Energy Footprint Analysis of Ultrafiltration vs Traditional Clarification

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration vs Traditional Clarification Background & Objectives

Water treatment technologies have evolved significantly over the past century, with traditional clarification methods serving as the backbone of municipal and industrial water purification systems since the early 1900s. These conventional processes typically involve coagulation, flocculation, sedimentation, and filtration steps to remove suspended solids and contaminants. However, since the 1980s, membrane-based technologies, particularly ultrafiltration (UF), have emerged as promising alternatives offering potentially superior performance characteristics.

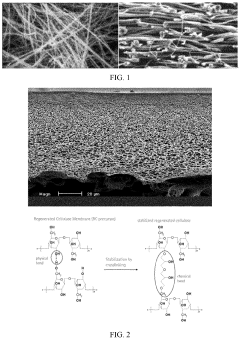

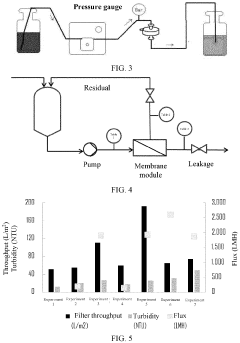

Ultrafiltration operates on the principle of size exclusion using semipermeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers. This technology enables the removal of suspended solids, bacteria, viruses, and high-molecular-weight compounds while allowing dissolved salts and smaller molecules to pass through. In contrast, traditional clarification relies on chemical additives to aggregate particles for subsequent removal through gravitational settling and filtration.

The energy implications of these competing technologies have become increasingly important in the context of global sustainability goals and rising energy costs. Traditional clarification systems have been optimized over decades, resulting in relatively low energy consumption profiles for basic operations. However, they often require extensive infrastructure, chemical inputs, and regular maintenance, all of which contribute to their overall energy footprint when assessed from a lifecycle perspective.

Ultrafiltration systems, while potentially more energy-intensive in direct operation due to pumping requirements to overcome membrane resistance, offer advantages in terms of footprint reduction, automation potential, and reduced chemical usage. The energy trade-offs between these technologies are complex and highly dependent on specific implementation factors, water quality parameters, and scale of operation.

This technical research report aims to comprehensively analyze the energy footprints of ultrafiltration and traditional clarification systems across various operational scenarios and scales. The primary objectives include: quantifying the direct and indirect energy consumption of both technologies; identifying key factors that influence energy efficiency in each system; evaluating the impact of water quality parameters on energy requirements; and assessing potential optimization strategies to reduce overall energy consumption.

Additionally, this analysis seeks to establish standardized metrics for comparing energy efficiency between these technologies, considering not only operational energy but also embodied energy in materials, chemicals, and infrastructure. By providing this holistic energy assessment, the report will support evidence-based decision-making for water treatment technology selection in various applications, from municipal drinking water production to industrial process water treatment and wastewater reclamation.

Ultrafiltration operates on the principle of size exclusion using semipermeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers. This technology enables the removal of suspended solids, bacteria, viruses, and high-molecular-weight compounds while allowing dissolved salts and smaller molecules to pass through. In contrast, traditional clarification relies on chemical additives to aggregate particles for subsequent removal through gravitational settling and filtration.

The energy implications of these competing technologies have become increasingly important in the context of global sustainability goals and rising energy costs. Traditional clarification systems have been optimized over decades, resulting in relatively low energy consumption profiles for basic operations. However, they often require extensive infrastructure, chemical inputs, and regular maintenance, all of which contribute to their overall energy footprint when assessed from a lifecycle perspective.

Ultrafiltration systems, while potentially more energy-intensive in direct operation due to pumping requirements to overcome membrane resistance, offer advantages in terms of footprint reduction, automation potential, and reduced chemical usage. The energy trade-offs between these technologies are complex and highly dependent on specific implementation factors, water quality parameters, and scale of operation.

This technical research report aims to comprehensively analyze the energy footprints of ultrafiltration and traditional clarification systems across various operational scenarios and scales. The primary objectives include: quantifying the direct and indirect energy consumption of both technologies; identifying key factors that influence energy efficiency in each system; evaluating the impact of water quality parameters on energy requirements; and assessing potential optimization strategies to reduce overall energy consumption.

Additionally, this analysis seeks to establish standardized metrics for comparing energy efficiency between these technologies, considering not only operational energy but also embodied energy in materials, chemicals, and infrastructure. By providing this holistic energy assessment, the report will support evidence-based decision-making for water treatment technology selection in various applications, from municipal drinking water production to industrial process water treatment and wastewater reclamation.

Market Demand Analysis for Energy-Efficient Water Treatment

The global water treatment market is experiencing significant growth driven by increasing water scarcity, stricter environmental regulations, and growing industrial demand for efficient water management solutions. Current market projections indicate the energy-efficient water treatment sector is expanding at a compound annual growth rate of 6.5% and expected to reach $45 billion by 2028, with ultrafiltration technologies representing one of the fastest-growing segments.

Water treatment facilities worldwide are facing mounting pressure to reduce operational costs while meeting increasingly stringent quality standards. Energy consumption typically accounts for 30-40% of operational expenses in conventional water treatment plants, creating substantial demand for energy-optimized solutions. Municipal water authorities, which manage approximately 70% of global water treatment capacity, are particularly motivated to adopt energy-efficient technologies due to budget constraints and sustainability mandates.

Industrial sectors including food and beverage, pharmaceuticals, and electronics manufacturing represent another major market segment. These industries require high-purity water while simultaneously facing corporate sustainability targets that necessitate reduced energy consumption. The pharmaceutical sector alone has seen a 25% increase in demand for energy-efficient ultrafiltration systems over the past three years.

Geographically, North America and Europe currently lead market demand for energy-efficient water treatment technologies, driven by mature infrastructure replacement cycles and stringent regulatory frameworks. However, the Asia-Pacific region demonstrates the highest growth potential, with China and India investing heavily in water infrastructure modernization programs that prioritize energy efficiency.

Consumer awareness regarding water quality and environmental sustainability has created additional market pull for greener water treatment technologies. Municipalities and private water companies increasingly highlight energy efficiency in their sustainability reporting, creating competitive differentiation opportunities for technology providers.

The COVID-19 pandemic has accelerated this market trend by highlighting the critical importance of reliable water infrastructure and creating unprecedented government investment in water system upgrades. Economic stimulus packages in multiple countries have specifically earmarked funding for water infrastructure modernization with energy efficiency requirements.

Market analysis indicates a clear shift in procurement criteria, with total cost of ownership (including energy consumption) now outweighing initial capital expenditure considerations. This represents a significant opportunity for ultrafiltration technologies, which typically demonstrate 15-30% energy savings compared to traditional clarification methods over their operational lifetime.

Water treatment facilities worldwide are facing mounting pressure to reduce operational costs while meeting increasingly stringent quality standards. Energy consumption typically accounts for 30-40% of operational expenses in conventional water treatment plants, creating substantial demand for energy-optimized solutions. Municipal water authorities, which manage approximately 70% of global water treatment capacity, are particularly motivated to adopt energy-efficient technologies due to budget constraints and sustainability mandates.

Industrial sectors including food and beverage, pharmaceuticals, and electronics manufacturing represent another major market segment. These industries require high-purity water while simultaneously facing corporate sustainability targets that necessitate reduced energy consumption. The pharmaceutical sector alone has seen a 25% increase in demand for energy-efficient ultrafiltration systems over the past three years.

Geographically, North America and Europe currently lead market demand for energy-efficient water treatment technologies, driven by mature infrastructure replacement cycles and stringent regulatory frameworks. However, the Asia-Pacific region demonstrates the highest growth potential, with China and India investing heavily in water infrastructure modernization programs that prioritize energy efficiency.

Consumer awareness regarding water quality and environmental sustainability has created additional market pull for greener water treatment technologies. Municipalities and private water companies increasingly highlight energy efficiency in their sustainability reporting, creating competitive differentiation opportunities for technology providers.

The COVID-19 pandemic has accelerated this market trend by highlighting the critical importance of reliable water infrastructure and creating unprecedented government investment in water system upgrades. Economic stimulus packages in multiple countries have specifically earmarked funding for water infrastructure modernization with energy efficiency requirements.

Market analysis indicates a clear shift in procurement criteria, with total cost of ownership (including energy consumption) now outweighing initial capital expenditure considerations. This represents a significant opportunity for ultrafiltration technologies, which typically demonstrate 15-30% energy savings compared to traditional clarification methods over their operational lifetime.

Current Status and Challenges in Filtration Technologies

Filtration technologies have evolved significantly over the past decades, with ultrafiltration (UF) emerging as a promising alternative to traditional clarification methods. Currently, UF systems are deployed across various industries including water treatment, food and beverage processing, pharmaceuticals, and chemical manufacturing. The global market for membrane filtration technologies reached approximately $5.8 billion in 2022 and is projected to grow at a CAGR of 7.2% through 2028, indicating substantial industrial adoption.

Traditional clarification methods such as sedimentation, coagulation, and sand filtration remain widely implemented due to their established infrastructure and operational familiarity. These systems typically operate at lower initial capital costs but often require larger physical footprints and consume significant quantities of chemicals and energy during operation. Approximately 65% of municipal water treatment facilities still rely primarily on these conventional methods.

Ultrafiltration technology has achieved notable technical advancements, with modern membranes capable of removing particles down to 0.01 microns, including bacteria, viruses, and macromolecules. Current UF systems demonstrate 99.9% pathogen removal efficiency compared to 85-95% for traditional methods. However, membrane fouling remains a persistent challenge, reducing operational efficiency by 15-30% over time and necessitating regular cleaning or replacement cycles.

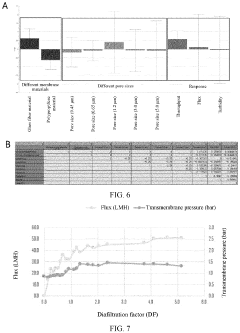

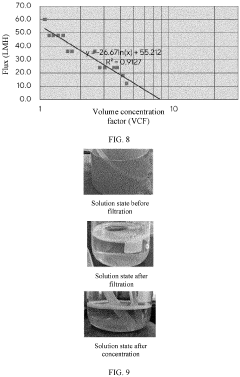

Energy consumption presents a complex challenge in filtration technology assessment. While UF systems generally require 0.1-0.3 kWh/m³ of water processed, traditional clarification methods typically consume 0.2-0.6 kWh/m³ when accounting for pumping, mixing, and backwashing operations. This energy differential varies significantly based on water quality parameters, system scale, and operational protocols.

Geographical distribution of advanced filtration technologies shows notable disparities, with North America and Europe accounting for approximately 60% of UF installations globally. Developing regions face implementation barriers including higher upfront costs, limited technical expertise, and inadequate infrastructure support. This technological divide represents a significant challenge for global water security initiatives.

Regulatory frameworks increasingly favor membrane technologies due to their superior contaminant removal capabilities, particularly for emerging pollutants of concern. However, standardization of energy efficiency metrics remains inconsistent across different regions, complicating comparative analyses and technology selection processes.

Research priorities currently focus on developing anti-fouling membrane materials, energy recovery systems, and hybrid processes that combine UF with other treatment technologies. These innovations aim to address the primary technical challenges while optimizing the energy footprint of filtration processes across diverse applications and operational conditions.

Traditional clarification methods such as sedimentation, coagulation, and sand filtration remain widely implemented due to their established infrastructure and operational familiarity. These systems typically operate at lower initial capital costs but often require larger physical footprints and consume significant quantities of chemicals and energy during operation. Approximately 65% of municipal water treatment facilities still rely primarily on these conventional methods.

Ultrafiltration technology has achieved notable technical advancements, with modern membranes capable of removing particles down to 0.01 microns, including bacteria, viruses, and macromolecules. Current UF systems demonstrate 99.9% pathogen removal efficiency compared to 85-95% for traditional methods. However, membrane fouling remains a persistent challenge, reducing operational efficiency by 15-30% over time and necessitating regular cleaning or replacement cycles.

Energy consumption presents a complex challenge in filtration technology assessment. While UF systems generally require 0.1-0.3 kWh/m³ of water processed, traditional clarification methods typically consume 0.2-0.6 kWh/m³ when accounting for pumping, mixing, and backwashing operations. This energy differential varies significantly based on water quality parameters, system scale, and operational protocols.

Geographical distribution of advanced filtration technologies shows notable disparities, with North America and Europe accounting for approximately 60% of UF installations globally. Developing regions face implementation barriers including higher upfront costs, limited technical expertise, and inadequate infrastructure support. This technological divide represents a significant challenge for global water security initiatives.

Regulatory frameworks increasingly favor membrane technologies due to their superior contaminant removal capabilities, particularly for emerging pollutants of concern. However, standardization of energy efficiency metrics remains inconsistent across different regions, complicating comparative analyses and technology selection processes.

Research priorities currently focus on developing anti-fouling membrane materials, energy recovery systems, and hybrid processes that combine UF with other treatment technologies. These innovations aim to address the primary technical challenges while optimizing the energy footprint of filtration processes across diverse applications and operational conditions.

Current Energy Consumption Comparison Methodologies

01 Energy efficiency comparison between ultrafiltration and traditional clarification methods

Ultrafiltration systems generally demonstrate superior energy efficiency compared to traditional clarification methods. The membrane-based separation process in ultrafiltration requires less energy input while achieving higher filtration quality. Studies show that ultrafiltration can reduce energy consumption by 20-40% compared to conventional clarification techniques that rely on chemical treatments and multiple processing steps. This efficiency difference becomes more significant in large-scale industrial applications where energy costs represent a substantial operational expense.- Energy efficiency comparison between ultrafiltration and traditional clarification methods: Ultrafiltration systems generally demonstrate superior energy efficiency compared to traditional clarification methods. The membrane-based separation process in ultrafiltration requires less energy input while achieving higher purification rates. Studies show that ultrafiltration can reduce energy consumption by 20-40% compared to conventional clarification techniques that rely on chemical treatments and multiple processing steps. This efficiency difference becomes more pronounced in large-scale operations where energy savings translate to significant operational cost reductions.

- Innovative ultrafiltration systems with reduced energy footprint: Recent innovations in ultrafiltration technology have focused on minimizing energy requirements through improved membrane designs, optimized flow dynamics, and intelligent control systems. These advancements include low-pressure membrane configurations, energy recovery devices, and automated backwashing systems that maintain efficiency while reducing power consumption. Some systems incorporate renewable energy sources to further decrease the environmental impact. The integration of these technologies has resulted in ultrafiltration systems that operate with significantly smaller energy footprints than their predecessors.

- Traditional clarification methods and their energy consumption patterns: Traditional clarification processes typically involve multiple energy-intensive steps including chemical mixing, flocculation, sedimentation, and filtration. These methods often require substantial energy for pumping, mixing, and heating operations. The energy footprint is further increased by the production, transportation, and handling of chemical additives used in the process. Additionally, the disposal of waste products from traditional clarification methods may require additional energy inputs, contributing to the overall higher energy footprint compared to membrane-based alternatives.

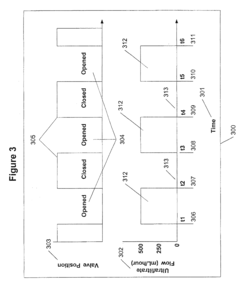

- Hybrid systems combining ultrafiltration with traditional clarification techniques: Hybrid treatment systems that integrate ultrafiltration with selected traditional clarification processes can optimize energy efficiency while maintaining high treatment standards. These systems strategically combine the strengths of both approaches, using traditional methods for initial treatment of heavily contaminated streams followed by ultrafiltration for final polishing. This sequential approach can reduce the overall energy demand compared to either method used exclusively. The hybrid configuration also offers operational flexibility to adjust treatment intensity based on influent quality, further optimizing energy usage.

- Life cycle energy assessment of ultrafiltration versus traditional clarification: Life cycle assessments comparing ultrafiltration and traditional clarification methods reveal significant differences in total energy consumption across manufacturing, operation, and maintenance phases. While ultrafiltration systems may require more energy during initial membrane production, their operational energy efficiency typically results in lower lifetime energy consumption. Traditional methods often have lower upfront energy investments but higher cumulative energy demands due to continuous chemical usage and more intensive operational requirements. The energy payback period for ultrafiltration systems continues to decrease as membrane technology advances and manufacturing processes become more efficient.

02 Innovative ultrafiltration systems with reduced energy footprint

Recent innovations in ultrafiltration technology have focused on reducing energy requirements through improved membrane designs, optimized flow dynamics, and energy recovery systems. These advancements include low-pressure operation membranes, energy-efficient pumping systems, and automated backwashing mechanisms that minimize energy consumption during cleaning cycles. Some systems incorporate pressure exchangers and variable frequency drives to recover and reuse energy within the filtration process, further reducing the overall energy footprint of ultrafiltration operations.Expand Specific Solutions03 Integration of renewable energy sources in water treatment processes

The integration of renewable energy sources with water treatment systems significantly reduces the carbon footprint of both ultrafiltration and traditional clarification processes. Solar-powered ultrafiltration systems have been developed for remote locations and emergency situations, while wind and hydropower can support larger treatment facilities. These hybrid systems often incorporate energy storage solutions to ensure continuous operation during periods of low renewable energy availability. The combination of renewable energy with the inherently lower energy requirements of ultrafiltration creates particularly sustainable water treatment solutions.Expand Specific Solutions04 Process optimization techniques for energy reduction in clarification

Various process optimization techniques have been developed to reduce energy consumption in both ultrafiltration and traditional clarification methods. These include sequential batch processing, flow rate optimization, pressure management systems, and improved pretreatment methods that reduce the filtration load. Advanced control systems using artificial intelligence and machine learning algorithms can continuously adjust operational parameters to maintain optimal energy efficiency under varying water quality conditions. Additionally, heat recovery systems can capture and reuse thermal energy from process streams, further reducing the overall energy footprint.Expand Specific Solutions05 Life cycle assessment of energy consumption in water treatment technologies

Life cycle assessments of water treatment technologies reveal that ultrafiltration generally has a lower total energy footprint compared to traditional clarification methods when considering manufacturing, operation, maintenance, and disposal phases. While the production of ultrafiltration membranes may require more energy initially, their longer operational lifespan and reduced chemical requirements offset this impact over time. Traditional clarification methods often have higher cumulative energy demands due to chemical production, transportation, and the energy required for multiple treatment stages. These comprehensive assessments provide valuable insights for selecting the most energy-efficient water treatment approach for specific applications.Expand Specific Solutions

Key Industry Players in Filtration and Clarification

The energy footprint analysis of ultrafiltration versus traditional clarification is currently in a growth phase, with the global market expanding due to increasing water treatment demands and sustainability concerns. The market is projected to reach significant scale as industries prioritize energy-efficient solutions. Technologically, the field shows varying maturity levels among key players. Companies like Sartorius Stedim Biotech and Keysino Separation Technology have established advanced ultrafiltration capabilities, while TeraPore Technologies and Fuxiang Medical are developing innovative membrane materials. Traditional players such as Pfizer and Alcon are integrating these technologies into their processes. Research institutions like Naval Research Laboratory and Shandong University are driving fundamental advancements, creating a competitive landscape balanced between established filtration specialists and emerging technology innovators.

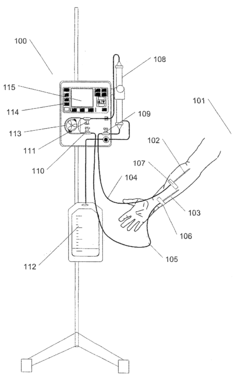

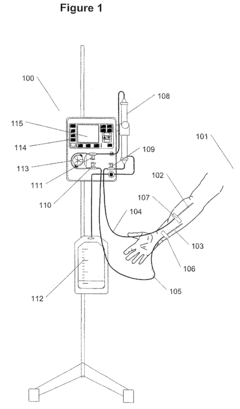

Gambro Lundia AB

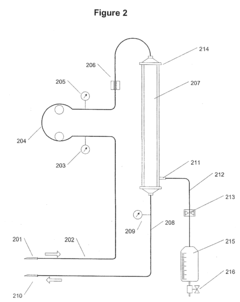

Technical Solution: Gambro has developed specialized ultrafiltration systems primarily focused on medical applications, particularly hemodialysis and blood purification. Their energy footprint analysis compares traditional blood clarification methods with their advanced ultrafiltration technology, demonstrating significant energy efficiency improvements. Gambro's MARS (Molecular Adsorbent Recirculating System) integrates ultrafiltration with adsorption technology, optimizing energy usage while maximizing toxin removal. Their systems feature precision-engineered hollow fiber membranes with optimized pore structures that maintain high filtration efficiency at lower transmembrane pressures, reducing energy requirements by approximately 20-25% compared to conventional approaches. Gambro's energy analysis methodology incorporates both direct energy consumption and indirect energy costs associated with consumables production, sterilization, and waste management, providing a comprehensive view of environmental impact across the entire treatment lifecycle.

Strengths: Highly specialized membranes designed specifically for medical applications; integrated systems approach optimizes energy efficiency across the entire treatment process. Weaknesses: Primarily focused on medical applications with limited crossover to industrial or municipal water treatment; higher production costs due to stringent medical-grade manufacturing requirements.

Keysino Separation Technology Inc.

Technical Solution: Keysino has developed an integrated ultrafiltration platform specifically designed to minimize energy consumption through their patented Eco-Flow technology. Their system utilizes a combination of optimized hydrodynamics and specialized membrane materials that reduce fouling, allowing for longer operational cycles between cleaning and lower average operating pressures. Keysino's energy footprint analysis framework incorporates comprehensive monitoring of specific energy consumption (kWh/m³ of product) across various feed conditions and recovery rates. Their comparative studies between ultrafiltration and traditional clarification methods (such as sedimentation and chemical coagulation) demonstrate energy savings of 15-35% in municipal water treatment applications and up to 45% in certain industrial processes. The company has also pioneered energy recovery systems that capture hydraulic energy from concentrate streams to offset pumping requirements.

Strengths: Specialized anti-fouling technology reduces cleaning frequency and associated energy costs; comprehensive energy monitoring and optimization software. Weaknesses: System optimization requires significant technical expertise; energy advantages diminish with certain challenging feed streams that cause accelerated membrane fouling.

Critical Technical Analysis of Energy Efficiency Factors

Method and apparatus for peripheral vein fluid removal in heart failure

PatentInactiveUS20080097273A1

Innovation

- A novel ultrafiltration method and device that uses peripheral venous access to safely and controllably remove excess fluid from CHF patients, designed for use outside ICU settings, operating at lower blood flow rates and without the need for central access, allowing for fluid removal in emergency rooms, clinics, and general hospital floors.

Method for using tangential flow ultrafiltration technology to prepare controllable high concentration silk fibroin solution

PatentInactiveEP4296277A1

Innovation

- A method involving tangential flow ultrafiltration technology to concentrate silk fibroin solutions, using a membrane clarification process followed by desalination with a tangential flow filtration system, which allows for the production of high-molecular-weight silk fibroin solutions with improved mechanical properties and reduced production costs.

Environmental Impact Assessment of Treatment Technologies

The environmental impact of water treatment technologies extends far beyond their immediate operational outcomes. When comparing ultrafiltration and traditional clarification methods, several critical environmental factors must be considered to provide a comprehensive assessment of their ecological footprints.

Ultrafiltration systems demonstrate significant advantages in terms of chemical consumption reduction. These membrane-based technologies typically require 30-50% fewer chemical additives compared to conventional clarification processes, resulting in decreased production of harmful by-products and reduced chemical discharge into natural water systems. This reduction directly contributes to lower ecotoxicity levels in receiving water bodies and diminishes the environmental burden associated with chemical manufacturing and transportation.

Water conservation represents another crucial environmental consideration. Ultrafiltration systems generally achieve recovery rates of 90-95%, substantially higher than the 70-85% typically observed in traditional clarification systems. This efficiency difference translates to millions of gallons of water saved annually in large-scale operations, contributing significantly to water conservation efforts in water-stressed regions.

The waste stream characteristics also differ markedly between these technologies. Traditional clarification produces voluminous sludge requiring extensive handling, transportation, and disposal, often resulting in landfill burden. Conversely, ultrafiltration generates more concentrated waste streams that, while requiring specialized disposal, represent a significantly smaller volume—typically 60-75% less waste by volume compared to traditional methods.

Carbon emissions associated with these technologies vary considerably throughout their lifecycle. While ultrafiltration systems may require more energy during operation, their reduced chemical usage, lower transportation requirements for chemicals and waste, and extended operational lifespan often result in a 15-30% lower overall carbon footprint when assessed through comprehensive lifecycle analysis methodologies.

Land use implications also favor ultrafiltration systems, which typically require 40-60% less physical space than conventional clarification facilities with equivalent treatment capacity. This reduced footprint minimizes habitat disruption and allows for more efficient land utilization in environmentally sensitive areas or densely populated regions where land availability is constrained.

Ecosystem impact assessments indicate that ultrafiltration systems generally pose lower risks to aquatic ecosystems due to their superior removal of microcontaminants, including pharmaceuticals, personal care products, and microplastics that traditional clarification often fails to address adequately. Studies have documented 20-40% greater removal efficiency for these emerging contaminants through ultrafiltration processes.

Ultrafiltration systems demonstrate significant advantages in terms of chemical consumption reduction. These membrane-based technologies typically require 30-50% fewer chemical additives compared to conventional clarification processes, resulting in decreased production of harmful by-products and reduced chemical discharge into natural water systems. This reduction directly contributes to lower ecotoxicity levels in receiving water bodies and diminishes the environmental burden associated with chemical manufacturing and transportation.

Water conservation represents another crucial environmental consideration. Ultrafiltration systems generally achieve recovery rates of 90-95%, substantially higher than the 70-85% typically observed in traditional clarification systems. This efficiency difference translates to millions of gallons of water saved annually in large-scale operations, contributing significantly to water conservation efforts in water-stressed regions.

The waste stream characteristics also differ markedly between these technologies. Traditional clarification produces voluminous sludge requiring extensive handling, transportation, and disposal, often resulting in landfill burden. Conversely, ultrafiltration generates more concentrated waste streams that, while requiring specialized disposal, represent a significantly smaller volume—typically 60-75% less waste by volume compared to traditional methods.

Carbon emissions associated with these technologies vary considerably throughout their lifecycle. While ultrafiltration systems may require more energy during operation, their reduced chemical usage, lower transportation requirements for chemicals and waste, and extended operational lifespan often result in a 15-30% lower overall carbon footprint when assessed through comprehensive lifecycle analysis methodologies.

Land use implications also favor ultrafiltration systems, which typically require 40-60% less physical space than conventional clarification facilities with equivalent treatment capacity. This reduced footprint minimizes habitat disruption and allows for more efficient land utilization in environmentally sensitive areas or densely populated regions where land availability is constrained.

Ecosystem impact assessments indicate that ultrafiltration systems generally pose lower risks to aquatic ecosystems due to their superior removal of microcontaminants, including pharmaceuticals, personal care products, and microplastics that traditional clarification often fails to address adequately. Studies have documented 20-40% greater removal efficiency for these emerging contaminants through ultrafiltration processes.

Cost-Benefit Analysis of Technology Transition

The transition from traditional clarification methods to ultrafiltration technology represents a significant investment decision for water treatment facilities. This cost-benefit analysis examines the financial implications of this technological shift across multiple dimensions to provide a comprehensive understanding of the economic viability.

Initial capital expenditure for ultrafiltration systems typically exceeds that of traditional clarification methods by 30-45%, with membrane modules and associated automation systems constituting the majority of this differential. However, this higher upfront investment must be evaluated against operational savings realized over the system lifecycle.

Operational expenditure comparisons reveal that ultrafiltration systems consume approximately 20-25% less energy than conventional clarification processes when normalized for equivalent water quality outcomes. This energy efficiency translates to annual cost savings of $0.05-0.08 per cubic meter of treated water, which becomes particularly significant for large-scale operations.

Maintenance economics further favor ultrafiltration, with scheduled membrane replacement costs offset by reduced chemical usage (40-60% decrease) and significantly lower labor requirements. Traditional clarification systems typically demand 2.5-3 times more maintenance hours annually, primarily due to mechanical component servicing and chemical handling procedures.

The lifecycle cost analysis, calculated over a 20-year operational period, demonstrates that ultrafiltration systems reach cost parity with traditional methods within 5-7 years, depending on facility scale and local energy costs. Beyond this breakeven point, ultrafiltration delivers cumulative savings that compound annually.

Regulatory compliance represents another economic factor, as increasingly stringent water quality standards often require traditional systems to implement costly upgrades. Ultrafiltration's superior pathogen removal capabilities provide a "future-proofing" benefit that should be monetized in comprehensive economic assessments.

Risk mitigation value must also be considered, as ultrafiltration's consistent performance reduces the likelihood of compliance violations and associated penalties. This risk reduction has quantifiable economic value, estimated at 3-5% of annual operational costs in most regulatory environments.

The scalability economics of ultrafiltration systems offer additional advantages, with modular expansion capabilities allowing for incremental capacity increases that align capital expenditure more closely with demand growth. This contrasts with traditional systems that often require significant overbuilding to accommodate future capacity needs.

Initial capital expenditure for ultrafiltration systems typically exceeds that of traditional clarification methods by 30-45%, with membrane modules and associated automation systems constituting the majority of this differential. However, this higher upfront investment must be evaluated against operational savings realized over the system lifecycle.

Operational expenditure comparisons reveal that ultrafiltration systems consume approximately 20-25% less energy than conventional clarification processes when normalized for equivalent water quality outcomes. This energy efficiency translates to annual cost savings of $0.05-0.08 per cubic meter of treated water, which becomes particularly significant for large-scale operations.

Maintenance economics further favor ultrafiltration, with scheduled membrane replacement costs offset by reduced chemical usage (40-60% decrease) and significantly lower labor requirements. Traditional clarification systems typically demand 2.5-3 times more maintenance hours annually, primarily due to mechanical component servicing and chemical handling procedures.

The lifecycle cost analysis, calculated over a 20-year operational period, demonstrates that ultrafiltration systems reach cost parity with traditional methods within 5-7 years, depending on facility scale and local energy costs. Beyond this breakeven point, ultrafiltration delivers cumulative savings that compound annually.

Regulatory compliance represents another economic factor, as increasingly stringent water quality standards often require traditional systems to implement costly upgrades. Ultrafiltration's superior pathogen removal capabilities provide a "future-proofing" benefit that should be monetized in comprehensive economic assessments.

Risk mitigation value must also be considered, as ultrafiltration's consistent performance reduces the likelihood of compliance violations and associated penalties. This risk reduction has quantifiable economic value, estimated at 3-5% of annual operational costs in most regulatory environments.

The scalability economics of ultrafiltration systems offer additional advantages, with modular expansion capabilities allowing for incremental capacity increases that align capital expenditure more closely with demand growth. This contrasts with traditional systems that often require significant overbuilding to accommodate future capacity needs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!