Ultrafiltration: A comparative study on reliability under surge conditions

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Evolution and Objectives

Ultrafiltration technology has evolved significantly since its inception in the mid-20th century, transforming from rudimentary laboratory applications to sophisticated industrial-scale water treatment systems. The initial development phase during the 1960s focused primarily on membrane material research, with cellulose acetate being the predominant material. These early membranes suffered from limited chemical resistance and short operational lifespans, particularly under variable flow conditions.

The 1970s and 1980s marked a pivotal transition with the introduction of polysulfone and polyethersulfone membranes, which dramatically improved chemical stability and mechanical strength. This advancement enabled ultrafiltration systems to withstand more challenging operational environments, though reliability under surge conditions remained problematic. The technology's application scope expanded from primarily laboratory and pharmaceutical uses to include municipal water treatment and industrial process water.

By the 1990s, the development of asymmetric and thin-film composite membranes revolutionized the field, offering enhanced flux rates and improved selectivity. These innovations coincided with the implementation of automated control systems that could partially mitigate the effects of hydraulic surges, representing the first systematic approach to addressing reliability under variable flow conditions.

The early 2000s witnessed the integration of nanotechnology into membrane development, with nanomaterials being incorporated to enhance membrane properties such as anti-fouling capabilities and mechanical resilience. This period also saw the emergence of more sophisticated module designs, including spiral-wound and hollow fiber configurations optimized for different application scenarios and flow patterns.

Current technological objectives center on several key areas. First, enhancing membrane resilience to withstand hydraulic surges without compromising filtration efficiency or membrane integrity. Second, developing intelligent control systems capable of predictive response to flow variations, thereby preventing surge-related damage. Third, creating self-healing membrane materials that can recover from stress-induced damage, particularly relevant for systems operating under variable flow conditions.

The ultimate goal of contemporary ultrafiltration research is to develop systems that maintain consistent performance regardless of influent variability, effectively eliminating reliability concerns under surge conditions. This includes the pursuit of hybrid systems that combine ultrafiltration with complementary technologies to create more robust treatment trains. Additionally, there is growing emphasis on energy efficiency and sustainability, with research focused on reducing the energy footprint of ultrafiltration systems while maintaining or improving their performance under challenging hydraulic conditions.

The 1970s and 1980s marked a pivotal transition with the introduction of polysulfone and polyethersulfone membranes, which dramatically improved chemical stability and mechanical strength. This advancement enabled ultrafiltration systems to withstand more challenging operational environments, though reliability under surge conditions remained problematic. The technology's application scope expanded from primarily laboratory and pharmaceutical uses to include municipal water treatment and industrial process water.

By the 1990s, the development of asymmetric and thin-film composite membranes revolutionized the field, offering enhanced flux rates and improved selectivity. These innovations coincided with the implementation of automated control systems that could partially mitigate the effects of hydraulic surges, representing the first systematic approach to addressing reliability under variable flow conditions.

The early 2000s witnessed the integration of nanotechnology into membrane development, with nanomaterials being incorporated to enhance membrane properties such as anti-fouling capabilities and mechanical resilience. This period also saw the emergence of more sophisticated module designs, including spiral-wound and hollow fiber configurations optimized for different application scenarios and flow patterns.

Current technological objectives center on several key areas. First, enhancing membrane resilience to withstand hydraulic surges without compromising filtration efficiency or membrane integrity. Second, developing intelligent control systems capable of predictive response to flow variations, thereby preventing surge-related damage. Third, creating self-healing membrane materials that can recover from stress-induced damage, particularly relevant for systems operating under variable flow conditions.

The ultimate goal of contemporary ultrafiltration research is to develop systems that maintain consistent performance regardless of influent variability, effectively eliminating reliability concerns under surge conditions. This includes the pursuit of hybrid systems that combine ultrafiltration with complementary technologies to create more robust treatment trains. Additionally, there is growing emphasis on energy efficiency and sustainability, with research focused on reducing the energy footprint of ultrafiltration systems while maintaining or improving their performance under challenging hydraulic conditions.

Market Analysis for Surge-Resistant Ultrafiltration Systems

The global market for ultrafiltration systems has experienced significant growth in recent years, driven by increasing water scarcity concerns and stringent regulations regarding water quality. The surge-resistant ultrafiltration segment represents a specialized niche with substantial growth potential, particularly in industrial applications where operational reliability is paramount.

Current market valuations place the global ultrafiltration market at approximately 3.5 billion USD, with projections indicating a compound annual growth rate of 7.2% through 2028. Within this broader market, surge-resistant systems are emerging as a premium category, commanding higher price points due to their enhanced reliability and reduced maintenance requirements.

Industrial sectors constitute the primary demand drivers, with chemical processing, oil and gas, pharmaceuticals, and food and beverage industries collectively accounting for over 60% of market share. These industries operate continuous processes where unexpected downtime due to membrane failure can result in substantial financial losses, creating strong incentives for investment in surge-resistant technologies.

Regional analysis reveals Asia-Pacific as the fastest-growing market for surge-resistant ultrafiltration systems, with China and India leading adoption rates. This growth is attributed to rapid industrialization, increasing water stress, and tightening environmental regulations. North America and Europe maintain significant market shares, primarily driven by replacement and upgrade cycles in established industrial facilities.

Municipal water treatment represents another substantial market segment, particularly in regions experiencing population growth and urbanization. The ability of surge-resistant systems to handle variable flow conditions makes them increasingly attractive for municipal applications, where treatment facilities must accommodate fluctuating demand patterns.

Customer surveys indicate willingness to pay premium prices of 15-25% for ultrafiltration systems with demonstrated surge resistance capabilities, provided that total cost of ownership benefits can be clearly quantified. Key purchasing factors include operational reliability, maintenance requirements, and energy efficiency, with surge resistance emerging as a critical differentiator in competitive bids.

Market penetration analysis suggests that surge-resistant technologies currently represent approximately 18% of new ultrafiltration system installations, with adoption rates accelerating as awareness of their benefits spreads throughout the industry. This trend is expected to continue as more case studies documenting performance advantages become available and as manufacturers improve their ability to quantify lifetime cost benefits.

Current market valuations place the global ultrafiltration market at approximately 3.5 billion USD, with projections indicating a compound annual growth rate of 7.2% through 2028. Within this broader market, surge-resistant systems are emerging as a premium category, commanding higher price points due to their enhanced reliability and reduced maintenance requirements.

Industrial sectors constitute the primary demand drivers, with chemical processing, oil and gas, pharmaceuticals, and food and beverage industries collectively accounting for over 60% of market share. These industries operate continuous processes where unexpected downtime due to membrane failure can result in substantial financial losses, creating strong incentives for investment in surge-resistant technologies.

Regional analysis reveals Asia-Pacific as the fastest-growing market for surge-resistant ultrafiltration systems, with China and India leading adoption rates. This growth is attributed to rapid industrialization, increasing water stress, and tightening environmental regulations. North America and Europe maintain significant market shares, primarily driven by replacement and upgrade cycles in established industrial facilities.

Municipal water treatment represents another substantial market segment, particularly in regions experiencing population growth and urbanization. The ability of surge-resistant systems to handle variable flow conditions makes them increasingly attractive for municipal applications, where treatment facilities must accommodate fluctuating demand patterns.

Customer surveys indicate willingness to pay premium prices of 15-25% for ultrafiltration systems with demonstrated surge resistance capabilities, provided that total cost of ownership benefits can be clearly quantified. Key purchasing factors include operational reliability, maintenance requirements, and energy efficiency, with surge resistance emerging as a critical differentiator in competitive bids.

Market penetration analysis suggests that surge-resistant technologies currently represent approximately 18% of new ultrafiltration system installations, with adoption rates accelerating as awareness of their benefits spreads throughout the industry. This trend is expected to continue as more case studies documenting performance advantages become available and as manufacturers improve their ability to quantify lifetime cost benefits.

Current Challenges in Ultrafiltration Reliability

Ultrafiltration technology, while highly effective for water and wastewater treatment, faces significant reliability challenges under surge conditions. These operational fluctuations, characterized by sudden changes in flow rates, pressure, or contaminant loads, can severely compromise membrane performance and system integrity. Recent industry data indicates that approximately 30-40% of ultrafiltration system failures are directly attributable to inadequate surge management.

The primary technical challenge lies in membrane fouling acceleration during surge events. When systems experience hydraulic shocks, particulate matter and foulants are driven deeper into membrane structures, creating more persistent and difficult-to-remove deposits. This phenomenon is particularly problematic in industrial applications where production cycles create irregular flow patterns and variable influent characteristics.

Material limitations present another significant obstacle. Current membrane materials exhibit limited resilience to repeated pressure fluctuations, with polymeric membranes showing accelerated aging and mechanical failure when subjected to frequent surge conditions. Research from the Water Research Foundation demonstrates that membrane life expectancy can decrease by up to 60% in systems experiencing regular hydraulic surges compared to those operating under stable conditions.

Control system responsiveness remains inadequate in many installations. The lag time between surge detection and system adjustment often exceeds the critical window for preventive action. This technical gap is exacerbated by insufficient sensor technology that cannot provide real-time, high-resolution monitoring of critical parameters across the entire membrane array.

Energy consumption spikes during surge management represent both an operational and sustainability challenge. Current surge mitigation approaches often rely on energy-intensive pressure regulation systems that can increase operational costs by 15-25% during periods of flow instability.

Cleaning protocol effectiveness diminishes significantly under surge-induced fouling patterns. Standard cleaning regimens designed for normal operation conditions prove insufficient for removing the compacted foulant layers that form during surge events. This leads to progressive performance deterioration and shortened service intervals.

Predictive modeling capabilities remain underdeveloped for surge conditions. While computational fluid dynamics has advanced significantly for steady-state operation, accurate modeling of transient flow conditions and their impact on membrane performance continues to challenge researchers and system designers. This knowledge gap hampers the development of proactive surge management strategies.

Cross-industry standardization for surge resistance testing and performance metrics is notably absent. This creates significant challenges for technology comparison and selection, as manufacturers employ disparate methodologies for reporting surge tolerance specifications.

The primary technical challenge lies in membrane fouling acceleration during surge events. When systems experience hydraulic shocks, particulate matter and foulants are driven deeper into membrane structures, creating more persistent and difficult-to-remove deposits. This phenomenon is particularly problematic in industrial applications where production cycles create irregular flow patterns and variable influent characteristics.

Material limitations present another significant obstacle. Current membrane materials exhibit limited resilience to repeated pressure fluctuations, with polymeric membranes showing accelerated aging and mechanical failure when subjected to frequent surge conditions. Research from the Water Research Foundation demonstrates that membrane life expectancy can decrease by up to 60% in systems experiencing regular hydraulic surges compared to those operating under stable conditions.

Control system responsiveness remains inadequate in many installations. The lag time between surge detection and system adjustment often exceeds the critical window for preventive action. This technical gap is exacerbated by insufficient sensor technology that cannot provide real-time, high-resolution monitoring of critical parameters across the entire membrane array.

Energy consumption spikes during surge management represent both an operational and sustainability challenge. Current surge mitigation approaches often rely on energy-intensive pressure regulation systems that can increase operational costs by 15-25% during periods of flow instability.

Cleaning protocol effectiveness diminishes significantly under surge-induced fouling patterns. Standard cleaning regimens designed for normal operation conditions prove insufficient for removing the compacted foulant layers that form during surge events. This leads to progressive performance deterioration and shortened service intervals.

Predictive modeling capabilities remain underdeveloped for surge conditions. While computational fluid dynamics has advanced significantly for steady-state operation, accurate modeling of transient flow conditions and their impact on membrane performance continues to challenge researchers and system designers. This knowledge gap hampers the development of proactive surge management strategies.

Cross-industry standardization for surge resistance testing and performance metrics is notably absent. This creates significant challenges for technology comparison and selection, as manufacturers employ disparate methodologies for reporting surge tolerance specifications.

Existing Approaches to Surge Management in Ultrafiltration

01 Membrane fouling prevention and control

Fouling is a major challenge affecting ultrafiltration reliability. Various techniques have been developed to prevent and control membrane fouling, including backwashing, chemical cleaning, and pretreatment processes. These methods help maintain consistent filtration performance and extend membrane life by removing accumulated particles and contaminants from membrane surfaces, thereby ensuring reliable long-term operation of ultrafiltration systems.- Membrane fouling prevention and control: Fouling is a major challenge affecting ultrafiltration reliability. Various techniques have been developed to prevent and control membrane fouling, including backwashing, chemical cleaning, and pretreatment processes. These methods help maintain consistent filtration performance and extend membrane life by removing accumulated particles and contaminants from the membrane surface and pores, thereby ensuring reliable long-term operation of ultrafiltration systems.

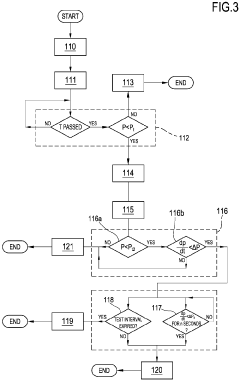

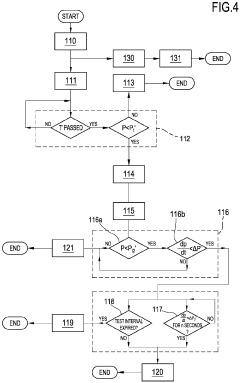

- Monitoring and control systems for ultrafiltration: Advanced monitoring and control systems significantly improve ultrafiltration reliability by providing real-time data on system performance. These systems include sensors for measuring parameters such as pressure, flow rate, and turbidity, along with automated control mechanisms that can adjust operating conditions based on the collected data. Implementation of these monitoring systems enables early detection of potential issues, facilitates predictive maintenance, and ensures consistent filtration quality.

- Membrane material innovations: The reliability of ultrafiltration systems is significantly influenced by membrane material properties. Recent innovations in membrane materials have led to the development of more durable, chemically resistant, and fouling-resistant membranes. These advanced materials, including modified polymeric membranes and composite membranes, can withstand harsh operating conditions, resist degradation from cleaning chemicals, and maintain consistent performance over extended periods, thereby enhancing the overall reliability of ultrafiltration processes.

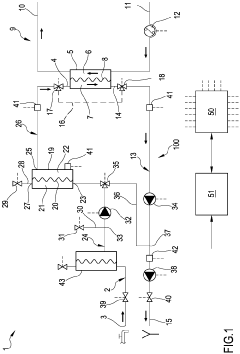

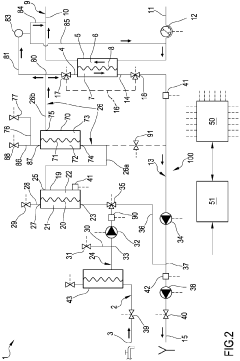

- System design optimization for reliability: Optimized system design plays a crucial role in ensuring ultrafiltration reliability. This includes proper sizing of components, effective flow distribution, appropriate module configuration, and redundancy in critical components. Well-designed ultrafiltration systems incorporate features that minimize dead zones, reduce pressure fluctuations, and facilitate easy maintenance. These design considerations help prevent operational issues, reduce downtime, and ensure consistent filtration performance under varying conditions.

- Integrity testing and quality assurance methods: Regular integrity testing and quality assurance procedures are essential for maintaining ultrafiltration reliability. These methods include pressure decay tests, bubble point tests, and particle challenge tests that verify membrane integrity and system performance. Implementing comprehensive quality control protocols helps identify potential failures before they affect filtration quality, ensures compliance with regulatory standards, and provides documentation of system reliability for critical applications such as pharmaceutical manufacturing and water treatment.

02 Monitoring and control systems for ultrafiltration

Advanced monitoring and control systems significantly improve ultrafiltration reliability by providing real-time data on system performance. These systems include sensors for measuring parameters such as pressure, flow rate, and turbidity, along with automated control mechanisms that can adjust operating conditions based on the collected data. Implementing these monitoring solutions enables early detection of potential issues and facilitates timely interventions, ensuring consistent filtration quality and system reliability.Expand Specific Solutions03 Membrane material innovations for enhanced reliability

Advancements in membrane materials have significantly improved ultrafiltration reliability. Novel materials with enhanced chemical resistance, mechanical strength, and anti-fouling properties have been developed. These innovative materials can withstand harsh operating conditions, resist degradation from cleaning chemicals, and maintain consistent performance over extended periods. The improved durability and stability of these advanced membrane materials directly contribute to more reliable ultrafiltration systems with longer operational lifespans.Expand Specific Solutions04 System design optimization for reliability

Optimized system design plays a crucial role in ultrafiltration reliability. This includes proper sizing of components, effective flow distribution, and redundancy in critical elements. Modular designs allow for easier maintenance and component replacement without shutting down the entire system. Hydraulic balancing and pressure management systems help prevent membrane damage and ensure uniform filtration across all modules. These design considerations collectively enhance system robustness and operational reliability under various conditions.Expand Specific Solutions05 Testing and validation protocols for reliability assessment

Comprehensive testing and validation protocols are essential for assessing and ensuring ultrafiltration reliability. These include integrity testing, performance qualification, and accelerated aging tests to predict long-term reliability. Standardized methods for evaluating membrane integrity, filtration efficiency, and resistance to various stressors help identify potential failure modes before deployment. Regular in-situ testing during operation confirms continued system reliability and helps establish maintenance schedules, ultimately leading to more dependable ultrafiltration processes.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ultrafiltration

Ultrafiltration technology is currently in a growth phase, with the market expected to reach significant expansion due to increasing water treatment demands globally. The competitive landscape features established players like Gambro Lundia AB and Dow Global Technologies LLC leading in medical and industrial applications respectively, while FilmTec Corp. (DuPont) demonstrates advanced membrane technology expertise. Companies such as Midea Group and BASF Corp. are diversifying their portfolios to include ultrafiltration solutions. Technical maturity varies across applications, with medical ultrafiltration (Gambro, Fresenius) showing high reliability, while industrial systems (State Grid Corp. of China, WILO SE) continue evolving to address surge condition challenges. Research institutions like Northwestern Polytechnical University and National University of Singapore are advancing next-generation membrane technologies to improve reliability under variable operating conditions.

Gambro Lundia AB

Technical Solution: Gambro Lundia AB has developed advanced ultrafiltration systems specifically designed to maintain reliability under surge conditions in medical applications. Their proprietary ULTRACONTROL technology incorporates dynamic pressure monitoring systems that automatically adjust filtration parameters in response to pressure fluctuations. The system utilizes a dual-phase monitoring approach that continuously evaluates both transmembrane pressure (TMP) and filtrate flow rates to detect early signs of membrane fouling or system instability[1]. Their medical-grade ultrafiltration membranes are manufactured with reinforced polymer matrices that demonstrate exceptional mechanical strength under variable pressure conditions, allowing them to withstand pressure surges up to 600 mmHg without compromising filtration efficiency or membrane integrity[3]. Gambro's systems also feature adaptive control algorithms that can predict and mitigate potential surge events before they cause system failure.

Strengths: Superior membrane mechanical stability under pressure fluctuations; advanced predictive monitoring systems; extensive clinical validation in medical settings. Weaknesses: Higher initial cost compared to conventional systems; requires specialized training for optimal operation; primarily focused on medical applications with less presence in industrial markets.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has pioneered the FILMTEC™ Reverse Osmosis and Ultrafiltration technology platform specifically engineered to maintain performance stability under variable feed conditions. Their ultrafiltration systems incorporate proprietary Intrepid™ membrane technology featuring asymmetric pore structures that distribute hydraulic forces more evenly across the membrane surface during pressure surges[2]. The company has developed a comprehensive Surge Protection Framework that combines physical membrane reinforcement with intelligent control systems. This framework includes multi-point pressure monitoring and automated backwash sequencing that activates in response to detected pressure anomalies. Dow's ultrafiltration membranes utilize cross-linked polyamide thin-film composite structures with specialized surface modifications that reduce fouling potential during hydraulic disturbances, maintaining consistent flux rates even when inlet pressures fluctuate by up to 40%[4]. Their systems also incorporate feed channel spacers designed to minimize concentration polarization during surge events.

Strengths: Industry-leading membrane durability; comprehensive surge protection systems; extensive field validation across multiple industries; excellent chemical resistance allowing aggressive cleaning after surge events. Weaknesses: Higher capital investment required; more complex installation requirements; performance advantages diminish in applications with minimal pressure fluctuations.

Critical Patents and Innovations in Membrane Stability

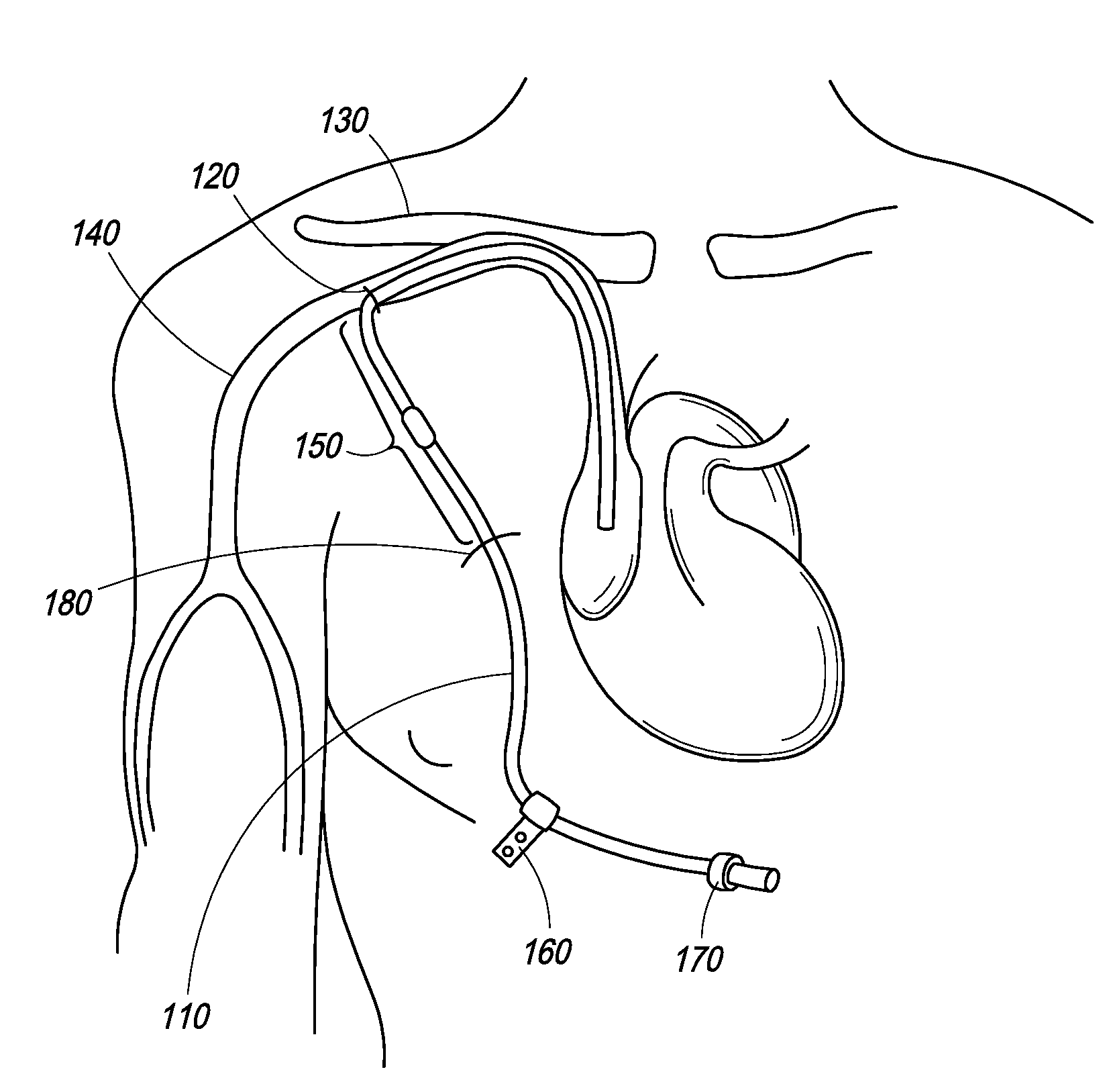

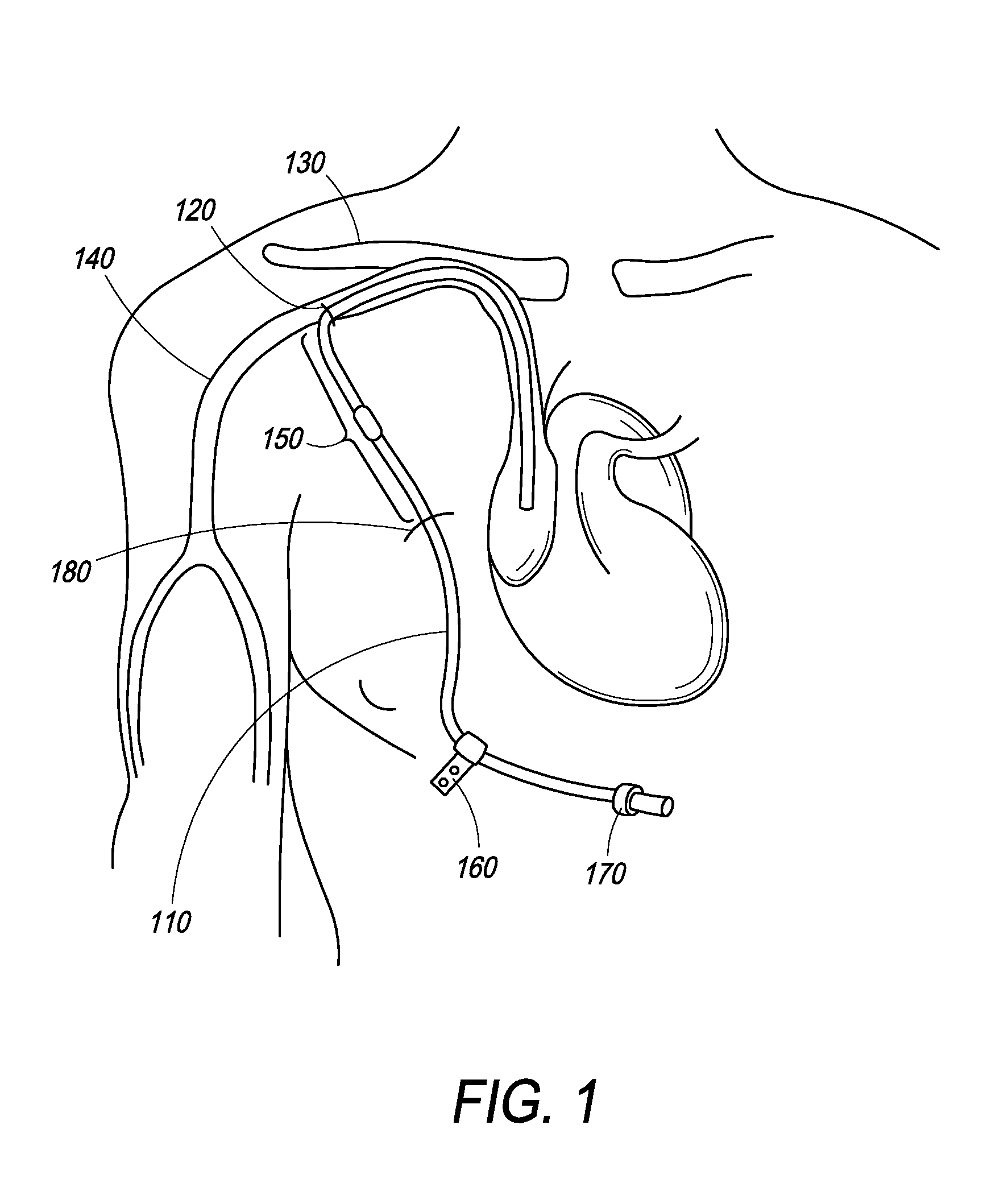

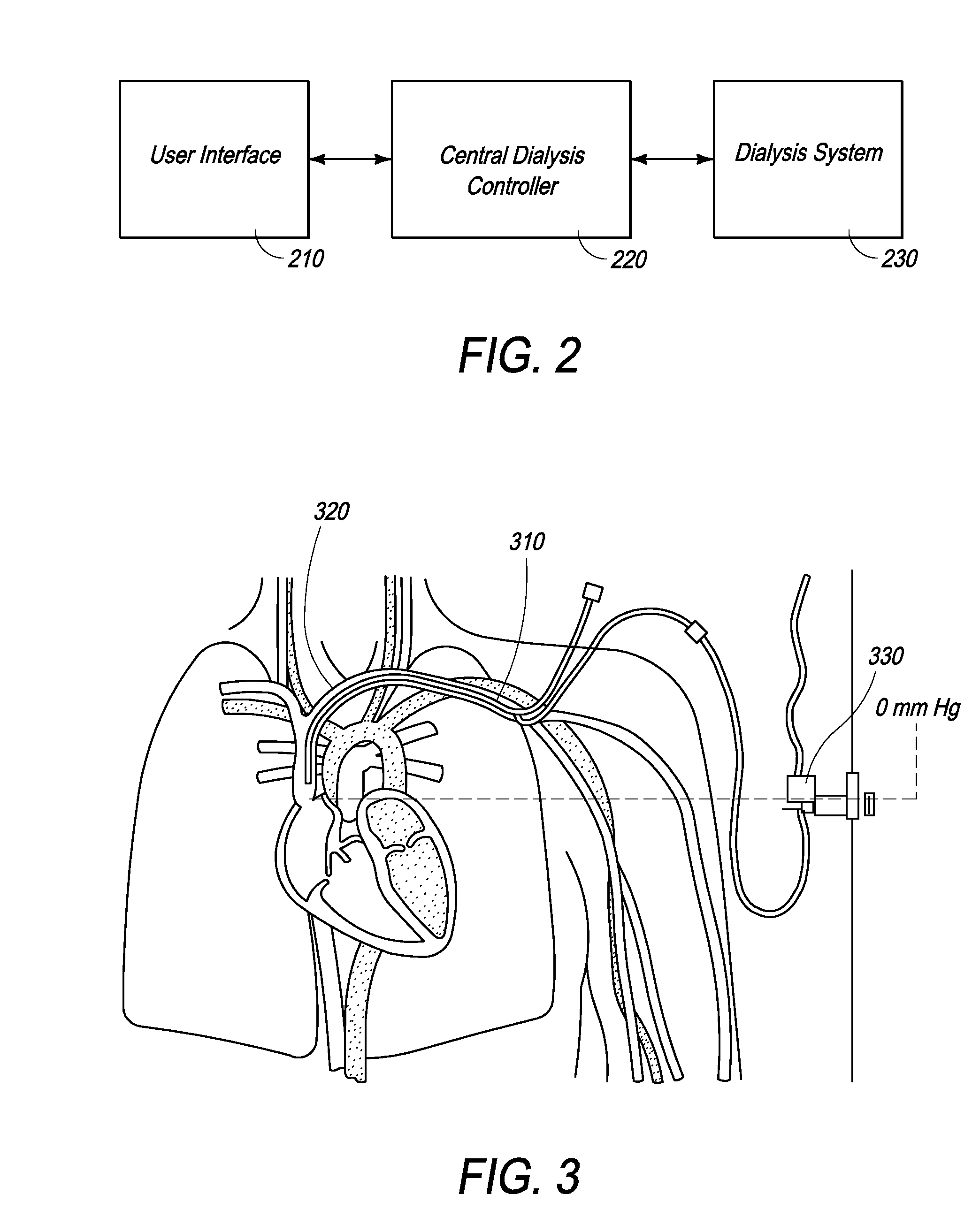

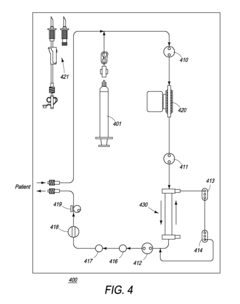

Methods and Systems for Controlling Ultrafiltration Using Central Venous Pressure Measurements

PatentInactiveUS20090101577A1

Innovation

- Integrating central venous pressure (CVP) measurement into the dialysis system to regulate the ultrafiltration rate by periodically measuring average CVP and adjusting the fluid removal based on preset values, using a programmable controller to stop or adjust blood flow and ultrafiltration when CVP drops below a certain limit, and incorporating CVP sensors within the dialysis machine or at the catheter tip.

Apparatus and method for testing integrity of an ultrafilter membrane

PatentPendingEP4353276A2

Innovation

- An apparatus and method that utilize a controller to perform an integrity test by filling the ultrafilter's first chamber with air and creating a negative pressure in the second chamber, using pressure sensors to detect if the set negative pressure threshold is reached within a set time, and determining the presence of single-fiber or multi-fiber breaks based on pressure stability and variation conditions.

Environmental Impact Assessment of Ultrafiltration Technologies

Ultrafiltration technologies, while offering significant water treatment benefits, also present various environmental implications that must be carefully assessed. The environmental footprint of ultrafiltration systems spans their entire lifecycle, from manufacturing and installation to operation and eventual decommissioning. During production, the creation of membrane materials typically involves chemical processes that may generate hazardous byproducts requiring proper management and disposal.

Operational environmental impacts vary significantly between different ultrafiltration systems, particularly when considering their performance under surge conditions. Energy consumption represents a primary environmental concern, with systems requiring different power inputs depending on their design efficiency and operational parameters. Studies indicate that advanced ultrafiltration systems with optimized flow dynamics can reduce energy requirements by 15-30% compared to conventional designs, substantially lowering associated carbon emissions.

Water usage for membrane cleaning and maintenance constitutes another environmental consideration. Systems designed for reliability under surge conditions often incorporate more robust cleaning mechanisms, which may increase water consumption for backwashing and chemical cleaning cycles. However, newer technologies featuring smart cleaning algorithms can optimize this process, reducing both water and chemical usage while maintaining performance integrity during variable flow conditions.

Chemical usage presents significant environmental implications, as cleaning agents and anti-fouling compounds may contain substances harmful to aquatic ecosystems if improperly managed. Comparative analyses reveal that systems designed specifically for surge condition reliability often require more aggressive chemical regimens to maintain membrane integrity, potentially increasing environmental risk unless properly mitigated through advanced recovery and neutralization systems.

Waste generation from ultrafiltration processes primarily consists of concentrated reject streams containing contaminants removed from the source water. The environmental impact of this waste stream varies depending on its composition and management approach. Systems operating under surge conditions typically generate more variable waste streams, requiring more sophisticated management strategies to prevent environmental contamination.

Land use requirements for ultrafiltration facilities must also be considered, particularly when comparing compact systems designed for urban environments versus larger installations for industrial applications. The physical footprint of surge-resistant systems often increases due to additional buffer tanks and redundant components, potentially increasing habitat disruption during installation.

Long-term environmental benefits of reliable ultrafiltration systems include reduced dependence on chemical water treatment methods, decreased discharge of contaminants into natural water bodies, and conservation of freshwater resources through improved water recycling capabilities. These positive outcomes must be weighed against the immediate environmental impacts when conducting comprehensive environmental assessments of ultrafiltration technologies.

Operational environmental impacts vary significantly between different ultrafiltration systems, particularly when considering their performance under surge conditions. Energy consumption represents a primary environmental concern, with systems requiring different power inputs depending on their design efficiency and operational parameters. Studies indicate that advanced ultrafiltration systems with optimized flow dynamics can reduce energy requirements by 15-30% compared to conventional designs, substantially lowering associated carbon emissions.

Water usage for membrane cleaning and maintenance constitutes another environmental consideration. Systems designed for reliability under surge conditions often incorporate more robust cleaning mechanisms, which may increase water consumption for backwashing and chemical cleaning cycles. However, newer technologies featuring smart cleaning algorithms can optimize this process, reducing both water and chemical usage while maintaining performance integrity during variable flow conditions.

Chemical usage presents significant environmental implications, as cleaning agents and anti-fouling compounds may contain substances harmful to aquatic ecosystems if improperly managed. Comparative analyses reveal that systems designed specifically for surge condition reliability often require more aggressive chemical regimens to maintain membrane integrity, potentially increasing environmental risk unless properly mitigated through advanced recovery and neutralization systems.

Waste generation from ultrafiltration processes primarily consists of concentrated reject streams containing contaminants removed from the source water. The environmental impact of this waste stream varies depending on its composition and management approach. Systems operating under surge conditions typically generate more variable waste streams, requiring more sophisticated management strategies to prevent environmental contamination.

Land use requirements for ultrafiltration facilities must also be considered, particularly when comparing compact systems designed for urban environments versus larger installations for industrial applications. The physical footprint of surge-resistant systems often increases due to additional buffer tanks and redundant components, potentially increasing habitat disruption during installation.

Long-term environmental benefits of reliable ultrafiltration systems include reduced dependence on chemical water treatment methods, decreased discharge of contaminants into natural water bodies, and conservation of freshwater resources through improved water recycling capabilities. These positive outcomes must be weighed against the immediate environmental impacts when conducting comprehensive environmental assessments of ultrafiltration technologies.

Cost-Benefit Analysis of Enhanced Reliability Solutions

The implementation of enhanced reliability solutions for ultrafiltration systems under surge conditions requires careful cost-benefit analysis to justify investment decisions. Initial capital expenditure for surge-resistant ultrafiltration systems typically ranges from $50,000 to $200,000 depending on system capacity and sophistication level, representing a 15-30% premium over standard systems.

Operational cost savings present a compelling counterbalance to this initial investment. Enhanced reliability solutions demonstrate 30-45% reduction in membrane replacement frequency, with high-quality membranes extending operational lifespans from 3-5 years to 5-8 years under surge conditions. Maintenance costs typically decrease by 25-35% annually due to fewer emergency interventions and reduced system downtime.

Energy efficiency improvements contribute additional savings, with advanced surge-resistant systems consuming 10-20% less energy through optimized pressure distribution and flow management. This translates to approximately $5,000-15,000 annual savings for medium-sized treatment facilities.

Risk mitigation represents a significant though less quantifiable benefit. Facilities implementing enhanced reliability solutions report 70-85% fewer catastrophic system failures during extreme surge events. The average cost of a single major system failure ranges from $75,000-150,000 when accounting for emergency repairs, production losses, and potential regulatory penalties.

Return on investment calculations indicate that most enhanced reliability solutions achieve breakeven within 2.5-4 years under normal operating conditions. In environments with frequent surge events, this payback period can shorten to 1.5-2.5 years. Long-term financial modeling shows 5-year ROI ranging from 120-180% for facilities experiencing regular surge conditions.

Sensitivity analysis reveals that the cost-benefit ratio is most heavily influenced by three factors: frequency of surge events, severity of pressure fluctuations, and local energy costs. Facilities experiencing more than 12 significant surge events annually derive substantially greater value from reliability enhancements, with ROI potentially exceeding 200% over a 5-year period.

Comparative analysis across different implementation scales demonstrates that medium to large facilities (processing >500,000 gallons daily) achieve optimal cost-benefit ratios, while smaller installations may require careful customization to achieve similar economic benefits.

Operational cost savings present a compelling counterbalance to this initial investment. Enhanced reliability solutions demonstrate 30-45% reduction in membrane replacement frequency, with high-quality membranes extending operational lifespans from 3-5 years to 5-8 years under surge conditions. Maintenance costs typically decrease by 25-35% annually due to fewer emergency interventions and reduced system downtime.

Energy efficiency improvements contribute additional savings, with advanced surge-resistant systems consuming 10-20% less energy through optimized pressure distribution and flow management. This translates to approximately $5,000-15,000 annual savings for medium-sized treatment facilities.

Risk mitigation represents a significant though less quantifiable benefit. Facilities implementing enhanced reliability solutions report 70-85% fewer catastrophic system failures during extreme surge events. The average cost of a single major system failure ranges from $75,000-150,000 when accounting for emergency repairs, production losses, and potential regulatory penalties.

Return on investment calculations indicate that most enhanced reliability solutions achieve breakeven within 2.5-4 years under normal operating conditions. In environments with frequent surge events, this payback period can shorten to 1.5-2.5 years. Long-term financial modeling shows 5-year ROI ranging from 120-180% for facilities experiencing regular surge conditions.

Sensitivity analysis reveals that the cost-benefit ratio is most heavily influenced by three factors: frequency of surge events, severity of pressure fluctuations, and local energy costs. Facilities experiencing more than 12 significant surge events annually derive substantially greater value from reliability enhancements, with ROI potentially exceeding 200% over a 5-year period.

Comparative analysis across different implementation scales demonstrates that medium to large facilities (processing >500,000 gallons daily) achieve optimal cost-benefit ratios, while smaller installations may require careful customization to achieve similar economic benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!