Ultrafiltration vs Reverse Osmosis: Which Ensures Better Filtration?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Water Filtration Technology Evolution and Objectives

Water filtration technology has evolved significantly over the past century, transitioning from basic sand and gravel filtration methods to sophisticated membrane-based systems. The journey began with conventional filtration techniques in the early 20th century, primarily focused on removing visible particulates. By mid-century, advancements in material science led to the development of more refined filtration media capable of capturing smaller contaminants.

The 1960s marked a pivotal moment with the commercialization of reverse osmosis (RO) technology, initially developed for seawater desalination. This innovation revolutionized water purification by enabling the removal of dissolved salts and microscopic contaminants. Ultrafiltration (UF) technology emerged in the 1980s as a cost-effective alternative for certain applications, offering excellent particulate removal without the energy requirements of RO systems.

Recent decades have witnessed remarkable improvements in membrane materials, energy efficiency, and system integration. Modern filtration technologies now incorporate smart sensors, automated cleaning mechanisms, and hybrid approaches combining multiple filtration methods. The industry has progressively moved toward more sustainable solutions with reduced chemical usage and lower environmental footprints.

The primary objective in comparing ultrafiltration and reverse osmosis technologies is to determine optimal filtration solutions for specific water quality challenges. This evaluation must consider removal efficiency across various contaminant types, energy consumption, maintenance requirements, and overall cost-effectiveness. Understanding the fundamental differences between these technologies is crucial for appropriate application selection.

For ultrafiltration, the key technical goals include improving membrane durability, enhancing fouling resistance, and increasing flux rates while maintaining selectivity. For reverse osmosis, objectives focus on developing membranes with higher rejection rates at lower operating pressures, reducing concentration polarization, and minimizing energy consumption.

Both technologies aim to address emerging contaminants of concern, including pharmaceutical residues, microplastics, and PFAS compounds. The industry is also pursuing innovations in modular design to enhance scalability and adaptability across diverse deployment scenarios, from household units to municipal treatment plants.

The evolution trajectory suggests convergence toward integrated systems that leverage the strengths of both technologies while mitigating their respective limitations. Future development will likely emphasize smart water systems with real-time monitoring capabilities, predictive maintenance features, and adaptive operation based on influent water quality variations.

The 1960s marked a pivotal moment with the commercialization of reverse osmosis (RO) technology, initially developed for seawater desalination. This innovation revolutionized water purification by enabling the removal of dissolved salts and microscopic contaminants. Ultrafiltration (UF) technology emerged in the 1980s as a cost-effective alternative for certain applications, offering excellent particulate removal without the energy requirements of RO systems.

Recent decades have witnessed remarkable improvements in membrane materials, energy efficiency, and system integration. Modern filtration technologies now incorporate smart sensors, automated cleaning mechanisms, and hybrid approaches combining multiple filtration methods. The industry has progressively moved toward more sustainable solutions with reduced chemical usage and lower environmental footprints.

The primary objective in comparing ultrafiltration and reverse osmosis technologies is to determine optimal filtration solutions for specific water quality challenges. This evaluation must consider removal efficiency across various contaminant types, energy consumption, maintenance requirements, and overall cost-effectiveness. Understanding the fundamental differences between these technologies is crucial for appropriate application selection.

For ultrafiltration, the key technical goals include improving membrane durability, enhancing fouling resistance, and increasing flux rates while maintaining selectivity. For reverse osmosis, objectives focus on developing membranes with higher rejection rates at lower operating pressures, reducing concentration polarization, and minimizing energy consumption.

Both technologies aim to address emerging contaminants of concern, including pharmaceutical residues, microplastics, and PFAS compounds. The industry is also pursuing innovations in modular design to enhance scalability and adaptability across diverse deployment scenarios, from household units to municipal treatment plants.

The evolution trajectory suggests convergence toward integrated systems that leverage the strengths of both technologies while mitigating their respective limitations. Future development will likely emphasize smart water systems with real-time monitoring capabilities, predictive maintenance features, and adaptive operation based on influent water quality variations.

Market Analysis of Advanced Water Filtration Systems

The global water filtration market has experienced substantial growth in recent years, driven by increasing concerns about water quality, growing industrialization, and stricter environmental regulations. The advanced water filtration systems market, particularly focusing on ultrafiltration (UF) and reverse osmosis (RO) technologies, was valued at approximately $29.2 billion in 2022 and is projected to reach $44.5 billion by 2028, growing at a CAGR of 7.3%.

Residential applications currently dominate the market share, accounting for nearly 40% of total revenue. This is primarily due to rising awareness about waterborne diseases and increasing disposable income in developing economies. Commercial and industrial sectors follow closely, with healthcare facilities showing the fastest growth rate at 9.1% annually due to stringent water quality requirements.

Geographically, North America leads the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid urbanization, industrial development, and increasing government initiatives for clean water access in countries like China, India, and Southeast Asian nations.

The ultrafiltration segment currently holds about 38% of the advanced filtration market, valued at $11.1 billion, while reverse osmosis systems account for 45% at $13.1 billion. The remaining market share is distributed among nanofiltration and other emerging technologies.

Consumer preferences are increasingly shifting toward integrated systems that combine multiple filtration technologies. Systems offering both ultrafiltration and reverse osmosis capabilities have seen a 23% increase in demand over the past two years, indicating a growing market for comprehensive water purification solutions.

Price sensitivity varies significantly across regions, with developed markets focusing more on technological advancements and efficiency, while developing markets prioritize affordability and maintenance costs. The average price point for residential UF systems ranges from $200-600, while RO systems typically cost between $300-1,200 depending on capacity and features.

Distribution channels are evolving, with online sales growing at 15% annually compared to traditional retail channels at 5%. Direct-to-consumer models are gaining traction, particularly for replacement filters and maintenance services, creating new revenue streams for manufacturers.

The competitive landscape features both established players like Pentair, Dow Chemical Company, and 3M, alongside emerging specialized companies focusing on technological innovations. Market consolidation through mergers and acquisitions has increased by 18% in the past three years, indicating a trend toward industry concentration.

Residential applications currently dominate the market share, accounting for nearly 40% of total revenue. This is primarily due to rising awareness about waterborne diseases and increasing disposable income in developing economies. Commercial and industrial sectors follow closely, with healthcare facilities showing the fastest growth rate at 9.1% annually due to stringent water quality requirements.

Geographically, North America leads the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid urbanization, industrial development, and increasing government initiatives for clean water access in countries like China, India, and Southeast Asian nations.

The ultrafiltration segment currently holds about 38% of the advanced filtration market, valued at $11.1 billion, while reverse osmosis systems account for 45% at $13.1 billion. The remaining market share is distributed among nanofiltration and other emerging technologies.

Consumer preferences are increasingly shifting toward integrated systems that combine multiple filtration technologies. Systems offering both ultrafiltration and reverse osmosis capabilities have seen a 23% increase in demand over the past two years, indicating a growing market for comprehensive water purification solutions.

Price sensitivity varies significantly across regions, with developed markets focusing more on technological advancements and efficiency, while developing markets prioritize affordability and maintenance costs. The average price point for residential UF systems ranges from $200-600, while RO systems typically cost between $300-1,200 depending on capacity and features.

Distribution channels are evolving, with online sales growing at 15% annually compared to traditional retail channels at 5%. Direct-to-consumer models are gaining traction, particularly for replacement filters and maintenance services, creating new revenue streams for manufacturers.

The competitive landscape features both established players like Pentair, Dow Chemical Company, and 3M, alongside emerging specialized companies focusing on technological innovations. Market consolidation through mergers and acquisitions has increased by 18% in the past three years, indicating a trend toward industry concentration.

UF vs RO: Technical Challenges and Limitations

Ultrafiltration (UF) and Reverse Osmosis (RO) technologies face distinct technical challenges that impact their filtration efficiency and application suitability. UF systems primarily struggle with membrane fouling, where particulates accumulate on membrane surfaces, reducing permeability and filtration effectiveness. This fouling occurs through various mechanisms including cake formation, pore blocking, and concentration polarization, requiring frequent cleaning cycles that increase operational downtime and maintenance costs.

Temperature sensitivity presents another significant limitation for UF membranes, as performance characteristics change substantially across different thermal conditions. Most UF membranes operate optimally between 20-40°C, with efficiency decreasing markedly outside this range, restricting their application in certain industrial processes with extreme temperature requirements.

RO systems face even more severe fouling issues due to their tighter membrane structure, with biological fouling (biofouling) presenting a particularly persistent challenge. Microorganisms form biofilms on membrane surfaces that are difficult to remove even with aggressive cleaning protocols, often necessitating membrane replacement rather than restoration.

Energy consumption represents RO's most significant limitation. The high pressure required to overcome osmotic pressure (typically 200-1,000 psi compared to UF's 10-100 psi) translates to substantial energy costs, making RO economically challenging for large-scale applications in regions with high electricity prices. This energy intensity also contributes to a larger carbon footprint compared to UF systems.

Recovery rate disparities exist between the technologies, with RO systems typically achieving only 50-85% water recovery versus UF's 90-95%. This means RO systems produce more waste concentrate that requires proper disposal, creating additional environmental and cost considerations.

Membrane durability presents ongoing challenges for both technologies. UF membranes typically last 3-5 years while RO membranes may require replacement every 2-3 years under optimal conditions. However, in challenging water conditions with high fouling potential, membrane lifespan can decrease dramatically, increasing operational costs.

Selective filtration capabilities create application limitations. UF cannot remove dissolved salts or most dissolved organics, making it unsuitable for desalination. Conversely, RO's extremely tight filtration removes beneficial minerals along with contaminants, potentially requiring remineralization for drinking water applications.

Scale formation particularly affects RO systems when minerals exceed their solubility limits and precipitate onto membrane surfaces. This scaling reduces membrane performance and can cause permanent damage if not properly managed through antiscalant chemicals and pretreatment systems.

Temperature sensitivity presents another significant limitation for UF membranes, as performance characteristics change substantially across different thermal conditions. Most UF membranes operate optimally between 20-40°C, with efficiency decreasing markedly outside this range, restricting their application in certain industrial processes with extreme temperature requirements.

RO systems face even more severe fouling issues due to their tighter membrane structure, with biological fouling (biofouling) presenting a particularly persistent challenge. Microorganisms form biofilms on membrane surfaces that are difficult to remove even with aggressive cleaning protocols, often necessitating membrane replacement rather than restoration.

Energy consumption represents RO's most significant limitation. The high pressure required to overcome osmotic pressure (typically 200-1,000 psi compared to UF's 10-100 psi) translates to substantial energy costs, making RO economically challenging for large-scale applications in regions with high electricity prices. This energy intensity also contributes to a larger carbon footprint compared to UF systems.

Recovery rate disparities exist between the technologies, with RO systems typically achieving only 50-85% water recovery versus UF's 90-95%. This means RO systems produce more waste concentrate that requires proper disposal, creating additional environmental and cost considerations.

Membrane durability presents ongoing challenges for both technologies. UF membranes typically last 3-5 years while RO membranes may require replacement every 2-3 years under optimal conditions. However, in challenging water conditions with high fouling potential, membrane lifespan can decrease dramatically, increasing operational costs.

Selective filtration capabilities create application limitations. UF cannot remove dissolved salts or most dissolved organics, making it unsuitable for desalination. Conversely, RO's extremely tight filtration removes beneficial minerals along with contaminants, potentially requiring remineralization for drinking water applications.

Scale formation particularly affects RO systems when minerals exceed their solubility limits and precipitate onto membrane surfaces. This scaling reduces membrane performance and can cause permanent damage if not properly managed through antiscalant chemicals and pretreatment systems.

Current UF and RO Implementation Methods

01 Membrane configuration and materials for filtration quality

The quality of ultrafiltration and reverse osmosis filtration systems is significantly influenced by membrane configuration and materials. Advanced membrane materials such as composite polymers and ceramic membranes offer improved filtration efficiency, durability, and resistance to fouling. Specific configurations like spiral-wound, hollow fiber, and tubular membranes are designed to optimize flow patterns and increase filtration surface area, thereby enhancing filtration quality while minimizing energy consumption.- Membrane filtration system design for improved quality: Advanced membrane filtration systems that combine ultrafiltration and reverse osmosis technologies can significantly improve water quality. These systems often incorporate multi-stage filtration processes where ultrafiltration serves as pre-treatment for reverse osmosis, removing larger particles and microorganisms before the RO stage removes dissolved solids and smaller contaminants. This sequential approach enhances overall filtration efficiency and extends membrane life while producing higher quality filtrate.

- Monitoring and control systems for filtration quality: Automated monitoring and control systems are essential for maintaining consistent filtration quality in ultrafiltration and reverse osmosis processes. These systems typically include sensors that continuously measure parameters such as pressure, flow rate, conductivity, and turbidity. Real-time data analysis allows for automatic adjustments to operating conditions, optimizing performance and ensuring consistent water quality output while minimizing energy consumption and detecting potential membrane fouling early.

- Membrane fouling prevention and cleaning methods: Effective membrane fouling prevention and cleaning strategies are crucial for maintaining filtration quality in ultrafiltration and reverse osmosis systems. These include chemical cleaning protocols using specific agents to remove organic, inorganic, and biological foulants, as well as physical cleaning methods such as backwashing and air scouring. Advanced pretreatment technologies and optimized operating conditions can significantly reduce fouling rates, extending membrane life and maintaining consistent filtration performance.

- Specialized filtration applications for industrial processes: Customized ultrafiltration and reverse osmosis systems designed for specific industrial applications can achieve superior filtration quality for specialized needs. These systems are engineered with particular membrane materials, pore sizes, and configurations to handle unique industrial fluids such as pharmaceutical products, food and beverage processing streams, or industrial wastewater with challenging contaminants. The filtration parameters are precisely calibrated to meet industry-specific quality standards while optimizing operational efficiency.

- Hybrid and integrated filtration technologies: Hybrid filtration systems that integrate ultrafiltration and reverse osmosis with other treatment technologies can achieve enhanced water quality outcomes. These systems may combine membrane filtration with advanced oxidation processes, ion exchange, activated carbon filtration, or electrodeionization. The synergistic effects of these combined technologies allow for more comprehensive contaminant removal, addressing a wider spectrum of water quality parameters than membrane filtration alone could achieve.

02 Pre-treatment systems for improved filtration performance

Pre-treatment systems play a crucial role in maintaining high-quality ultrafiltration and reverse osmosis processes. These systems remove larger particles, organic matter, and potential foulants before water reaches the main filtration membranes. Effective pre-treatment methods include coagulation, flocculation, sedimentation, and preliminary filtration stages. By reducing membrane fouling and scaling, pre-treatment systems extend membrane life, maintain consistent permeate quality, and reduce operational costs in filtration systems.Expand Specific Solutions03 Monitoring and control systems for filtration quality assurance

Advanced monitoring and control systems are essential for ensuring consistent filtration quality in ultrafiltration and reverse osmosis processes. These systems incorporate sensors that continuously measure parameters such as pressure differential, flow rate, conductivity, pH, and turbidity. Real-time data analysis allows for automated adjustments to operating conditions, early detection of membrane fouling or failure, and optimization of cleaning cycles. Integration with digital control systems enables precise management of filtration quality across varying water conditions.Expand Specific Solutions04 Cleaning and maintenance protocols for sustained filtration quality

Effective cleaning and maintenance protocols are critical for maintaining high-quality filtration in ultrafiltration and reverse osmosis systems. Regular chemical cleaning processes remove organic fouling, scaling, and biofilm formation that degrade membrane performance. Backwashing, air scouring, and chemical cleaning with specific agents target different types of foulants. Preventive maintenance schedules, including integrity testing and membrane replacement strategies, ensure consistent filtration quality and extend system lifespan while minimizing operational disruptions.Expand Specific Solutions05 Hybrid and multi-stage filtration systems for enhanced quality

Hybrid and multi-stage filtration systems combine ultrafiltration, reverse osmosis, and other filtration technologies to achieve superior water quality. These integrated approaches leverage the strengths of each filtration method while compensating for individual limitations. Ultrafiltration effectively removes larger particles and serves as an excellent pre-treatment for reverse osmosis, which then removes dissolved solids and smaller contaminants. This sequential arrangement optimizes overall system efficiency, improves permeate quality, and reduces energy consumption compared to single-technology approaches.Expand Specific Solutions

Leading Manufacturers and Market Competition

The ultrafiltration versus reverse osmosis filtration market is currently in a growth phase, with an estimated global market size exceeding $15 billion and projected to expand at 7-9% CAGR through 2028. While ultrafiltration technology has reached maturity with widespread adoption in municipal and industrial applications, reverse osmosis continues to evolve with innovations in membrane efficiency. Leading players include Dow Global Technologies (FilmTec) with advanced RO membrane technology, Asahi Kasei offering comprehensive filtration solutions, and 3M Innovative Properties contributing significant intellectual property. Emerging competitors like EconoPure Water Systems and Spot Zero are disrupting the market with specialized applications, while Chinese manufacturers such as Huawei Technologies and SINOPEC are rapidly expanding their technological capabilities, particularly in industrial water treatment segments.

EconoPure Water Systems LLC

Technical Solution: EconoPure has developed a proprietary Low-Energy Reverse Osmosis (LERO™) technology that addresses one of the primary disadvantages of traditional RO systems - high energy consumption. Their system operates at pressures 40-60% lower than conventional RO while maintaining comparable filtration efficiency. The technology utilizes a unique flow configuration and membrane arrangement that reduces concentration polarization (the buildup of rejected solutes at the membrane surface). For ultrafiltration applications, EconoPure offers systems with hollow fiber membranes featuring pore sizes around 0.01-0.02 microns that operate at pressures below 30 psi. Their integrated approach combines ultrafiltration as pre-treatment for their LERO™ systems, creating a multi-barrier approach that optimizes overall performance and energy efficiency. EconoPure's systems are designed with modular architecture allowing for scalability from residential to commercial applications.

Strengths: Significantly reduced energy consumption compared to traditional RO, lower operating costs over system lifetime, and modular design allowing easy capacity expansion. Weaknesses: Relatively newer technology with less long-term performance data, higher initial capital cost than standard systems, and more limited global service network compared to larger established competitors.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced FilmTec™ reverse osmosis (RO) membranes that utilize thin-film composite technology with proprietary automated precision fabrication. Their FILMTEC™ membranes feature an ultra-thin polyamide barrier layer on top of a microporous polysulfone support, creating a semi-permeable membrane that allows water molecules to pass through while rejecting dissolved salts and other contaminants. Dow's RO systems operate at pressures between 100-1,000 psi, achieving salt rejection rates exceeding 99.5%. Their technology includes innovations like integrally-skinned asymmetric membranes and spiral-wound element configurations that maximize surface area while minimizing footprint. Dow has also developed complementary ultrafiltration solutions with PVDF hollow fiber membranes that operate at lower pressures (10-100 psi) and target larger contaminants like bacteria, viruses, and colloids.

Strengths: Industry-leading salt rejection rates (>99.5%), high durability membranes with extended operational life, and comprehensive product range for various applications from industrial to residential. Weaknesses: Higher energy consumption compared to ultrafiltration, requires pre-treatment to prevent membrane fouling, and higher initial capital investment than simpler filtration technologies.

Key Patents and Innovations in Membrane Technology

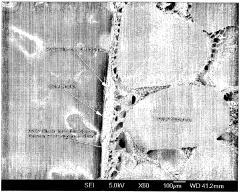

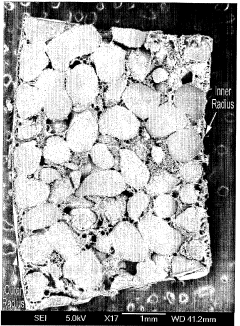

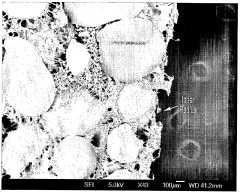

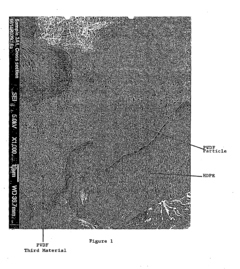

Composite porous materials and methods of making and using the same

PatentWO2005047857A2

Innovation

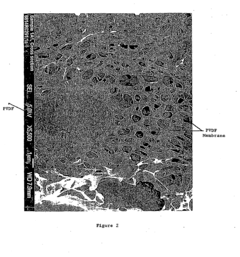

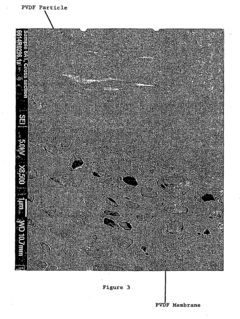

- The development of composite porous materials where a second material with smaller pores is fused to a first material with larger pores, both made from polymers soluble in a common solvent, enhancing adhesion and resistance to delamination, and allowing for steam sterilization and improved backpressure resistance.

Porous composite membrane materials and applications thereof

PatentInactiveEP1926547B1

Innovation

- The development of porous composite materials with dissimilar materials that utilize particles or fibers dispersed throughout the substrate to form points of attachment with a chemically similar membrane, enhancing stability and resistance to degradative forces, allowing for the combination of inexpensive substrates with expensive membrane materials.

Environmental Impact and Sustainability Considerations

The environmental impact of water filtration technologies has become increasingly important as global water scarcity and pollution concerns intensify. When comparing ultrafiltration (UF) and reverse osmosis (RO) systems, their environmental footprints differ significantly across multiple dimensions.

Energy consumption represents one of the most critical environmental considerations. Reverse osmosis systems typically require 2-3 times more energy than ultrafiltration systems due to the high pressure needed to overcome osmotic pressure. This increased energy demand translates directly to higher carbon emissions when powered by non-renewable energy sources, making UF generally more environmentally friendly from an operational perspective.

Waste generation patterns also differ markedly between these technologies. RO systems typically reject 15-50% of feed water as concentrate, which often contains concentrated contaminants that require proper disposal. In contrast, ultrafiltration systems generally operate with higher recovery rates of 90-95%, producing significantly less waste stream. This difference becomes particularly important in water-scarce regions where maximizing water recovery is essential.

Chemical usage presents another environmental consideration. RO membranes typically require more intensive chemical cleaning regimens and anti-scaling compounds to prevent fouling and maintain performance. These chemicals eventually enter waste streams and may require specialized treatment. Ultrafiltration systems generally require fewer chemical inputs, though they still need periodic cleaning to maintain efficiency.

The manufacturing environmental impact of both technologies must also be considered. RO membranes typically have shorter operational lifespans (3-5 years) compared to UF membranes (5-10 years), resulting in more frequent replacement and associated manufacturing impacts. The production processes for both membrane types involve energy-intensive steps and potentially hazardous chemicals, though advances in green manufacturing are gradually reducing these impacts.

From a sustainability perspective, ultrafiltration offers advantages in water-limited environments due to its higher recovery rates and lower energy requirements. However, RO remains essential for applications requiring salt removal, such as desalination. The most sustainable approach often involves combining these technologies in integrated systems that leverage the strengths of each while minimizing their environmental drawbacks.

Recent innovations are addressing the environmental limitations of both technologies, including the development of low-fouling membranes that reduce cleaning requirements, energy recovery devices for RO systems, and renewable energy integration to power filtration operations. These advances are progressively narrowing the sustainability gap between these important water treatment technologies.

Energy consumption represents one of the most critical environmental considerations. Reverse osmosis systems typically require 2-3 times more energy than ultrafiltration systems due to the high pressure needed to overcome osmotic pressure. This increased energy demand translates directly to higher carbon emissions when powered by non-renewable energy sources, making UF generally more environmentally friendly from an operational perspective.

Waste generation patterns also differ markedly between these technologies. RO systems typically reject 15-50% of feed water as concentrate, which often contains concentrated contaminants that require proper disposal. In contrast, ultrafiltration systems generally operate with higher recovery rates of 90-95%, producing significantly less waste stream. This difference becomes particularly important in water-scarce regions where maximizing water recovery is essential.

Chemical usage presents another environmental consideration. RO membranes typically require more intensive chemical cleaning regimens and anti-scaling compounds to prevent fouling and maintain performance. These chemicals eventually enter waste streams and may require specialized treatment. Ultrafiltration systems generally require fewer chemical inputs, though they still need periodic cleaning to maintain efficiency.

The manufacturing environmental impact of both technologies must also be considered. RO membranes typically have shorter operational lifespans (3-5 years) compared to UF membranes (5-10 years), resulting in more frequent replacement and associated manufacturing impacts. The production processes for both membrane types involve energy-intensive steps and potentially hazardous chemicals, though advances in green manufacturing are gradually reducing these impacts.

From a sustainability perspective, ultrafiltration offers advantages in water-limited environments due to its higher recovery rates and lower energy requirements. However, RO remains essential for applications requiring salt removal, such as desalination. The most sustainable approach often involves combining these technologies in integrated systems that leverage the strengths of each while minimizing their environmental drawbacks.

Recent innovations are addressing the environmental limitations of both technologies, including the development of low-fouling membranes that reduce cleaning requirements, energy recovery devices for RO systems, and renewable energy integration to power filtration operations. These advances are progressively narrowing the sustainability gap between these important water treatment technologies.

Cost-Benefit Analysis of UF vs RO Systems

When evaluating ultrafiltration (UF) and reverse osmosis (RO) systems, cost-benefit analysis reveals significant differences in initial investment, operational expenses, and long-term value. The initial capital expenditure for RO systems typically ranges from $2,000-$10,000 for residential applications and can exceed $100,000 for industrial installations, approximately 30-50% higher than comparable UF systems. This price differential stems from RO's more complex membrane technology and additional components required for higher pressure operation.

Operational costs present another critical distinction. RO systems consume 2-3 times more energy than UF systems due to the higher pressure requirements needed to overcome osmotic pressure. For industrial applications, this translates to approximately $0.25-$0.50 per cubic meter of treated water for RO versus $0.10-$0.20 for UF. Additionally, RO membranes typically require replacement every 2-5 years at costs ranging from $100-$300 for residential units to several thousand dollars for industrial systems.

Maintenance requirements further differentiate these technologies. UF systems generally demand less frequent maintenance, with membrane cleaning intervals of 3-6 months compared to 1-3 months for RO systems. This difference results in lower labor costs and reduced downtime for UF installations. However, RO systems compensate through superior filtration efficiency, removing dissolved salts, heavy metals, and most contaminants down to 0.0001 microns, while UF typically filters to 0.01-0.1 microns.

Water recovery rates significantly impact overall efficiency, with UF systems achieving 90-95% recovery compared to 50-75% for traditional RO systems. This difference means RO systems produce more wastewater, increasing disposal costs and environmental impact. Modern RO systems with energy recovery devices have improved this metric but still lag behind UF efficiency.

Lifespan considerations reveal that properly maintained RO membranes typically last 2-5 years, while UF membranes can function effectively for 3-7 years. This extended operational life partially offsets UF's lower filtration capability when calculating total cost of ownership.

The return on investment timeline varies by application. For industrial processes requiring high-purity water, RO systems typically achieve ROI within 2-4 years despite higher initial costs. For residential or light commercial applications where dissolved solids removal is less critical, UF systems often provide better financial returns with ROI periods of 1-3 years.

Operational costs present another critical distinction. RO systems consume 2-3 times more energy than UF systems due to the higher pressure requirements needed to overcome osmotic pressure. For industrial applications, this translates to approximately $0.25-$0.50 per cubic meter of treated water for RO versus $0.10-$0.20 for UF. Additionally, RO membranes typically require replacement every 2-5 years at costs ranging from $100-$300 for residential units to several thousand dollars for industrial systems.

Maintenance requirements further differentiate these technologies. UF systems generally demand less frequent maintenance, with membrane cleaning intervals of 3-6 months compared to 1-3 months for RO systems. This difference results in lower labor costs and reduced downtime for UF installations. However, RO systems compensate through superior filtration efficiency, removing dissolved salts, heavy metals, and most contaminants down to 0.0001 microns, while UF typically filters to 0.01-0.1 microns.

Water recovery rates significantly impact overall efficiency, with UF systems achieving 90-95% recovery compared to 50-75% for traditional RO systems. This difference means RO systems produce more wastewater, increasing disposal costs and environmental impact. Modern RO systems with energy recovery devices have improved this metric but still lag behind UF efficiency.

Lifespan considerations reveal that properly maintained RO membranes typically last 2-5 years, while UF membranes can function effectively for 3-7 years. This extended operational life partially offsets UF's lower filtration capability when calculating total cost of ownership.

The return on investment timeline varies by application. For industrial processes requiring high-purity water, RO systems typically achieve ROI within 2-4 years despite higher initial costs. For residential or light commercial applications where dissolved solids removal is less critical, UF systems often provide better financial returns with ROI periods of 1-3 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!