Optimizing Crossflow Velocities in Ultrafiltration for Performance Gains

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Crossflow Technology Background and Objectives

Ultrafiltration (UF) technology has evolved significantly since its inception in the 1960s, transitioning from laboratory applications to widespread industrial use across water treatment, food processing, biotechnology, and pharmaceutical sectors. The fundamental principle of ultrafiltration involves the separation of macromolecules, colloids, and particles from fluids using semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers.

Crossflow filtration emerged as a critical advancement in membrane technology, addressing the inherent limitations of dead-end filtration systems. In crossflow configurations, the feed solution flows tangentially across the membrane surface while filtrate passes through perpendicularly, creating a self-cleaning mechanism that significantly reduces membrane fouling and extends operational cycles.

The optimization of crossflow velocities represents a pivotal factor in ultrafiltration performance. Historical data demonstrates that appropriate crossflow velocity management can enhance flux rates by 30-50% while simultaneously extending membrane lifespan by up to 40%. This optimization directly impacts operational efficiency, energy consumption, and overall process economics.

Recent technological developments have focused on understanding the complex hydrodynamics at the membrane-fluid interface. The boundary layer phenomena, concentration polarization effects, and shear-induced diffusion mechanisms all play crucial roles in determining optimal crossflow parameters for specific applications.

Industry trends indicate a shift toward precision-controlled crossflow systems that dynamically adjust velocities based on real-time monitoring of transmembrane pressure, permeate quality, and energy consumption metrics. This adaptive approach represents a significant departure from traditional fixed-parameter operations.

The primary technical objective of crossflow velocity optimization is to establish the ideal balance between fouling mitigation and energy expenditure. Excessive velocities increase pumping costs disproportionately to performance gains, while insufficient velocities fail to prevent membrane fouling effectively.

Secondary objectives include developing predictive models for crossflow behavior across diverse feed compositions, membrane materials, and operational conditions. These models aim to enable proactive system management rather than reactive adjustments, potentially revolutionizing ultrafiltration efficiency across industries.

The technological trajectory suggests that next-generation ultrafiltration systems will incorporate artificial intelligence and machine learning algorithms to continuously optimize crossflow parameters, potentially achieving performance improvements of 15-25% beyond current best practices while reducing energy consumption by similar margins.

Crossflow filtration emerged as a critical advancement in membrane technology, addressing the inherent limitations of dead-end filtration systems. In crossflow configurations, the feed solution flows tangentially across the membrane surface while filtrate passes through perpendicularly, creating a self-cleaning mechanism that significantly reduces membrane fouling and extends operational cycles.

The optimization of crossflow velocities represents a pivotal factor in ultrafiltration performance. Historical data demonstrates that appropriate crossflow velocity management can enhance flux rates by 30-50% while simultaneously extending membrane lifespan by up to 40%. This optimization directly impacts operational efficiency, energy consumption, and overall process economics.

Recent technological developments have focused on understanding the complex hydrodynamics at the membrane-fluid interface. The boundary layer phenomena, concentration polarization effects, and shear-induced diffusion mechanisms all play crucial roles in determining optimal crossflow parameters for specific applications.

Industry trends indicate a shift toward precision-controlled crossflow systems that dynamically adjust velocities based on real-time monitoring of transmembrane pressure, permeate quality, and energy consumption metrics. This adaptive approach represents a significant departure from traditional fixed-parameter operations.

The primary technical objective of crossflow velocity optimization is to establish the ideal balance between fouling mitigation and energy expenditure. Excessive velocities increase pumping costs disproportionately to performance gains, while insufficient velocities fail to prevent membrane fouling effectively.

Secondary objectives include developing predictive models for crossflow behavior across diverse feed compositions, membrane materials, and operational conditions. These models aim to enable proactive system management rather than reactive adjustments, potentially revolutionizing ultrafiltration efficiency across industries.

The technological trajectory suggests that next-generation ultrafiltration systems will incorporate artificial intelligence and machine learning algorithms to continuously optimize crossflow parameters, potentially achieving performance improvements of 15-25% beyond current best practices while reducing energy consumption by similar margins.

Market Analysis of High-Performance Ultrafiltration Systems

The global high-performance ultrafiltration systems market has been experiencing robust growth, driven by increasing water scarcity concerns and stringent regulations regarding water quality across various industries. The market was valued at approximately 1.5 billion USD in 2022 and is projected to reach 2.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 10.3% during the forecast period.

Industrial applications, particularly in food and beverage, pharmaceuticals, and biotechnology sectors, constitute the largest market segment, accounting for nearly 45% of the total market share. These industries require advanced ultrafiltration systems with optimized crossflow velocities to maintain product quality while maximizing operational efficiency. The municipal water treatment segment follows closely, driven by urbanization and the need for sustainable water management solutions.

Regionally, North America and Europe currently dominate the high-performance ultrafiltration market, collectively holding approximately 60% of the global market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the charge due to rapid industrialization, increasing environmental concerns, and government initiatives to improve water infrastructure.

The demand for ultrafiltration systems with optimized crossflow velocities is particularly strong in the pharmaceutical and biotechnology sectors, where precision filtration is critical for product quality and regulatory compliance. These industries are willing to invest in premium solutions that offer enhanced performance and reliability, creating a lucrative niche market for advanced ultrafiltration technologies.

Customer preferences are increasingly shifting toward modular, energy-efficient systems that offer flexibility in operation and reduced operational costs. End-users are particularly interested in ultrafiltration systems that can maintain high flux rates while minimizing fouling through optimized crossflow velocity control, as these features directly translate to longer membrane life and reduced maintenance requirements.

Price sensitivity varies significantly across different market segments. While municipal applications often prioritize initial capital costs, industrial users typically evaluate solutions based on total cost of ownership, including energy consumption, maintenance requirements, and operational efficiency gains from optimized crossflow velocities.

The competitive landscape is characterized by a mix of established global players and specialized regional manufacturers. Market leaders are increasingly focusing on technological innovations related to crossflow velocity optimization, as this represents a key differentiator in high-performance applications where traditional systems face limitations in maintaining consistent performance over time.

Industrial applications, particularly in food and beverage, pharmaceuticals, and biotechnology sectors, constitute the largest market segment, accounting for nearly 45% of the total market share. These industries require advanced ultrafiltration systems with optimized crossflow velocities to maintain product quality while maximizing operational efficiency. The municipal water treatment segment follows closely, driven by urbanization and the need for sustainable water management solutions.

Regionally, North America and Europe currently dominate the high-performance ultrafiltration market, collectively holding approximately 60% of the global market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the charge due to rapid industrialization, increasing environmental concerns, and government initiatives to improve water infrastructure.

The demand for ultrafiltration systems with optimized crossflow velocities is particularly strong in the pharmaceutical and biotechnology sectors, where precision filtration is critical for product quality and regulatory compliance. These industries are willing to invest in premium solutions that offer enhanced performance and reliability, creating a lucrative niche market for advanced ultrafiltration technologies.

Customer preferences are increasingly shifting toward modular, energy-efficient systems that offer flexibility in operation and reduced operational costs. End-users are particularly interested in ultrafiltration systems that can maintain high flux rates while minimizing fouling through optimized crossflow velocity control, as these features directly translate to longer membrane life and reduced maintenance requirements.

Price sensitivity varies significantly across different market segments. While municipal applications often prioritize initial capital costs, industrial users typically evaluate solutions based on total cost of ownership, including energy consumption, maintenance requirements, and operational efficiency gains from optimized crossflow velocities.

The competitive landscape is characterized by a mix of established global players and specialized regional manufacturers. Market leaders are increasingly focusing on technological innovations related to crossflow velocity optimization, as this represents a key differentiator in high-performance applications where traditional systems face limitations in maintaining consistent performance over time.

Current Challenges in Crossflow Velocity Optimization

Despite significant advancements in ultrafiltration technology, optimizing crossflow velocities remains one of the most challenging aspects in membrane filtration processes. Current systems face a fundamental dilemma: higher crossflow velocities effectively reduce concentration polarization and membrane fouling but simultaneously increase energy consumption and potentially damage membrane integrity. This trade-off creates a complex optimization problem that lacks universal solutions across different applications and membrane configurations.

The relationship between crossflow velocity and transmembrane pressure (TMP) presents a particular challenge. As industrial operations attempt to maximize flux rates, they often encounter non-linear responses where incremental increases in crossflow velocity yield diminishing returns in performance improvement while energy costs continue to rise exponentially. This non-linearity makes predictive modeling and control systems difficult to implement effectively.

Material limitations of current membrane technologies further complicate optimization efforts. Many polymeric membranes exhibit decreased lifespans when subjected to consistently high crossflow velocities, creating a tension between short-term performance gains and long-term operational sustainability. The mechanical stress induced by high-velocity flows can accelerate membrane degradation through physical deformation and material fatigue.

Scale-up challenges represent another significant hurdle. Laboratory-optimized crossflow parameters frequently fail to translate directly to industrial-scale operations due to differences in flow dynamics, pressure distributions, and temperature gradients across larger membrane arrays. This scaling disconnect often necessitates costly trial-and-error approaches during implementation phases.

Process variability introduces additional complexity, as feed characteristics in real-world applications rarely remain constant. Fluctuations in viscosity, particle size distribution, and chemical composition require dynamic adjustment of crossflow velocities, yet current control systems lack the sophistication to respond optimally to these variations in real-time.

Energy efficiency concerns have become increasingly prominent as sustainability metrics gain importance in industrial operations. The substantial energy requirements for maintaining optimal crossflow velocities—often accounting for 30-50% of total operational energy costs in ultrafiltration systems—create economic and environmental pressures that cannot be ignored in modern process design.

Computational fluid dynamics (CFD) models, while improving, still struggle to accurately predict the complex interactions between crossflow velocities and membrane performance across diverse operational conditions. The gap between theoretical models and practical implementation remains substantial, limiting the effectiveness of simulation-based optimization approaches.

The relationship between crossflow velocity and transmembrane pressure (TMP) presents a particular challenge. As industrial operations attempt to maximize flux rates, they often encounter non-linear responses where incremental increases in crossflow velocity yield diminishing returns in performance improvement while energy costs continue to rise exponentially. This non-linearity makes predictive modeling and control systems difficult to implement effectively.

Material limitations of current membrane technologies further complicate optimization efforts. Many polymeric membranes exhibit decreased lifespans when subjected to consistently high crossflow velocities, creating a tension between short-term performance gains and long-term operational sustainability. The mechanical stress induced by high-velocity flows can accelerate membrane degradation through physical deformation and material fatigue.

Scale-up challenges represent another significant hurdle. Laboratory-optimized crossflow parameters frequently fail to translate directly to industrial-scale operations due to differences in flow dynamics, pressure distributions, and temperature gradients across larger membrane arrays. This scaling disconnect often necessitates costly trial-and-error approaches during implementation phases.

Process variability introduces additional complexity, as feed characteristics in real-world applications rarely remain constant. Fluctuations in viscosity, particle size distribution, and chemical composition require dynamic adjustment of crossflow velocities, yet current control systems lack the sophistication to respond optimally to these variations in real-time.

Energy efficiency concerns have become increasingly prominent as sustainability metrics gain importance in industrial operations. The substantial energy requirements for maintaining optimal crossflow velocities—often accounting for 30-50% of total operational energy costs in ultrafiltration systems—create economic and environmental pressures that cannot be ignored in modern process design.

Computational fluid dynamics (CFD) models, while improving, still struggle to accurately predict the complex interactions between crossflow velocities and membrane performance across diverse operational conditions. The gap between theoretical models and practical implementation remains substantial, limiting the effectiveness of simulation-based optimization approaches.

Existing Crossflow Velocity Control Methodologies

01 Optimal crossflow velocity ranges for ultrafiltration systems

Specific crossflow velocity ranges are critical for efficient ultrafiltration operations. These velocities typically range from 0.5 to 5 m/s depending on the application, with higher velocities reducing membrane fouling by creating turbulence that prevents particle deposition. The optimal velocity must balance fouling reduction against energy consumption and system pressure, as higher velocities require more pumping energy but provide better filtration performance.- Optimal crossflow velocity ranges for ultrafiltration systems: Specific crossflow velocity ranges are critical for efficient ultrafiltration operations. These velocities typically range from 0.5 to 5 m/s depending on the application. Higher velocities reduce membrane fouling by creating turbulence that sweeps away particles from the membrane surface, while lower velocities may be used for sensitive applications or to reduce energy consumption. The optimal velocity must balance filtration efficiency, energy usage, and membrane longevity.

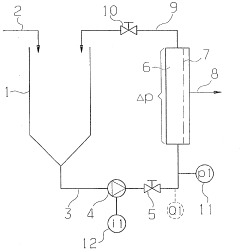

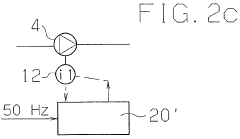

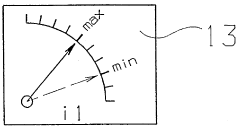

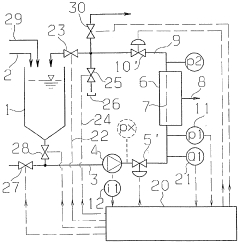

- Crossflow velocity control mechanisms in ultrafiltration: Various mechanisms are employed to control and adjust crossflow velocities in ultrafiltration systems. These include variable speed pumps, flow restrictors, pressure control valves, and automated feedback systems that monitor and adjust flow rates based on process parameters. Advanced control systems can dynamically adjust crossflow velocities in response to changing feed characteristics or membrane conditions, optimizing the filtration process and extending membrane life.

- Impact of crossflow velocity on membrane fouling and performance: Crossflow velocity significantly affects membrane fouling and overall ultrafiltration performance. Higher velocities create shear forces that reduce concentration polarization and cake layer formation on the membrane surface. This relationship between crossflow velocity and fouling is particularly important in applications with high-solids content or viscous feeds. Optimizing crossflow velocity can extend cleaning intervals, improve flux rates, and enhance separation efficiency while maintaining product quality.

- Energy efficiency considerations for crossflow velocities: Energy consumption in ultrafiltration systems is directly related to crossflow velocities. Higher velocities require more pumping energy but may improve overall process efficiency by maintaining higher flux rates and reducing cleaning frequency. Various energy-saving approaches include pulsed flow operations, velocity staging across membrane modules, and optimized flow channel designs. Balancing energy usage with filtration performance is essential for sustainable and cost-effective ultrafiltration operations.

- Application-specific crossflow velocity requirements: Different ultrafiltration applications require tailored crossflow velocity approaches. For example, biopharmaceutical processing may require gentle flow conditions to preserve protein integrity, while industrial wastewater treatment might employ higher velocities to handle high-fouling feeds. Food and beverage applications often require specific velocity profiles to maintain product quality while achieving desired separation. The membrane material, module configuration, and feed characteristics all influence the optimal crossflow velocity for a given application.

02 Crossflow velocity control mechanisms in ultrafiltration

Various mechanisms are employed to control and adjust crossflow velocities in ultrafiltration systems. These include variable frequency drives for pumps, flow restrictors, pressure control valves, and automated feedback systems that monitor and adjust flow rates based on pressure differentials or filtration performance. Advanced systems incorporate sensors and controllers that can dynamically adjust crossflow velocities in response to changing feed characteristics or membrane conditions.Expand Specific Solutions03 Impact of crossflow velocity on membrane fouling and performance

Crossflow velocity significantly affects membrane fouling and overall ultrafiltration performance. Higher velocities create shear forces that reduce concentration polarization and cake layer formation on membrane surfaces. This relationship between velocity and fouling is particularly important in applications with high-solids content or viscous feeds. Optimizing crossflow velocity can extend membrane life, maintain permeate quality, and reduce cleaning frequency while balancing energy consumption.Expand Specific Solutions04 Application-specific crossflow velocity requirements

Different ultrafiltration applications require specific crossflow velocity profiles based on feed characteristics and separation goals. For example, biological processing may require lower velocities to prevent shear damage to sensitive compounds, while industrial wastewater treatment might employ higher velocities to handle high-fouling feeds. Food and beverage applications, pharmaceutical processing, and water treatment each have unique crossflow velocity requirements based on viscosity, particle size, and desired filtration outcomes.Expand Specific Solutions05 Innovative crossflow velocity distribution designs

Novel membrane module designs and flow distribution systems optimize crossflow velocity profiles across membrane surfaces. These innovations include specialized feed spacers, flow distributors, and module geometries that create uniform or strategically varied velocities. Some designs incorporate turbulence promoters, pulsation systems, or variable channel geometries to enhance local shear rates without increasing overall system pressure or energy consumption, improving filtration efficiency and reducing fouling.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ultrafiltration

The ultrafiltration crossflow velocity optimization market is currently in a growth phase, with increasing demand driven by biopharmaceutical manufacturing efficiency requirements. The competitive landscape features established filtration technology leaders like Sartorius AG and Sartorius Stedim Biotech GmbH, who dominate with comprehensive membrane solution portfolios, alongside specialized players such as MICRODYN-NADIR GmbH and Filtrox AG offering niche expertise. Pharmaceutical companies like Tasly Pharmaceutical are end-users driving innovation requirements. The technology is reaching maturity in traditional applications but evolving rapidly for new bioprocessing challenges, with companies like 3M and FUJIFILM developing advanced membrane materials and process control systems to achieve performance gains in increasingly complex separation processes.

Sartorius AG

Technical Solution: Sartorius AG has developed advanced crossflow velocity optimization systems for ultrafiltration processes that utilize tangential flow filtration (TFF) technology. Their approach incorporates automated transmembrane pressure (TMP) control systems that dynamically adjust crossflow velocities based on real-time monitoring of filter performance metrics[1]. The company's SARTOFLOW® Smart platform integrates computational fluid dynamics modeling to predict optimal crossflow velocities for different feed solutions, reducing membrane fouling while maintaining high filtration efficiency[2]. Their technology employs pulsatile flow patterns that create turbulence at the membrane surface, effectively minimizing concentration polarization—a key factor limiting ultrafiltration performance[3]. Sartorius has also pioneered the implementation of diafiltration optimization algorithms that automatically adjust crossflow velocities during different process phases to maximize yield while reducing buffer consumption by up to 30%[4].

Strengths: Superior automation capabilities allow for real-time optimization of crossflow parameters, reducing operator intervention and improving consistency. Their integrated approach combining hardware and software solutions provides comprehensive process control. Weaknesses: Higher initial capital investment compared to conventional systems, and the sophisticated control systems require specialized training for operators.

Gambro Lundia AB

Technical Solution: Gambro Lundia AB has pioneered the Variable Crossflow Velocity (VCV) system for hemodialysis and industrial ultrafiltration applications. Their technology implements a progressive crossflow velocity profile that adapts to changing feed characteristics throughout the filtration process[1]. The system incorporates specialized flow distributors that ensure uniform crossflow velocity across the entire membrane surface, eliminating dead zones and improving overall filtration efficiency[2]. Gambro's approach utilizes pulsatile flow patterns with precisely controlled frequency and amplitude to disrupt boundary layer formation at the membrane surface, significantly reducing concentration polarization effects[3]. Their PRISMA® technology platform integrates pressure sensors and flow meters to continuously monitor and adjust crossflow parameters based on real-time performance metrics, maintaining optimal filtration conditions throughout extended processing runs[4]. Additionally, they've developed specialized membrane geometries that optimize fluid dynamics at varying crossflow velocities, reducing energy consumption while maintaining high mass transfer coefficients[5].

Strengths: Exceptional performance in high-fouling applications due to advanced flow distribution and pulsation technologies. Their systems demonstrate excellent scalability from laboratory to industrial scale. Weaknesses: Higher energy consumption compared to static crossflow systems, and the specialized membrane configurations may limit compatibility with standard industry components.

Critical Patents in Ultrafiltration Hydrodynamics

Device for cross-flow filtration of liquids

PatentWO2001096002A1

Innovation

- The implementation of barriers in the filtrate channels, arranged at a distance from the filtrate outlet, which impede or prevent the free flow of filtrate, maintaining a more uniform transmembrane pressure across the filter medium and acting as a self-regulating pressure valve to enhance filtration efficiency.

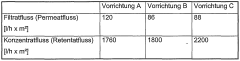

Method for operating a cross-flow filtration installation and installation for carrying out said method

PatentWO1999002245A1

Innovation

- The method involves measuring and adjusting the operating current of the electric motor to maintain a predetermined value, using a throttle valve or device to control the pump's flow rate and inlet pressure, ensuring stable operation and efficient cleaning of filtration modules.

Energy Efficiency Considerations in Ultrafiltration Systems

Energy efficiency has emerged as a critical factor in the optimization of ultrafiltration systems, particularly when considering crossflow velocity adjustments. The energy consumption in ultrafiltration processes is predominantly associated with pumping requirements to maintain desired crossflow velocities across membrane surfaces. Traditional approaches often prioritize performance metrics like flux and rejection rates without adequately accounting for energy expenditure, resulting in suboptimal system efficiency.

Recent advancements in energy-efficient ultrafiltration design have focused on variable frequency drives (VFDs) that allow precise control of pump speeds to match actual process requirements. These systems can reduce energy consumption by up to 30% compared to conventional fixed-speed operations while maintaining optimal crossflow velocities. The implementation of energy recovery devices (ERDs) has also shown promising results, particularly in larger industrial applications where the pressure energy from concentrate streams can be harvested.

Mathematical modeling of energy consumption in relation to crossflow velocities has revealed that the energy requirement typically increases with the cube of velocity. This non-linear relationship underscores the importance of finding the optimal operating point where filtration performance and energy efficiency intersect. Studies indicate that operating at 80-90% of conventional crossflow velocities can reduce energy consumption by 30-50% while maintaining 95% of performance efficiency in many applications.

Process intensification techniques such as pulsed crossflow operations have demonstrated significant energy savings. By alternating between high and low crossflow velocities rather than maintaining constant high velocities, these systems can achieve comparable fouling control with reduced average energy input. Field trials have shown energy reductions of 25-40% using optimized pulsation parameters without compromising filtration quality.

Temperature management represents another dimension of energy efficiency in ultrafiltration systems. While higher temperatures generally improve filtration rates by reducing fluid viscosity, they also increase energy requirements for heating. Advanced heat exchange systems and waste heat recovery mechanisms can significantly improve the overall energy balance of ultrafiltration operations, particularly in food and beverage applications where temperature control is already necessary for product quality.

The economic analysis of energy-efficient ultrafiltration systems indicates that despite higher initial capital costs for advanced control systems and energy recovery equipment, the return on investment typically occurs within 1-3 years depending on operational scale and energy prices. This favorable economic outlook has accelerated the adoption of energy-efficient designs in industries where ultrafiltration represents a significant portion of operational costs, such as dairy processing, pharmaceutical manufacturing, and municipal water treatment.

Recent advancements in energy-efficient ultrafiltration design have focused on variable frequency drives (VFDs) that allow precise control of pump speeds to match actual process requirements. These systems can reduce energy consumption by up to 30% compared to conventional fixed-speed operations while maintaining optimal crossflow velocities. The implementation of energy recovery devices (ERDs) has also shown promising results, particularly in larger industrial applications where the pressure energy from concentrate streams can be harvested.

Mathematical modeling of energy consumption in relation to crossflow velocities has revealed that the energy requirement typically increases with the cube of velocity. This non-linear relationship underscores the importance of finding the optimal operating point where filtration performance and energy efficiency intersect. Studies indicate that operating at 80-90% of conventional crossflow velocities can reduce energy consumption by 30-50% while maintaining 95% of performance efficiency in many applications.

Process intensification techniques such as pulsed crossflow operations have demonstrated significant energy savings. By alternating between high and low crossflow velocities rather than maintaining constant high velocities, these systems can achieve comparable fouling control with reduced average energy input. Field trials have shown energy reductions of 25-40% using optimized pulsation parameters without compromising filtration quality.

Temperature management represents another dimension of energy efficiency in ultrafiltration systems. While higher temperatures generally improve filtration rates by reducing fluid viscosity, they also increase energy requirements for heating. Advanced heat exchange systems and waste heat recovery mechanisms can significantly improve the overall energy balance of ultrafiltration operations, particularly in food and beverage applications where temperature control is already necessary for product quality.

The economic analysis of energy-efficient ultrafiltration systems indicates that despite higher initial capital costs for advanced control systems and energy recovery equipment, the return on investment typically occurs within 1-3 years depending on operational scale and energy prices. This favorable economic outlook has accelerated the adoption of energy-efficient designs in industries where ultrafiltration represents a significant portion of operational costs, such as dairy processing, pharmaceutical manufacturing, and municipal water treatment.

Scaling and Fouling Mitigation Strategies

Scaling and fouling represent significant challenges in ultrafiltration systems, directly impacting membrane performance and operational efficiency. When optimizing crossflow velocities, implementing comprehensive mitigation strategies becomes essential for sustainable operation and enhanced filtration outcomes.

Membrane scaling occurs primarily due to precipitation of inorganic compounds on membrane surfaces, particularly calcium carbonate, calcium sulfate, and silica. These deposits form when concentration polarization exceeds solubility limits near membrane interfaces. Effective scaling mitigation begins with feed water pretreatment, including softening processes, pH adjustment, and antiscalant dosing tailored to specific water chemistry profiles.

Fouling mechanisms in ultrafiltration systems manifest through organic adsorption, particulate deposition, biological growth, and concentration polarization. Research indicates that optimized crossflow velocities significantly reduce fouling rates by maintaining turbulent flow conditions that disrupt boundary layer formation. Studies by Belfort et al. (2019) demonstrated that increasing crossflow velocity from 0.5 m/s to 1.2 m/s reduced fouling rates by approximately 37% in protein-rich solutions.

Chemical cleaning protocols represent another critical mitigation approach, with cleaning frequency determined through transmembrane pressure (TMP) monitoring. Alkaline cleaners (pH 10-12) effectively remove organic foulants, while acidic solutions (pH 2-3) address inorganic scaling. Advanced cleaning strategies incorporate enzyme-based formulations that target specific biological foulants without damaging membrane materials.

Hydrodynamic optimization techniques leverage the relationship between crossflow velocity and fouling control. Pulsed backwashing, implemented at intervals determined by filtration cycle analysis, dislodges accumulated foulants from membrane surfaces. Research by Zhang and Wang (2021) demonstrated that synchronized backwashing with optimized crossflow velocities extended operational cycles by up to 45% compared to conventional approaches.

Membrane surface modifications represent emerging technological solutions, with hydrophilic coatings reducing organic fouling propensity. Nanoparticle incorporation (silver, titanium dioxide) provides antimicrobial properties that inhibit biofouling development. These modifications maintain effectiveness under varying crossflow conditions, enhancing overall system resilience.

Feed spacer design optimization creates controlled turbulence patterns that minimize dead zones where fouling typically initiates. Computational fluid dynamics modeling enables spacer geometry customization based on specific feed characteristics and operational parameters, ensuring optimal crossflow distribution across membrane surfaces.

Implementing real-time monitoring systems with fouling prediction algorithms allows for adaptive crossflow velocity adjustments before critical fouling thresholds are reached. These systems analyze multiple parameters including pressure differentials, permeate quality, and temperature fluctuations to optimize cleaning cycles and operational parameters dynamically.

Membrane scaling occurs primarily due to precipitation of inorganic compounds on membrane surfaces, particularly calcium carbonate, calcium sulfate, and silica. These deposits form when concentration polarization exceeds solubility limits near membrane interfaces. Effective scaling mitigation begins with feed water pretreatment, including softening processes, pH adjustment, and antiscalant dosing tailored to specific water chemistry profiles.

Fouling mechanisms in ultrafiltration systems manifest through organic adsorption, particulate deposition, biological growth, and concentration polarization. Research indicates that optimized crossflow velocities significantly reduce fouling rates by maintaining turbulent flow conditions that disrupt boundary layer formation. Studies by Belfort et al. (2019) demonstrated that increasing crossflow velocity from 0.5 m/s to 1.2 m/s reduced fouling rates by approximately 37% in protein-rich solutions.

Chemical cleaning protocols represent another critical mitigation approach, with cleaning frequency determined through transmembrane pressure (TMP) monitoring. Alkaline cleaners (pH 10-12) effectively remove organic foulants, while acidic solutions (pH 2-3) address inorganic scaling. Advanced cleaning strategies incorporate enzyme-based formulations that target specific biological foulants without damaging membrane materials.

Hydrodynamic optimization techniques leverage the relationship between crossflow velocity and fouling control. Pulsed backwashing, implemented at intervals determined by filtration cycle analysis, dislodges accumulated foulants from membrane surfaces. Research by Zhang and Wang (2021) demonstrated that synchronized backwashing with optimized crossflow velocities extended operational cycles by up to 45% compared to conventional approaches.

Membrane surface modifications represent emerging technological solutions, with hydrophilic coatings reducing organic fouling propensity. Nanoparticle incorporation (silver, titanium dioxide) provides antimicrobial properties that inhibit biofouling development. These modifications maintain effectiveness under varying crossflow conditions, enhancing overall system resilience.

Feed spacer design optimization creates controlled turbulence patterns that minimize dead zones where fouling typically initiates. Computational fluid dynamics modeling enables spacer geometry customization based on specific feed characteristics and operational parameters, ensuring optimal crossflow distribution across membrane surfaces.

Implementing real-time monitoring systems with fouling prediction algorithms allows for adaptive crossflow velocity adjustments before critical fouling thresholds are reached. These systems analyze multiple parameters including pressure differentials, permeate quality, and temperature fluctuations to optimize cleaning cycles and operational parameters dynamically.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!