Real-time Performance Tracking for Industrial Ultrafiltration Applications

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Performance Tracking Background and Objectives

Ultrafiltration technology has evolved significantly over the past five decades, transitioning from laboratory-scale applications to widespread industrial implementation. Initially developed in the 1960s for water treatment, ultrafiltration has expanded into diverse sectors including pharmaceuticals, food processing, and chemical manufacturing. The evolution of membrane materials—from cellulose acetate to advanced polymeric and ceramic compositions—has dramatically enhanced filtration efficiency, durability, and application versatility.

Recent technological advancements have focused on membrane fouling reduction, energy efficiency improvements, and integration with complementary separation technologies. Despite these advances, real-time performance monitoring remains a critical challenge in industrial ultrafiltration systems, often relying on indirect measurements or periodic offline analysis that fails to capture dynamic operational conditions.

The global market for ultrafiltration systems continues to grow at approximately 6.5% annually, driven by increasing water scarcity concerns, stringent regulatory requirements for process water quality, and growing demand for high-purity products in pharmaceutical and food industries. This market expansion has accelerated innovation in monitoring technologies, with particular emphasis on non-invasive and continuous measurement solutions.

Current performance tracking methodologies typically involve pressure differential monitoring, permeate flow measurement, and periodic sampling for quality analysis. These approaches present significant limitations: they often detect performance degradation only after substantial efficiency loss has occurred, provide limited insight into fouling mechanisms, and offer minimal predictive capability for maintenance scheduling.

The primary objective of real-time performance tracking for industrial ultrafiltration is to develop comprehensive monitoring systems that provide instantaneous, accurate assessment of membrane condition and filtration efficiency. Such systems aim to detect early signs of performance deterioration, identify specific fouling mechanisms, and enable predictive maintenance strategies to optimize operational continuity and resource utilization.

Secondary objectives include reducing energy consumption through optimized operation, extending membrane lifetime through timely intervention, minimizing product quality variations, and enabling adaptive process control based on real-time performance data. These objectives align with broader industry trends toward digital transformation, predictive analytics, and sustainable manufacturing practices.

The technological trajectory suggests convergence toward integrated sensor networks, advanced data analytics, and machine learning algorithms capable of processing multiple parameters simultaneously to provide holistic performance assessment. This evolution represents a paradigm shift from reactive to proactive ultrafiltration system management, with significant implications for operational efficiency, maintenance strategies, and overall process economics.

Recent technological advancements have focused on membrane fouling reduction, energy efficiency improvements, and integration with complementary separation technologies. Despite these advances, real-time performance monitoring remains a critical challenge in industrial ultrafiltration systems, often relying on indirect measurements or periodic offline analysis that fails to capture dynamic operational conditions.

The global market for ultrafiltration systems continues to grow at approximately 6.5% annually, driven by increasing water scarcity concerns, stringent regulatory requirements for process water quality, and growing demand for high-purity products in pharmaceutical and food industries. This market expansion has accelerated innovation in monitoring technologies, with particular emphasis on non-invasive and continuous measurement solutions.

Current performance tracking methodologies typically involve pressure differential monitoring, permeate flow measurement, and periodic sampling for quality analysis. These approaches present significant limitations: they often detect performance degradation only after substantial efficiency loss has occurred, provide limited insight into fouling mechanisms, and offer minimal predictive capability for maintenance scheduling.

The primary objective of real-time performance tracking for industrial ultrafiltration is to develop comprehensive monitoring systems that provide instantaneous, accurate assessment of membrane condition and filtration efficiency. Such systems aim to detect early signs of performance deterioration, identify specific fouling mechanisms, and enable predictive maintenance strategies to optimize operational continuity and resource utilization.

Secondary objectives include reducing energy consumption through optimized operation, extending membrane lifetime through timely intervention, minimizing product quality variations, and enabling adaptive process control based on real-time performance data. These objectives align with broader industry trends toward digital transformation, predictive analytics, and sustainable manufacturing practices.

The technological trajectory suggests convergence toward integrated sensor networks, advanced data analytics, and machine learning algorithms capable of processing multiple parameters simultaneously to provide holistic performance assessment. This evolution represents a paradigm shift from reactive to proactive ultrafiltration system management, with significant implications for operational efficiency, maintenance strategies, and overall process economics.

Industrial Market Demand for Real-time Filtration Monitoring

The industrial ultrafiltration market has witnessed significant growth in recent years, driven by increasing water scarcity concerns and stringent regulations regarding wastewater treatment across various industries. The global industrial filtration market was valued at approximately $29.5 billion in 2021 and is projected to reach $41.1 billion by 2026, growing at a CAGR of 6.9%. Within this broader market, ultrafiltration represents one of the fastest-growing segments due to its effectiveness in removing suspended solids, bacteria, viruses, endotoxins, and other pathogens.

Industries such as food and beverage, pharmaceuticals, chemical processing, and municipal water treatment are increasingly adopting ultrafiltration technologies. The pharmaceutical sector, in particular, shows robust demand growth due to the need for high-purity water in manufacturing processes. Similarly, the food and beverage industry requires reliable filtration systems to ensure product quality and safety, creating a substantial market for advanced monitoring solutions.

Real-time performance tracking systems for ultrafiltration applications address critical pain points in industrial operations. According to industry surveys, approximately 78% of plant managers report that unexpected filtration system failures result in significant production downtime, with associated costs ranging from $10,000 to $50,000 per hour depending on the industry and scale of operations.

The demand for real-time monitoring is further amplified by the shift toward predictive maintenance strategies across industrial sectors. Traditional time-based maintenance approaches are being replaced by condition-based methodologies that rely on continuous monitoring data. This transition is expected to reduce maintenance costs by 25-30% while extending equipment lifespan by 20-40%.

Energy efficiency concerns also drive market demand for real-time filtration monitoring. Ultrafiltration systems typically account for 15-20% of energy consumption in water-intensive industrial processes. Real-time performance tracking enables optimization of operating parameters, potentially reducing energy consumption by 10-15% through early detection of membrane fouling and timely intervention.

Geographically, North America and Europe currently represent the largest markets for advanced filtration monitoring systems, accounting for approximately 60% of global demand. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization in countries like China and India, alongside increasing environmental regulations.

The COVID-19 pandemic has further accelerated market demand, as industries prioritize automation and remote monitoring capabilities to ensure operational continuity with reduced on-site personnel. This trend is expected to persist post-pandemic, supporting sustained growth in the real-time filtration monitoring market.

Industries such as food and beverage, pharmaceuticals, chemical processing, and municipal water treatment are increasingly adopting ultrafiltration technologies. The pharmaceutical sector, in particular, shows robust demand growth due to the need for high-purity water in manufacturing processes. Similarly, the food and beverage industry requires reliable filtration systems to ensure product quality and safety, creating a substantial market for advanced monitoring solutions.

Real-time performance tracking systems for ultrafiltration applications address critical pain points in industrial operations. According to industry surveys, approximately 78% of plant managers report that unexpected filtration system failures result in significant production downtime, with associated costs ranging from $10,000 to $50,000 per hour depending on the industry and scale of operations.

The demand for real-time monitoring is further amplified by the shift toward predictive maintenance strategies across industrial sectors. Traditional time-based maintenance approaches are being replaced by condition-based methodologies that rely on continuous monitoring data. This transition is expected to reduce maintenance costs by 25-30% while extending equipment lifespan by 20-40%.

Energy efficiency concerns also drive market demand for real-time filtration monitoring. Ultrafiltration systems typically account for 15-20% of energy consumption in water-intensive industrial processes. Real-time performance tracking enables optimization of operating parameters, potentially reducing energy consumption by 10-15% through early detection of membrane fouling and timely intervention.

Geographically, North America and Europe currently represent the largest markets for advanced filtration monitoring systems, accounting for approximately 60% of global demand. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization in countries like China and India, alongside increasing environmental regulations.

The COVID-19 pandemic has further accelerated market demand, as industries prioritize automation and remote monitoring capabilities to ensure operational continuity with reduced on-site personnel. This trend is expected to persist post-pandemic, supporting sustained growth in the real-time filtration monitoring market.

Current Challenges in Industrial Ultrafiltration Monitoring

Industrial ultrafiltration systems face significant monitoring challenges that impede optimal performance tracking in real-time applications. Traditional monitoring approaches rely heavily on periodic sampling and laboratory analysis, creating substantial time lags between operational changes and performance feedback. This delay prevents timely intervention when membrane fouling or process deviations occur, resulting in efficiency losses and increased operational costs.

Membrane fouling represents the most persistent challenge in ultrafiltration monitoring. The progressive accumulation of particles, colloids, and biological materials on membrane surfaces alters filtration dynamics in complex ways that are difficult to detect until significant performance degradation has occurred. Current sensors struggle to differentiate between various fouling mechanisms (cake formation, pore blocking, concentration polarization) that require different mitigation strategies.

Data integration presents another substantial hurdle. Ultrafiltration systems generate heterogeneous data streams from pressure transducers, flow meters, turbidity sensors, and conductivity probes. These diverse data sources operate at different sampling frequencies and precision levels, making real-time data fusion and interpretation exceptionally challenging. The lack of standardized data protocols further complicates cross-platform integration efforts.

Sensor limitations constitute a critical barrier to effective monitoring. Existing sensor technologies face trade-offs between accuracy, response time, and robustness in harsh industrial environments. Many sensors suffer from drift over time, requiring frequent recalibration that disrupts continuous monitoring. Additionally, sensor placement optimization remains problematic, as the ideal monitoring points may be physically inaccessible or create flow disturbances that affect the very parameters being measured.

Computational challenges further complicate real-time performance tracking. Processing large volumes of sensor data with sufficient speed for actionable insights requires sophisticated algorithms and substantial computing resources. Current predictive models for membrane performance often lack the accuracy needed for proactive intervention, particularly when operating conditions deviate from those used during model training.

Economic constraints also influence monitoring capabilities. The high cost of advanced sensing technologies and analytical systems limits their implementation, particularly in smaller facilities or developing regions. This creates a technological divide where only premium operations can afford comprehensive monitoring solutions, while others rely on basic parameters that provide incomplete performance visibility.

Regulatory compliance adds another layer of complexity, as monitoring systems must satisfy increasingly stringent documentation requirements while maintaining operational efficiency. This necessitates reliable data storage, retrieval, and reporting capabilities that seamlessly integrate with process control systems.

Membrane fouling represents the most persistent challenge in ultrafiltration monitoring. The progressive accumulation of particles, colloids, and biological materials on membrane surfaces alters filtration dynamics in complex ways that are difficult to detect until significant performance degradation has occurred. Current sensors struggle to differentiate between various fouling mechanisms (cake formation, pore blocking, concentration polarization) that require different mitigation strategies.

Data integration presents another substantial hurdle. Ultrafiltration systems generate heterogeneous data streams from pressure transducers, flow meters, turbidity sensors, and conductivity probes. These diverse data sources operate at different sampling frequencies and precision levels, making real-time data fusion and interpretation exceptionally challenging. The lack of standardized data protocols further complicates cross-platform integration efforts.

Sensor limitations constitute a critical barrier to effective monitoring. Existing sensor technologies face trade-offs between accuracy, response time, and robustness in harsh industrial environments. Many sensors suffer from drift over time, requiring frequent recalibration that disrupts continuous monitoring. Additionally, sensor placement optimization remains problematic, as the ideal monitoring points may be physically inaccessible or create flow disturbances that affect the very parameters being measured.

Computational challenges further complicate real-time performance tracking. Processing large volumes of sensor data with sufficient speed for actionable insights requires sophisticated algorithms and substantial computing resources. Current predictive models for membrane performance often lack the accuracy needed for proactive intervention, particularly when operating conditions deviate from those used during model training.

Economic constraints also influence monitoring capabilities. The high cost of advanced sensing technologies and analytical systems limits their implementation, particularly in smaller facilities or developing regions. This creates a technological divide where only premium operations can afford comprehensive monitoring solutions, while others rely on basic parameters that provide incomplete performance visibility.

Regulatory compliance adds another layer of complexity, as monitoring systems must satisfy increasingly stringent documentation requirements while maintaining operational efficiency. This necessitates reliable data storage, retrieval, and reporting capabilities that seamlessly integrate with process control systems.

Existing Real-time Monitoring Solutions and Architectures

01 Real-time monitoring systems for ultrafiltration performance

Advanced monitoring systems that track ultrafiltration performance in real-time, allowing for immediate detection of performance issues. These systems utilize sensors and data collection devices to continuously measure key parameters such as flow rate, pressure differential, and filtrate quality. The real-time data enables operators to quickly identify deviations from optimal performance and take corrective actions before significant problems develop.- Real-time monitoring systems for ultrafiltration performance: Advanced monitoring systems that track ultrafiltration performance in real-time, allowing for immediate detection of efficiency changes, membrane fouling, or system failures. These systems typically incorporate sensors that continuously measure parameters such as flow rate, pressure differential, and filtrate quality, enabling operators to optimize operation and schedule maintenance based on actual performance rather than fixed intervals.

- Data analytics and predictive maintenance for ultrafiltration systems: Implementation of data analytics and machine learning algorithms to analyze ultrafiltration performance data, identify patterns, and predict potential system failures before they occur. These solutions process historical and real-time performance data to establish baseline performance metrics, detect anomalies, and recommend preventive maintenance actions, thereby reducing downtime and extending membrane life.

- Automated control systems for ultrafiltration optimization: Automated control systems that adjust ultrafiltration parameters based on performance tracking data to maintain optimal efficiency. These systems can automatically modify operating conditions such as transmembrane pressure, cross-flow velocity, and backwash frequency in response to changing feed characteristics or membrane conditions, ensuring consistent performance and extending membrane lifespan.

- Performance tracking through membrane integrity testing: Methods and devices for tracking ultrafiltration performance through regular membrane integrity testing, which helps identify breaches or damage that could compromise filtration efficiency. These approaches include pressure decay tests, bubble point tests, and particle counting in the filtrate to ensure that membranes maintain their separation capabilities and meet required quality standards throughout their operational life.

- Remote monitoring and cloud-based ultrafiltration performance management: Cloud-based platforms and remote monitoring solutions that enable off-site tracking of ultrafiltration system performance across multiple facilities. These technologies allow for centralized data collection, analysis, and visualization, facilitating comparison between different systems, benchmarking performance, and implementing best practices across operations. Remote access enables experts to troubleshoot issues without being physically present at the installation site.

02 Predictive analytics for ultrafiltration membrane fouling

Predictive analytics solutions that use historical and real-time data to forecast membrane fouling and performance degradation in ultrafiltration systems. These solutions employ machine learning algorithms to analyze patterns in operational data and predict when maintenance will be required. By anticipating fouling issues before they cause significant performance drops, these systems help optimize cleaning schedules and extend membrane life.Expand Specific Solutions03 Automated performance tracking and reporting systems

Comprehensive software solutions that automatically track, analyze, and report on ultrafiltration system performance metrics. These systems collect data from multiple points in the filtration process, generate performance reports, and provide dashboards for visualizing key performance indicators. The automated reporting reduces manual data collection efforts and provides standardized performance evaluation across multiple ultrafiltration units or facilities.Expand Specific Solutions04 Integrated membrane integrity testing and performance monitoring

Systems that combine membrane integrity testing with continuous performance monitoring to ensure ultrafiltration effectiveness. These solutions periodically test membrane integrity while simultaneously tracking operational parameters to provide a comprehensive view of system health. The integration allows operators to correlate performance changes with potential membrane damage or integrity issues, enabling more targeted maintenance approaches.Expand Specific Solutions05 Mobile and IoT-based ultrafiltration monitoring solutions

Mobile applications and Internet of Things (IoT) devices designed for remote monitoring of ultrafiltration systems. These solutions enable operators to track performance metrics from anywhere using smartphones or tablets, receive alerts when parameters exceed thresholds, and manage multiple filtration systems from a central platform. The mobility aspect improves response times to performance issues and enhances operational flexibility.Expand Specific Solutions

Leading Companies in Industrial Ultrafiltration Monitoring

The real-time performance tracking market for industrial ultrafiltration applications is currently in a growth phase, with increasing demand driven by efficiency requirements in manufacturing processes. The market is expected to reach significant scale as industries prioritize process optimization and quality control. From a technological maturity perspective, established industrial players like Siemens AG, Robert Bosch GmbH, and Halliburton Energy Services lead with comprehensive monitoring solutions, while specialized companies such as DarkVision Technologies and BL Technology offer innovative ultrasound-based tracking systems. Academic institutions including Huazhong University of Science & Technology and Hefei University of Technology contribute fundamental research, creating a competitive landscape where industrial expertise meets emerging sensing technologies and data analytics capabilities.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed a comprehensive real-time performance tracking system for industrial ultrafiltration applications specifically tailored for oil and gas operations. Their solution, integrated within their Landmark Digital platform, combines advanced sensor technology with edge computing capabilities to monitor critical ultrafiltration parameters in challenging environments. The system employs ruggedized pressure transducers, flow meters, and conductivity sensors that can withstand harsh conditions including high temperatures, corrosive fluids, and vibration. Halliburton's technology incorporates real-time data analytics that correlate ultrafiltration performance with specific operational conditions in oil field water treatment, enabling adaptive control strategies. Their platform features specialized algorithms designed to detect and compensate for the unique fouling mechanisms encountered in produced water treatment, including oil emulsions, suspended solids, and scaling minerals. The system includes automated chemical injection control that adjusts antiscalant and cleaning agent dosing based on real-time membrane performance metrics, optimizing both membrane longevity and operational costs.

Strengths: Exceptional durability in harsh industrial environments, specialized algorithms optimized for oil and gas applications, and seamless integration with existing field operations management systems. The platform's ability to function in remote locations with limited connectivity provides operational continuity in challenging deployment scenarios. Weaknesses: Higher cost compared to general-purpose monitoring systems, limited flexibility for non-oil and gas applications, and requires specialized training for maintenance personnel.

Koninklijke Philips NV

Technical Solution: Philips has engineered a sophisticated real-time ultrafiltration monitoring platform specifically designed for industrial applications requiring high purity water. Their system utilizes advanced optical sensors and spectroscopic analysis to monitor membrane performance without interrupting the filtration process. The technology incorporates multi-parameter sensing arrays that simultaneously track turbidity, particle counts, organic content, and specific contaminants in both feed and permeate streams. Philips' solution features proprietary algorithms that correlate multiple data points to identify specific fouling mechanisms (organic, inorganic, biological) in real time, allowing for targeted intervention strategies. The system employs a modular architecture with standardized communication protocols (OPC UA, MQTT) to ensure compatibility with various industrial control systems. Their platform includes automated membrane integrity testing capabilities that can detect microscopic breaches before they affect product quality, using pressure decay and bubble point testing methodologies integrated into the continuous monitoring workflow.

Strengths: Superior optical sensing technology provides exceptional sensitivity for early fouling detection, modular design allows for scalability across different plant sizes, and the system offers industry-leading specificity in identifying fouling mechanisms. Weaknesses: Higher energy consumption compared to simpler monitoring systems, requires specialized technical expertise for calibration and maintenance, and the optical components may need more frequent cleaning in applications with high turbidity.

Key Sensor Technologies for Ultrafiltration Performance Analysis

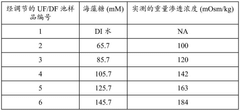

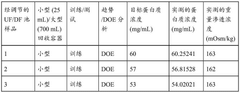

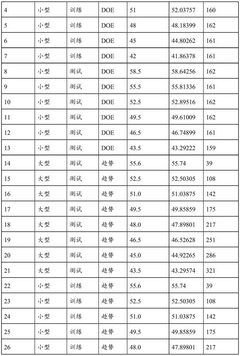

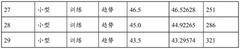

Real-time automated monitoring and control of ultrafiltration/diafiltration (UF/DF) regulation and dilution processes

PatentPendingCN120344842A

Innovation

- Raman spectrometer is used to monitor the quality attributes of UF/DF pools in real time, and predict product quality through machine learning models. Combined with the addition of processor control buffers, real-time automated monitoring and control of UF/DF pools are achieved.

Fluid quality control using broad spectrum impedance spectroscopy

PatentWO2005080951A1

Innovation

- The system employs impedance spectroscopy measurements at three or more frequencies, analyzed using statistical techniques like Principal Component Regression or equivalent circuit modeling, to generate IS signatures that compare the properties of test fluids to calibration fluids, enabling real-time quality control adjustments.

Data Integration and Industrial IoT Implementation Strategies

Effective data integration forms the foundation of any successful real-time performance tracking system for industrial ultrafiltration applications. The implementation requires a multi-layered approach that begins with sensor selection and deployment. Industrial ultrafiltration systems benefit from strategic placement of pressure transducers, flow meters, turbidity sensors, and conductivity meters at critical points throughout the filtration train. These sensors must be calibrated to withstand harsh industrial environments while maintaining measurement accuracy within operational parameters.

Data collection protocols must address the challenges of varying sampling rates across different sensor types. Pressure data may require millisecond-level sampling to detect transient events like water hammer effects, while chemical parameters might be adequately monitored at longer intervals. Implementing edge computing devices near sensor clusters enables preliminary data processing, reducing bandwidth requirements and allowing for immediate response to critical operational deviations.

Industrial IoT architecture for ultrafiltration monitoring typically employs a three-tier structure. The perception layer consists of physical sensors and actuators interfacing directly with filtration equipment. The network layer facilitates secure data transmission through industrial protocols such as OPC UA, MQTT, or Modbus TCP/IP, with appropriate encryption and authentication mechanisms. The application layer hosts analytics engines, visualization platforms, and decision support systems that transform raw data into actionable insights.

Data standardization presents significant challenges in ultrafiltration environments where legacy equipment may coexist with modern IoT-enabled systems. Implementation strategies should include protocol converters and middleware solutions that normalize data formats before transmission to central repositories. Time-series databases like InfluxDB or TimescaleDB offer superior performance for storing and querying the high-frequency measurements typical in ultrafiltration monitoring.

Integration with existing enterprise systems requires careful planning of API development and implementation. RESTful APIs provide flexible integration points between ultrafiltration monitoring systems and enterprise resource planning (ERP), manufacturing execution systems (MES), or computerized maintenance management systems (CMMS). This integration enables holistic operational visibility and facilitates automated workflows based on filtration performance metrics.

Scalability considerations must account for both horizontal expansion (additional filtration units) and vertical integration (increased data granularity). Cloud-based architectures with containerized microservices offer the flexibility to scale computational resources dynamically in response to changing monitoring requirements. Edge-to-cloud architectures balance the need for real-time local processing with the benefits of centralized analytics and historical data storage.

Data collection protocols must address the challenges of varying sampling rates across different sensor types. Pressure data may require millisecond-level sampling to detect transient events like water hammer effects, while chemical parameters might be adequately monitored at longer intervals. Implementing edge computing devices near sensor clusters enables preliminary data processing, reducing bandwidth requirements and allowing for immediate response to critical operational deviations.

Industrial IoT architecture for ultrafiltration monitoring typically employs a three-tier structure. The perception layer consists of physical sensors and actuators interfacing directly with filtration equipment. The network layer facilitates secure data transmission through industrial protocols such as OPC UA, MQTT, or Modbus TCP/IP, with appropriate encryption and authentication mechanisms. The application layer hosts analytics engines, visualization platforms, and decision support systems that transform raw data into actionable insights.

Data standardization presents significant challenges in ultrafiltration environments where legacy equipment may coexist with modern IoT-enabled systems. Implementation strategies should include protocol converters and middleware solutions that normalize data formats before transmission to central repositories. Time-series databases like InfluxDB or TimescaleDB offer superior performance for storing and querying the high-frequency measurements typical in ultrafiltration monitoring.

Integration with existing enterprise systems requires careful planning of API development and implementation. RESTful APIs provide flexible integration points between ultrafiltration monitoring systems and enterprise resource planning (ERP), manufacturing execution systems (MES), or computerized maintenance management systems (CMMS). This integration enables holistic operational visibility and facilitates automated workflows based on filtration performance metrics.

Scalability considerations must account for both horizontal expansion (additional filtration units) and vertical integration (increased data granularity). Cloud-based architectures with containerized microservices offer the flexibility to scale computational resources dynamically in response to changing monitoring requirements. Edge-to-cloud architectures balance the need for real-time local processing with the benefits of centralized analytics and historical data storage.

Environmental Impact and Sustainability Considerations

The implementation of real-time performance tracking systems in industrial ultrafiltration applications presents significant environmental implications that warrant careful consideration. These systems optimize filtration processes by continuously monitoring parameters such as flux rates, transmembrane pressure, and membrane fouling, thereby reducing resource consumption and environmental footprint. When properly implemented, real-time monitoring can decrease energy usage by 15-25% through optimized pump operations and timely maintenance interventions, directly contributing to reduced carbon emissions.

Water conservation represents another critical environmental benefit of performance tracking in ultrafiltration. By precisely identifying optimal backwash timing and duration, these systems minimize water wastage during cleaning cycles. Studies indicate that advanced monitoring can reduce backwash water consumption by up to 30% compared to time-based maintenance schedules, particularly valuable in water-stressed regions where industrial water usage faces increasing scrutiny.

Chemical consumption in membrane cleaning processes also decreases substantially with real-time performance tracking. The ability to detect early signs of fouling allows for targeted, data-driven cleaning interventions rather than aggressive chemical treatments. This approach typically reduces chemical usage by 20-40%, minimizing the environmental impact of cleaning agents and their subsequent discharge into water systems.

Membrane lifespan extension represents a significant sustainability advantage of performance tracking systems. By preventing severe fouling events and optimizing operating conditions, these technologies can extend membrane life by 30-50%. This reduction in replacement frequency translates directly to decreased manufacturing demand for new membranes, lowering associated resource extraction, energy consumption, and waste generation throughout the product lifecycle.

The environmental benefits extend to waste management considerations as well. Real-time monitoring enables precise control over concentrate streams and rejection rates, potentially allowing for resource recovery from waste streams. Advanced systems can identify opportunities for recovering valuable components from reject streams, transforming what was previously considered waste into potential revenue streams while reducing disposal requirements.

Looking forward, the integration of real-time performance tracking with broader sustainability initiatives presents compelling opportunities. These systems can provide valuable data for environmental compliance reporting, sustainability certifications, and corporate social responsibility initiatives. As regulatory frameworks increasingly emphasize resource efficiency and environmental protection, the implementation of these monitoring technologies positions industrial ultrafiltration operations advantageously for future compliance requirements while delivering tangible environmental benefits.

Water conservation represents another critical environmental benefit of performance tracking in ultrafiltration. By precisely identifying optimal backwash timing and duration, these systems minimize water wastage during cleaning cycles. Studies indicate that advanced monitoring can reduce backwash water consumption by up to 30% compared to time-based maintenance schedules, particularly valuable in water-stressed regions where industrial water usage faces increasing scrutiny.

Chemical consumption in membrane cleaning processes also decreases substantially with real-time performance tracking. The ability to detect early signs of fouling allows for targeted, data-driven cleaning interventions rather than aggressive chemical treatments. This approach typically reduces chemical usage by 20-40%, minimizing the environmental impact of cleaning agents and their subsequent discharge into water systems.

Membrane lifespan extension represents a significant sustainability advantage of performance tracking systems. By preventing severe fouling events and optimizing operating conditions, these technologies can extend membrane life by 30-50%. This reduction in replacement frequency translates directly to decreased manufacturing demand for new membranes, lowering associated resource extraction, energy consumption, and waste generation throughout the product lifecycle.

The environmental benefits extend to waste management considerations as well. Real-time monitoring enables precise control over concentrate streams and rejection rates, potentially allowing for resource recovery from waste streams. Advanced systems can identify opportunities for recovering valuable components from reject streams, transforming what was previously considered waste into potential revenue streams while reducing disposal requirements.

Looking forward, the integration of real-time performance tracking with broader sustainability initiatives presents compelling opportunities. These systems can provide valuable data for environmental compliance reporting, sustainability certifications, and corporate social responsibility initiatives. As regulatory frameworks increasingly emphasize resource efficiency and environmental protection, the implementation of these monitoring technologies positions industrial ultrafiltration operations advantageously for future compliance requirements while delivering tangible environmental benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!