Assess the Environmental Impact of Scaling Up Ultrafiltration Systems

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration (UF) technology has evolved significantly since its inception in the mid-20th century, transitioning from laboratory-scale applications to industrial-scale implementations across various sectors. Initially developed for medical applications such as hemodialysis, ultrafiltration has expanded into water treatment, food processing, and pharmaceutical manufacturing due to its efficient separation capabilities at the molecular level.

The fundamental principle of ultrafiltration involves the use of semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers, allowing for the separation of macromolecules, colloids, proteins, and other large particles from fluids. This technology operates primarily through size exclusion and, to a lesser extent, charge interactions, making it highly effective for removing bacteria, viruses, and high-molecular-weight compounds without the chemical additives required in conventional treatment methods.

Recent technological advancements have focused on enhancing membrane materials, improving energy efficiency, and developing more robust system designs. Polymeric membranes, particularly polysulfone, polyethersulfone, and polyvinylidene fluoride, have dominated the market due to their balance of performance, durability, and cost-effectiveness. Ceramic membranes, though more expensive, offer superior chemical and thermal stability for specialized applications.

The global trajectory of ultrafiltration technology shows a clear trend toward more sustainable and efficient systems. Innovations in membrane chemistry have led to reduced fouling propensities, while advanced module designs have improved flow dynamics and reduced energy consumption. These developments are particularly relevant as the industry moves toward larger-scale implementations that must maintain efficiency while minimizing environmental footprint.

The primary objectives of current ultrafiltration research and development center on addressing several key challenges. First, reducing energy consumption remains paramount, as pumping requirements constitute a significant portion of operational costs and environmental impact. Second, extending membrane lifespan through improved fouling resistance and cleaning protocols directly affects both economic viability and waste generation. Third, optimizing chemical usage in membrane maintenance processes is essential for minimizing environmental discharge.

As ultrafiltration systems scale up to meet growing global demands for clean water and efficient industrial processes, understanding their comprehensive environmental impact becomes increasingly critical. This includes not only the direct effects of operation but also the embodied energy in manufacturing, transportation, and disposal of system components. The technology's evolution must therefore balance performance improvements with environmental sustainability across the entire lifecycle.

The ultimate goal of this assessment is to provide a framework for evaluating the environmental implications of large-scale ultrafiltration deployment, identifying key impact factors, and recommending pathways for sustainable scaling that aligns with global environmental objectives and regulatory requirements.

The fundamental principle of ultrafiltration involves the use of semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers, allowing for the separation of macromolecules, colloids, proteins, and other large particles from fluids. This technology operates primarily through size exclusion and, to a lesser extent, charge interactions, making it highly effective for removing bacteria, viruses, and high-molecular-weight compounds without the chemical additives required in conventional treatment methods.

Recent technological advancements have focused on enhancing membrane materials, improving energy efficiency, and developing more robust system designs. Polymeric membranes, particularly polysulfone, polyethersulfone, and polyvinylidene fluoride, have dominated the market due to their balance of performance, durability, and cost-effectiveness. Ceramic membranes, though more expensive, offer superior chemical and thermal stability for specialized applications.

The global trajectory of ultrafiltration technology shows a clear trend toward more sustainable and efficient systems. Innovations in membrane chemistry have led to reduced fouling propensities, while advanced module designs have improved flow dynamics and reduced energy consumption. These developments are particularly relevant as the industry moves toward larger-scale implementations that must maintain efficiency while minimizing environmental footprint.

The primary objectives of current ultrafiltration research and development center on addressing several key challenges. First, reducing energy consumption remains paramount, as pumping requirements constitute a significant portion of operational costs and environmental impact. Second, extending membrane lifespan through improved fouling resistance and cleaning protocols directly affects both economic viability and waste generation. Third, optimizing chemical usage in membrane maintenance processes is essential for minimizing environmental discharge.

As ultrafiltration systems scale up to meet growing global demands for clean water and efficient industrial processes, understanding their comprehensive environmental impact becomes increasingly critical. This includes not only the direct effects of operation but also the embodied energy in manufacturing, transportation, and disposal of system components. The technology's evolution must therefore balance performance improvements with environmental sustainability across the entire lifecycle.

The ultimate goal of this assessment is to provide a framework for evaluating the environmental implications of large-scale ultrafiltration deployment, identifying key impact factors, and recommending pathways for sustainable scaling that aligns with global environmental objectives and regulatory requirements.

Market Demand Analysis for Scaled Ultrafiltration Systems

The global market for ultrafiltration systems is experiencing robust growth, driven primarily by increasing water scarcity concerns and stringent regulations regarding water quality and environmental protection. Current market valuations indicate that the ultrafiltration market reached approximately 1.5 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 8.2% through 2030, potentially reaching 2.9 billion USD by the end of the forecast period.

Industrial sectors represent the largest demand segment for scaled ultrafiltration systems, particularly in manufacturing, food and beverage processing, pharmaceutical production, and chemical industries. These sectors require high-volume water treatment solutions that can handle continuous operation while meeting specific quality parameters. The municipal water treatment sector follows closely, with growing implementation of ultrafiltration technologies in both developed and developing regions to address drinking water quality concerns.

Geographically, Asia-Pacific demonstrates the highest growth potential, with China and India leading regional demand due to rapid industrialization, urbanization, and increasing government investments in water infrastructure. North America and Europe maintain significant market shares, primarily driven by replacement of aging water treatment infrastructure and adoption of advanced filtration technologies to meet evolving regulatory standards.

Consumer awareness regarding water quality has substantially increased market demand for point-of-use and point-of-entry ultrafiltration systems in residential applications. This segment is expected to grow at a faster rate than industrial applications in certain regions, particularly where tap water quality remains a concern.

Environmental regulations continue to be a primary market driver, with increasingly stringent discharge requirements forcing industries to adopt more effective water treatment technologies. The European Union's Water Framework Directive and similar regulations in other regions have created substantial demand for advanced filtration systems capable of removing emerging contaminants.

Cost considerations remain a significant factor influencing market adoption. While initial capital expenditure for scaled ultrafiltration systems remains high compared to conventional filtration methods, the total cost of ownership analysis increasingly favors ultrafiltration when accounting for operational efficiency, maintenance requirements, and longevity. Market research indicates that industries are increasingly willing to invest in higher-cost systems that offer superior performance and compliance with environmental regulations.

The COVID-19 pandemic temporarily disrupted supply chains but simultaneously heightened awareness about water quality and safety, potentially accelerating long-term market growth. Post-pandemic recovery has shown increased investment in water infrastructure across multiple regions, further supporting market expansion for scaled ultrafiltration systems.

Industrial sectors represent the largest demand segment for scaled ultrafiltration systems, particularly in manufacturing, food and beverage processing, pharmaceutical production, and chemical industries. These sectors require high-volume water treatment solutions that can handle continuous operation while meeting specific quality parameters. The municipal water treatment sector follows closely, with growing implementation of ultrafiltration technologies in both developed and developing regions to address drinking water quality concerns.

Geographically, Asia-Pacific demonstrates the highest growth potential, with China and India leading regional demand due to rapid industrialization, urbanization, and increasing government investments in water infrastructure. North America and Europe maintain significant market shares, primarily driven by replacement of aging water treatment infrastructure and adoption of advanced filtration technologies to meet evolving regulatory standards.

Consumer awareness regarding water quality has substantially increased market demand for point-of-use and point-of-entry ultrafiltration systems in residential applications. This segment is expected to grow at a faster rate than industrial applications in certain regions, particularly where tap water quality remains a concern.

Environmental regulations continue to be a primary market driver, with increasingly stringent discharge requirements forcing industries to adopt more effective water treatment technologies. The European Union's Water Framework Directive and similar regulations in other regions have created substantial demand for advanced filtration systems capable of removing emerging contaminants.

Cost considerations remain a significant factor influencing market adoption. While initial capital expenditure for scaled ultrafiltration systems remains high compared to conventional filtration methods, the total cost of ownership analysis increasingly favors ultrafiltration when accounting for operational efficiency, maintenance requirements, and longevity. Market research indicates that industries are increasingly willing to invest in higher-cost systems that offer superior performance and compliance with environmental regulations.

The COVID-19 pandemic temporarily disrupted supply chains but simultaneously heightened awareness about water quality and safety, potentially accelerating long-term market growth. Post-pandemic recovery has shown increased investment in water infrastructure across multiple regions, further supporting market expansion for scaled ultrafiltration systems.

Current Status and Challenges in Ultrafiltration Scaling

Ultrafiltration technology has witnessed significant global advancement in recent years, with applications expanding from traditional water treatment to pharmaceutical processing, food industry, and biotechnology. Currently, the global market for ultrafiltration systems is valued at approximately $2.3 billion, with projections indicating growth to $3.8 billion by 2026. This expansion reflects the increasing adoption of membrane-based separation technologies across various industries.

Despite its growth, the scaling up of ultrafiltration systems faces several critical challenges. Membrane fouling remains the primary technical obstacle, significantly reducing operational efficiency and increasing maintenance costs. Studies indicate that fouling can decrease flux rates by 30-70% depending on feed characteristics, necessitating frequent cleaning cycles that impact both economic viability and environmental footprint.

Energy consumption presents another substantial challenge, particularly when scaling to industrial levels. Current ultrafiltration systems require 1-5 kWh per cubic meter of processed fluid, with energy costs representing 20-40% of operational expenses. This energy intensity becomes increasingly problematic as systems scale up, creating a tension between processing capacity and sustainability goals.

Material limitations also constrain ultrafiltration scaling efforts. Most commercial membranes utilize synthetic polymers derived from petrochemical sources, raising concerns about resource depletion and end-of-life disposal. Advanced ceramic and composite membranes offer improved performance but at significantly higher production costs, limiting their widespread adoption in large-scale applications.

Geographically, ultrafiltration technology development shows distinct patterns. North America and Europe lead in research and innovation, holding approximately 65% of relevant patents. However, manufacturing capacity is increasingly shifting to Asia, particularly China and Singapore, where production costs are lower. This geographical distribution creates challenges in technology transfer and standardization across global markets.

Regulatory frameworks present varying challenges across regions. While the European Union has established comprehensive standards for ultrafiltration applications in drinking water and wastewater treatment, many developing countries lack clear regulatory guidelines. This regulatory heterogeneity complicates the scaling of ultrafiltration technologies across international markets and creates uncertainty for technology developers and investors.

Water recovery rates and concentrate management represent significant technical and environmental challenges. Current systems typically achieve 75-90% recovery rates, meaning 10-25% of feed water becomes concentrate stream requiring further treatment or disposal. As systems scale up, the absolute volume of this concentrate increases proportionally, creating potential environmental impacts if not properly managed.

Despite its growth, the scaling up of ultrafiltration systems faces several critical challenges. Membrane fouling remains the primary technical obstacle, significantly reducing operational efficiency and increasing maintenance costs. Studies indicate that fouling can decrease flux rates by 30-70% depending on feed characteristics, necessitating frequent cleaning cycles that impact both economic viability and environmental footprint.

Energy consumption presents another substantial challenge, particularly when scaling to industrial levels. Current ultrafiltration systems require 1-5 kWh per cubic meter of processed fluid, with energy costs representing 20-40% of operational expenses. This energy intensity becomes increasingly problematic as systems scale up, creating a tension between processing capacity and sustainability goals.

Material limitations also constrain ultrafiltration scaling efforts. Most commercial membranes utilize synthetic polymers derived from petrochemical sources, raising concerns about resource depletion and end-of-life disposal. Advanced ceramic and composite membranes offer improved performance but at significantly higher production costs, limiting their widespread adoption in large-scale applications.

Geographically, ultrafiltration technology development shows distinct patterns. North America and Europe lead in research and innovation, holding approximately 65% of relevant patents. However, manufacturing capacity is increasingly shifting to Asia, particularly China and Singapore, where production costs are lower. This geographical distribution creates challenges in technology transfer and standardization across global markets.

Regulatory frameworks present varying challenges across regions. While the European Union has established comprehensive standards for ultrafiltration applications in drinking water and wastewater treatment, many developing countries lack clear regulatory guidelines. This regulatory heterogeneity complicates the scaling of ultrafiltration technologies across international markets and creates uncertainty for technology developers and investors.

Water recovery rates and concentrate management represent significant technical and environmental challenges. Current systems typically achieve 75-90% recovery rates, meaning 10-25% of feed water becomes concentrate stream requiring further treatment or disposal. As systems scale up, the absolute volume of this concentrate increases proportionally, creating potential environmental impacts if not properly managed.

Current Technical Solutions for Large-Scale Ultrafiltration

01 Energy efficiency and resource conservation in ultrafiltration systems

Ultrafiltration systems can be designed to minimize environmental impact through improved energy efficiency and resource conservation. These innovations include optimized membrane configurations, energy recovery devices, and smart control systems that reduce power consumption. Advanced designs incorporate renewable energy sources and waste heat recovery to further decrease the carbon footprint of filtration operations.- Energy efficiency and resource conservation in ultrafiltration systems: Ultrafiltration systems can be designed to minimize environmental impact through improved energy efficiency and resource conservation. These designs incorporate advanced energy recovery devices, optimized membrane configurations, and smart control systems that reduce power consumption. Additionally, some systems utilize renewable energy sources to further decrease their carbon footprint. These innovations help balance the environmental benefits of water treatment with the energy costs of operation.

- Waste reduction and membrane lifecycle management: Environmental impact of ultrafiltration systems can be reduced through effective waste management strategies and extending membrane lifecycle. This includes developing cleaning protocols that minimize chemical usage, implementing membrane regeneration techniques, and creating disposal methods for spent membranes that reduce landfill waste. Some systems incorporate biodegradable materials or recyclable components to further decrease environmental footprint. Proper maintenance regimes can significantly extend membrane life, reducing replacement frequency and associated waste.

- Water conservation and reuse applications: Ultrafiltration systems play a crucial role in water conservation by enabling wastewater reuse and reducing freshwater demand. These systems can be integrated into closed-loop water cycles in industrial settings, agricultural irrigation systems, and municipal water treatment facilities. By treating and reclaiming water that would otherwise be discharged, ultrafiltration technology helps preserve natural water resources and reduces pollution discharge into the environment. Some advanced systems are specifically designed to handle challenging waste streams, making previously unusable water suitable for various applications.

- Chemical usage reduction and eco-friendly alternatives: Environmental impact of ultrafiltration systems can be minimized by reducing chemical usage in membrane cleaning and pretreatment processes. Innovations include developing bio-based cleaning agents, implementing physical cleaning methods like backwashing and air scouring, and utilizing enzymatic treatments that break down foulants without harsh chemicals. Some systems incorporate smart dosing technology that optimizes chemical use based on real-time water quality parameters. These approaches reduce the environmental burden associated with chemical manufacturing, transportation, and disposal while maintaining effective system performance.

- Environmental monitoring and impact assessment frameworks: Comprehensive environmental monitoring and impact assessment frameworks have been developed specifically for ultrafiltration systems. These frameworks include life cycle assessment methodologies, carbon footprint calculations, and environmental performance indicators tailored to membrane filtration processes. Real-time monitoring systems can track energy consumption, waste generation, and treatment efficiency to identify opportunities for environmental optimization. Some advanced systems incorporate predictive analytics to balance treatment goals with environmental impact, allowing operators to make informed decisions that minimize ecological footprint while maintaining water quality standards.

02 Waste reduction and membrane lifecycle management

Environmental impact of ultrafiltration systems can be reduced through effective waste management strategies and extending membrane lifecycle. This includes developing cleaning protocols that minimize chemical usage, implementing membrane regeneration techniques, and creating disposal methods for spent membranes. Innovations focus on biodegradable membrane materials and recycling processes that reduce landfill waste from ultrafiltration operations.Expand Specific Solutions03 Water conservation and wastewater treatment applications

Ultrafiltration systems contribute positively to environmental sustainability through water conservation and wastewater treatment applications. These systems enable water reuse in industrial processes, reduce discharge of contaminants into natural water bodies, and help preserve freshwater resources. Advanced ultrafiltration technologies can treat various types of wastewater, including industrial effluents and municipal sewage, making them suitable for closed-loop water systems.Expand Specific Solutions04 Monitoring and optimization systems for environmental performance

Environmental impact of ultrafiltration systems can be minimized through advanced monitoring and optimization technologies. These include real-time sensors, predictive analytics, and automated control systems that optimize operational parameters based on environmental conditions. Such systems can detect inefficiencies, prevent membrane fouling, and adjust chemical dosing to minimize environmental footprint while maintaining filtration performance.Expand Specific Solutions05 Sustainable materials and manufacturing processes

Environmental impact of ultrafiltration systems can be reduced through the use of sustainable materials and manufacturing processes. This includes developing membranes from renewable or recycled materials, implementing green chemistry principles in membrane production, and designing components for eventual recycling or biodegradation. Manufacturing innovations focus on reducing chemical usage, water consumption, and energy requirements during production of ultrafiltration components.Expand Specific Solutions

Key Industry Players in Ultrafiltration Market

The ultrafiltration systems market is currently in a growth phase, with increasing adoption driven by water scarcity concerns and stricter environmental regulations. The global market size is projected to reach approximately $8-10 billion by 2027, growing at a CAGR of 12-15%. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include established industrial giants like Siemens AG, DuPont Safety & Construction, and Ecolab USA, who focus on large-scale commercial applications, while specialized companies such as IDE Technologies and Pure Blue Tech are driving innovation in membrane technology. Academic institutions including Technion Research Foundation, Arizona State University, and Tongji University are contributing significant research to improve environmental performance and energy efficiency. Chinese entities like China Waterborne Transport Research Institute and Qingdao Haiwan Zhongshui are rapidly expanding their presence, particularly in municipal applications.

Siemens AG

Technical Solution: Siemens has developed the EcoFilter ultrafiltration platform specifically designed to minimize environmental impact during large-scale deployment. Their system utilizes digitally-optimized membrane configurations that reduce energy consumption by up to 30% through computational fluid dynamics modeling of flow patterns[5]. Siemens' approach incorporates AI-driven predictive maintenance that optimizes cleaning cycles based on actual membrane condition rather than fixed schedules, reducing chemical usage by approximately 25%. Their manufacturing facilities utilize renewable energy and have achieved zero-waste-to-landfill status for membrane production. The EcoFilter system features a modular design with standardized components that facilitates end-of-life recycling and material recovery. Siemens has implemented a comprehensive environmental monitoring system that tracks key performance indicators including energy consumption, chemical usage, waste generation, and water efficiency in real-time, enabling continuous optimization.

Strengths: Industry-leading digital optimization reduces resource consumption; comprehensive lifecycle approach from manufacturing through operation to end-of-life; strong global support infrastructure facilitates optimal operation. Weaknesses: Higher initial technology investment; complex digital systems require specialized expertise; integration with existing infrastructure may present challenges in retrofit scenarios.

IDE Technologies Ltd.

Technical Solution: IDE Technologies has developed advanced Eco-UF (Ecological Ultrafiltration) systems that incorporate energy recovery devices and optimized membrane configurations to reduce environmental footprint. Their technology utilizes a proprietary PFAS-free membrane composition that eliminates harmful forever chemicals while maintaining high filtration efficiency. The system employs a closed-loop chemical cleaning process that reduces cleaning chemical consumption by up to 30% compared to conventional systems[1]. IDE's ultrafiltration technology integrates with their Eco-RO systems to create comprehensive water treatment solutions with minimal environmental impact, featuring automated backwashing that optimizes water usage and extends membrane life by preventing fouling. Their modular design approach allows for scalable implementation with minimal construction footprint and reduced material waste during expansion phases.

Strengths: Significantly lower chemical consumption and waste generation; energy-efficient design with recovery systems; modular approach enables gradual scaling with minimal environmental disruption. Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized maintenance expertise; performance may vary in extremely challenging water conditions.

Core Innovations in Membrane Technology

Method of cleaning fouled and/or scaled membranes

PatentActiveUS7674382B2

Innovation

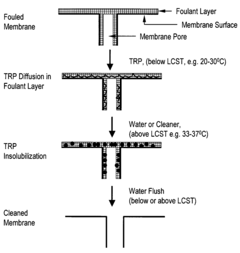

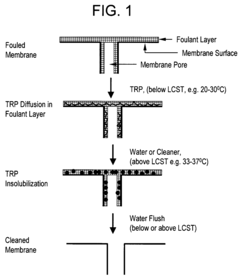

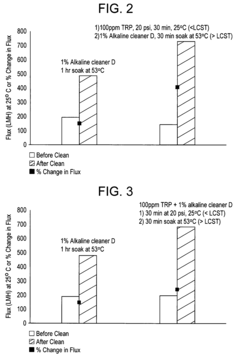

- The method involves treating fouled and/or scaled membranes with a thermoresponsive polymer (TRP) solution that diffuses into the foulant layer, becoming insoluble at a specific temperature to break up the foulant layer, followed by rinsing and optional backwashing to remove the foulant and TRP.

“system and method for producing sericin coated membranes”

PatentActiveIN201922013927A

Innovation

- The development of Sericin-coated filtration membranes, where Sericin is coated on polymeric ultrafiltration membranes through a process involving preconditioning, coating, crosslinking, and curing, enhancing the membrane's hydrophilicity and antifouling properties, thereby improving separation efficiency and extending membrane life.

Life Cycle Assessment of Ultrafiltration Systems

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of ultrafiltration systems throughout their entire lifecycle. This methodology examines impacts from raw material extraction through manufacturing, operation, maintenance, and end-of-life disposal. For ultrafiltration systems, the assessment typically encompasses membrane production, module assembly, energy consumption during operation, chemical usage for cleaning, and disposal considerations.

When scaling up ultrafiltration systems, several environmental impact categories must be quantified. These include energy consumption, greenhouse gas emissions, water usage, chemical consumption, waste generation, and resource depletion. The energy intensity of ultrafiltration operations represents a significant environmental concern, particularly in large-scale applications where pumping requirements increase substantially with system size.

Material selection for membranes and supporting infrastructure contributes significantly to the overall environmental footprint. Polymer-based membranes, commonly used in ultrafiltration, have varying environmental impacts depending on their composition, manufacturing processes, and durability. Ceramic membranes, while more energy-intensive to produce, often demonstrate longer operational lifespans, potentially reducing long-term environmental impacts despite higher initial embodied energy.

Chemical cleaning regimes present another critical consideration in LCA studies. As ultrafiltration systems scale up, the volume of cleaning chemicals increases proportionally, leading to potential aquatic toxicity and eutrophication impacts if not properly managed. Advanced cleaning protocols that optimize chemical usage while maintaining membrane performance can significantly reduce these impacts.

The operational phase typically dominates the environmental profile of ultrafiltration systems. Energy consumption for pumping and pressure maintenance increases with scale, though economies of scale may improve efficiency per unit volume of treated water. Comparative LCA studies indicate that ultrafiltration generally has lower environmental impacts than thermal separation processes but higher impacts than conventional filtration methods for comparable applications.

End-of-life considerations become increasingly important as ultrafiltration deployment expands. Current disposal practices often involve landfilling of spent membranes, representing a lost opportunity for material recovery. Emerging recycling technologies for membrane materials show promise but remain limited in commercial implementation. The development of biodegradable membrane materials represents an active research area that could substantially improve end-of-life environmental performance.

Geographical context significantly influences LCA results for ultrafiltration systems. Local energy grid composition, water scarcity conditions, and waste management infrastructure all affect the relative importance of different impact categories. This contextual dependence highlights the importance of region-specific assessments when evaluating the sustainability of scaled ultrafiltration implementations.

When scaling up ultrafiltration systems, several environmental impact categories must be quantified. These include energy consumption, greenhouse gas emissions, water usage, chemical consumption, waste generation, and resource depletion. The energy intensity of ultrafiltration operations represents a significant environmental concern, particularly in large-scale applications where pumping requirements increase substantially with system size.

Material selection for membranes and supporting infrastructure contributes significantly to the overall environmental footprint. Polymer-based membranes, commonly used in ultrafiltration, have varying environmental impacts depending on their composition, manufacturing processes, and durability. Ceramic membranes, while more energy-intensive to produce, often demonstrate longer operational lifespans, potentially reducing long-term environmental impacts despite higher initial embodied energy.

Chemical cleaning regimes present another critical consideration in LCA studies. As ultrafiltration systems scale up, the volume of cleaning chemicals increases proportionally, leading to potential aquatic toxicity and eutrophication impacts if not properly managed. Advanced cleaning protocols that optimize chemical usage while maintaining membrane performance can significantly reduce these impacts.

The operational phase typically dominates the environmental profile of ultrafiltration systems. Energy consumption for pumping and pressure maintenance increases with scale, though economies of scale may improve efficiency per unit volume of treated water. Comparative LCA studies indicate that ultrafiltration generally has lower environmental impacts than thermal separation processes but higher impacts than conventional filtration methods for comparable applications.

End-of-life considerations become increasingly important as ultrafiltration deployment expands. Current disposal practices often involve landfilling of spent membranes, representing a lost opportunity for material recovery. Emerging recycling technologies for membrane materials show promise but remain limited in commercial implementation. The development of biodegradable membrane materials represents an active research area that could substantially improve end-of-life environmental performance.

Geographical context significantly influences LCA results for ultrafiltration systems. Local energy grid composition, water scarcity conditions, and waste management infrastructure all affect the relative importance of different impact categories. This contextual dependence highlights the importance of region-specific assessments when evaluating the sustainability of scaled ultrafiltration implementations.

Energy Efficiency Optimization Strategies

Energy efficiency optimization in ultrafiltration systems represents a critical pathway to mitigate environmental impacts when scaling these systems. Current ultrafiltration installations typically consume between 0.5-2.0 kWh per cubic meter of treated water, with energy costs accounting for approximately 30-40% of operational expenses. Implementing variable frequency drives (VFDs) on pumping systems can reduce energy consumption by 20-30% by allowing pumps to operate at optimal efficiency points rather than throttling flow.

Advanced membrane materials with lower transmembrane pressure requirements present another significant opportunity for energy reduction. Recent developments in nanocomposite membranes have demonstrated potential energy savings of 15-25% compared to conventional polymeric membranes, while maintaining or improving filtration performance. These materials optimize the trade-off between permeability and selectivity, reducing the energy needed to achieve desired separation outcomes.

Process optimization through intelligent control systems represents a third frontier in energy efficiency. Machine learning algorithms that continuously adjust operational parameters based on feed water quality, membrane condition, and production requirements can achieve energy savings of 10-15%. These systems predict fouling patterns and optimize cleaning cycles, reducing both energy consumption and chemical usage while extending membrane life.

Heat recovery systems integrated with ultrafiltration processes can capture thermal energy from reject streams and backwash water. This recovered energy can be redirected to preheat incoming feed water or support other facility operations, improving overall system efficiency by 5-10% depending on temperature differentials and flow rates.

Hybrid energy solutions incorporating renewable sources present compelling opportunities for ultrafiltration facilities. Solar photovoltaic arrays coupled with energy storage systems can offset 40-60% of grid electricity requirements in suitable locations, while wind energy integration can provide similar benefits in regions with favorable wind profiles. The intermittent nature of these renewable sources can be managed through smart grid integration and demand response strategies.

Modular system design enables right-sizing of ultrafiltration installations, preventing energy waste from oversized equipment operating at suboptimal conditions. This approach allows for incremental capacity expansion that matches actual demand growth, with each module operating at peak efficiency. Studies indicate that properly sized systems can operate with 15-25% greater energy efficiency compared to oversized systems designed for projected future capacity.

Advanced membrane materials with lower transmembrane pressure requirements present another significant opportunity for energy reduction. Recent developments in nanocomposite membranes have demonstrated potential energy savings of 15-25% compared to conventional polymeric membranes, while maintaining or improving filtration performance. These materials optimize the trade-off between permeability and selectivity, reducing the energy needed to achieve desired separation outcomes.

Process optimization through intelligent control systems represents a third frontier in energy efficiency. Machine learning algorithms that continuously adjust operational parameters based on feed water quality, membrane condition, and production requirements can achieve energy savings of 10-15%. These systems predict fouling patterns and optimize cleaning cycles, reducing both energy consumption and chemical usage while extending membrane life.

Heat recovery systems integrated with ultrafiltration processes can capture thermal energy from reject streams and backwash water. This recovered energy can be redirected to preheat incoming feed water or support other facility operations, improving overall system efficiency by 5-10% depending on temperature differentials and flow rates.

Hybrid energy solutions incorporating renewable sources present compelling opportunities for ultrafiltration facilities. Solar photovoltaic arrays coupled with energy storage systems can offset 40-60% of grid electricity requirements in suitable locations, while wind energy integration can provide similar benefits in regions with favorable wind profiles. The intermittent nature of these renewable sources can be managed through smart grid integration and demand response strategies.

Modular system design enables right-sizing of ultrafiltration installations, preventing energy waste from oversized equipment operating at suboptimal conditions. This approach allows for incremental capacity expansion that matches actual demand growth, with each module operating at peak efficiency. Studies indicate that properly sized systems can operate with 15-25% greater energy efficiency compared to oversized systems designed for projected future capacity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!