Exploring Smart Ultrafiltration Solutions for Real-Time Adjustments

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Ultrafiltration Technology Background and Objectives

Ultrafiltration technology has evolved significantly over the past five decades, transforming from simple membrane-based separation processes to sophisticated systems capable of handling complex filtration challenges. Initially developed in the 1960s for laboratory applications, ultrafiltration has progressively expanded into industrial water treatment, bioprocessing, and medical applications. The fundamental principle remains consistent: the use of semi-permeable membranes with pore sizes typically ranging from 0.001 to 0.1 micrometers to separate macromolecules and colloids from solutions.

Recent technological advancements have shifted focus toward "smart" ultrafiltration systems that incorporate real-time monitoring and adjustment capabilities. This evolution represents a paradigm shift from static, predetermined filtration parameters to dynamic, responsive systems that can adapt to changing input conditions. The integration of sensors, advanced control algorithms, and automation has enabled this transition, allowing for optimization of filtration processes under varying conditions.

The global water crisis and increasing industrial demands for precise separation technologies have accelerated research in this field. Smart ultrafiltration systems address critical challenges in water reuse, pharmaceutical production, food processing, and biomedical applications where consistent quality and efficiency are paramount. The technology's trajectory shows a clear movement toward greater intelligence, connectivity, and sustainability.

Current smart ultrafiltration systems typically incorporate pressure sensors, flow meters, turbidity analyzers, and conductivity monitors that feed data to control systems. However, these implementations often lack true adaptive intelligence and predictive capabilities. The next generation aims to incorporate machine learning algorithms that can anticipate fouling events, optimize cleaning cycles, and automatically adjust operational parameters based on influent characteristics.

The primary objectives of smart ultrafiltration technology development include: reducing energy consumption through optimized operation; extending membrane life by preventing excessive fouling; improving filtrate quality through precise control; minimizing chemical usage in cleaning processes; and enabling remote monitoring and management of distributed filtration systems. These objectives align with broader industry goals of sustainability, cost reduction, and process intensification.

Technical challenges remain in sensor reliability under harsh conditions, algorithm development for complex multi-parameter optimization, and system integration across diverse operational environments. Additionally, there is a growing need for standardization of communication protocols and data formats to enable interoperability between components from different manufacturers and facilitate broader adoption of smart ultrafiltration technologies.

The convergence of ultrafiltration with Internet of Things (IoT) capabilities, artificial intelligence, and advanced materials science presents unprecedented opportunities for innovation. As these technologies mature, we anticipate ultrafiltration systems that not only react to changing conditions but predict optimal operational parameters based on historical performance and environmental factors.

Recent technological advancements have shifted focus toward "smart" ultrafiltration systems that incorporate real-time monitoring and adjustment capabilities. This evolution represents a paradigm shift from static, predetermined filtration parameters to dynamic, responsive systems that can adapt to changing input conditions. The integration of sensors, advanced control algorithms, and automation has enabled this transition, allowing for optimization of filtration processes under varying conditions.

The global water crisis and increasing industrial demands for precise separation technologies have accelerated research in this field. Smart ultrafiltration systems address critical challenges in water reuse, pharmaceutical production, food processing, and biomedical applications where consistent quality and efficiency are paramount. The technology's trajectory shows a clear movement toward greater intelligence, connectivity, and sustainability.

Current smart ultrafiltration systems typically incorporate pressure sensors, flow meters, turbidity analyzers, and conductivity monitors that feed data to control systems. However, these implementations often lack true adaptive intelligence and predictive capabilities. The next generation aims to incorporate machine learning algorithms that can anticipate fouling events, optimize cleaning cycles, and automatically adjust operational parameters based on influent characteristics.

The primary objectives of smart ultrafiltration technology development include: reducing energy consumption through optimized operation; extending membrane life by preventing excessive fouling; improving filtrate quality through precise control; minimizing chemical usage in cleaning processes; and enabling remote monitoring and management of distributed filtration systems. These objectives align with broader industry goals of sustainability, cost reduction, and process intensification.

Technical challenges remain in sensor reliability under harsh conditions, algorithm development for complex multi-parameter optimization, and system integration across diverse operational environments. Additionally, there is a growing need for standardization of communication protocols and data formats to enable interoperability between components from different manufacturers and facilitate broader adoption of smart ultrafiltration technologies.

The convergence of ultrafiltration with Internet of Things (IoT) capabilities, artificial intelligence, and advanced materials science presents unprecedented opportunities for innovation. As these technologies mature, we anticipate ultrafiltration systems that not only react to changing conditions but predict optimal operational parameters based on historical performance and environmental factors.

Market Demand Analysis for Real-Time Adjustable Filtration Systems

The global market for real-time adjustable filtration systems has witnessed significant growth in recent years, driven by increasing water scarcity concerns and stringent regulatory requirements for water quality across various industries. The demand for smart ultrafiltration solutions capable of making real-time adjustments is particularly pronounced in sectors such as municipal water treatment, industrial wastewater management, pharmaceutical manufacturing, and food and beverage processing.

Current market research indicates that the smart water management market, which includes intelligent filtration systems, is projected to grow at a compound annual growth rate of approximately 12% through 2028. This growth is primarily fueled by the need for more efficient water utilization and treatment processes that can adapt to fluctuating input conditions without human intervention.

In the municipal water treatment sector, utilities are increasingly seeking solutions that can automatically adjust filtration parameters based on incoming water quality, reducing chemical usage and extending membrane life. This demand is particularly strong in regions experiencing seasonal variations in source water quality or those dealing with emerging contaminants.

Industrial applications represent another significant market segment, with manufacturing facilities looking to optimize water usage while ensuring consistent quality for process applications. The ability to make real-time adjustments to filtration parameters based on production needs offers substantial cost savings through reduced downtime and improved resource efficiency.

The pharmaceutical and biotechnology industries have shown particular interest in smart ultrafiltration systems due to their stringent water quality requirements. These sectors value the ability to maintain precise filtration parameters and receive real-time validation of water quality metrics, supporting compliance with regulatory standards while minimizing production interruptions.

Market analysis reveals a growing preference for integrated solutions that combine advanced sensor technologies with artificial intelligence and machine learning capabilities. End-users are increasingly valuing systems that not only react to changing conditions but can predict maintenance needs and optimize performance parameters proactively.

Regional market assessment shows the highest adoption rates in North America and Europe, where water infrastructure modernization initiatives and stringent environmental regulations are driving implementation. However, the fastest growth is anticipated in Asia-Pacific markets, particularly China and India, where rapid industrialization and increasing water stress are creating urgent demand for more efficient filtration technologies.

Customer feedback indicates that return on investment considerations remain a primary factor in purchasing decisions, with buyers seeking solutions that demonstrate clear operational cost reductions through energy savings, reduced chemical usage, and extended equipment lifespan. This suggests significant market potential for solutions that can effectively communicate and quantify these benefits through comprehensive performance metrics and case studies.

Current market research indicates that the smart water management market, which includes intelligent filtration systems, is projected to grow at a compound annual growth rate of approximately 12% through 2028. This growth is primarily fueled by the need for more efficient water utilization and treatment processes that can adapt to fluctuating input conditions without human intervention.

In the municipal water treatment sector, utilities are increasingly seeking solutions that can automatically adjust filtration parameters based on incoming water quality, reducing chemical usage and extending membrane life. This demand is particularly strong in regions experiencing seasonal variations in source water quality or those dealing with emerging contaminants.

Industrial applications represent another significant market segment, with manufacturing facilities looking to optimize water usage while ensuring consistent quality for process applications. The ability to make real-time adjustments to filtration parameters based on production needs offers substantial cost savings through reduced downtime and improved resource efficiency.

The pharmaceutical and biotechnology industries have shown particular interest in smart ultrafiltration systems due to their stringent water quality requirements. These sectors value the ability to maintain precise filtration parameters and receive real-time validation of water quality metrics, supporting compliance with regulatory standards while minimizing production interruptions.

Market analysis reveals a growing preference for integrated solutions that combine advanced sensor technologies with artificial intelligence and machine learning capabilities. End-users are increasingly valuing systems that not only react to changing conditions but can predict maintenance needs and optimize performance parameters proactively.

Regional market assessment shows the highest adoption rates in North America and Europe, where water infrastructure modernization initiatives and stringent environmental regulations are driving implementation. However, the fastest growth is anticipated in Asia-Pacific markets, particularly China and India, where rapid industrialization and increasing water stress are creating urgent demand for more efficient filtration technologies.

Customer feedback indicates that return on investment considerations remain a primary factor in purchasing decisions, with buyers seeking solutions that demonstrate clear operational cost reductions through energy savings, reduced chemical usage, and extended equipment lifespan. This suggests significant market potential for solutions that can effectively communicate and quantify these benefits through comprehensive performance metrics and case studies.

Current Ultrafiltration Technology Landscape and Challenges

Ultrafiltration technology has evolved significantly over the past decades, transitioning from simple mechanical filtration systems to sophisticated membrane-based solutions. Currently, the global ultrafiltration market is dominated by polymeric membranes, particularly polysulfone, polyethersulfone, and polyvinylidene fluoride (PVDF) based systems. These materials offer excellent chemical resistance and thermal stability, making them suitable for various industrial applications including water treatment, food processing, and biopharmaceutical manufacturing.

Despite technological advancements, ultrafiltration systems face several persistent challenges. Membrane fouling remains the primary obstacle, significantly reducing operational efficiency and increasing maintenance costs. Conventional systems typically operate with fixed parameters, unable to adapt to changing feed compositions or environmental conditions in real-time. This limitation results in suboptimal performance and increased energy consumption, particularly in applications with variable input characteristics.

Geographically, ultrafiltration technology development is concentrated in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading in research and patent filings. European companies have traditionally focused on high-precision applications, while Asian manufacturers have gained market share through cost-effective solutions. This regional specialization has created distinct technological approaches and market segments.

The integration of digital monitoring capabilities into ultrafiltration systems represents an emerging trend, though most current implementations offer only basic data collection without true adaptive control. Sensors for pressure differential, flow rate, and turbidity are common, but more advanced parameters like specific contaminant detection remain limited in commercial systems. The lack of comprehensive real-time monitoring restricts the potential for dynamic system adjustments.

Energy efficiency presents another significant challenge, with conventional ultrafiltration systems requiring substantial power for maintaining transmembrane pressure and cross-flow velocities. Current technologies typically consume between 0.5-2.0 kWh per cubic meter of processed fluid, depending on application specifics and system design. This energy requirement constitutes a major operational cost and environmental consideration.

Regulatory frameworks across different regions add complexity to technology implementation, with varying standards for water quality, process validation, and equipment certification. These disparities create barriers to global technology standardization and complicate cross-border technology transfer. Additionally, the absence of unified protocols for evaluating smart ultrafiltration systems hampers comparative assessment of emerging solutions.

The technical gap between laboratory innovations and industrial-scale implementation remains substantial, with many promising smart ultrafiltration concepts failing to achieve commercial viability due to scalability issues, reliability concerns, or prohibitive costs. Bridging this gap requires interdisciplinary collaboration between membrane scientists, automation engineers, and data analytics specialists.

Despite technological advancements, ultrafiltration systems face several persistent challenges. Membrane fouling remains the primary obstacle, significantly reducing operational efficiency and increasing maintenance costs. Conventional systems typically operate with fixed parameters, unable to adapt to changing feed compositions or environmental conditions in real-time. This limitation results in suboptimal performance and increased energy consumption, particularly in applications with variable input characteristics.

Geographically, ultrafiltration technology development is concentrated in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading in research and patent filings. European companies have traditionally focused on high-precision applications, while Asian manufacturers have gained market share through cost-effective solutions. This regional specialization has created distinct technological approaches and market segments.

The integration of digital monitoring capabilities into ultrafiltration systems represents an emerging trend, though most current implementations offer only basic data collection without true adaptive control. Sensors for pressure differential, flow rate, and turbidity are common, but more advanced parameters like specific contaminant detection remain limited in commercial systems. The lack of comprehensive real-time monitoring restricts the potential for dynamic system adjustments.

Energy efficiency presents another significant challenge, with conventional ultrafiltration systems requiring substantial power for maintaining transmembrane pressure and cross-flow velocities. Current technologies typically consume between 0.5-2.0 kWh per cubic meter of processed fluid, depending on application specifics and system design. This energy requirement constitutes a major operational cost and environmental consideration.

Regulatory frameworks across different regions add complexity to technology implementation, with varying standards for water quality, process validation, and equipment certification. These disparities create barriers to global technology standardization and complicate cross-border technology transfer. Additionally, the absence of unified protocols for evaluating smart ultrafiltration systems hampers comparative assessment of emerging solutions.

The technical gap between laboratory innovations and industrial-scale implementation remains substantial, with many promising smart ultrafiltration concepts failing to achieve commercial viability due to scalability issues, reliability concerns, or prohibitive costs. Bridging this gap requires interdisciplinary collaboration between membrane scientists, automation engineers, and data analytics specialists.

Current Real-Time Adjustment Mechanisms and Implementations

01 Real-time monitoring and control systems for ultrafiltration

Advanced monitoring systems that provide real-time data on ultrafiltration performance parameters such as pressure, flow rate, and membrane condition. These systems enable immediate detection of operational anomalies and automatic adjustments to maintain optimal filtration efficiency. The technology incorporates sensors and controllers that continuously evaluate filtration metrics and implement necessary modifications to process parameters without human intervention.- Real-time monitoring and control systems for ultrafiltration: Advanced monitoring systems that provide real-time data on ultrafiltration performance metrics such as flow rate, pressure, and membrane condition. These systems enable immediate detection of operational anomalies and allow for automated adjustments to maintain optimal filtration efficiency. The technology incorporates sensors and analytical tools that continuously evaluate filtration parameters and trigger appropriate responses to changing conditions.

- Adaptive membrane fouling management: Smart solutions that dynamically adjust operational parameters to prevent and manage membrane fouling in ultrafiltration systems. These technologies use predictive algorithms to anticipate fouling conditions based on feed characteristics and system performance. The systems can automatically modify backwash frequency, chemical cleaning cycles, or flow patterns to extend membrane life and maintain filtration efficiency without manual intervention.

- Energy-efficient ultrafiltration with dynamic power management: Intelligent ultrafiltration systems that optimize energy consumption by making real-time adjustments to pump speeds, pressure settings, and filtration cycles. These solutions incorporate variable frequency drives and smart controllers that respond to changing filtration demands and water quality parameters. The technology enables significant energy savings while maintaining required filtration performance through continuous optimization of operational parameters.

- AI-driven process optimization for ultrafiltration: Ultrafiltration systems enhanced with artificial intelligence that continuously learn from operational data to improve filtration performance. These solutions analyze patterns in water quality, membrane performance, and system efficiency to make intelligent adjustments to operational parameters. The AI algorithms can predict maintenance needs, optimize chemical usage, and adapt to changing feed water conditions, resulting in more consistent filtration quality and reduced operational costs.

- Remote monitoring and cloud-based control of ultrafiltration systems: Networked ultrafiltration solutions that enable remote monitoring and control through cloud-based platforms. These systems collect operational data from distributed filtration units and centralize it for analysis and decision-making. Operators can view real-time performance metrics, receive alerts, and implement adjustments remotely. The technology facilitates predictive maintenance, performance benchmarking across multiple installations, and expert oversight without requiring on-site presence.

02 Adaptive membrane fouling management solutions

Intelligent systems that detect early signs of membrane fouling and automatically adjust operational parameters to extend membrane life and maintain filtration efficiency. These solutions analyze filtration resistance patterns and implement customized cleaning cycles, backwash sequences, or flow adjustments based on real-time fouling conditions. The technology optimizes chemical usage and energy consumption while ensuring consistent filtration quality through dynamic response to changing feed characteristics.Expand Specific Solutions03 AI-powered optimization for ultrafiltration processes

Machine learning and artificial intelligence algorithms that analyze historical and real-time ultrafiltration data to optimize operational parameters. These systems learn from past performance patterns to predict optimal settings for different feed conditions and quality requirements. The technology enables predictive maintenance, energy efficiency improvements, and autonomous decision-making capabilities that continuously refine the filtration process based on multiple input variables and desired output specifications.Expand Specific Solutions04 Smart energy management in ultrafiltration systems

Intelligent energy optimization systems that dynamically adjust power consumption based on filtration requirements and operational conditions. These solutions incorporate variable frequency drives, pressure recovery devices, and smart scheduling algorithms to minimize energy usage while maintaining filtration performance. The technology enables real-time load balancing, peak demand management, and utilization of renewable energy sources when available, resulting in significant operational cost reductions and environmental benefits.Expand Specific Solutions05 Integrated water quality management with feedback control

Comprehensive systems that continuously monitor output water quality parameters and automatically adjust ultrafiltration settings to maintain desired specifications. These solutions incorporate multiple sensor arrays that measure turbidity, particle counts, conductivity, and other quality indicators to ensure consistent product quality despite variations in feed water. The technology enables closed-loop control that responds to quality deviations by modifying flow rates, pressure differentials, or chemical dosing to maintain compliance with quality standards.Expand Specific Solutions

Key Industry Players in Smart Filtration Solutions

The smart ultrafiltration solutions market is currently in a growth phase, characterized by increasing adoption of real-time adjustment technologies across water treatment and medical applications. The global market size is expanding rapidly, projected to reach significant value as industries prioritize efficiency and automation. Technologically, the field shows varying maturity levels, with established players like Gambro Lundia AB leading in medical applications, while Siemens AG and Robert Bosch GmbH drive industrial innovation. Companies such as Koninklijke Philips and Samsung Electronics are leveraging their technological expertise to develop advanced monitoring systems. Meanwhile, specialized filtration companies like Boll & Kirch Filterbau and Seitzschenk Filtersystems are focusing on niche applications, creating a competitive landscape that balances innovation from tech giants with specialized expertise from industry-focused players.

Gambro Lundia AB

Technical Solution: Gambro's smart ultrafiltration technology centers on their Adaptive Dialysis Control System (ADCS) which continuously monitors patient parameters during hemodialysis treatments and automatically adjusts ultrafiltration rates in real-time. Their system incorporates multiple biosensors that track blood volume changes, blood pressure, and plasma refill rates to optimize fluid removal while minimizing adverse events like hypotension. The technology employs machine learning algorithms that adapt to individual patient profiles over time, creating personalized treatment protocols. Gambro's solution includes a closed-loop feedback system that can detect early signs of hemodynamic instability and make immediate adjustments to ultrafiltration parameters without requiring manual intervention from healthcare providers. This approach has demonstrated a 30% reduction in intradialytic hypotensive episodes compared to conventional methods.

Strengths: Specialized expertise in medical ultrafiltration with proven clinical outcomes; highly developed biosensor integration; personalized treatment algorithms. Weaknesses: Solutions primarily focused on medical applications rather than industrial settings; relatively high implementation costs; requires specialized training for healthcare staff.

Boll & Kirch Filterbau GmbH

Technical Solution: Boll & Kirch has developed an intelligent ultrafiltration system called BOLLFILTER Smart Control that incorporates real-time monitoring and adjustment capabilities for industrial filtration processes. Their technology utilizes differential pressure sensors, flow meters, and turbidity analyzers that continuously assess filtration performance and membrane condition. The system features an adaptive control algorithm that automatically optimizes backwashing cycles and filtration parameters based on actual contamination levels rather than fixed time intervals. Their solution includes remote monitoring capabilities through a cloud-based platform that enables predictive maintenance by analyzing performance trends and identifying potential issues before they cause system failures. The technology has been particularly successful in marine applications, where it has demonstrated up to 25% reduction in water consumption for filter cleaning while maintaining optimal filtration efficiency across varying water quality conditions.

Strengths: Robust industrial-grade solutions with proven reliability in harsh environments; comprehensive sensor integration; significant water and energy savings through optimized operations. Weaknesses: Higher initial investment compared to conventional systems; requires integration with existing industrial control systems; primarily focused on specific industrial sectors.

Core Patents and Innovations in Smart Ultrafiltration

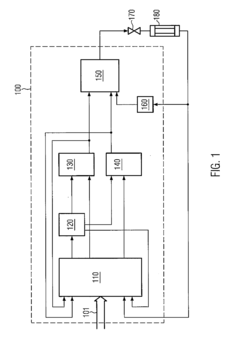

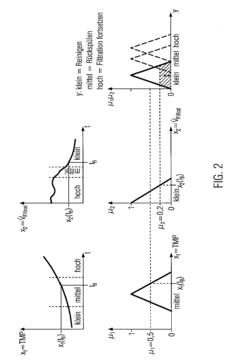

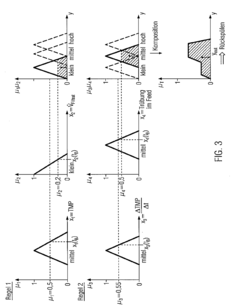

Method for controlling and/or regulation of filter systems for ultrafiltration

PatentInactiveEP2626126A1

Innovation

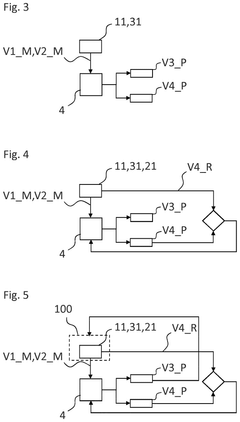

- A method utilizing fuzzy logic and artificial neural networks for intelligent control and regulation of filter systems, allowing for flexible adaptation to process variables and optimizing filtration and cleaning processes without requiring extensive expert knowledge.

Method for monitoring a filtration process

PatentPendingUS20240359136A1

Innovation

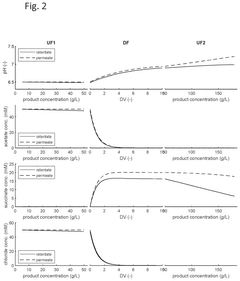

- A method utilizing a filtration process model that solves physical equations describing solute interactions, incorporating real-time measurement data to predict and adjust process variables, allowing for in-line monitoring and control of filtration processes, even beyond the calibrated process range.

Energy Efficiency and Sustainability Considerations

The energy efficiency of ultrafiltration systems represents a critical factor in their overall operational costs and environmental impact. Smart ultrafiltration solutions that enable real-time adjustments can significantly reduce energy consumption through optimized membrane operation and reduced fouling. Current ultrafiltration systems typically consume between 0.5-2.0 kWh per cubic meter of treated water, with energy costs accounting for approximately 30-40% of total operational expenses.

Advanced monitoring systems incorporating pressure sensors, flow meters, and water quality analyzers allow for dynamic adjustment of operating parameters based on actual filtration conditions. These adjustments can reduce energy consumption by 15-25% compared to conventional fixed-parameter systems. Particularly, the implementation of variable frequency drives (VFDs) for pumps enables precise control of transmembrane pressure and cross-flow velocity, resulting in substantial energy savings during periods of lower filtration demand.

Sustainability considerations extend beyond energy efficiency to include the lifecycle assessment of ultrafiltration membranes. Traditional membranes have limited lifespans (3-5 years) and often end up in landfills. Recent innovations in membrane materials have focused on developing bio-based polymers and recyclable components that reduce environmental footprint. For instance, membranes incorporating cellulose nanofibers have demonstrated comparable filtration performance while offering improved biodegradability.

Water recovery rates present another critical sustainability metric. Smart ultrafiltration systems can achieve recovery rates of 90-95% through optimized backwashing schedules and cleaning protocols determined by real-time fouling detection. This represents a significant improvement over conventional systems with typical recovery rates of 75-85%, thereby conserving water resources and reducing waste stream volumes.

Chemical consumption for membrane cleaning constitutes both an economic and environmental concern. Real-time monitoring of membrane fouling enables precise dosing and timing of chemical cleaning agents, potentially reducing chemical usage by 20-30%. Some advanced systems have implemented electrochemical cleaning methods that further minimize chemical requirements while maintaining effective membrane regeneration.

Carbon footprint reduction through smart ultrafiltration extends to remote operations capabilities, which reduce transportation requirements for maintenance personnel. Additionally, integration with renewable energy sources such as solar or wind power can create near-carbon-neutral filtration systems for remote applications. Several pilot projects have demonstrated successful implementation of solar-powered smart ultrafiltration units in rural communities, providing sustainable water treatment solutions while minimizing environmental impact.

Advanced monitoring systems incorporating pressure sensors, flow meters, and water quality analyzers allow for dynamic adjustment of operating parameters based on actual filtration conditions. These adjustments can reduce energy consumption by 15-25% compared to conventional fixed-parameter systems. Particularly, the implementation of variable frequency drives (VFDs) for pumps enables precise control of transmembrane pressure and cross-flow velocity, resulting in substantial energy savings during periods of lower filtration demand.

Sustainability considerations extend beyond energy efficiency to include the lifecycle assessment of ultrafiltration membranes. Traditional membranes have limited lifespans (3-5 years) and often end up in landfills. Recent innovations in membrane materials have focused on developing bio-based polymers and recyclable components that reduce environmental footprint. For instance, membranes incorporating cellulose nanofibers have demonstrated comparable filtration performance while offering improved biodegradability.

Water recovery rates present another critical sustainability metric. Smart ultrafiltration systems can achieve recovery rates of 90-95% through optimized backwashing schedules and cleaning protocols determined by real-time fouling detection. This represents a significant improvement over conventional systems with typical recovery rates of 75-85%, thereby conserving water resources and reducing waste stream volumes.

Chemical consumption for membrane cleaning constitutes both an economic and environmental concern. Real-time monitoring of membrane fouling enables precise dosing and timing of chemical cleaning agents, potentially reducing chemical usage by 20-30%. Some advanced systems have implemented electrochemical cleaning methods that further minimize chemical requirements while maintaining effective membrane regeneration.

Carbon footprint reduction through smart ultrafiltration extends to remote operations capabilities, which reduce transportation requirements for maintenance personnel. Additionally, integration with renewable energy sources such as solar or wind power can create near-carbon-neutral filtration systems for remote applications. Several pilot projects have demonstrated successful implementation of solar-powered smart ultrafiltration units in rural communities, providing sustainable water treatment solutions while minimizing environmental impact.

Integration with IoT and AI Control Systems

The integration of Internet of Things (IoT) and Artificial Intelligence (AI) control systems represents a transformative approach to smart ultrafiltration solutions. These technologies enable real-time monitoring, data collection, and autonomous decision-making capabilities that significantly enhance the performance and efficiency of ultrafiltration processes. Modern ultrafiltration systems equipped with IoT sensors can continuously measure critical parameters such as pressure differentials, flow rates, turbidity, and membrane integrity, creating a comprehensive data ecosystem.

This sensor network forms the foundation of a smart ultrafiltration infrastructure, transmitting operational data to cloud-based platforms where advanced analytics and machine learning algorithms process the information. The AI components analyze historical performance patterns, current operational conditions, and environmental factors to optimize filtration parameters dynamically. These systems can predict membrane fouling before it becomes critical, allowing for preemptive maintenance rather than reactive interventions.

Edge computing capabilities further enhance these integrated systems by enabling rapid processing of time-sensitive data directly at the filtration site. This distributed intelligence architecture reduces latency in control responses and ensures system resilience even during network connectivity issues. The AI algorithms continuously refine their predictive models through reinforcement learning, adapting to changing water quality conditions and operational requirements.

Remote monitoring interfaces provide operators with intuitive dashboards and mobile applications that visualize system performance and alert stakeholders to potential issues. These interfaces often incorporate augmented reality elements that guide maintenance personnel through complex procedures, reducing downtime and human error during interventions. The bidirectional communication capabilities allow for both automated adjustments and manual overrides when necessary.

Security considerations are paramount in these integrated systems, with encryption protocols and access controls protecting both the operational technology (OT) and information technology (IT) components. Blockchain technologies are increasingly being implemented to ensure data integrity and create immutable records of system adjustments and maintenance activities.

The economic benefits of IoT-AI integration in ultrafiltration systems extend beyond operational efficiency. These smart systems enable predictive maintenance scheduling, optimal chemical dosing, and energy consumption optimization, resulting in significant cost savings. Additionally, the detailed operational data collected enables compliance reporting automation and facilitates continuous improvement initiatives through advanced analytics.

This sensor network forms the foundation of a smart ultrafiltration infrastructure, transmitting operational data to cloud-based platforms where advanced analytics and machine learning algorithms process the information. The AI components analyze historical performance patterns, current operational conditions, and environmental factors to optimize filtration parameters dynamically. These systems can predict membrane fouling before it becomes critical, allowing for preemptive maintenance rather than reactive interventions.

Edge computing capabilities further enhance these integrated systems by enabling rapid processing of time-sensitive data directly at the filtration site. This distributed intelligence architecture reduces latency in control responses and ensures system resilience even during network connectivity issues. The AI algorithms continuously refine their predictive models through reinforcement learning, adapting to changing water quality conditions and operational requirements.

Remote monitoring interfaces provide operators with intuitive dashboards and mobile applications that visualize system performance and alert stakeholders to potential issues. These interfaces often incorporate augmented reality elements that guide maintenance personnel through complex procedures, reducing downtime and human error during interventions. The bidirectional communication capabilities allow for both automated adjustments and manual overrides when necessary.

Security considerations are paramount in these integrated systems, with encryption protocols and access controls protecting both the operational technology (OT) and information technology (IT) components. Blockchain technologies are increasingly being implemented to ensure data integrity and create immutable records of system adjustments and maintenance activities.

The economic benefits of IoT-AI integration in ultrafiltration systems extend beyond operational efficiency. These smart systems enable predictive maintenance scheduling, optimal chemical dosing, and energy consumption optimization, resulting in significant cost savings. Additionally, the detailed operational data collected enables compliance reporting automation and facilitates continuous improvement initiatives through advanced analytics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!