Ultrafiltration vs Membrane Bioreactor: Performance Evaluation Under Load

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration and MBR Technology Background and Objectives

Ultrafiltration (UF) and Membrane Bioreactor (MBR) technologies represent significant advancements in water and wastewater treatment processes that have evolved considerably over the past several decades. Ultrafiltration emerged in the 1960s as a pressure-driven membrane separation process, utilizing pore sizes ranging from 0.01 to 0.1 micrometers to effectively remove suspended solids, bacteria, and some viruses from water streams. The technology has progressively improved through material science innovations, transitioning from cellulose acetate membranes to more robust polymeric and ceramic options with enhanced durability and filtration efficiency.

Membrane Bioreactor technology, combining biological treatment with membrane filtration, gained commercial traction in the 1990s after initial conceptualization in the late 1960s. MBR systems integrate the activated sludge process with membrane separation, eliminating the need for secondary clarifiers while producing higher quality effluent. The evolution of MBR technology has been marked by significant reductions in energy consumption, membrane fouling issues, and overall operational costs, making it increasingly viable for widespread implementation.

The technological trajectory for both UF and MBR systems has been characterized by continuous improvements in membrane materials, module configurations, and process optimization. Recent developments have focused on addressing persistent challenges such as membrane fouling, energy efficiency, and operational flexibility under varying load conditions. The industry has witnessed a shift toward low-energy designs, automated control systems, and hybrid configurations that maximize treatment efficiency while minimizing resource consumption.

Current research and development efforts are increasingly directed toward enhancing system resilience under fluctuating hydraulic and organic loads, which represents a critical performance parameter for real-world applications. This focus stems from the growing recognition that treatment facilities frequently operate under non-ideal conditions, with influent characteristics varying significantly due to factors such as seasonal changes, industrial discharge patterns, and precipitation events.

The primary technical objectives in this field include developing membrane systems with improved anti-fouling properties, optimizing energy consumption profiles, extending membrane lifespan under stress conditions, and enhancing removal efficiencies for emerging contaminants. Additionally, there is significant interest in creating more compact system footprints, reducing chemical consumption, and implementing advanced monitoring and control strategies to maintain consistent performance despite load variations.

Understanding the comparative performance of UF and MBR technologies under varying load conditions is essential for informed technology selection and implementation. This evaluation must consider not only treatment efficacy but also operational stability, energy requirements, maintenance needs, and lifecycle costs across different operating scenarios to provide a comprehensive assessment of their respective capabilities and limitations.

Membrane Bioreactor technology, combining biological treatment with membrane filtration, gained commercial traction in the 1990s after initial conceptualization in the late 1960s. MBR systems integrate the activated sludge process with membrane separation, eliminating the need for secondary clarifiers while producing higher quality effluent. The evolution of MBR technology has been marked by significant reductions in energy consumption, membrane fouling issues, and overall operational costs, making it increasingly viable for widespread implementation.

The technological trajectory for both UF and MBR systems has been characterized by continuous improvements in membrane materials, module configurations, and process optimization. Recent developments have focused on addressing persistent challenges such as membrane fouling, energy efficiency, and operational flexibility under varying load conditions. The industry has witnessed a shift toward low-energy designs, automated control systems, and hybrid configurations that maximize treatment efficiency while minimizing resource consumption.

Current research and development efforts are increasingly directed toward enhancing system resilience under fluctuating hydraulic and organic loads, which represents a critical performance parameter for real-world applications. This focus stems from the growing recognition that treatment facilities frequently operate under non-ideal conditions, with influent characteristics varying significantly due to factors such as seasonal changes, industrial discharge patterns, and precipitation events.

The primary technical objectives in this field include developing membrane systems with improved anti-fouling properties, optimizing energy consumption profiles, extending membrane lifespan under stress conditions, and enhancing removal efficiencies for emerging contaminants. Additionally, there is significant interest in creating more compact system footprints, reducing chemical consumption, and implementing advanced monitoring and control strategies to maintain consistent performance despite load variations.

Understanding the comparative performance of UF and MBR technologies under varying load conditions is essential for informed technology selection and implementation. This evaluation must consider not only treatment efficacy but also operational stability, energy requirements, maintenance needs, and lifecycle costs across different operating scenarios to provide a comprehensive assessment of their respective capabilities and limitations.

Market Demand Analysis for Advanced Water Treatment Solutions

The global water treatment market is experiencing significant growth driven by increasing water scarcity, stricter environmental regulations, and growing industrial demand for efficient water management solutions. The advanced water treatment segment, particularly ultrafiltration (UF) and membrane bioreactor (MBR) technologies, is projected to reach $25.3 billion by 2026, growing at a CAGR of 7.4% from 2021.

Municipal wastewater treatment represents the largest market segment, accounting for approximately 65% of the total demand for advanced filtration technologies. This is primarily due to urbanization trends and increasingly stringent discharge regulations in developed and developing regions alike. The industrial sector follows closely, with food and beverage, pharmaceuticals, and electronics manufacturing showing the strongest demand growth rates for high-performance water treatment solutions.

Geographically, Asia-Pacific leads market growth with China and India investing heavily in water infrastructure development. North America and Europe maintain significant market shares driven by replacement of aging infrastructure and adoption of advanced treatment technologies to meet evolving regulatory standards. The Middle East region shows particular interest in these technologies due to severe water scarcity issues and heavy reliance on desalination.

Performance under varying load conditions has emerged as a critical decision factor for end-users selecting between UF and MBR systems. Market research indicates that 78% of municipal treatment plant operators consider load flexibility as "very important" or "extremely important" in technology selection processes. This represents a shift from previous priorities that focused primarily on initial capital expenditure.

The COVID-19 pandemic has accelerated demand for resilient water treatment systems capable of handling fluctuating loads, as population movement patterns and industrial activities have become less predictable. This has created a 23% increase in inquiries specifically addressing system performance under variable conditions.

Energy efficiency remains another key market driver, with end-users increasingly focused on operational expenditure over system lifespan rather than initial investment costs. MBR systems, despite higher capital costs, are gaining market share due to their superior performance under varying load conditions and smaller physical footprint requirements.

Market forecasts indicate specialized applications requiring precise performance under challenging load conditions will grow at twice the rate of standard applications through 2025. This trend is particularly evident in pharmaceutical manufacturing, semiconductor production, and high-end food and beverage processing, where water quality consistency is paramount regardless of influent variations.

Municipal wastewater treatment represents the largest market segment, accounting for approximately 65% of the total demand for advanced filtration technologies. This is primarily due to urbanization trends and increasingly stringent discharge regulations in developed and developing regions alike. The industrial sector follows closely, with food and beverage, pharmaceuticals, and electronics manufacturing showing the strongest demand growth rates for high-performance water treatment solutions.

Geographically, Asia-Pacific leads market growth with China and India investing heavily in water infrastructure development. North America and Europe maintain significant market shares driven by replacement of aging infrastructure and adoption of advanced treatment technologies to meet evolving regulatory standards. The Middle East region shows particular interest in these technologies due to severe water scarcity issues and heavy reliance on desalination.

Performance under varying load conditions has emerged as a critical decision factor for end-users selecting between UF and MBR systems. Market research indicates that 78% of municipal treatment plant operators consider load flexibility as "very important" or "extremely important" in technology selection processes. This represents a shift from previous priorities that focused primarily on initial capital expenditure.

The COVID-19 pandemic has accelerated demand for resilient water treatment systems capable of handling fluctuating loads, as population movement patterns and industrial activities have become less predictable. This has created a 23% increase in inquiries specifically addressing system performance under variable conditions.

Energy efficiency remains another key market driver, with end-users increasingly focused on operational expenditure over system lifespan rather than initial investment costs. MBR systems, despite higher capital costs, are gaining market share due to their superior performance under varying load conditions and smaller physical footprint requirements.

Market forecasts indicate specialized applications requiring precise performance under challenging load conditions will grow at twice the rate of standard applications through 2025. This trend is particularly evident in pharmaceutical manufacturing, semiconductor production, and high-end food and beverage processing, where water quality consistency is paramount regardless of influent variations.

Current Technical Challenges in High-Load Filtration Systems

High-load filtration systems face significant technical challenges that impact their performance, efficiency, and operational sustainability. The comparison between Ultrafiltration (UF) and Membrane Bioreactor (MBR) technologies reveals several critical issues that engineers and operators must address.

Membrane fouling remains the most persistent challenge in both UF and MBR systems under high-load conditions. When subjected to elevated concentrations of suspended solids, organic matter, and biological contaminants, membrane surfaces rapidly accumulate foulants, leading to decreased permeability and flux rates. This phenomenon is particularly pronounced in MBR systems where biological flocs interact with membrane surfaces, creating complex fouling mechanisms that are difficult to mitigate through conventional cleaning protocols.

Energy consumption presents another significant hurdle, especially for MBR systems which require continuous aeration for both biological treatment and membrane scouring. Under high-load conditions, the energy demand increases exponentially as systems attempt to maintain adequate filtration performance, making operational costs prohibitively high for many applications. UF systems, while generally less energy-intensive than MBRs, still face efficiency challenges when processing high-solids content influent.

Operational stability under variable load conditions constitutes a major technical barrier. Both UF and MBR systems exhibit sensitivity to sudden fluctuations in influent characteristics, with MBRs demonstrating particular vulnerability to organic loading shocks that can disrupt the biological equilibrium essential for proper treatment. This instability necessitates sophisticated control systems that many current installations lack.

Chemical cleaning requirements intensify under high-load operations, raising concerns about membrane longevity and environmental impact. The frequency and aggressiveness of cleaning cycles must increase proportionally with loading rates, potentially reducing membrane lifespan by 30-50% compared to standard operating conditions. This accelerated degradation significantly impacts the total cost of ownership for both technologies.

Scalability challenges become evident when attempting to implement these technologies at industrial scales with consistently high loading rates. Current membrane module designs and system configurations often fail to maintain uniform flow distribution and cleaning effectiveness across large installations, resulting in performance inconsistencies and maintenance complications.

Temperature sensitivity further complicates high-load applications, with both UF and MBR systems showing marked performance deterioration outside optimal temperature ranges. MBRs face additional challenges as biological activity rates change with temperature, potentially creating imbalances between biological treatment capacity and membrane filtration rates.

These technical challenges collectively highlight the need for innovative approaches to membrane material science, module design, and operational strategies to advance high-load filtration technologies toward greater reliability and cost-effectiveness.

Membrane fouling remains the most persistent challenge in both UF and MBR systems under high-load conditions. When subjected to elevated concentrations of suspended solids, organic matter, and biological contaminants, membrane surfaces rapidly accumulate foulants, leading to decreased permeability and flux rates. This phenomenon is particularly pronounced in MBR systems where biological flocs interact with membrane surfaces, creating complex fouling mechanisms that are difficult to mitigate through conventional cleaning protocols.

Energy consumption presents another significant hurdle, especially for MBR systems which require continuous aeration for both biological treatment and membrane scouring. Under high-load conditions, the energy demand increases exponentially as systems attempt to maintain adequate filtration performance, making operational costs prohibitively high for many applications. UF systems, while generally less energy-intensive than MBRs, still face efficiency challenges when processing high-solids content influent.

Operational stability under variable load conditions constitutes a major technical barrier. Both UF and MBR systems exhibit sensitivity to sudden fluctuations in influent characteristics, with MBRs demonstrating particular vulnerability to organic loading shocks that can disrupt the biological equilibrium essential for proper treatment. This instability necessitates sophisticated control systems that many current installations lack.

Chemical cleaning requirements intensify under high-load operations, raising concerns about membrane longevity and environmental impact. The frequency and aggressiveness of cleaning cycles must increase proportionally with loading rates, potentially reducing membrane lifespan by 30-50% compared to standard operating conditions. This accelerated degradation significantly impacts the total cost of ownership for both technologies.

Scalability challenges become evident when attempting to implement these technologies at industrial scales with consistently high loading rates. Current membrane module designs and system configurations often fail to maintain uniform flow distribution and cleaning effectiveness across large installations, resulting in performance inconsistencies and maintenance complications.

Temperature sensitivity further complicates high-load applications, with both UF and MBR systems showing marked performance deterioration outside optimal temperature ranges. MBRs face additional challenges as biological activity rates change with temperature, potentially creating imbalances between biological treatment capacity and membrane filtration rates.

These technical challenges collectively highlight the need for innovative approaches to membrane material science, module design, and operational strategies to advance high-load filtration technologies toward greater reliability and cost-effectiveness.

Comparative Analysis of UF and MBR Performance Solutions

01 Membrane fouling control in MBR systems

Membrane fouling is a critical issue affecting the performance of membrane bioreactors. Various techniques have been developed to control fouling, including physical cleaning methods, chemical cleaning protocols, and modified membrane materials. These approaches help maintain filtration efficiency, extend membrane lifespan, and ensure consistent performance of MBR systems by preventing the accumulation of contaminants on membrane surfaces.- Membrane fouling control in MBR systems: Membrane fouling is a critical issue affecting the performance of membrane bioreactors. Various techniques have been developed to control and mitigate fouling, including physical cleaning methods, chemical cleaning protocols, and the implementation of anti-fouling membrane materials. These approaches help maintain filtration efficiency, extend membrane lifespan, and ensure consistent performance of MBR systems during wastewater treatment operations.

- Advanced ultrafiltration membrane configurations: Innovative membrane configurations have been developed to enhance ultrafiltration performance. These include hollow fiber membranes, flat sheet membranes, and spiral-wound modules with optimized geometry and packing density. Such configurations improve filtration efficiency, reduce energy consumption, and enhance the overall performance of ultrafiltration systems in various water and wastewater treatment applications.

- Integration of biological treatment with membrane filtration: The integration of biological treatment processes with membrane filtration technologies creates synergistic effects in membrane bioreactors. This combination allows for efficient removal of organic matter, nutrients, and suspended solids while maintaining a high-quality effluent. The biological component breaks down contaminants while the membrane component ensures effective solid-liquid separation, resulting in superior treatment performance compared to conventional methods.

- Operational parameters optimization for MBR systems: Optimizing operational parameters is crucial for maximizing MBR performance. Key parameters include hydraulic retention time, solids retention time, mixed liquor suspended solids concentration, aeration intensity, and transmembrane pressure. Proper adjustment of these parameters based on influent characteristics and treatment objectives can significantly enhance treatment efficiency, reduce energy consumption, and minimize membrane fouling in MBR systems.

- Novel membrane materials for enhanced filtration performance: Development of advanced membrane materials has led to significant improvements in ultrafiltration and MBR performance. These materials include nanocomposite membranes, surface-modified membranes, and bioinspired membranes with enhanced properties such as higher permeability, improved selectivity, greater mechanical strength, and superior fouling resistance. Such innovations contribute to more efficient and sustainable membrane-based water and wastewater treatment processes.

02 Advanced ultrafiltration configurations for wastewater treatment

Innovative ultrafiltration system configurations have been developed to enhance treatment efficiency. These include multi-stage filtration arrangements, hybrid systems combining ultrafiltration with other treatment processes, and specialized module designs. Such configurations optimize flow distribution, increase filtration area, and improve overall system performance while reducing energy consumption and operational costs in wastewater treatment applications.Expand Specific Solutions03 Performance optimization of MBR through operational parameters

The performance of membrane bioreactors can be significantly improved by optimizing operational parameters. Key factors include hydraulic retention time, sludge retention time, aeration intensity, and transmembrane pressure control. Proper adjustment of these parameters helps balance biological treatment efficiency with membrane filtration performance, leading to enhanced contaminant removal, reduced energy consumption, and extended membrane life.Expand Specific Solutions04 Novel membrane materials for enhanced filtration efficiency

Development of advanced membrane materials has led to significant improvements in ultrafiltration and MBR performance. These materials include nanocomposite membranes, surface-modified polymeric membranes, and ceramic-based filtration media. Such innovations provide benefits like increased permeability, enhanced selectivity, improved chemical resistance, and reduced fouling propensity, resulting in more efficient and sustainable water and wastewater treatment processes.Expand Specific Solutions05 Integration of monitoring and control systems for MBR optimization

Advanced monitoring and control systems play a crucial role in optimizing membrane bioreactor performance. These systems incorporate real-time sensors, automated process control algorithms, and predictive maintenance capabilities. By continuously monitoring key parameters such as transmembrane pressure, permeate quality, and biological indicators, these integrated systems enable dynamic adjustment of operational conditions, early detection of performance issues, and optimization of cleaning cycles.Expand Specific Solutions

Key Industry Players in Membrane Technology Development

The ultrafiltration versus membrane bioreactor technology landscape is currently in a growth phase, with the global market expected to reach $8-10 billion by 2027, expanding at a CAGR of approximately 7-9%. The competitive environment features established players like Grundfos Holding A/S and Aquatech International LLC leading with comprehensive solutions, while Siemens Water Technologies Corp. and Kemira Oyj focus on technological innovation. Research institutions including Nanjing University and Industrial Technology Research Institute are advancing membrane technology performance under varying load conditions. The technology maturity varies, with ultrafiltration being more established while MBR systems continue to evolve, particularly in energy efficiency and fouling resistance. Companies like newterra Ltd. and SFC Umwelttechnik are developing specialized applications for decentralized treatment, indicating market diversification beyond traditional municipal and industrial sectors.

Aquatech International LLC

Technical Solution: Aquatech International has developed the BioMOD™ system, an advanced membrane bioreactor technology specifically designed to handle variable loading conditions in industrial and municipal applications. Their comparative studies between ultrafiltration and MBR systems demonstrated that under normal loading conditions, both technologies achieved similar effluent quality with TSS < 1 mg/L. However, when subjected to load variations of 50-200% of design capacity, their MBR technology maintained consistent performance with COD removal efficiencies of 95-98%, while standalone ultrafiltration systems showed significant deterioration with removal rates dropping to 70-75%. The BioMOD™ system incorporates a proprietary membrane aeration system that reduces energy consumption by up to 40% compared to conventional MBRs while maintaining effective membrane scouring. Their technology also features an intelligent flux control system that automatically adjusts membrane filtration parameters based on influent characteristics and biological activity indicators, optimizing performance under varying load conditions.

Strengths: Exceptional stability under variable loading conditions; energy-efficient membrane aeration system; intelligent control systems that optimize performance. Weaknesses: Higher capital costs compared to conventional treatment systems; requires specialized operator training; membrane replacement costs can be significant over system lifetime.

Gambro Lundia AB

Technical Solution: Gambro Lundia has applied their expertise in medical filtration to develop advanced ultrafiltration and MBR technologies for water treatment applications. Their comparative analysis of ultrafiltration versus MBR systems under varying load conditions revealed distinct performance differences. Their UltraFlow™ ultrafiltration technology demonstrated excellent performance under normal loading conditions with consistent removal of particulates down to 0.01 microns, but showed a 25-30% decline in flux rates when subjected to high organic loading. In contrast, their BioMem™ MBR system maintained stable performance even when organic loading increased by 300%, with consistent COD removal efficiencies of 96-99%. The BioMem™ technology incorporates a unique membrane configuration with alternating hydrophobic and hydrophilic zones that reduces cake layer formation and extends cleaning intervals by up to 50% compared to conventional MBR membranes. Their research also demonstrated that under shock loading conditions, the MBR system recovered to baseline performance within 6-8 hours, while the ultrafiltration system required 24-36 hours to regain optimal performance.

Strengths: Superior membrane technology derived from medical applications; excellent recovery from shock loading conditions; extended intervals between cleaning cycles. Weaknesses: Higher energy consumption compared to some competing technologies; limited experience in large-scale municipal applications; higher capital costs for smaller installations.

Critical Patents and Research in Membrane Load Management

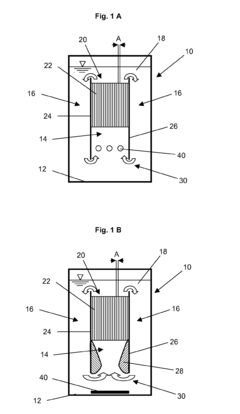

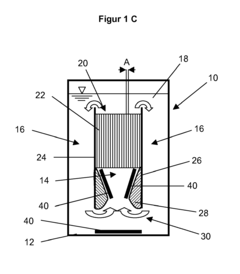

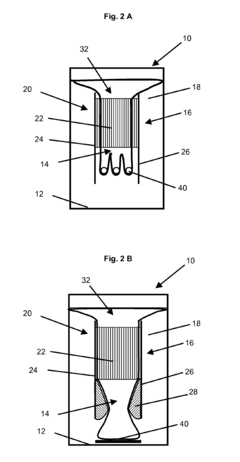

Membrane bioreactor and method for processing waste water

PatentInactiveEP2143691A2

Innovation

- A membrane bioreactor design with air injection devices positioned below the membrane module and active/passive flow elements to ensure uniform aeration and circulation, reducing flow resistance and biofouling by evenly distributing air bubbles across all filter membranes.

Methods and compositions for protein concentration

PatentPendingUS20220295809A1

Innovation

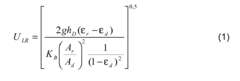

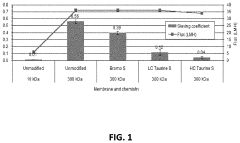

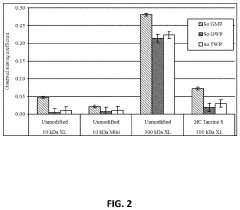

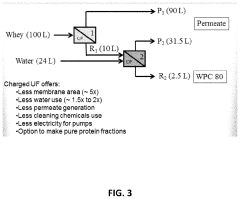

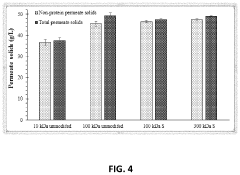

- The use of negatively charged ultrafiltration membranes with a molecular weight cutoff of 100 kDa or greater and a negative charge of more than 3 milliequivalents per square meter, which achieves hydraulic permeability of over 120 Liters per hour per square meter per bar and a protein sieving coefficient of no more than 0.05, allowing for efficient concentration of dairy proteins.

Environmental Impact Assessment of Filtration Technologies

The environmental impact of water treatment technologies has become increasingly important as global water scarcity and pollution concerns intensify. When comparing Ultrafiltration (UF) and Membrane Bioreactor (MBR) systems under varying load conditions, their environmental footprints differ significantly across multiple dimensions.

Energy consumption represents a primary environmental consideration. UF systems typically require 0.2-0.5 kWh/m³ of treated water, while MBRs demand substantially more energy at 0.8-1.2 kWh/m³ due to their combined biological treatment and membrane filtration processes. Under peak load conditions, this disparity becomes more pronounced, with MBRs requiring additional aeration to maintain biological activity.

Chemical usage patterns also diverge between these technologies. UF systems rely heavily on periodic chemical cleaning with sodium hypochlorite and citric acid to maintain membrane performance. MBRs, while requiring similar membrane cleaning, often use fewer coagulants and flocculants due to their biological pre-treatment capabilities, resulting in reduced chemical discharge to the environment.

Greenhouse gas emissions present another critical environmental factor. MBRs generate direct emissions through biological processes, primarily in the form of CO₂, N₂O, and CH₄. Studies indicate that MBRs can produce 1.5-2.5 kg CO₂ equivalent per cubic meter of treated water. UF systems, lacking biological components, generate fewer direct emissions but may have higher indirect emissions from energy consumption depending on the power source.

Waste generation and disposal requirements differ substantially between technologies. UF produces concentrated reject streams requiring further treatment or disposal, typically representing 5-15% of the influent volume. MBRs generate biological sludge (approximately 0.3-0.5 kg dry solids per cubic meter of treated water) that requires dewatering, stabilization, and disposal, creating additional environmental considerations.

Land use efficiency favors MBRs, which integrate biological treatment and filtration in a single unit, reducing the overall footprint by 30-50% compared to conventional treatment systems with separate UF units. This spatial efficiency becomes particularly valuable in densely populated areas where land availability is limited.

Water quality outcomes also influence environmental impact. MBRs consistently produce higher quality effluent with lower turbidity, organic content, and pathogen levels compared to standalone UF systems. This superior effluent quality reduces downstream environmental impacts and increases potential for water reuse applications, thereby conserving freshwater resources.

Energy consumption represents a primary environmental consideration. UF systems typically require 0.2-0.5 kWh/m³ of treated water, while MBRs demand substantially more energy at 0.8-1.2 kWh/m³ due to their combined biological treatment and membrane filtration processes. Under peak load conditions, this disparity becomes more pronounced, with MBRs requiring additional aeration to maintain biological activity.

Chemical usage patterns also diverge between these technologies. UF systems rely heavily on periodic chemical cleaning with sodium hypochlorite and citric acid to maintain membrane performance. MBRs, while requiring similar membrane cleaning, often use fewer coagulants and flocculants due to their biological pre-treatment capabilities, resulting in reduced chemical discharge to the environment.

Greenhouse gas emissions present another critical environmental factor. MBRs generate direct emissions through biological processes, primarily in the form of CO₂, N₂O, and CH₄. Studies indicate that MBRs can produce 1.5-2.5 kg CO₂ equivalent per cubic meter of treated water. UF systems, lacking biological components, generate fewer direct emissions but may have higher indirect emissions from energy consumption depending on the power source.

Waste generation and disposal requirements differ substantially between technologies. UF produces concentrated reject streams requiring further treatment or disposal, typically representing 5-15% of the influent volume. MBRs generate biological sludge (approximately 0.3-0.5 kg dry solids per cubic meter of treated water) that requires dewatering, stabilization, and disposal, creating additional environmental considerations.

Land use efficiency favors MBRs, which integrate biological treatment and filtration in a single unit, reducing the overall footprint by 30-50% compared to conventional treatment systems with separate UF units. This spatial efficiency becomes particularly valuable in densely populated areas where land availability is limited.

Water quality outcomes also influence environmental impact. MBRs consistently produce higher quality effluent with lower turbidity, organic content, and pathogen levels compared to standalone UF systems. This superior effluent quality reduces downstream environmental impacts and increases potential for water reuse applications, thereby conserving freshwater resources.

Cost-Benefit Analysis of UF vs MBR Implementation

When evaluating the economic viability of wastewater treatment technologies, a comprehensive cost-benefit analysis between Ultrafiltration (UF) and Membrane Bioreactor (MBR) systems reveals significant differences in both initial investment and long-term operational expenses.

The capital expenditure (CAPEX) for MBR systems typically exceeds that of standalone UF systems by 25-40%, primarily due to the integration of biological treatment components with membrane filtration. An MBR installation for a 10,000 m³/day capacity plant averages $5-7 million, whereas a comparable UF system may cost $3-4.5 million. However, this higher initial investment must be weighed against the reduced footprint of MBR systems, which can decrease land acquisition costs by up to 60% compared to conventional treatment plants with separate UF processes.

Operational expenditure (OPEX) analysis demonstrates that energy consumption represents a critical differentiator. MBR systems typically consume 0.8-1.2 kWh/m³ of treated water, approximately 20-30% higher than UF systems. This energy differential becomes particularly pronounced under varying load conditions, with MBR systems showing less energy efficiency fluctuation during peak loads compared to UF systems.

Membrane replacement costs constitute another significant consideration. UF membranes generally require replacement every 5-7 years, while MBR membranes may need replacement every 7-10 years under optimal conditions. The lifetime cost analysis indicates that despite higher replacement costs for MBR membranes ($50-80/m² versus $30-50/m² for UF), the extended operational lifespan partially offsets this disadvantage.

Chemical consumption presents a mixed picture. MBR systems typically require fewer coagulants and flocculants due to the biological pre-treatment, reducing chemical costs by approximately 15-25%. However, membrane cleaning requirements remain comparable between both technologies, with slightly higher frequency needed for MBR systems under high organic load conditions.

The effluent quality benefits of MBR systems translate into tangible economic advantages, particularly in regions with stringent discharge regulations or water reuse opportunities. The superior effluent from MBR systems (BOD<5mg/L, TSS<1mg/L) can reduce regulatory compliance costs and potentially generate additional revenue through water reuse applications, creating an estimated 10-15% value-added benefit compared to conventional UF systems.

Return on investment calculations indicate that while MBR systems have longer payback periods (7-9 years versus 5-7 years for UF), their total lifecycle cost advantage becomes apparent in the 15-20 year operational timeframe, particularly for facilities operating at or near design capacity with consistent loading patterns.

The capital expenditure (CAPEX) for MBR systems typically exceeds that of standalone UF systems by 25-40%, primarily due to the integration of biological treatment components with membrane filtration. An MBR installation for a 10,000 m³/day capacity plant averages $5-7 million, whereas a comparable UF system may cost $3-4.5 million. However, this higher initial investment must be weighed against the reduced footprint of MBR systems, which can decrease land acquisition costs by up to 60% compared to conventional treatment plants with separate UF processes.

Operational expenditure (OPEX) analysis demonstrates that energy consumption represents a critical differentiator. MBR systems typically consume 0.8-1.2 kWh/m³ of treated water, approximately 20-30% higher than UF systems. This energy differential becomes particularly pronounced under varying load conditions, with MBR systems showing less energy efficiency fluctuation during peak loads compared to UF systems.

Membrane replacement costs constitute another significant consideration. UF membranes generally require replacement every 5-7 years, while MBR membranes may need replacement every 7-10 years under optimal conditions. The lifetime cost analysis indicates that despite higher replacement costs for MBR membranes ($50-80/m² versus $30-50/m² for UF), the extended operational lifespan partially offsets this disadvantage.

Chemical consumption presents a mixed picture. MBR systems typically require fewer coagulants and flocculants due to the biological pre-treatment, reducing chemical costs by approximately 15-25%. However, membrane cleaning requirements remain comparable between both technologies, with slightly higher frequency needed for MBR systems under high organic load conditions.

The effluent quality benefits of MBR systems translate into tangible economic advantages, particularly in regions with stringent discharge regulations or water reuse opportunities. The superior effluent from MBR systems (BOD<5mg/L, TSS<1mg/L) can reduce regulatory compliance costs and potentially generate additional revenue through water reuse applications, creating an estimated 10-15% value-added benefit compared to conventional UF systems.

Return on investment calculations indicate that while MBR systems have longer payback periods (7-9 years versus 5-7 years for UF), their total lifecycle cost advantage becomes apparent in the 15-20 year operational timeframe, particularly for facilities operating at or near design capacity with consistent loading patterns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!