Ultrafiltration vs Clay Filtration: Efficiency in Mineral Particle Separation

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mineral Separation Technology Evolution and Objectives

Mineral separation technology has evolved significantly over the past century, transitioning from rudimentary mechanical methods to sophisticated physical and chemical processes. The earliest separation techniques relied primarily on gravity-based methods such as sluicing and panning, which exploited differences in mineral densities. By the early 20th century, flotation processes emerged as revolutionary techniques, enabling the separation of complex mineral assemblages based on surface properties rather than density alone.

The mid-20th century witnessed the introduction of magnetic and electrostatic separation methods, further expanding the toolkit available to mineral processing engineers. These developments allowed for more precise separation of minerals with similar physical properties but different magnetic or electrical characteristics. The late 20th century saw significant advancements in chemical separation techniques, including various leaching processes and solvent extraction methods.

In recent decades, filtration technologies have become increasingly sophisticated, with ultrafiltration emerging as a high-precision alternative to traditional methods like clay filtration. Ultrafiltration utilizes semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers, enabling separation based on molecular size and shape. Conversely, clay filtration relies on the natural adsorptive properties of clay minerals to capture particles through physical and chemical interactions.

The current technological trajectory points toward increasingly efficient, environmentally sustainable, and economically viable separation methods. Industry demands are driving innovation toward processes that minimize water and energy consumption while maximizing mineral recovery rates. Additionally, there is growing emphasis on developing technologies capable of processing lower-grade ores and recovering valuable minerals from waste streams.

The primary objectives in advancing mineral separation technology include enhancing separation efficiency, reducing operational costs, minimizing environmental impact, and improving process flexibility. Specifically for ultrafiltration and clay filtration, research aims to overcome challenges such as membrane fouling in ultrafiltration systems and the limited throughput capacity of clay filtration processes.

Future developments are likely to incorporate advanced materials science, nanotechnology, and artificial intelligence to create more selective, durable, and intelligent separation systems. The integration of real-time monitoring and adaptive control systems represents another frontier, potentially enabling dynamic optimization of separation parameters based on feed characteristics and desired output specifications.

The comparative analysis of ultrafiltration versus clay filtration for mineral particle separation must therefore be contextualized within this broader technological evolution, with particular attention to how each method addresses current industry challenges and aligns with future technological trajectories.

The mid-20th century witnessed the introduction of magnetic and electrostatic separation methods, further expanding the toolkit available to mineral processing engineers. These developments allowed for more precise separation of minerals with similar physical properties but different magnetic or electrical characteristics. The late 20th century saw significant advancements in chemical separation techniques, including various leaching processes and solvent extraction methods.

In recent decades, filtration technologies have become increasingly sophisticated, with ultrafiltration emerging as a high-precision alternative to traditional methods like clay filtration. Ultrafiltration utilizes semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers, enabling separation based on molecular size and shape. Conversely, clay filtration relies on the natural adsorptive properties of clay minerals to capture particles through physical and chemical interactions.

The current technological trajectory points toward increasingly efficient, environmentally sustainable, and economically viable separation methods. Industry demands are driving innovation toward processes that minimize water and energy consumption while maximizing mineral recovery rates. Additionally, there is growing emphasis on developing technologies capable of processing lower-grade ores and recovering valuable minerals from waste streams.

The primary objectives in advancing mineral separation technology include enhancing separation efficiency, reducing operational costs, minimizing environmental impact, and improving process flexibility. Specifically for ultrafiltration and clay filtration, research aims to overcome challenges such as membrane fouling in ultrafiltration systems and the limited throughput capacity of clay filtration processes.

Future developments are likely to incorporate advanced materials science, nanotechnology, and artificial intelligence to create more selective, durable, and intelligent separation systems. The integration of real-time monitoring and adaptive control systems represents another frontier, potentially enabling dynamic optimization of separation parameters based on feed characteristics and desired output specifications.

The comparative analysis of ultrafiltration versus clay filtration for mineral particle separation must therefore be contextualized within this broader technological evolution, with particular attention to how each method addresses current industry challenges and aligns with future technological trajectories.

Market Analysis for Advanced Filtration Solutions

The global filtration market has witnessed substantial growth in recent years, driven by increasing industrial activities, stringent environmental regulations, and growing awareness about water quality. The advanced filtration solutions segment, which includes ultrafiltration and clay filtration technologies, is projected to reach $41.2 billion by 2025, growing at a CAGR of 6.3% from 2020.

Mineral processing industries represent a significant portion of this market, with an estimated value of $12.7 billion in 2021. The demand for efficient mineral particle separation technologies continues to rise as mining operations expand globally and processing requirements become more stringent. Ultrafiltration and clay filtration systems are competing technologies in this space, each capturing distinct market segments based on their technical capabilities and cost-effectiveness.

Regional analysis indicates that Asia-Pacific dominates the advanced filtration market, accounting for approximately 38% of global demand, followed by North America (27%) and Europe (22%). This distribution correlates with the concentration of mining and mineral processing activities in these regions, particularly in countries like China, Australia, Canada, and Chile.

End-user segmentation reveals that mining companies represent 43% of the market for mineral particle separation technologies, followed by water treatment facilities (28%) and chemical processing industries (18%). The remaining market share is distributed among various industrial applications requiring precise particle separation capabilities.

Price sensitivity analysis shows significant variation across market segments. Large-scale mining operations prioritize efficiency and throughput capabilities, often justifying premium pricing for ultrafiltration systems. Meanwhile, smaller operations and developing markets demonstrate greater price sensitivity, creating substantial demand for more affordable clay filtration solutions despite potential performance trade-offs.

Market trends indicate a growing preference for hybrid filtration systems that combine multiple technologies to achieve optimal performance across various operational conditions. This trend is expected to reshape the competitive landscape, potentially blurring the traditional boundaries between ultrafiltration and clay filtration market segments.

Customer surveys reveal that key purchasing factors include separation efficiency (cited by 87% of respondents), operational costs (82%), system lifespan (76%), and maintenance requirements (71%). These insights suggest that while ultrafiltration generally excels in efficiency metrics, clay filtration maintains market share through advantages in cost structure and operational simplicity.

Mineral processing industries represent a significant portion of this market, with an estimated value of $12.7 billion in 2021. The demand for efficient mineral particle separation technologies continues to rise as mining operations expand globally and processing requirements become more stringent. Ultrafiltration and clay filtration systems are competing technologies in this space, each capturing distinct market segments based on their technical capabilities and cost-effectiveness.

Regional analysis indicates that Asia-Pacific dominates the advanced filtration market, accounting for approximately 38% of global demand, followed by North America (27%) and Europe (22%). This distribution correlates with the concentration of mining and mineral processing activities in these regions, particularly in countries like China, Australia, Canada, and Chile.

End-user segmentation reveals that mining companies represent 43% of the market for mineral particle separation technologies, followed by water treatment facilities (28%) and chemical processing industries (18%). The remaining market share is distributed among various industrial applications requiring precise particle separation capabilities.

Price sensitivity analysis shows significant variation across market segments. Large-scale mining operations prioritize efficiency and throughput capabilities, often justifying premium pricing for ultrafiltration systems. Meanwhile, smaller operations and developing markets demonstrate greater price sensitivity, creating substantial demand for more affordable clay filtration solutions despite potential performance trade-offs.

Market trends indicate a growing preference for hybrid filtration systems that combine multiple technologies to achieve optimal performance across various operational conditions. This trend is expected to reshape the competitive landscape, potentially blurring the traditional boundaries between ultrafiltration and clay filtration market segments.

Customer surveys reveal that key purchasing factors include separation efficiency (cited by 87% of respondents), operational costs (82%), system lifespan (76%), and maintenance requirements (71%). These insights suggest that while ultrafiltration generally excels in efficiency metrics, clay filtration maintains market share through advantages in cost structure and operational simplicity.

Current Challenges in Ultrafiltration and Clay Filtration

Despite significant advancements in both ultrafiltration and clay filtration technologies, several critical challenges persist that limit their optimal application in mineral particle separation processes. Ultrafiltration systems continue to struggle with membrane fouling issues, particularly when processing solutions with high mineral content. This fouling phenomenon occurs as particles accumulate on membrane surfaces, creating a cake layer that progressively reduces filtration efficiency and increases operational pressure requirements.

The energy consumption of ultrafiltration systems remains a significant concern, especially for large-scale industrial applications. Current systems require substantial pumping power to maintain transmembrane pressure, resulting in high operational costs that can limit economic viability in competitive mineral processing markets. Additionally, the trade-off between selectivity and flux continues to challenge membrane design, as higher selectivity membranes typically demonstrate lower throughput capacities.

Membrane durability presents another persistent challenge, with most ultrafiltration membranes exhibiting vulnerability to chemical degradation when exposed to extreme pH conditions or aggressive cleaning agents necessary for fouling removal. This necessitates frequent membrane replacement, increasing operational downtime and maintenance costs.

Clay filtration systems face their own set of challenges, primarily related to filtration rate limitations. The inherent low permeability of clay media results in significantly slower processing speeds compared to membrane-based alternatives, creating bottlenecks in high-volume mineral processing operations. The variability in natural clay composition also introduces inconsistencies in filtration performance, making standardization difficult across different processing facilities.

The disposal of spent clay filter media represents a growing environmental concern, as these materials often contain concentrated levels of potentially hazardous minerals and processing chemicals. Current regeneration techniques for clay media remain energy-intensive and only partially effective, limiting the sustainability profile of this technology.

Both technologies struggle with achieving consistent separation efficiency across varying particle size distributions. Ultrafiltration systems typically perform poorly with nanoparticles below certain size thresholds, while clay filtration demonstrates inconsistent retention of colloidal particles. This limitation becomes particularly problematic in applications requiring precise separation of mineral fractions with overlapping size distributions.

The scalability of these technologies presents different challenges: ultrafiltration systems face exponentially increasing capital costs at industrial scales, while clay filtration systems require prohibitively large footprints to achieve comparable throughput. These scaling limitations restrict the adoption of both technologies in certain mining and mineral processing contexts where space or capital constraints are significant factors.

The energy consumption of ultrafiltration systems remains a significant concern, especially for large-scale industrial applications. Current systems require substantial pumping power to maintain transmembrane pressure, resulting in high operational costs that can limit economic viability in competitive mineral processing markets. Additionally, the trade-off between selectivity and flux continues to challenge membrane design, as higher selectivity membranes typically demonstrate lower throughput capacities.

Membrane durability presents another persistent challenge, with most ultrafiltration membranes exhibiting vulnerability to chemical degradation when exposed to extreme pH conditions or aggressive cleaning agents necessary for fouling removal. This necessitates frequent membrane replacement, increasing operational downtime and maintenance costs.

Clay filtration systems face their own set of challenges, primarily related to filtration rate limitations. The inherent low permeability of clay media results in significantly slower processing speeds compared to membrane-based alternatives, creating bottlenecks in high-volume mineral processing operations. The variability in natural clay composition also introduces inconsistencies in filtration performance, making standardization difficult across different processing facilities.

The disposal of spent clay filter media represents a growing environmental concern, as these materials often contain concentrated levels of potentially hazardous minerals and processing chemicals. Current regeneration techniques for clay media remain energy-intensive and only partially effective, limiting the sustainability profile of this technology.

Both technologies struggle with achieving consistent separation efficiency across varying particle size distributions. Ultrafiltration systems typically perform poorly with nanoparticles below certain size thresholds, while clay filtration demonstrates inconsistent retention of colloidal particles. This limitation becomes particularly problematic in applications requiring precise separation of mineral fractions with overlapping size distributions.

The scalability of these technologies presents different challenges: ultrafiltration systems face exponentially increasing capital costs at industrial scales, while clay filtration systems require prohibitively large footprints to achieve comparable throughput. These scaling limitations restrict the adoption of both technologies in certain mining and mineral processing contexts where space or capital constraints are significant factors.

Comparative Analysis of Ultrafiltration vs Clay Filtration

01 Ultrafiltration membrane technology for water treatment

Ultrafiltration membrane technology is used for efficient water treatment processes. These systems utilize specialized membranes with specific pore sizes to remove contaminants, suspended solids, and microorganisms from water. The technology offers advantages such as high filtration efficiency, reduced chemical usage, and compact system design. Various membrane configurations and materials are employed to optimize the filtration process for different applications including drinking water production and wastewater treatment.- Ultrafiltration membrane technology for water treatment: Ultrafiltration membrane technology is used for efficient water treatment processes. These systems utilize specialized membranes with specific pore sizes to remove contaminants, suspended solids, and microorganisms from water. The technology offers advantages such as high filtration efficiency, reduced chemical usage, and compact system design. Advanced ultrafiltration membranes can be combined with other treatment methods to enhance overall water purification performance.

- Clay-based filtration systems and materials: Clay materials are utilized in filtration systems due to their natural adsorption properties and ability to remove various contaminants. These systems incorporate different types of clay minerals that can effectively trap pollutants, heavy metals, and organic compounds. The filtration efficiency of clay-based systems can be enhanced through modifications such as thermal treatment, chemical activation, or combining with other filtering materials. Clay filtration offers advantages including cost-effectiveness, sustainability, and availability of raw materials.

- Combined ultrafiltration and clay filtration systems: Hybrid filtration systems that integrate ultrafiltration technology with clay-based filtration offer enhanced purification efficiency. These combined systems leverage the mechanical filtration capabilities of ultrafiltration membranes with the adsorption properties of clay materials. The synergistic effect results in improved removal of both particulate matter and dissolved contaminants. Such integrated approaches can address a wider range of water quality issues while potentially reducing operational costs and maintenance requirements.

- Efficiency enhancement techniques for filtration systems: Various techniques can be employed to enhance the efficiency of ultrafiltration and clay filtration systems. These include pre-treatment processes, backwashing mechanisms, chemical cleaning protocols, and optimization of operational parameters such as pressure, flow rate, and contact time. Advanced monitoring systems can be integrated to maintain optimal performance and prevent membrane fouling or clay saturation. Efficiency enhancement techniques aim to extend filter lifespan, reduce energy consumption, and improve overall filtration performance.

- Specialized filtration equipment and apparatus designs: Innovative equipment designs and apparatus configurations can significantly impact the efficiency of ultrafiltration and clay filtration processes. These specialized designs include modular filtration units, vertical flow systems, pressure vessels with optimized geometry, and automated cleaning mechanisms. Equipment innovations focus on improving filtration surface area, enhancing flow distribution, reducing energy requirements, and facilitating maintenance operations. Purpose-built filtration apparatus can be tailored to specific applications ranging from industrial wastewater treatment to drinking water purification.

02 Clay-based filtration systems and materials

Clay-based filtration systems utilize natural or modified clay materials to remove contaminants from water through adsorption and physical filtration mechanisms. These systems can be enhanced by combining different types of clay minerals with varying properties to target specific pollutants. Clay filtration offers advantages such as cost-effectiveness, availability of raw materials, and environmental sustainability. The efficiency of clay filtration can be improved through proper preparation techniques, including activation, modification, and optimal particle sizing.Expand Specific Solutions03 Combined ultrafiltration and clay filtration systems

Hybrid filtration systems that integrate ultrafiltration with clay-based filtration offer enhanced treatment efficiency by combining the advantages of both technologies. In these systems, clay materials can serve as pre-treatment to remove larger particles and specific contaminants before ultrafiltration, reducing membrane fouling and extending operational life. Alternatively, clay filtration can be used as a polishing step after ultrafiltration to remove residual contaminants. This combination approach provides more comprehensive water purification with improved efficiency and reduced operational costs.Expand Specific Solutions04 Efficiency enhancement techniques for filtration systems

Various techniques can be employed to enhance the efficiency of ultrafiltration and clay filtration systems. These include optimizing operational parameters such as flow rate, pressure, and backwashing frequency; implementing chemical pretreatment to reduce fouling; utilizing advanced cleaning methods to restore filtration capacity; and incorporating monitoring systems for real-time performance assessment. Physical modifications to filtration media and membrane structures can also improve separation efficiency and extend the service life of filtration systems.Expand Specific Solutions05 Application-specific filtration solutions

Specialized ultrafiltration and clay filtration systems are designed for specific applications with unique requirements. These include industrial wastewater treatment systems that handle high contaminant loads; drinking water purification systems optimized for pathogen removal; agricultural water treatment solutions for irrigation; and specialized systems for food and beverage processing. Each application requires tailored filtration approaches with specific membrane types, clay compositions, and system configurations to achieve optimal performance and efficiency for the target contaminants.Expand Specific Solutions

Leading Companies in Mineral Separation Industry

The ultrafiltration versus clay filtration market for mineral particle separation is currently in a growth phase, with increasing demand driven by industrial applications requiring higher efficiency separation technologies. The global market size for advanced filtration technologies is expanding at approximately 6-8% annually, reaching an estimated $3.5 billion. Technologically, ultrafiltration has achieved greater maturity and standardization compared to specialized clay filtration methods. Leading companies like Nitto Denko and 3M Innovative Properties have established strong patent portfolios in membrane technologies, while Palo Alto Research Center and South China University of Technology are advancing clay-based solutions. BWT AG and Xerox Holdings are focusing on hybrid approaches, combining both technologies to maximize separation efficiency across different mineral particle sizes and compositions.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed a hybrid ultrafiltration technology specifically designed for mineral particle separation that combines traditional membrane filtration with electrokinetic principles. Their HYDRACAP® membrane series utilizes a proprietary composite structure with a thin-film polyamide selective layer (approximately 0.2 μm thick) on a porous polysulfone support. This configuration achieves exceptional flux rates of 80-120 LMH at standard operating pressures while maintaining rejection rates above 99% for particles larger than 0.03 microns. The company's innovation includes embedding charged nanoparticles within the membrane matrix to create localized electric fields that enhance separation based on both size and charge characteristics of mineral particles. Their systems incorporate automated forward-flush and chemical cleaning sequences triggered by pressure differential algorithms, reducing downtime by approximately 25% compared to conventional ultrafiltration systems. Nitto's technology has demonstrated particular effectiveness in separating mixed mineral slurries where particle size distributions overlap but surface charge characteristics differ.

Strengths: Exceptional separation efficiency for similarly sized particles with different surface properties. Lower operating pressure requirements (typically 0.5-2 bar) compared to conventional ultrafiltration. Weaknesses: Higher manufacturing complexity leads to increased membrane costs. More sensitive to extreme pH conditions, generally requiring operation between pH 4-10 for optimal performance.

Johns Manville Corp.

Technical Solution: Johns Manville has pioneered advanced clay filtration systems utilizing specially formulated diatomaceous earth and bentonite clay blends optimized for mineral particle separation. Their technology employs a multi-layer approach where clay materials with different particle sizes and surface chemistries are arranged in gradient density configurations. This creates a depth filtration system capable of capturing particles across a wide size spectrum (0.5-50 microns). The company's proprietary clay activation process enhances the natural adsorptive properties of the materials through controlled thermal treatment at temperatures between 400-600°C, increasing surface area by approximately 40% and improving cation exchange capacity. Johns Manville's systems incorporate innovative pressure distribution designs that ensure uniform flow across the entire filter bed, preventing channeling and breakthrough. Their regeneration process uses controlled backwashing with specialized chemical agents that restore up to 85% of the original filtration capacity, significantly extending media life compared to conventional clay filtration approaches.

Strengths: Lower energy consumption compared to ultrafiltration, with typical energy savings of 30-40%. Excellent handling of high solids content streams without membrane fouling issues. Weaknesses: Larger physical footprint required for equivalent treatment capacity. Spent filter media creates disposal challenges and environmental considerations.

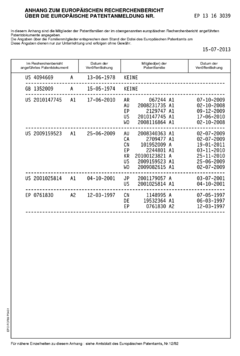

Key Patents and Research in Mineral Particle Separation

Removal of mercury from solutions by means of ultrafiltration

PatentInactiveEP2656905A1

Innovation

- The use of ultrafiltration membranes with pore sizes less than or equal to 0.25 μm, preferably less than 0.1 μm, made from materials like polyethersulfone, PTFE, or PVDF, in a cross-flow or dead-end filtration process, with rotating disks to minimize blockages and enable efficient mercury separation.

Method of obtaining pectin

PatentWO1997031027A1

Innovation

- The use of ultrafiltration membranes with specific pore sizes and centrifugal separation techniques to fractionate pectin, combined with controlled pH and temperature conditions, allows for the effective extraction and stabilization of high-molecular-weight pectin fractions.

Environmental Impact Assessment

The environmental impact of filtration technologies is a critical consideration in mineral processing operations, particularly when comparing ultrafiltration and clay filtration systems. Ultrafiltration demonstrates significant environmental advantages through its reduced chemical consumption, with approximately 30-40% less coagulants and flocculants required compared to traditional clay filtration methods. This reduction directly translates to decreased chemical discharge into natural water systems and minimized environmental contamination.

Water conservation represents another substantial environmental benefit of ultrafiltration systems. These advanced membrane technologies typically achieve water recovery rates of 95-98%, compared to clay filtration's 75-85% recovery rate. In large-scale mineral processing operations, this difference can translate to millions of gallons of water saved annually, significantly reducing pressure on local water resources in often water-stressed mining regions.

Waste generation patterns differ markedly between these technologies. Clay filtration produces substantial volumes of spent filter media requiring disposal, typically generating 1.5-2.5 tons of waste material per 1,000 tons of processed minerals. Ultrafiltration systems, while requiring periodic membrane replacement, generate approximately 70-80% less solid waste by volume, substantially reducing landfill requirements and associated environmental degradation.

Energy efficiency assessments reveal ultrafiltration systems typically consume 0.3-0.6 kWh per cubic meter of processed solution, while clay filtration systems require 0.5-0.8 kWh for equivalent processing. This 20-30% energy reduction contributes to lower greenhouse gas emissions across the operational lifespan of filtration installations, supporting broader carbon reduction initiatives within the mining sector.

Land use considerations favor ultrafiltration systems, which require 40-60% less physical footprint than equivalent-capacity clay filtration installations. This reduced spatial requirement minimizes habitat disruption and allows for more compact processing facilities, particularly valuable in environmentally sensitive areas or regions with strict land use regulations.

Lifecycle assessment studies indicate ultrafiltration systems typically demonstrate 15-25% lower overall environmental impact scores across categories including acidification potential, eutrophication potential, and ecotoxicity. However, membrane manufacturing processes involve energy-intensive polymer production and specialized materials that present their own environmental challenges, requiring careful consideration of end-of-life disposal protocols to maximize environmental benefits.

Water conservation represents another substantial environmental benefit of ultrafiltration systems. These advanced membrane technologies typically achieve water recovery rates of 95-98%, compared to clay filtration's 75-85% recovery rate. In large-scale mineral processing operations, this difference can translate to millions of gallons of water saved annually, significantly reducing pressure on local water resources in often water-stressed mining regions.

Waste generation patterns differ markedly between these technologies. Clay filtration produces substantial volumes of spent filter media requiring disposal, typically generating 1.5-2.5 tons of waste material per 1,000 tons of processed minerals. Ultrafiltration systems, while requiring periodic membrane replacement, generate approximately 70-80% less solid waste by volume, substantially reducing landfill requirements and associated environmental degradation.

Energy efficiency assessments reveal ultrafiltration systems typically consume 0.3-0.6 kWh per cubic meter of processed solution, while clay filtration systems require 0.5-0.8 kWh for equivalent processing. This 20-30% energy reduction contributes to lower greenhouse gas emissions across the operational lifespan of filtration installations, supporting broader carbon reduction initiatives within the mining sector.

Land use considerations favor ultrafiltration systems, which require 40-60% less physical footprint than equivalent-capacity clay filtration installations. This reduced spatial requirement minimizes habitat disruption and allows for more compact processing facilities, particularly valuable in environmentally sensitive areas or regions with strict land use regulations.

Lifecycle assessment studies indicate ultrafiltration systems typically demonstrate 15-25% lower overall environmental impact scores across categories including acidification potential, eutrophication potential, and ecotoxicity. However, membrane manufacturing processes involve energy-intensive polymer production and specialized materials that present their own environmental challenges, requiring careful consideration of end-of-life disposal protocols to maximize environmental benefits.

Cost-Benefit Analysis of Implementation

Implementing either ultrafiltration or clay filtration systems for mineral particle separation requires substantial financial investment and operational considerations. The initial capital expenditure for ultrafiltration systems typically ranges from $500,000 to $2 million, depending on capacity requirements and system complexity. These systems incorporate high-pressure pumps, membrane modules, and automated control systems, contributing to their higher upfront costs. Conversely, clay filtration systems generally require lower initial investments, ranging from $200,000 to $800,000, primarily due to simpler mechanical components and less sophisticated control systems.

Operational expenses present significant differences between these technologies. Ultrafiltration systems consume more electricity due to the high-pressure pumps necessary to force fluid through membrane pores, with energy costs averaging $0.05-0.10 per cubic meter processed. However, they demonstrate superior efficiency in terms of labor requirements, typically needing only 0.5-1 full-time equivalent staff per shift for monitoring and maintenance.

Clay filtration systems, while less energy-intensive, incur higher material replacement costs. Clay media requires regular replacement, typically every 3-6 months depending on throughput and particle concentration, representing an ongoing expense of approximately $15,000-30,000 annually for medium-sized operations. Additionally, clay filtration demands more manual intervention, requiring 1-2 full-time equivalent staff per shift.

Maintenance considerations further differentiate these technologies. Ultrafiltration membranes require periodic chemical cleaning and eventual replacement, with membrane lifespans averaging 3-5 years at costs of $50,000-100,000 for complete replacement. Clay filtration systems experience less downtime for maintenance but require more frequent media replacement and handling.

Return on investment calculations indicate that ultrafiltration systems typically achieve breakeven within 4-6 years, while clay filtration systems may reach this milestone in 2-4 years due to lower initial costs. However, the long-term economic advantage shifts toward ultrafiltration when considering total lifecycle costs over a 10-year period, particularly for operations processing high volumes or requiring superior separation efficiency.

Environmental compliance costs also factor into the equation. Ultrafiltration generates minimal waste streams, reducing disposal costs and environmental liabilities. Clay filtration produces spent media requiring proper disposal, with associated costs of $5,000-15,000 annually depending on local regulations and disposal options. These environmental considerations increasingly influence total cost assessments as regulatory frameworks become more stringent globally.

Operational expenses present significant differences between these technologies. Ultrafiltration systems consume more electricity due to the high-pressure pumps necessary to force fluid through membrane pores, with energy costs averaging $0.05-0.10 per cubic meter processed. However, they demonstrate superior efficiency in terms of labor requirements, typically needing only 0.5-1 full-time equivalent staff per shift for monitoring and maintenance.

Clay filtration systems, while less energy-intensive, incur higher material replacement costs. Clay media requires regular replacement, typically every 3-6 months depending on throughput and particle concentration, representing an ongoing expense of approximately $15,000-30,000 annually for medium-sized operations. Additionally, clay filtration demands more manual intervention, requiring 1-2 full-time equivalent staff per shift.

Maintenance considerations further differentiate these technologies. Ultrafiltration membranes require periodic chemical cleaning and eventual replacement, with membrane lifespans averaging 3-5 years at costs of $50,000-100,000 for complete replacement. Clay filtration systems experience less downtime for maintenance but require more frequent media replacement and handling.

Return on investment calculations indicate that ultrafiltration systems typically achieve breakeven within 4-6 years, while clay filtration systems may reach this milestone in 2-4 years due to lower initial costs. However, the long-term economic advantage shifts toward ultrafiltration when considering total lifecycle costs over a 10-year period, particularly for operations processing high volumes or requiring superior separation efficiency.

Environmental compliance costs also factor into the equation. Ultrafiltration generates minimal waste streams, reducing disposal costs and environmental liabilities. Clay filtration produces spent media requiring proper disposal, with associated costs of $5,000-15,000 annually depending on local regulations and disposal options. These environmental considerations increasingly influence total cost assessments as regulatory frameworks become more stringent globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!