How to Use Ultrafiltration to Enhance Reusability of Gray Water

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration technology has evolved significantly over the past four decades, transitioning from laboratory experiments to widespread industrial and municipal applications. Initially developed in the 1960s as a membrane separation process, ultrafiltration has become increasingly sophisticated with advancements in membrane materials, module designs, and process optimization. The technology operates on the principle of size exclusion, utilizing semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers to separate suspended solids, bacteria, viruses, and high molecular weight compounds from water.

The evolution of ultrafiltration has been marked by several key milestones, including the development of hollow fiber membranes in the 1980s, the introduction of backwashing techniques in the 1990s, and more recently, the integration of smart monitoring systems and energy recovery devices. These advancements have significantly improved the efficiency, reliability, and cost-effectiveness of ultrafiltration systems, making them increasingly viable for water treatment applications.

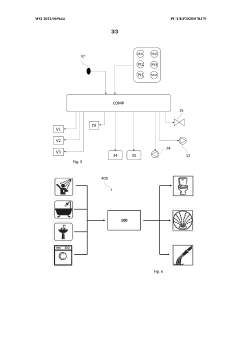

In the context of gray water reuse, ultrafiltration represents a promising technology due to its ability to effectively remove suspended solids, microorganisms, and certain organic compounds without the use of chemicals. Gray water, which constitutes 50-80% of residential wastewater from sources such as showers, bathtubs, washing machines, and bathroom sinks, contains valuable resources that can be reclaimed through proper treatment.

The primary technical objective for ultrafiltration in gray water reuse is to develop robust, energy-efficient systems capable of consistently producing water that meets safety standards for non-potable reuse applications such as irrigation, toilet flushing, and cleaning. This involves optimizing membrane performance to minimize fouling, reduce energy consumption, and extend operational lifespans while maintaining high filtration efficiency.

Secondary objectives include the development of compact, modular systems suitable for decentralized applications, from single-family homes to multi-story buildings and communities. These systems must be designed with user-friendly interfaces, minimal maintenance requirements, and automated operation to ensure widespread adoption.

The technological trajectory points toward the integration of ultrafiltration with complementary technologies such as biological treatment processes, advanced oxidation, and smart monitoring systems. Future developments are likely to focus on novel membrane materials with enhanced anti-fouling properties, improved energy efficiency through pressure recovery systems, and the incorporation of artificial intelligence for predictive maintenance and performance optimization.

As water scarcity intensifies globally due to climate change and population growth, the importance of efficient water reuse technologies becomes increasingly critical. Ultrafiltration stands at the forefront of this challenge, offering a sustainable solution for transforming gray water into a valuable resource rather than a waste product.

The evolution of ultrafiltration has been marked by several key milestones, including the development of hollow fiber membranes in the 1980s, the introduction of backwashing techniques in the 1990s, and more recently, the integration of smart monitoring systems and energy recovery devices. These advancements have significantly improved the efficiency, reliability, and cost-effectiveness of ultrafiltration systems, making them increasingly viable for water treatment applications.

In the context of gray water reuse, ultrafiltration represents a promising technology due to its ability to effectively remove suspended solids, microorganisms, and certain organic compounds without the use of chemicals. Gray water, which constitutes 50-80% of residential wastewater from sources such as showers, bathtubs, washing machines, and bathroom sinks, contains valuable resources that can be reclaimed through proper treatment.

The primary technical objective for ultrafiltration in gray water reuse is to develop robust, energy-efficient systems capable of consistently producing water that meets safety standards for non-potable reuse applications such as irrigation, toilet flushing, and cleaning. This involves optimizing membrane performance to minimize fouling, reduce energy consumption, and extend operational lifespans while maintaining high filtration efficiency.

Secondary objectives include the development of compact, modular systems suitable for decentralized applications, from single-family homes to multi-story buildings and communities. These systems must be designed with user-friendly interfaces, minimal maintenance requirements, and automated operation to ensure widespread adoption.

The technological trajectory points toward the integration of ultrafiltration with complementary technologies such as biological treatment processes, advanced oxidation, and smart monitoring systems. Future developments are likely to focus on novel membrane materials with enhanced anti-fouling properties, improved energy efficiency through pressure recovery systems, and the incorporation of artificial intelligence for predictive maintenance and performance optimization.

As water scarcity intensifies globally due to climate change and population growth, the importance of efficient water reuse technologies becomes increasingly critical. Ultrafiltration stands at the forefront of this challenge, offering a sustainable solution for transforming gray water into a valuable resource rather than a waste product.

Market Analysis for Gray Water Reuse Solutions

The global market for gray water reuse solutions has experienced significant growth in recent years, driven by increasing water scarcity concerns and sustainability initiatives. The market value reached approximately $711 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 13.5% through 2030, potentially reaching $1.9 billion by the end of the forecast period.

Regionally, North America currently dominates the market with about 35% share, followed by Europe at 28% and Asia-Pacific at 24%. The fastest growth is anticipated in the Asia-Pacific region, particularly in countries facing severe water stress like India, China, and Australia, where annual growth rates exceed 15%.

Residential applications currently account for 45% of the market, while commercial and industrial sectors represent 30% and 25% respectively. Ultrafiltration-based systems specifically have shown remarkable market penetration, growing from 18% market share in 2018 to approximately 27% in 2023, demonstrating increasing acceptance of this technology.

Consumer demand patterns reveal growing interest in integrated water management systems that incorporate ultrafiltration for gray water treatment. Market surveys indicate that 68% of new commercial buildings in water-stressed regions now include some form of water recycling infrastructure, with ultrafiltration being the preferred technology in 41% of these installations.

Price sensitivity remains a significant factor influencing market adoption. The average installation cost for residential ultrafiltration systems ranges from $2,000 to $5,500, with operational costs averaging $0.30-$0.45 per cubic meter of treated water. Commercial systems demonstrate better economies of scale, with costs dropping to $0.18-$0.25 per cubic meter for larger installations.

Regulatory frameworks are increasingly favorable toward gray water reuse technologies. Over 35 countries have updated their building codes and water regulations since 2020 to facilitate gray water recycling. This regulatory support has created market opportunities estimated at $320 million annually for ultrafiltration system providers.

Market forecasts suggest that ultrafiltration technologies for gray water reuse will see particularly strong growth in hospitality (hotels), institutional (schools, hospitals), and multi-unit residential sectors, with these segments expected to grow at 16.8%, 15.2%, and 14.7% respectively through 2028. The technology's ability to remove contaminants while maintaining relatively low energy consumption compared to alternatives positions it favorably in these market segments.

Regionally, North America currently dominates the market with about 35% share, followed by Europe at 28% and Asia-Pacific at 24%. The fastest growth is anticipated in the Asia-Pacific region, particularly in countries facing severe water stress like India, China, and Australia, where annual growth rates exceed 15%.

Residential applications currently account for 45% of the market, while commercial and industrial sectors represent 30% and 25% respectively. Ultrafiltration-based systems specifically have shown remarkable market penetration, growing from 18% market share in 2018 to approximately 27% in 2023, demonstrating increasing acceptance of this technology.

Consumer demand patterns reveal growing interest in integrated water management systems that incorporate ultrafiltration for gray water treatment. Market surveys indicate that 68% of new commercial buildings in water-stressed regions now include some form of water recycling infrastructure, with ultrafiltration being the preferred technology in 41% of these installations.

Price sensitivity remains a significant factor influencing market adoption. The average installation cost for residential ultrafiltration systems ranges from $2,000 to $5,500, with operational costs averaging $0.30-$0.45 per cubic meter of treated water. Commercial systems demonstrate better economies of scale, with costs dropping to $0.18-$0.25 per cubic meter for larger installations.

Regulatory frameworks are increasingly favorable toward gray water reuse technologies. Over 35 countries have updated their building codes and water regulations since 2020 to facilitate gray water recycling. This regulatory support has created market opportunities estimated at $320 million annually for ultrafiltration system providers.

Market forecasts suggest that ultrafiltration technologies for gray water reuse will see particularly strong growth in hospitality (hotels), institutional (schools, hospitals), and multi-unit residential sectors, with these segments expected to grow at 16.8%, 15.2%, and 14.7% respectively through 2028. The technology's ability to remove contaminants while maintaining relatively low energy consumption compared to alternatives positions it favorably in these market segments.

Current Ultrafiltration Technologies and Challenges

Ultrafiltration (UF) technology has emerged as a promising solution for gray water treatment due to its ability to effectively remove suspended solids, bacteria, and some viruses. Current UF systems typically employ hollow fiber or flat sheet membrane configurations with pore sizes ranging from 0.01 to 0.1 micrometers, positioning them between microfiltration and nanofiltration in the membrane filtration spectrum. These systems operate under low transmembrane pressure (typically 1-5 bar), making them energy-efficient compared to reverse osmosis systems.

The market has seen significant advancements in membrane materials, with polysulfone (PS), polyethersulfone (PES), and polyvinylidene fluoride (PVDF) emerging as dominant materials due to their excellent chemical resistance and mechanical stability. Recent innovations include the development of modified membranes with antimicrobial properties to reduce biofouling, a persistent challenge in gray water filtration.

Despite these advancements, several technical challenges continue to impede widespread adoption of UF for gray water reuse. Membrane fouling remains the most significant operational challenge, caused by the accumulation of organic matter, scaling minerals, and biofilm formation on membrane surfaces. This fouling leads to decreased flux rates, increased energy consumption, and shortened membrane lifespan, ultimately raising operational costs.

Chemical compatibility presents another challenge, as household gray water often contains detergents, soaps, and other chemicals that can degrade membrane materials over time. Current research focuses on developing more chemically resistant membranes and optimizing cleaning protocols to extend membrane life without compromising filtration efficiency.

Energy consumption, while lower than other advanced treatment technologies, remains a concern for large-scale implementation. Innovations in energy recovery systems and low-pressure operation are being explored to further reduce the energy footprint of UF systems for gray water treatment.

Standardization and regulatory frameworks present non-technical challenges. The lack of uniform quality standards for treated gray water reuse across different jurisdictions creates uncertainty for technology developers and potential users. This regulatory variability complicates the design of UF systems that can meet diverse requirements while remaining cost-effective.

Scale-up challenges persist when transitioning from laboratory or pilot-scale systems to full-scale implementations. Issues related to flow distribution, backwashing efficiency, and membrane module configuration become more pronounced at larger scales, requiring careful engineering solutions.

Recent technological trends include the integration of UF with other treatment processes in hybrid systems, such as UF combined with biological treatment or activated carbon filtration, to address multiple contaminants simultaneously and produce higher quality effluent suitable for more demanding reuse applications.

The market has seen significant advancements in membrane materials, with polysulfone (PS), polyethersulfone (PES), and polyvinylidene fluoride (PVDF) emerging as dominant materials due to their excellent chemical resistance and mechanical stability. Recent innovations include the development of modified membranes with antimicrobial properties to reduce biofouling, a persistent challenge in gray water filtration.

Despite these advancements, several technical challenges continue to impede widespread adoption of UF for gray water reuse. Membrane fouling remains the most significant operational challenge, caused by the accumulation of organic matter, scaling minerals, and biofilm formation on membrane surfaces. This fouling leads to decreased flux rates, increased energy consumption, and shortened membrane lifespan, ultimately raising operational costs.

Chemical compatibility presents another challenge, as household gray water often contains detergents, soaps, and other chemicals that can degrade membrane materials over time. Current research focuses on developing more chemically resistant membranes and optimizing cleaning protocols to extend membrane life without compromising filtration efficiency.

Energy consumption, while lower than other advanced treatment technologies, remains a concern for large-scale implementation. Innovations in energy recovery systems and low-pressure operation are being explored to further reduce the energy footprint of UF systems for gray water treatment.

Standardization and regulatory frameworks present non-technical challenges. The lack of uniform quality standards for treated gray water reuse across different jurisdictions creates uncertainty for technology developers and potential users. This regulatory variability complicates the design of UF systems that can meet diverse requirements while remaining cost-effective.

Scale-up challenges persist when transitioning from laboratory or pilot-scale systems to full-scale implementations. Issues related to flow distribution, backwashing efficiency, and membrane module configuration become more pronounced at larger scales, requiring careful engineering solutions.

Recent technological trends include the integration of UF with other treatment processes in hybrid systems, such as UF combined with biological treatment or activated carbon filtration, to address multiple contaminants simultaneously and produce higher quality effluent suitable for more demanding reuse applications.

Current Ultrafiltration Solutions for Gray Water Treatment

01 Membrane cleaning and regeneration techniques

Various methods for cleaning and regenerating ultrafiltration membranes to extend their reusability. These techniques include chemical cleaning processes, backwashing protocols, and specialized treatments to remove fouling materials. Effective cleaning procedures can significantly increase membrane lifespan and maintain filtration efficiency over multiple use cycles.- Membrane cleaning and regeneration techniques: Various methods for cleaning and regenerating ultrafiltration membranes to extend their reusability. These techniques include chemical cleaning processes, backwashing procedures, and specialized regeneration protocols that remove fouling materials and restore membrane performance. Effective cleaning methods can significantly increase the operational lifespan of ultrafiltration systems and maintain consistent filtration efficiency over multiple use cycles.

- Fouling prevention strategies: Approaches to prevent or minimize membrane fouling in ultrafiltration systems, thereby enhancing reusability. These strategies include pretreatment of feed solutions, modification of membrane surface properties, optimization of operational parameters, and implementation of anti-fouling additives. By reducing fouling, these methods help maintain consistent permeate flux and separation efficiency, extending the functional lifetime of ultrafiltration membranes.

- Automated cleaning and monitoring systems: Integrated systems for automated cleaning, monitoring, and maintenance of ultrafiltration membranes to enhance reusability. These systems incorporate sensors for real-time performance monitoring, automated cleaning cycles, and predictive maintenance algorithms. By optimizing cleaning intervals and parameters based on actual membrane condition, these systems maximize membrane lifespan and operational efficiency while reducing manual intervention requirements.

- Membrane material innovations: Development of advanced membrane materials with enhanced reusability characteristics for ultrafiltration applications. These innovations include self-cleaning surfaces, chemically resistant polymers, composite materials with improved mechanical strength, and modified surface properties. Novel membrane materials can withstand multiple cleaning cycles, resist degradation, and maintain consistent separation performance over extended periods of use.

- Regeneration and recycling of spent ultrafiltration systems: Methods for regenerating and recycling end-of-life ultrafiltration membranes and modules. These approaches include refurbishment techniques, component recycling processes, and sustainable disposal methods. By extending the useful life of ultrafiltration systems beyond their conventional operational period, these methods reduce waste, lower replacement costs, and improve the overall sustainability of ultrafiltration processes.

02 Fouling prevention strategies

Approaches to prevent or minimize membrane fouling in ultrafiltration systems, thereby enhancing reusability. These strategies include pre-treatment of feed solutions, modification of membrane surface properties, optimization of operating conditions, and implementation of anti-fouling additives. Preventing fouling extends membrane life and reduces the frequency of cleaning or replacement.Expand Specific Solutions03 Automated monitoring and maintenance systems

Automated systems for monitoring ultrafiltration performance and implementing maintenance protocols to ensure reusability. These systems include sensors for real-time monitoring, predictive maintenance algorithms, automated cleaning cycles, and performance optimization software. Automation improves consistency in maintenance procedures and extends the operational life of ultrafiltration systems.Expand Specific Solutions04 Membrane material innovations

Development of advanced membrane materials with enhanced reusability characteristics for ultrafiltration applications. These innovations include self-cleaning membranes, materials with improved chemical and mechanical stability, composite membranes with specialized coatings, and novel polymer formulations. Advanced materials can withstand multiple cleaning cycles and maintain consistent performance over extended periods.Expand Specific Solutions05 Regeneration and recycling of ultrafiltration systems

Methods for comprehensive regeneration and recycling of ultrafiltration systems beyond simple cleaning, including refurbishment techniques, component replacement strategies, and system reconfiguration approaches. These methods address not only membrane reusability but also the sustainability of the entire filtration system, including housing, supports, and auxiliary components.Expand Specific Solutions

Leading Companies in Ultrafiltration Membrane Industry

Ultrafiltration for gray water reusability is in a growth phase, with the global water reuse market expanding rapidly due to increasing water scarcity concerns. The technology has reached moderate maturity, with established players like Veolia Water Solutions, Siemens AG, and Hansgrohe SE offering commercial solutions alongside innovative companies such as INTEWA GmbH and HBiO Reto XXI SL specializing in gray water recycling systems. Academic institutions including Tongji University and Washington University in St. Louis are advancing research in this field. The market is characterized by a mix of large multinational corporations and specialized water technology firms, with growing interest from both developed and developing markets as water conservation becomes increasingly critical for sustainable development.

Veolia Water Solutions & Technologies Support SAS

Technical Solution: Veolia has pioneered an integrated ultrafiltration system for gray water recycling called Aquavista™ that combines UF technology with biological treatment processes. Their system utilizes PVDF (polyvinylidene fluoride) hollow fiber membranes with nominal pore size of 0.03 microns, providing a robust physical barrier against contaminants. The process begins with a screening stage to remove large debris, followed by a biological treatment tank where specific bacteria break down organic compounds. The water then passes through the UF membrane modules operating at trans-membrane pressures of 0.1-0.5 bar. Veolia's system incorporates their proprietary IntelliFlux® control system that optimizes filtration cycles, backwash frequency, and chemical cleaning based on real-time membrane performance data. This smart control system has demonstrated up to 20% reduction in energy consumption and 15% increase in water recovery rates compared to conventional control systems. The treated water meets or exceeds ISO 20761:2018 standards for non-potable water reuse applications.

Strengths: Advanced control systems optimize performance and reduce operational costs; combined biological-physical treatment provides superior organic contaminant removal; extensive global installation base demonstrates proven reliability. Weaknesses: Complex system requires skilled operators; higher capital and maintenance costs than simpler systems; biological component requires careful monitoring to maintain microbial population health.

INTEWA GmbH

Technical Solution: INTEWA has developed the AQUALOOP ultrafiltration system specifically designed for decentralized gray water recycling. Their approach utilizes submerged UF membrane modules with hollow fibers made of recyclable PES (polyethersulfone) material with a pore size of approximately 0.02 microns. The system operates on a gravity-based principle where gray water first enters a collection tank with pre-filtration, then undergoes biological treatment in an aerated bioreactor. The UF membranes are submerged directly in the bioreactor, creating a membrane bioreactor (MBR) configuration that combines biological degradation with physical filtration. INTEWA's system operates at very low trans-membrane pressure (0.05-0.2 bar), reducing energy consumption to approximately 1.5-2.0 kWh per cubic meter of treated water. Their patented air-scouring system creates turbulence around the membrane surface to minimize fouling while using up to 30% less air than conventional systems. The modular design allows for capacity expansion by simply adding membrane modules, with systems ranging from 300 liters/day for single households to 10,000+ liters/day for commercial applications.

Strengths: Low energy consumption due to gravity-based operation; compact design suitable for retrofitting in existing buildings; simple maintenance requirements accessible to non-technical users. Weaknesses: Limited capacity for handling sudden flow variations; requires regular membrane cleaning; biological component needs stabilization period after system startup or dormant periods.

Key Membrane Technologies for Gray Water Filtration

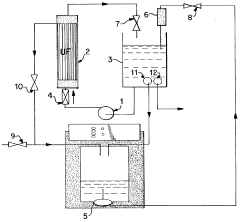

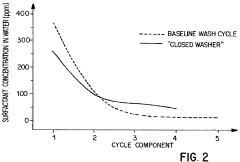

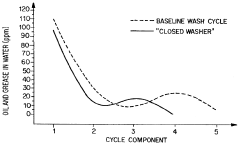

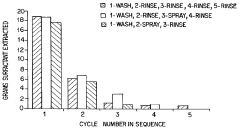

Process and system for recycling and reusing gray water

PatentInactiveUS5868937A

Innovation

- Implementing a hollow-fiber membrane ultrafiltration system with a molecular weight cutoff range of 5,000 to 500,000 in a closed-loop recycle process, where the permeate is reused for additional cleaning extractions in clothes washers, and incorporating necessary system components for long-life operation and prefiltration to manage debris and lint.

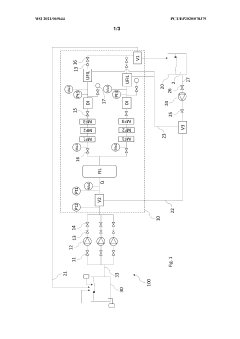

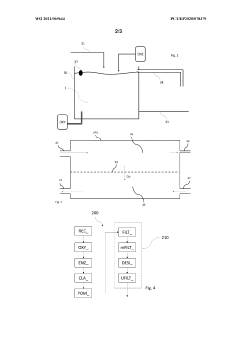

Grey water treatment and recycling system, grey water treatment and recycling process, system control method

PatentWO2021069644A1

Innovation

- A gray water treatment system comprising a first reception tank with an oxygenation unit and enzyme delivery, a fluidic treatment circuit with filtration, microfiltration, disinfection, and membrane ultrafiltration units, and a control automaton that manages pressure and filling information to automate the treatment process, allowing for efficient and modular treatment.

Regulatory Framework for Water Reuse Systems

The regulatory landscape governing water reuse systems varies significantly across regions and countries, creating a complex framework that ultrafiltration technology must navigate. At the international level, organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) provide guidelines that serve as reference points for national regulations. These guidelines typically focus on water quality parameters, treatment requirements, and monitoring protocols to ensure public health protection.

In the United States, the Environmental Protection Agency (EPA) has established the Guidelines for Water Reuse, which provides comprehensive recommendations for different categories of reclaimed water use. However, actual regulations are implemented at the state level, resulting in varying standards. States like California, Arizona, and Florida have developed robust regulatory frameworks due to their water scarcity challenges. California's Title 22 regulations are particularly noteworthy, setting stringent standards for treated wastewater quality based on intended use.

The European Union operates under the Water Framework Directive and has recently adopted specific regulations on minimum requirements for water reuse (EU 2020/741), which will be fully applicable by 2023. These regulations establish harmonized minimum water quality requirements for agricultural irrigation across member states, with ultrafiltration systems needing to meet specific performance criteria.

In Australia, the National Water Quality Management Strategy provides guidelines for water recycling, with state-based regulatory frameworks implementing these recommendations. The Australian Guidelines for Water Recycling emphasize a risk management approach, requiring comprehensive hazard analysis and critical control points (HACCP) for water reuse systems.

Regulatory compliance for ultrafiltration systems in gray water reuse typically involves several key components: water quality standards (microbiological, chemical, and physical parameters), treatment process validation, monitoring requirements, and reporting obligations. Many jurisdictions employ a fit-for-purpose approach, where water quality requirements are tailored to the intended end-use of the reclaimed water.

Emerging regulatory trends include increased focus on emerging contaminants of concern, such as pharmaceuticals and personal care products, which ultrafiltration systems must address. Additionally, there is growing regulatory interest in decentralized water reuse systems, with authorities developing frameworks to ensure these smaller-scale applications maintain appropriate safety standards.

For technology developers and implementers, navigating this complex regulatory landscape requires ongoing engagement with regulatory authorities, participation in standards development, and investment in compliance testing and documentation to demonstrate that ultrafiltration-based gray water reuse systems meet applicable requirements.

In the United States, the Environmental Protection Agency (EPA) has established the Guidelines for Water Reuse, which provides comprehensive recommendations for different categories of reclaimed water use. However, actual regulations are implemented at the state level, resulting in varying standards. States like California, Arizona, and Florida have developed robust regulatory frameworks due to their water scarcity challenges. California's Title 22 regulations are particularly noteworthy, setting stringent standards for treated wastewater quality based on intended use.

The European Union operates under the Water Framework Directive and has recently adopted specific regulations on minimum requirements for water reuse (EU 2020/741), which will be fully applicable by 2023. These regulations establish harmonized minimum water quality requirements for agricultural irrigation across member states, with ultrafiltration systems needing to meet specific performance criteria.

In Australia, the National Water Quality Management Strategy provides guidelines for water recycling, with state-based regulatory frameworks implementing these recommendations. The Australian Guidelines for Water Recycling emphasize a risk management approach, requiring comprehensive hazard analysis and critical control points (HACCP) for water reuse systems.

Regulatory compliance for ultrafiltration systems in gray water reuse typically involves several key components: water quality standards (microbiological, chemical, and physical parameters), treatment process validation, monitoring requirements, and reporting obligations. Many jurisdictions employ a fit-for-purpose approach, where water quality requirements are tailored to the intended end-use of the reclaimed water.

Emerging regulatory trends include increased focus on emerging contaminants of concern, such as pharmaceuticals and personal care products, which ultrafiltration systems must address. Additionally, there is growing regulatory interest in decentralized water reuse systems, with authorities developing frameworks to ensure these smaller-scale applications maintain appropriate safety standards.

For technology developers and implementers, navigating this complex regulatory landscape requires ongoing engagement with regulatory authorities, participation in standards development, and investment in compliance testing and documentation to demonstrate that ultrafiltration-based gray water reuse systems meet applicable requirements.

Energy Efficiency in Ultrafiltration Processes

Energy efficiency represents a critical factor in the implementation of ultrafiltration systems for gray water treatment. Current ultrafiltration processes typically consume between 0.5-2.0 kWh per cubic meter of treated water, depending on system configuration and operational parameters. This energy consumption significantly impacts the economic viability and environmental sustainability of gray water reuse initiatives.

The primary energy demands in ultrafiltration systems stem from pumping requirements to overcome transmembrane pressure, backwashing operations, and peripheral equipment such as monitoring systems and chemical dosing units. Research indicates that pumping alone can account for 60-80% of the total energy consumption in ultrafiltration processes, highlighting the importance of optimizing hydraulic design and pressure management.

Recent technological innovations have demonstrated promising approaches to enhance energy efficiency. Variable frequency drives (VFDs) for pumps have shown potential to reduce energy consumption by 20-30% by adjusting operational speeds based on real-time demand. Additionally, energy recovery devices, similar to those used in reverse osmosis systems, are being adapted for ultrafiltration applications with preliminary results showing energy savings of 15-25%.

Membrane fouling represents a significant challenge to energy efficiency, as it necessitates higher operating pressures and more frequent cleaning cycles. Advanced anti-fouling membranes incorporating nanomaterials have demonstrated the ability to maintain stable flux rates for longer periods, thereby reducing energy requirements by up to 18% compared to conventional membranes. Similarly, optimized backwashing protocols based on real-time monitoring rather than fixed schedules can reduce energy consumption by 10-15%.

System design considerations also play a crucial role in energy optimization. Decentralized systems located closer to gray water sources can minimize pumping distances and associated energy losses. Furthermore, hybrid systems that combine ultrafiltration with low-energy biological treatment processes have shown promising results, with overall energy reductions of 25-40% compared to standalone ultrafiltration systems.

Renewable energy integration represents another frontier in improving the sustainability of ultrafiltration systems. Solar-powered ultrafiltration units have been successfully deployed in various pilot projects, particularly in remote or off-grid locations. These systems can achieve near-zero operational carbon footprints, though initial capital costs remain higher than conventional grid-powered alternatives.

The primary energy demands in ultrafiltration systems stem from pumping requirements to overcome transmembrane pressure, backwashing operations, and peripheral equipment such as monitoring systems and chemical dosing units. Research indicates that pumping alone can account for 60-80% of the total energy consumption in ultrafiltration processes, highlighting the importance of optimizing hydraulic design and pressure management.

Recent technological innovations have demonstrated promising approaches to enhance energy efficiency. Variable frequency drives (VFDs) for pumps have shown potential to reduce energy consumption by 20-30% by adjusting operational speeds based on real-time demand. Additionally, energy recovery devices, similar to those used in reverse osmosis systems, are being adapted for ultrafiltration applications with preliminary results showing energy savings of 15-25%.

Membrane fouling represents a significant challenge to energy efficiency, as it necessitates higher operating pressures and more frequent cleaning cycles. Advanced anti-fouling membranes incorporating nanomaterials have demonstrated the ability to maintain stable flux rates for longer periods, thereby reducing energy requirements by up to 18% compared to conventional membranes. Similarly, optimized backwashing protocols based on real-time monitoring rather than fixed schedules can reduce energy consumption by 10-15%.

System design considerations also play a crucial role in energy optimization. Decentralized systems located closer to gray water sources can minimize pumping distances and associated energy losses. Furthermore, hybrid systems that combine ultrafiltration with low-energy biological treatment processes have shown promising results, with overall energy reductions of 25-40% compared to standalone ultrafiltration systems.

Renewable energy integration represents another frontier in improving the sustainability of ultrafiltration systems. Solar-powered ultrafiltration units have been successfully deployed in various pilot projects, particularly in remote or off-grid locations. These systems can achieve near-zero operational carbon footprints, though initial capital costs remain higher than conventional grid-powered alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!