How to Boost Ultrafiltration Capacity with Minimal Infrastructure Changes

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration (UF) technology has evolved significantly since its inception in the mid-20th century, transitioning from laboratory-scale applications to widespread industrial implementation. Initially developed for protein concentration and fractionation in the 1960s, UF has expanded into diverse sectors including water treatment, food processing, biotechnology, and pharmaceutical manufacturing. The fundamental principle of UF involves the separation of particles and macromolecules from solutions using semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers.

The evolution of membrane materials has been pivotal in UF advancement. Early cellulose acetate membranes have given way to more robust materials such as polysulfone, polyethersulfone, and ceramic composites, significantly enhancing chemical resistance, thermal stability, and operational lifespan. Parallel developments in module configurations—from plate-and-frame to spiral-wound and hollow fiber designs—have optimized flow dynamics and filtration efficiency.

Recent technological trends in UF focus on addressing persistent challenges such as membrane fouling, energy consumption, and capacity limitations. Innovations include anti-fouling membrane surface modifications, energy-efficient operational protocols, and smart monitoring systems that employ real-time data analytics to optimize performance. The integration of nanotechnology has also enabled the development of membranes with precisely controlled pore sizes and enhanced selectivity.

The primary objective of contemporary UF technology development is to maximize throughput capacity while minimizing infrastructure footprint and operational costs. This aligns with industry demands for more sustainable and economically viable filtration solutions. Specific technical goals include increasing membrane flux rates without compromising rejection efficiency, extending membrane lifespan through improved fouling resistance, and reducing energy consumption through optimized hydrodynamics and operational parameters.

Another critical objective is enhancing the adaptability of UF systems to fluctuating feed characteristics and operational conditions, enabling more versatile applications across industries. This includes developing modular and scalable systems that can be easily integrated into existing infrastructure with minimal modifications.

The convergence of UF with complementary technologies such as forward osmosis, membrane distillation, and electrochemical processes represents an emerging frontier, potentially offering hybrid solutions that overcome traditional limitations. Additionally, the incorporation of artificial intelligence and machine learning algorithms for predictive maintenance and performance optimization is becoming increasingly important in advancing UF technology toward more autonomous and efficient operation.

The evolution of membrane materials has been pivotal in UF advancement. Early cellulose acetate membranes have given way to more robust materials such as polysulfone, polyethersulfone, and ceramic composites, significantly enhancing chemical resistance, thermal stability, and operational lifespan. Parallel developments in module configurations—from plate-and-frame to spiral-wound and hollow fiber designs—have optimized flow dynamics and filtration efficiency.

Recent technological trends in UF focus on addressing persistent challenges such as membrane fouling, energy consumption, and capacity limitations. Innovations include anti-fouling membrane surface modifications, energy-efficient operational protocols, and smart monitoring systems that employ real-time data analytics to optimize performance. The integration of nanotechnology has also enabled the development of membranes with precisely controlled pore sizes and enhanced selectivity.

The primary objective of contemporary UF technology development is to maximize throughput capacity while minimizing infrastructure footprint and operational costs. This aligns with industry demands for more sustainable and economically viable filtration solutions. Specific technical goals include increasing membrane flux rates without compromising rejection efficiency, extending membrane lifespan through improved fouling resistance, and reducing energy consumption through optimized hydrodynamics and operational parameters.

Another critical objective is enhancing the adaptability of UF systems to fluctuating feed characteristics and operational conditions, enabling more versatile applications across industries. This includes developing modular and scalable systems that can be easily integrated into existing infrastructure with minimal modifications.

The convergence of UF with complementary technologies such as forward osmosis, membrane distillation, and electrochemical processes represents an emerging frontier, potentially offering hybrid solutions that overcome traditional limitations. Additionally, the incorporation of artificial intelligence and machine learning algorithms for predictive maintenance and performance optimization is becoming increasingly important in advancing UF technology toward more autonomous and efficient operation.

Market Demand Analysis for Enhanced Ultrafiltration

The ultrafiltration (UF) market has experienced significant growth in recent years, driven by increasing water scarcity, stricter environmental regulations, and growing industrial demand for efficient water treatment solutions. The global ultrafiltration market was valued at approximately 1.5 billion USD in 2021 and is projected to reach 2.9 billion USD by 2028, representing a compound annual growth rate of 9.8% during this forecast period.

Water treatment facilities across municipal and industrial sectors are facing mounting pressure to enhance their treatment capacities without major capital investments. This demand stems from several converging factors: aging infrastructure in developed nations, rapid urbanization in developing regions, and increasingly stringent water quality standards worldwide. According to industry surveys, over 65% of water treatment plant operators report the need to increase capacity by at least 20% within the next five years while facing budget constraints.

The industrial sector represents a particularly strong growth segment for enhanced ultrafiltration solutions. Food and beverage, pharmaceutical, and biotechnology industries require increasingly efficient separation processes to maintain product quality while maximizing throughput. These industries value solutions that can increase filtration capacity without disrupting existing production lines or requiring extensive downtime for implementation.

Municipal water treatment facilities constitute another major market segment seeking capacity enhancement solutions. With urban populations growing at unprecedented rates, especially in Asia-Pacific and Latin American regions, water utilities must process larger volumes while maintaining quality standards. The ability to upgrade existing ultrafiltration systems rather than building entirely new facilities represents significant cost savings, estimated at 40-60% compared to new construction.

Environmental sustainability considerations are also driving demand for optimized ultrafiltration systems. Solutions that can increase capacity while reducing energy consumption, chemical usage, and waste generation align with corporate sustainability goals and regulatory requirements. Market research indicates that solutions offering at least 15% reduction in energy consumption alongside capacity increases command premium pricing and faster adoption rates.

Geographically, the Asia-Pacific region represents the fastest-growing market for enhanced ultrafiltration solutions, with China and India leading demand due to rapid industrialization and increasing water quality regulations. North America and Europe represent mature markets focused on infrastructure upgrades and efficiency improvements rather than new installations.

Customer surveys reveal that the ideal enhanced ultrafiltration solution would deliver 30-50% capacity increases with implementation timeframes under two weeks and payback periods of less than 18 months. Price sensitivity varies significantly by region and application, with industrial users generally willing to pay premium prices for solutions that minimize production disruptions.

Water treatment facilities across municipal and industrial sectors are facing mounting pressure to enhance their treatment capacities without major capital investments. This demand stems from several converging factors: aging infrastructure in developed nations, rapid urbanization in developing regions, and increasingly stringent water quality standards worldwide. According to industry surveys, over 65% of water treatment plant operators report the need to increase capacity by at least 20% within the next five years while facing budget constraints.

The industrial sector represents a particularly strong growth segment for enhanced ultrafiltration solutions. Food and beverage, pharmaceutical, and biotechnology industries require increasingly efficient separation processes to maintain product quality while maximizing throughput. These industries value solutions that can increase filtration capacity without disrupting existing production lines or requiring extensive downtime for implementation.

Municipal water treatment facilities constitute another major market segment seeking capacity enhancement solutions. With urban populations growing at unprecedented rates, especially in Asia-Pacific and Latin American regions, water utilities must process larger volumes while maintaining quality standards. The ability to upgrade existing ultrafiltration systems rather than building entirely new facilities represents significant cost savings, estimated at 40-60% compared to new construction.

Environmental sustainability considerations are also driving demand for optimized ultrafiltration systems. Solutions that can increase capacity while reducing energy consumption, chemical usage, and waste generation align with corporate sustainability goals and regulatory requirements. Market research indicates that solutions offering at least 15% reduction in energy consumption alongside capacity increases command premium pricing and faster adoption rates.

Geographically, the Asia-Pacific region represents the fastest-growing market for enhanced ultrafiltration solutions, with China and India leading demand due to rapid industrialization and increasing water quality regulations. North America and Europe represent mature markets focused on infrastructure upgrades and efficiency improvements rather than new installations.

Customer surveys reveal that the ideal enhanced ultrafiltration solution would deliver 30-50% capacity increases with implementation timeframes under two weeks and payback periods of less than 18 months. Price sensitivity varies significantly by region and application, with industrial users generally willing to pay premium prices for solutions that minimize production disruptions.

Current Limitations and Technical Challenges

Ultrafiltration technology currently faces several significant limitations that hinder its capacity expansion without major infrastructure investments. The primary challenge lies in membrane fouling, which occurs when particles, colloids, and biological materials accumulate on membrane surfaces, reducing permeability and filtration efficiency. This phenomenon necessitates frequent cleaning cycles and membrane replacements, directly impacting operational costs and system downtime.

Pressure drop across the membrane system represents another critical constraint. As flow rates increase to boost capacity, the corresponding pressure requirements escalate exponentially, creating energy efficiency challenges. Most existing ultrafiltration systems were designed with specific hydraulic limitations that cannot be easily exceeded without risking mechanical failure or compromising filtration quality.

Spatial constraints within existing facilities present a practical barrier to capacity enhancement. Many ultrafiltration installations operate in environments where physical expansion is limited by surrounding infrastructure, equipment, or property boundaries. This reality forces engineers to seek solutions that maximize throughput within the current footprint rather than expanding horizontally or vertically.

The energy intensity of ultrafiltration processes constitutes a significant operational limitation. Current systems typically require 0.2-0.5 kWh per cubic meter of filtered water, with energy costs representing 30-40% of operational expenses. Any capacity increase that proportionally increases energy consumption may prove economically unfeasible, particularly for facilities operating with tight margins or sustainability commitments.

Control system limitations also impede capacity enhancement efforts. Many existing ultrafiltration installations utilize older automation systems that lack the sophistication to optimize operations dynamically. These systems often operate with fixed parameters rather than adapting to changing feed water conditions, resulting in suboptimal performance during capacity stretching attempts.

From a technical perspective, the hydraulic design of manifolds and flow distribution systems in conventional ultrafiltration units creates inherent bottlenecks. These systems were typically engineered for specific flow ranges, and exceeding these parameters leads to uneven flow distribution across membrane modules, creating dead zones and preferential flow paths that reduce effective filtration area.

Temperature sensitivity represents another challenge, as most ultrafiltration membranes operate optimally within narrow temperature bands. Attempts to increase throughput often generate additional heat through pumping and friction, potentially pushing operating temperatures beyond optimal ranges and accelerating membrane degradation or reducing rejection capabilities.

Pressure drop across the membrane system represents another critical constraint. As flow rates increase to boost capacity, the corresponding pressure requirements escalate exponentially, creating energy efficiency challenges. Most existing ultrafiltration systems were designed with specific hydraulic limitations that cannot be easily exceeded without risking mechanical failure or compromising filtration quality.

Spatial constraints within existing facilities present a practical barrier to capacity enhancement. Many ultrafiltration installations operate in environments where physical expansion is limited by surrounding infrastructure, equipment, or property boundaries. This reality forces engineers to seek solutions that maximize throughput within the current footprint rather than expanding horizontally or vertically.

The energy intensity of ultrafiltration processes constitutes a significant operational limitation. Current systems typically require 0.2-0.5 kWh per cubic meter of filtered water, with energy costs representing 30-40% of operational expenses. Any capacity increase that proportionally increases energy consumption may prove economically unfeasible, particularly for facilities operating with tight margins or sustainability commitments.

Control system limitations also impede capacity enhancement efforts. Many existing ultrafiltration installations utilize older automation systems that lack the sophistication to optimize operations dynamically. These systems often operate with fixed parameters rather than adapting to changing feed water conditions, resulting in suboptimal performance during capacity stretching attempts.

From a technical perspective, the hydraulic design of manifolds and flow distribution systems in conventional ultrafiltration units creates inherent bottlenecks. These systems were typically engineered for specific flow ranges, and exceeding these parameters leads to uneven flow distribution across membrane modules, creating dead zones and preferential flow paths that reduce effective filtration area.

Temperature sensitivity represents another challenge, as most ultrafiltration membranes operate optimally within narrow temperature bands. Attempts to increase throughput often generate additional heat through pumping and friction, potentially pushing operating temperatures beyond optimal ranges and accelerating membrane degradation or reducing rejection capabilities.

Current Solutions for Capacity Enhancement

01 Membrane design for enhanced ultrafiltration capacity

Advanced membrane designs can significantly improve ultrafiltration capacity. These designs include modifications to membrane structure, pore size distribution, and surface properties to enhance filtration efficiency and throughput. Innovations in membrane materials and configurations help reduce fouling, increase flux rates, and extend operational lifespans, ultimately leading to higher ultrafiltration capacity in various applications.- Membrane design for enhanced ultrafiltration capacity: Advanced membrane designs can significantly improve ultrafiltration capacity. These designs include modifications to membrane structure, pore size distribution, and surface properties to enhance filtration efficiency while reducing fouling. Innovations in membrane materials and configurations allow for higher flux rates and improved separation capabilities, resulting in increased ultrafiltration capacity for various applications.

- Ultrafiltration systems for water treatment: Specialized ultrafiltration systems designed for water treatment applications offer enhanced capacity for removing contaminants from water sources. These systems incorporate optimized flow patterns, pressure control mechanisms, and cleaning protocols to maintain high filtration capacity over extended operation periods. The systems can be scaled to accommodate various treatment volumes while maintaining filtration efficiency.

- Medical applications of ultrafiltration technology: Ultrafiltration technologies in medical applications focus on achieving precise filtration capacity for therapeutic purposes. These include blood purification systems, dialysis equipment, and pharmaceutical processing. The ultrafiltration capacity in these applications is carefully controlled to remove specific molecules while preserving essential components, with designs that prioritize biocompatibility and safety alongside filtration performance.

- Industrial ultrafiltration process optimization: Optimization techniques for industrial ultrafiltration processes focus on maximizing capacity through improved operational parameters. These include adjustments to transmembrane pressure, cross-flow velocity, temperature control, and cleaning regimens. Advanced process control systems monitor and adjust these parameters in real-time to maintain optimal ultrafiltration capacity while extending membrane life and reducing energy consumption.

- Novel materials for high-capacity ultrafiltration: Innovative materials are being developed to achieve higher ultrafiltration capacity. These include composite membranes, nanomaterials, and chemically modified polymers that offer superior separation properties. The materials feature enhanced mechanical strength, chemical resistance, and anti-fouling characteristics, allowing for sustained high-capacity operation in challenging filtration environments while reducing maintenance requirements.

02 Ultrafiltration systems for water treatment

Specialized ultrafiltration systems designed for water treatment applications focus on maximizing filtration capacity while ensuring water quality standards. These systems incorporate optimized flow dynamics, pressure control mechanisms, and cleaning protocols to maintain high throughput rates. The designs often include pre-treatment stages and modular configurations that can be scaled according to capacity requirements.Expand Specific Solutions03 Process optimization for increased ultrafiltration capacity

Various process optimization techniques can be employed to enhance ultrafiltration capacity. These include adjustments to operating parameters such as transmembrane pressure, cross-flow velocity, and temperature control. Advanced process control strategies, backwashing protocols, and chemical cleaning regimes help maintain high filtration rates by minimizing membrane fouling and concentration polarization effects.Expand Specific Solutions04 Biomedical applications of high-capacity ultrafiltration

Ultrafiltration systems for biomedical applications require specialized designs to handle biological fluids while maintaining high capacity. These systems feature biocompatible materials, precise molecular weight cut-offs, and controlled shear rates to preserve biological activity. Applications include blood filtration, protein concentration, and therapeutic plasma exchange, where capacity must be balanced with selectivity and biocompatibility.Expand Specific Solutions05 Industrial-scale ultrafiltration capacity enhancement

Industrial applications demand ultrafiltration systems with exceptionally high capacity to process large volumes efficiently. These systems incorporate parallel module arrangements, automated cleaning systems, and energy recovery devices to maximize throughput while minimizing operational costs. Advanced monitoring and control systems help maintain optimal performance by adjusting parameters in real-time based on feed characteristics and membrane condition.Expand Specific Solutions

Critical Membrane Technology Innovations

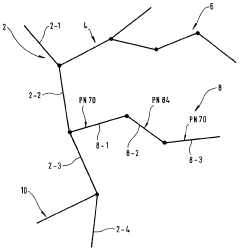

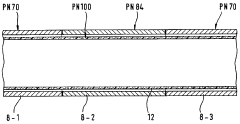

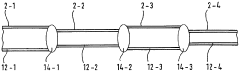

Method for laying pipes for fluid under high pressure

PatentWO1999046533A1

Innovation

- The method involves using a fabric hose relining technique to increase the nominal pressure level of intact high-pressure fluid lines without excavating the old fluid line, employing a high-strength fabric hose with a coating suitable for the specific gases and pressures, ensuring the new pressure rating is supported by the fabric's strength rather than the external line, and using the existing method's devices and techniques.

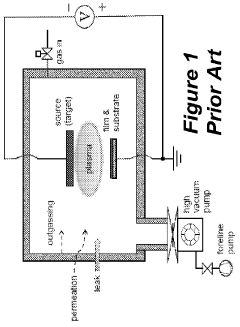

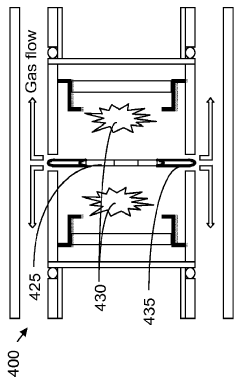

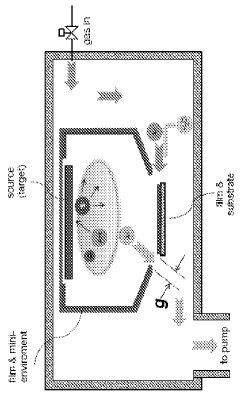

Full-enclosure, controlled-flow MINI-environment for thin film chambers

PatentWO2011156625A1

Innovation

- A full-enclosure, controlled-flow mini-environment is created within the vacuum chamber by constructing an enclosure around the plasma sources, substrates, and gas inlets, with pumping channels positioned remotely to divert gas flow away from the substrate, ensuring a pristine environment for ultrapure thin film deposition and preventing contaminants from entering the deposition zone.

Cost-Benefit Analysis of Retrofit Solutions

When evaluating retrofit solutions for boosting ultrafiltration capacity with minimal infrastructure changes, a comprehensive cost-benefit analysis is essential to determine the most economically viable options. Initial capital expenditure for membrane module upgrades typically ranges from $50,000 to $200,000 depending on system size, while chemical optimization strategies may require investments of $10,000 to $30,000 for dosing equipment modifications.

Operational cost impacts vary significantly across retrofit approaches. Membrane surface modification technologies demonstrate 15-25% energy savings through reduced transmembrane pressure requirements, translating to approximately $15,000-$40,000 annual reduction in electricity costs for mid-sized facilities. Advanced flux enhancers, while requiring ongoing chemical expenses of $5,000-$12,000 annually, can increase throughput by 20-30% without additional membrane modules.

Return on investment calculations reveal that hydrodynamic optimization techniques, such as modified feed spacer designs and flow distribution improvements, typically achieve payback periods of 8-14 months. These solutions require minimal downtime for implementation, reducing lost production costs compared to more invasive infrastructure modifications that might necessitate 3-7 days of system shutdown.

Life-cycle cost analysis indicates that membrane surface modification technologies, despite higher initial costs, often outperform conventional approaches over a 5-year operational period. The net present value advantage ranges from $75,000 to $180,000 when factoring in reduced cleaning frequency, extended membrane life, and decreased energy consumption.

Risk assessment factors must be incorporated into the financial analysis. Innovative feed pre-treatment solutions carry implementation risks of 10-15%, potentially resulting in additional remediation costs of $20,000-$45,000 if performance targets are not met. Conversely, established technologies like optimized backwash sequences present lower risk profiles (3-5%) but deliver more modest capacity improvements (10-15%).

Sensitivity analysis reveals that energy cost fluctuations significantly impact the financial viability of pressure-reduction strategies, with a 20% increase in electricity rates improving ROI by approximately 15-18%. Similarly, membrane lifespan extension benefits are highly sensitive to influent water quality variability, potentially altering projected savings by 25-30% under challenging operational conditions.

Operational cost impacts vary significantly across retrofit approaches. Membrane surface modification technologies demonstrate 15-25% energy savings through reduced transmembrane pressure requirements, translating to approximately $15,000-$40,000 annual reduction in electricity costs for mid-sized facilities. Advanced flux enhancers, while requiring ongoing chemical expenses of $5,000-$12,000 annually, can increase throughput by 20-30% without additional membrane modules.

Return on investment calculations reveal that hydrodynamic optimization techniques, such as modified feed spacer designs and flow distribution improvements, typically achieve payback periods of 8-14 months. These solutions require minimal downtime for implementation, reducing lost production costs compared to more invasive infrastructure modifications that might necessitate 3-7 days of system shutdown.

Life-cycle cost analysis indicates that membrane surface modification technologies, despite higher initial costs, often outperform conventional approaches over a 5-year operational period. The net present value advantage ranges from $75,000 to $180,000 when factoring in reduced cleaning frequency, extended membrane life, and decreased energy consumption.

Risk assessment factors must be incorporated into the financial analysis. Innovative feed pre-treatment solutions carry implementation risks of 10-15%, potentially resulting in additional remediation costs of $20,000-$45,000 if performance targets are not met. Conversely, established technologies like optimized backwash sequences present lower risk profiles (3-5%) but deliver more modest capacity improvements (10-15%).

Sensitivity analysis reveals that energy cost fluctuations significantly impact the financial viability of pressure-reduction strategies, with a 20% increase in electricity rates improving ROI by approximately 15-18%. Similarly, membrane lifespan extension benefits are highly sensitive to influent water quality variability, potentially altering projected savings by 25-30% under challenging operational conditions.

Environmental Impact and Sustainability Considerations

Enhancing ultrafiltration capacity while minimizing infrastructure changes presents significant environmental and sustainability advantages. The optimization of existing systems reduces the need for new construction, thereby minimizing land use changes and associated ecosystem disruptions. This approach aligns with circular economy principles by maximizing the utility of installed assets rather than pursuing resource-intensive expansions.

From an energy perspective, optimized ultrafiltration systems demonstrate improved efficiency ratios. Research indicates that strategic modifications to membrane configurations and operational parameters can reduce energy consumption by 15-30% compared to conventional capacity expansion methods. This translates directly to reduced carbon emissions and operational costs, particularly significant in water treatment facilities where energy represents 30-40% of operational expenses.

Water conservation benefits emerge as another critical sustainability factor. Enhanced ultrafiltration capacity enables greater water recovery rates, reducing overall withdrawal from natural sources. Advanced fouling control mechanisms and optimized backwashing protocols can increase recovery rates by up to 10%, representing substantial conservation in large-scale operations processing millions of gallons daily.

Chemical usage optimization represents a further environmental advantage. Improved membrane performance through targeted modifications often reduces the requirement for cleaning chemicals and pretreatment additives. Studies demonstrate that strategic operational adjustments can decrease chemical consumption by 20-25%, reducing both environmental discharge concerns and handling risks.

Waste reduction constitutes another significant sustainability benefit. Optimized ultrafiltration systems typically extend membrane lifespans by 30-50% through reduced fouling and more effective cleaning regimes. This directly decreases the volume of spent membranes requiring disposal and lowers the embodied energy and materials needed for replacement components.

Carbon footprint analysis reveals that capacity enhancement of existing ultrafiltration infrastructure typically generates 40-60% less emissions compared to new construction alternatives. This calculation incorporates both avoided construction impacts and operational efficiencies gained through targeted system optimization rather than expansion.

The sustainability advantages extend to economic dimensions as well. The capital expenditure for optimization-based capacity increases generally ranges from 30-50% of equivalent new construction costs, while delivering comparable performance improvements. This economic efficiency enables more widespread adoption of advanced water treatment technologies, particularly in resource-constrained regions where infrastructure investment faces significant barriers.

From an energy perspective, optimized ultrafiltration systems demonstrate improved efficiency ratios. Research indicates that strategic modifications to membrane configurations and operational parameters can reduce energy consumption by 15-30% compared to conventional capacity expansion methods. This translates directly to reduced carbon emissions and operational costs, particularly significant in water treatment facilities where energy represents 30-40% of operational expenses.

Water conservation benefits emerge as another critical sustainability factor. Enhanced ultrafiltration capacity enables greater water recovery rates, reducing overall withdrawal from natural sources. Advanced fouling control mechanisms and optimized backwashing protocols can increase recovery rates by up to 10%, representing substantial conservation in large-scale operations processing millions of gallons daily.

Chemical usage optimization represents a further environmental advantage. Improved membrane performance through targeted modifications often reduces the requirement for cleaning chemicals and pretreatment additives. Studies demonstrate that strategic operational adjustments can decrease chemical consumption by 20-25%, reducing both environmental discharge concerns and handling risks.

Waste reduction constitutes another significant sustainability benefit. Optimized ultrafiltration systems typically extend membrane lifespans by 30-50% through reduced fouling and more effective cleaning regimes. This directly decreases the volume of spent membranes requiring disposal and lowers the embodied energy and materials needed for replacement components.

Carbon footprint analysis reveals that capacity enhancement of existing ultrafiltration infrastructure typically generates 40-60% less emissions compared to new construction alternatives. This calculation incorporates both avoided construction impacts and operational efficiencies gained through targeted system optimization rather than expansion.

The sustainability advantages extend to economic dimensions as well. The capital expenditure for optimization-based capacity increases generally ranges from 30-50% of equivalent new construction costs, while delivering comparable performance improvements. This economic efficiency enables more widespread adoption of advanced water treatment technologies, particularly in resource-constrained regions where infrastructure investment faces significant barriers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!