introduction of asymmetric cellulose acetate membranes. The 1970s and 1980s witnessed substantial advancements with the development of polysulfone and polyethersulfone membranes, which offered improved chemical resistance and thermal stability.

The 1990s marked a pivotal shift toward more efficient module designs, transitioning from plate-and-frame configurations to hollow fiber and spiral-wound modules that significantly enhanced surface area-to-volume ratios. This period also saw the integration of automated control systems, enabling more precise operation and monitoring capabilities.

In the early 2000s, the focus shifted toward enhancing membrane fouling resistance through surface modifications and novel material compositions. Nanotechnology integration began influencing membrane design, with nanomaterials incorporated to improve selectivity and flux rates. The development of chlorine-resistant membranes also expanded ultrafiltration applications in water treatment facilities.

The past decade has witnessed a paradigm shift toward adaptive ultrafiltration systems that can respond dynamically to changing feed conditions. These systems incorporate real-time monitoring sensors, automated backwashing protocols, and variable flux operation capabilities. Machine learning algorithms have been integrated to predict fouling patterns and optimize cleaning cycles, representing a significant advancement in operational efficiency.

Current technological trends indicate movement toward energy-efficient designs with reduced pressure requirements and enhanced recovery rates. Biomimetic membrane development is gaining traction, with structures inspired by natural filtration systems demonstrating promising performance characteristics. Additionally, hybrid systems combining ultrafiltration with other separation technologies are emerging as versatile solutions for complex separation challenges.

The primary objectives for adaptive ultrafiltration system development include maximizing operational flexibility across varying feed compositions and flow rates while maintaining consistent permeate quality. Energy efficiency remains a critical goal, with emphasis on reducing the specific energy consumption per unit volume of treated fluid. Minimizing chemical cleaning requirements through improved anti-fouling designs represents another key objective.

Extending membrane lifespan through advanced materials and optimized operating protocols constitutes an important economic consideration. Additionally, developing systems with smaller footprints and modular designs addresses space constraints in industrial settings while enabling scalability. The integration of digital monitoring and control systems aims to facilitate predictive maintenance and remote operation capabilities, aligning with broader Industry 4.0 initiatives.

The 1990s marked a pivotal shift toward more efficient module designs, transitioning from plate-and-frame configurations to hollow fiber and spiral-wound modules that significantly enhanced surface area-to-volume ratios. This period also saw the integration of automated control systems, enabling more precise operation and monitoring capabilities.

In the early 2000s, the focus shifted toward enhancing membrane fouling resistance through surface modifications and novel material compositions. Nanotechnology integration began influencing membrane design, with nanomaterials incorporated to improve selectivity and flux rates. The development of chlorine-resistant membranes also expanded ultrafiltration applications in water treatment facilities.

The past decade has witnessed a paradigm shift toward adaptive ultrafiltration systems that can respond dynamically to changing feed conditions. These systems incorporate real-time monitoring sensors, automated backwashing protocols, and variable flux operation capabilities. Machine learning algorithms have been integrated to predict fouling patterns and optimize cleaning cycles, representing a significant advancement in operational efficiency.

Current technological trends indicate movement toward energy-efficient designs with reduced pressure requirements and enhanced recovery rates. Biomimetic membrane development is gaining traction, with structures inspired by natural filtration systems demonstrating promising performance characteristics. Additionally, hybrid systems combining ultrafiltration with other separation technologies are emerging as versatile solutions for complex separation challenges.

The primary objectives for adaptive ultrafiltration system development include maximizing operational flexibility across varying feed compositions and flow rates while maintaining consistent permeate quality. Energy efficiency remains a critical goal, with emphasis on reducing the specific energy consumption per unit volume of treated fluid. Minimizing chemical cleaning requirements through improved anti-fouling designs represents another key objective.

Extending membrane lifespan through advanced materials and optimized operating protocols constitutes an important economic consideration. Additionally, developing systems with smaller footprints and modular designs addresses space constraints in industrial settings while enabling scalability. The integration of digital monitoring and control systems aims to facilitate predictive maintenance and remote operation capabilities, aligning with broader Industry 4.0 initiatives.

Market Analysis for Adaptive Ultrafiltration Systems

The global market for adaptive ultrafiltration systems is experiencing robust growth, driven by increasing water scarcity concerns and stringent regulations regarding water quality across various industries. Current market valuation stands at approximately 5.7 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 7.8% through 2030, potentially reaching 9.6 billion USD by the end of the forecast period.

Industrial applications represent the largest market segment, accounting for roughly 42% of the total market share. This dominance stems from the critical need for efficient water treatment and recycling processes in manufacturing, particularly in chemical processing, food and beverage production, and pharmaceutical manufacturing. The municipal water treatment sector follows closely, representing approximately 35% of the market, with growing implementation in urban water management systems.

Geographically, North America and Europe currently lead the market with a combined share of 58%, attributed to advanced infrastructure and stringent environmental regulations. However, the Asia-Pacific region is emerging as the fastest-growing market with an anticipated CAGR of 9.3%, driven by rapid industrialization in China and India, alongside increasing government initiatives for clean water access.

Customer demand patterns reveal a significant shift toward systems offering higher adaptability to varying water conditions and contaminant profiles. End-users increasingly prioritize solutions that can automatically adjust filtration parameters based on real-time water quality data, minimizing downtime and operational interventions. This trend is particularly pronounced in regions experiencing seasonal variations in water quality or facilities processing multiple product lines with different water specifications.

Cost considerations remain a primary market driver, with potential customers seeking systems that demonstrate clear return on investment through reduced energy consumption, extended membrane life, and decreased maintenance requirements. Market research indicates that systems offering 15-20% improvement in energy efficiency compared to conventional ultrafiltration systems command premium pricing despite higher initial investment costs.

Competitive analysis reveals market fragmentation with several specialized players rather than dominant leaders. Recent merger and acquisition activities suggest market consolidation is underway, with larger water treatment conglomerates acquiring innovative startups to enhance their adaptive technology portfolios. This trend is expected to continue as the technology matures and standardization increases across the industry.

Industrial applications represent the largest market segment, accounting for roughly 42% of the total market share. This dominance stems from the critical need for efficient water treatment and recycling processes in manufacturing, particularly in chemical processing, food and beverage production, and pharmaceutical manufacturing. The municipal water treatment sector follows closely, representing approximately 35% of the market, with growing implementation in urban water management systems.

Geographically, North America and Europe currently lead the market with a combined share of 58%, attributed to advanced infrastructure and stringent environmental regulations. However, the Asia-Pacific region is emerging as the fastest-growing market with an anticipated CAGR of 9.3%, driven by rapid industrialization in China and India, alongside increasing government initiatives for clean water access.

Customer demand patterns reveal a significant shift toward systems offering higher adaptability to varying water conditions and contaminant profiles. End-users increasingly prioritize solutions that can automatically adjust filtration parameters based on real-time water quality data, minimizing downtime and operational interventions. This trend is particularly pronounced in regions experiencing seasonal variations in water quality or facilities processing multiple product lines with different water specifications.

Cost considerations remain a primary market driver, with potential customers seeking systems that demonstrate clear return on investment through reduced energy consumption, extended membrane life, and decreased maintenance requirements. Market research indicates that systems offering 15-20% improvement in energy efficiency compared to conventional ultrafiltration systems command premium pricing despite higher initial investment costs.

Competitive analysis reveals market fragmentation with several specialized players rather than dominant leaders. Recent merger and acquisition activities suggest market consolidation is underway, with larger water treatment conglomerates acquiring innovative startups to enhance their adaptive technology portfolios. This trend is expected to continue as the technology matures and standardization increases across the industry.

Current Challenges in Ultrafiltration Technology

Ultrafiltration technology, while highly effective for separation processes, faces several significant challenges that limit its widespread adoption and efficiency in various applications. The primary challenge is membrane fouling, which occurs when particles, colloids, and biological materials accumulate on membrane surfaces, reducing permeability and separation efficiency. This phenomenon necessitates frequent cleaning cycles, increases operational costs, and shortens membrane lifespan.

Energy consumption represents another major hurdle in ultrafiltration systems. Current designs require substantial pumping power to maintain transmembrane pressure, particularly as fouling progresses. This energy intensity makes ultrafiltration less economically viable for many applications, especially in resource-constrained environments or when processing large volumes of fluid.

The adaptability of ultrafiltration systems to varying feed compositions presents a persistent technical challenge. Most existing systems are optimized for specific operating conditions and struggle to maintain performance when faced with fluctuations in feed characteristics such as pH, temperature, solids content, or chemical composition. This limitation restricts their application in industries with variable process streams.

Membrane selectivity and the trade-off between flux and rejection rates continue to challenge engineers. Current membrane technologies often cannot achieve optimal separation of similarly sized molecules without sacrificing throughput. This fundamental limitation affects product purity and recovery rates across pharmaceutical, biotechnology, and food processing applications.

Scale-up challenges persist when transitioning from laboratory to industrial implementation. Flow distribution, pressure drop management, and maintaining uniform membrane performance across large surface areas remain problematic. These issues frequently result in decreased efficiency and increased operational complexity at industrial scales.

The lack of real-time monitoring and control systems represents a significant technological gap. Most ultrafiltration operations rely on periodic offline measurements rather than continuous monitoring, limiting the ability to implement adaptive control strategies that could optimize performance and respond to changing conditions.

Membrane material limitations also constrain ultrafiltration technology advancement. Current materials often lack sufficient chemical resistance, thermal stability, or mechanical strength for demanding applications. Additionally, the environmental footprint of membrane manufacturing and disposal raises sustainability concerns as ultrafiltration applications expand globally.

Cross-industry standardization remains underdeveloped, with different sectors employing varied metrics and methodologies for system evaluation. This fragmentation hampers knowledge transfer and technological advancement across application domains, slowing the overall pace of innovation in adaptive ultrafiltration systems.

Energy consumption represents another major hurdle in ultrafiltration systems. Current designs require substantial pumping power to maintain transmembrane pressure, particularly as fouling progresses. This energy intensity makes ultrafiltration less economically viable for many applications, especially in resource-constrained environments or when processing large volumes of fluid.

The adaptability of ultrafiltration systems to varying feed compositions presents a persistent technical challenge. Most existing systems are optimized for specific operating conditions and struggle to maintain performance when faced with fluctuations in feed characteristics such as pH, temperature, solids content, or chemical composition. This limitation restricts their application in industries with variable process streams.

Membrane selectivity and the trade-off between flux and rejection rates continue to challenge engineers. Current membrane technologies often cannot achieve optimal separation of similarly sized molecules without sacrificing throughput. This fundamental limitation affects product purity and recovery rates across pharmaceutical, biotechnology, and food processing applications.

Scale-up challenges persist when transitioning from laboratory to industrial implementation. Flow distribution, pressure drop management, and maintaining uniform membrane performance across large surface areas remain problematic. These issues frequently result in decreased efficiency and increased operational complexity at industrial scales.

The lack of real-time monitoring and control systems represents a significant technological gap. Most ultrafiltration operations rely on periodic offline measurements rather than continuous monitoring, limiting the ability to implement adaptive control strategies that could optimize performance and respond to changing conditions.

Membrane material limitations also constrain ultrafiltration technology advancement. Current materials often lack sufficient chemical resistance, thermal stability, or mechanical strength for demanding applications. Additionally, the environmental footprint of membrane manufacturing and disposal raises sustainability concerns as ultrafiltration applications expand globally.

Cross-industry standardization remains underdeveloped, with different sectors employing varied metrics and methodologies for system evaluation. This fragmentation hampers knowledge transfer and technological advancement across application domains, slowing the overall pace of innovation in adaptive ultrafiltration systems.

Current Adaptive Ultrafiltration Design Solutions

01 Sensor-based adaptive control systems for ultrafiltration

Advanced ultrafiltration systems incorporate sensor networks that continuously monitor key parameters such as pressure differentials, flow rates, and membrane conditions. These sensors provide real-time data that enables the system to automatically adjust operational parameters, optimizing filtration efficiency while preventing membrane fouling. The adaptive control algorithms can respond to changing feed water conditions, extending membrane life and reducing energy consumption during the filtration process.- Sensor-based adaptive control systems: Ultrafiltration systems equipped with advanced sensors can dynamically adjust filtration parameters based on real-time data. These systems monitor various parameters such as pressure, flow rate, and membrane fouling to automatically optimize the filtration process. The adaptive control algorithms enable the system to respond to changing input conditions, ensuring consistent filtration quality while maximizing efficiency and extending membrane life.

- Energy-efficient ultrafiltration designs: Modern ultrafiltration systems incorporate energy-saving features that significantly reduce operational costs while maintaining high performance. These designs include optimized pump configurations, energy recovery devices, and intelligent flow distribution systems. By minimizing energy consumption during operation, these systems achieve better sustainability metrics while delivering consistent filtration results, making them particularly valuable for large-scale industrial applications.

- Self-cleaning and fouling-resistant membranes: Advanced ultrafiltration systems feature innovative membrane technologies that resist fouling and incorporate automated cleaning mechanisms. These membranes utilize specialized surface treatments, novel materials, and optimized pore structures to minimize adhesion of contaminants. The self-cleaning capabilities include backwash cycles, air scouring, and chemical cleaning sequences that are triggered adaptively based on performance metrics, significantly extending operational periods between maintenance interventions.

- Modular and scalable ultrafiltration platforms: Modular ultrafiltration systems offer exceptional adaptability through their ability to scale operations according to changing demand. These platforms consist of standardized filtration units that can be added or removed as needed, allowing for flexible capacity adjustment. The modular design facilitates easier maintenance, component replacement, and system upgrades without disrupting the entire operation, making these systems particularly suitable for applications with variable processing requirements.

- Smart integration with process control systems: Next-generation ultrafiltration systems feature comprehensive integration with broader process control architectures, enabling coordinated operation within complex industrial environments. These systems utilize industrial IoT connectivity, cloud-based analytics, and machine learning algorithms to optimize performance based on historical data and predicted conditions. The intelligent integration allows for remote monitoring, predictive maintenance scheduling, and automated adjustment of filtration parameters to match upstream and downstream process requirements.

02 Self-cleaning and fouling prevention mechanisms

Modern adaptive ultrafiltration systems feature innovative self-cleaning mechanisms that significantly improve operational efficiency. These systems can detect early signs of membrane fouling and automatically initiate backwashing, air scouring, or chemical cleaning cycles. By adapting cleaning frequencies and intensities based on actual fouling conditions rather than fixed schedules, these systems maintain optimal flux rates while minimizing chemical usage and downtime, resulting in more sustainable and cost-effective operation.Expand Specific Solutions03 Energy optimization through variable frequency drives

Adaptive ultrafiltration systems incorporate variable frequency drives (VFDs) that adjust pump speeds based on filtration demands. This technology enables the system to operate at optimal energy efficiency points regardless of flow variations or pressure requirements. The intelligent control systems continuously analyze performance metrics and adjust power consumption accordingly, resulting in significant energy savings compared to conventional fixed-speed systems while maintaining consistent filtration quality across varying operational conditions.Expand Specific Solutions04 Modular design for scalability and flexibility

Advanced ultrafiltration systems feature modular architectures that allow for easy scaling and adaptation to changing capacity requirements. These systems can be expanded incrementally by adding filtration modules without disrupting existing operations. The modular approach also enables selective maintenance of individual components without shutting down the entire system. This design philosophy enhances system adaptability to varying water quality challenges and fluctuating demand patterns while optimizing capital investment and operational efficiency.Expand Specific Solutions05 AI and machine learning integration for predictive maintenance

Next-generation adaptive ultrafiltration systems leverage artificial intelligence and machine learning algorithms to analyze operational data and predict maintenance needs. These systems can identify patterns indicating potential membrane failure or performance degradation before conventional monitoring systems detect problems. By transitioning from reactive to predictive maintenance strategies, these intelligent systems minimize unexpected downtime, optimize cleaning cycles, and extend equipment lifespan, significantly improving overall system reliability and operational efficiency.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The adaptive ultrafiltration system design market is currently in a growth phase, characterized by increasing demand for more efficient and flexible filtration solutions across multiple industries. The global market size is estimated to exceed $5 billion, with projected annual growth of 6-8% driven by stringent environmental regulations and water scarcity concerns. Leading players include established industrial filtration specialists like HYDAC Filtertechnik and MANN+HUMMEL, who leverage decades of engineering expertise, alongside innovative water technology companies such as COWAY and Gambro Lundia focusing on specialized applications. Academic institutions like Northwestern Polytechnical University and California Institute of Technology are advancing fundamental research in membrane technology and adaptive control systems. The competitive landscape is further shaped by automotive giants Mercedes-Benz and LG Electronics integrating advanced filtration into their products, while regional players like Zhongye Changtian and Xi'an West Hot Water Environmental Protection are rapidly expanding their technological capabilities.

HYDAC Filtertechnik GmbH

Technical Solution: HYDAC's Adaptive Ultrafiltration System employs a dynamic pressure-controlled filtration approach with real-time monitoring capabilities. Their system features intelligent filter elements that can adjust pore size and filtration area based on fluid conditions and contamination levels. The technology incorporates a network of pressure sensors and flow meters that continuously analyze system parameters, allowing for automatic backwashing cycles triggered by differential pressure measurements rather than fixed time intervals. HYDAC's solution includes their patented AquaBoll automatic filter technology with adaptive cleaning mechanisms that adjust based on particle load and flow conditions. The system utilizes predictive maintenance algorithms that analyze filtration performance trends to optimize cleaning cycles and predict element replacement needs before efficiency drops below critical thresholds.

Strengths: Superior energy efficiency through demand-based operation rather than continuous filtration; excellent adaptability to varying contamination loads; reduced downtime due to predictive maintenance capabilities. Weaknesses: Higher initial investment costs compared to conventional systems; requires more sophisticated control systems; potential complexity in integration with existing infrastructure.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL has developed an Adaptive Ultrafiltration System that features their proprietary Intelligent Filter Management (IFM) technology. This system incorporates variable-geometry membrane configurations that can modify filtration surface area in response to changing flow conditions. Their solution employs a multi-stage filtration approach with adaptive cross-flow velocities that automatically adjust based on feed water quality and desired output specifications. The system utilizes MANN+HUMMEL's advanced membrane technology with self-cleaning capabilities triggered by intelligent sensors that detect fouling conditions. A key innovation is their Dynamic Flux Control system that continuously optimizes transmembrane pressure to maintain optimal filtration efficiency while minimizing energy consumption. The technology includes automated chemical cleaning protocols that adjust cleaning agent concentration and duration based on membrane condition analysis.

Strengths: Highly responsive to fluctuating input conditions; excellent membrane longevity due to intelligent cleaning protocols; reduced chemical consumption through targeted cleaning. Weaknesses: Complex control algorithms require specialized maintenance personnel; higher energy consumption during peak adaptation phases; limited scalability for very large industrial applications.

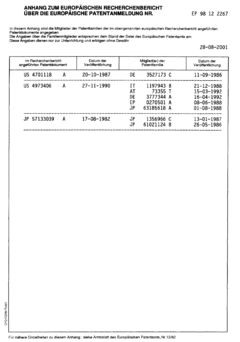

Critical Patents in Adaptive Ultrafiltration Technology

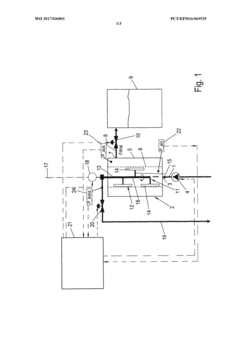

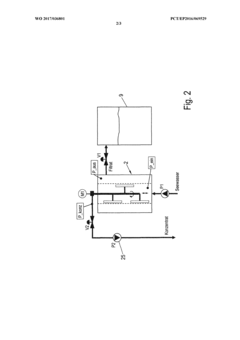

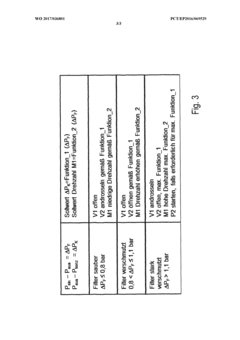

Method for filtering seawater onboard a ship

PatentWO2017036801A1

Innovation

- An adaptive filter control system that monitors differential pressures to optimize filtration efficiency, using suction elements to remove contaminants while minimizing water loss and maintaining continuous operation by adjusting the suction pressure difference based on contamination levels, ensuring maximum filtrate flow to ballast water tanks.

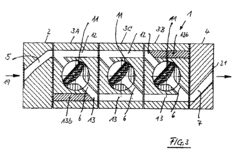

Filter apparatus for a fluid stream and filter module for use in such an apparatus

PatentInactiveEP0919353A3

Innovation

- A modular fluid filtration device design that allows for flexible adaptation by detachably connecting distribution, filter, and end modules, enabling the easy addition or removal of filter modules to adjust filter area and channel configurations, thereby optimizing filtration performance and maintenance.

Energy Efficiency Optimization Strategies

Energy efficiency in adaptive ultrafiltration systems represents a critical optimization frontier that directly impacts operational costs, environmental sustainability, and system performance. Current ultrafiltration systems typically consume significant energy during operation, primarily through pumping requirements and cleaning processes. Advanced energy optimization strategies focus on several interconnected approaches to maximize efficiency while maintaining filtration effectiveness.

Variable frequency drives (VFDs) have emerged as a fundamental component in energy-efficient ultrafiltration designs, allowing pumps to operate at precisely the required flow rates rather than at constant speeds. Implementation data indicates energy savings of 20-30% when VFDs are properly integrated with intelligent control systems that respond to changing membrane conditions and filtration demands.

Pressure recovery devices represent another significant advancement, capturing and reusing hydraulic energy that would otherwise be lost. These systems are particularly valuable in high-pressure ultrafiltration applications, where energy recovery can reduce overall consumption by up to 40% compared to conventional designs. Recent innovations in pressure exchanger technology have further improved efficiency ratios to 0.95-0.98 in optimal conditions.

Membrane configuration optimization plays a crucial role in energy efficiency. Research demonstrates that strategic arrangement of membrane modules can reduce pressure drops and improve flow distribution, resulting in lower pumping energy requirements. Computational fluid dynamics modeling has enabled the development of novel module designs that minimize energy-intensive turbulence while maximizing filtration surface area utilization.

Smart scheduling algorithms represent a software-based approach to energy optimization. These systems analyze historical performance data, current membrane conditions, and anticipated filtration demands to schedule operations during optimal periods. Machine learning enhancements to these algorithms have demonstrated additional 15-18% energy savings by predicting fouling patterns and proactively adjusting operational parameters.

Thermal energy recovery systems capture waste heat from ultrafiltration processes, particularly in applications where temperature control is necessary. This recovered energy can be redirected to preheat feed streams or support other facility operations, creating a more integrated and efficient energy ecosystem. Recent pilot implementations have shown that up to 25% of thermal energy can be effectively recovered and repurposed.

Combined optimization strategies that integrate multiple approaches typically yield the most significant efficiency improvements. Case studies from industrial implementations indicate that comprehensive energy optimization can reduce total energy consumption by 35-50% while maintaining or even improving filtration performance and system adaptability.

Variable frequency drives (VFDs) have emerged as a fundamental component in energy-efficient ultrafiltration designs, allowing pumps to operate at precisely the required flow rates rather than at constant speeds. Implementation data indicates energy savings of 20-30% when VFDs are properly integrated with intelligent control systems that respond to changing membrane conditions and filtration demands.

Pressure recovery devices represent another significant advancement, capturing and reusing hydraulic energy that would otherwise be lost. These systems are particularly valuable in high-pressure ultrafiltration applications, where energy recovery can reduce overall consumption by up to 40% compared to conventional designs. Recent innovations in pressure exchanger technology have further improved efficiency ratios to 0.95-0.98 in optimal conditions.

Membrane configuration optimization plays a crucial role in energy efficiency. Research demonstrates that strategic arrangement of membrane modules can reduce pressure drops and improve flow distribution, resulting in lower pumping energy requirements. Computational fluid dynamics modeling has enabled the development of novel module designs that minimize energy-intensive turbulence while maximizing filtration surface area utilization.

Smart scheduling algorithms represent a software-based approach to energy optimization. These systems analyze historical performance data, current membrane conditions, and anticipated filtration demands to schedule operations during optimal periods. Machine learning enhancements to these algorithms have demonstrated additional 15-18% energy savings by predicting fouling patterns and proactively adjusting operational parameters.

Thermal energy recovery systems capture waste heat from ultrafiltration processes, particularly in applications where temperature control is necessary. This recovered energy can be redirected to preheat feed streams or support other facility operations, creating a more integrated and efficient energy ecosystem. Recent pilot implementations have shown that up to 25% of thermal energy can be effectively recovered and repurposed.

Combined optimization strategies that integrate multiple approaches typically yield the most significant efficiency improvements. Case studies from industrial implementations indicate that comprehensive energy optimization can reduce total energy consumption by 35-50% while maintaining or even improving filtration performance and system adaptability.

Regulatory Framework for Water Treatment Technologies

The regulatory landscape for water treatment technologies, particularly adaptive ultrafiltration systems, is complex and multifaceted, spanning international, national, and local jurisdictions. At the international level, organizations such as the World Health Organization (WHO) establish guidelines for drinking water quality that influence regulatory frameworks worldwide. These guidelines provide scientific basis for standards development but allow flexibility in implementation based on regional conditions and technological capabilities.

In the United States, the Environmental Protection Agency (EPA) regulates water treatment technologies under the Safe Drinking Water Act (SDWA) and Clean Water Act (CWA). For ultrafiltration systems, compliance with NSF/ANSI Standard 61 for drinking water system components and NSF/ANSI 419 for public water treatment system performance is mandatory. The EPA's Long Term 2 Enhanced Surface Water Treatment Rule specifically addresses filtration technologies, including provisions relevant to adaptive ultrafiltration systems.

The European Union operates under the Drinking Water Directive (98/83/EC, updated in 2020), which establishes minimum quality standards for water intended for human consumption. The directive emphasizes a risk-based approach to water safety, requiring water suppliers to conduct risk assessments and implement appropriate treatment technologies. European standards EN 14652 and EN 15975 provide specific guidance for membrane filtration systems used in water treatment.

Regulatory frameworks increasingly incorporate sustainability metrics, requiring manufacturers to demonstrate energy efficiency and waste minimization. For adaptive ultrafiltration systems, this translates to specific requirements regarding backwash water recovery, energy consumption per volume of treated water, and chemical usage optimization. The ISO 14001 environmental management standard has become a de facto requirement for technology providers in many markets.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements. This approach allows for greater innovation in adaptive system designs while maintaining focus on outcome metrics such as pathogen removal efficiency, operational reliability, and adaptability to varying water quality conditions. Recent regulatory updates in Australia, Singapore, and Israel exemplify this trend, establishing frameworks that evaluate technologies based on their ability to adapt to changing conditions while maintaining treatment efficacy.

Compliance with these diverse regulatory frameworks presents significant challenges for manufacturers of adaptive ultrafiltration systems. The development of globally marketable solutions requires careful consideration of regional variations in water quality standards, operational requirements, and certification processes. Successful navigation of this regulatory landscape necessitates early engagement with certification bodies and regulatory agencies during the design phase to ensure compliance while maximizing the adaptive capabilities that define next-generation ultrafiltration systems.

In the United States, the Environmental Protection Agency (EPA) regulates water treatment technologies under the Safe Drinking Water Act (SDWA) and Clean Water Act (CWA). For ultrafiltration systems, compliance with NSF/ANSI Standard 61 for drinking water system components and NSF/ANSI 419 for public water treatment system performance is mandatory. The EPA's Long Term 2 Enhanced Surface Water Treatment Rule specifically addresses filtration technologies, including provisions relevant to adaptive ultrafiltration systems.

The European Union operates under the Drinking Water Directive (98/83/EC, updated in 2020), which establishes minimum quality standards for water intended for human consumption. The directive emphasizes a risk-based approach to water safety, requiring water suppliers to conduct risk assessments and implement appropriate treatment technologies. European standards EN 14652 and EN 15975 provide specific guidance for membrane filtration systems used in water treatment.

Regulatory frameworks increasingly incorporate sustainability metrics, requiring manufacturers to demonstrate energy efficiency and waste minimization. For adaptive ultrafiltration systems, this translates to specific requirements regarding backwash water recovery, energy consumption per volume of treated water, and chemical usage optimization. The ISO 14001 environmental management standard has become a de facto requirement for technology providers in many markets.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements. This approach allows for greater innovation in adaptive system designs while maintaining focus on outcome metrics such as pathogen removal efficiency, operational reliability, and adaptability to varying water quality conditions. Recent regulatory updates in Australia, Singapore, and Israel exemplify this trend, establishing frameworks that evaluate technologies based on their ability to adapt to changing conditions while maintaining treatment efficacy.

Compliance with these diverse regulatory frameworks presents significant challenges for manufacturers of adaptive ultrafiltration systems. The development of globally marketable solutions requires careful consideration of regional variations in water quality standards, operational requirements, and certification processes. Successful navigation of this regulatory landscape necessitates early engagement with certification bodies and regulatory agencies during the design phase to ensure compliance while maximizing the adaptive capabilities that define next-generation ultrafiltration systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!