Ultrafiltration System Performance Trajectories for Continuous Improvement

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration technology has evolved significantly since its inception in the 1960s, transforming from laboratory-scale applications to widespread industrial implementation. Initially developed for water purification, ultrafiltration has expanded into diverse sectors including pharmaceuticals, food processing, and wastewater treatment. The technology operates on the principle of size exclusion, utilizing semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers to separate macromolecules, colloids, and suspended particles from fluids.

The evolution of ultrafiltration technology has been marked by continuous improvements in membrane materials, module designs, and operational strategies. Early membranes were primarily cellulose-based, offering limited chemical and thermal stability. Modern ultrafiltration systems employ advanced materials such as polysulfone, polyethersulfone, and PVDF (polyvinylidene fluoride), which demonstrate superior durability, fouling resistance, and separation efficiency.

Recent technological advancements have focused on addressing persistent challenges in ultrafiltration operations, particularly membrane fouling, energy consumption, and system longevity. Innovations include the development of anti-fouling membranes, energy-efficient module configurations, and intelligent monitoring systems that optimize performance through real-time data analysis.

The primary objective of continuous improvement in ultrafiltration systems is to enhance operational efficiency while reducing resource consumption. This includes minimizing energy requirements, extending membrane lifespan, optimizing cleaning protocols, and maximizing throughput without compromising filtration quality. These improvements directly translate to reduced operational costs and environmental impact.

Another critical goal is increasing system adaptability to handle variable feed compositions and flow rates, which is particularly important in industrial applications where input conditions may fluctuate significantly. This adaptability requires sophisticated control systems capable of responding dynamically to changing conditions while maintaining consistent output quality.

The trajectory of ultrafiltration technology development is increasingly focused on sustainability, with emphasis on reducing chemical usage in cleaning processes, minimizing waste generation, and developing recyclable or biodegradable membrane materials. These environmental considerations align with global trends toward greener industrial processes and circular economy principles.

Looking forward, the integration of ultrafiltration with complementary technologies such as advanced oxidation processes, nanofiltration, and reverse osmosis presents opportunities for creating more comprehensive and efficient separation systems. The development of hybrid processes that leverage the strengths of multiple technologies represents a promising direction for addressing complex separation challenges across various industries.

The evolution of ultrafiltration technology has been marked by continuous improvements in membrane materials, module designs, and operational strategies. Early membranes were primarily cellulose-based, offering limited chemical and thermal stability. Modern ultrafiltration systems employ advanced materials such as polysulfone, polyethersulfone, and PVDF (polyvinylidene fluoride), which demonstrate superior durability, fouling resistance, and separation efficiency.

Recent technological advancements have focused on addressing persistent challenges in ultrafiltration operations, particularly membrane fouling, energy consumption, and system longevity. Innovations include the development of anti-fouling membranes, energy-efficient module configurations, and intelligent monitoring systems that optimize performance through real-time data analysis.

The primary objective of continuous improvement in ultrafiltration systems is to enhance operational efficiency while reducing resource consumption. This includes minimizing energy requirements, extending membrane lifespan, optimizing cleaning protocols, and maximizing throughput without compromising filtration quality. These improvements directly translate to reduced operational costs and environmental impact.

Another critical goal is increasing system adaptability to handle variable feed compositions and flow rates, which is particularly important in industrial applications where input conditions may fluctuate significantly. This adaptability requires sophisticated control systems capable of responding dynamically to changing conditions while maintaining consistent output quality.

The trajectory of ultrafiltration technology development is increasingly focused on sustainability, with emphasis on reducing chemical usage in cleaning processes, minimizing waste generation, and developing recyclable or biodegradable membrane materials. These environmental considerations align with global trends toward greener industrial processes and circular economy principles.

Looking forward, the integration of ultrafiltration with complementary technologies such as advanced oxidation processes, nanofiltration, and reverse osmosis presents opportunities for creating more comprehensive and efficient separation systems. The development of hybrid processes that leverage the strengths of multiple technologies represents a promising direction for addressing complex separation challenges across various industries.

Market Demand Analysis for Advanced Filtration Systems

The global market for advanced filtration systems has witnessed substantial growth in recent years, driven by increasing water scarcity concerns, stringent environmental regulations, and growing industrial demand for efficient separation technologies. The ultrafiltration segment specifically has emerged as a critical component of this market, with projected growth rates exceeding 15% annually through 2030.

Water treatment applications represent the largest market segment for advanced filtration systems, accounting for approximately 40% of total demand. Municipal water treatment facilities are increasingly adopting ultrafiltration technologies to meet more stringent drinking water standards and address emerging contaminants. Industrial applications follow closely, with food and beverage, pharmaceutical, and chemical processing industries driving significant demand for high-performance filtration solutions.

Geographically, Asia-Pacific represents the fastest-growing market for advanced filtration systems, particularly in China and India where rapid industrialization and urbanization have intensified water quality challenges. North America and Europe maintain substantial market shares, primarily driven by replacement demand and regulatory compliance requirements.

Consumer preferences are shifting toward filtration systems that offer improved energy efficiency, reduced maintenance requirements, and extended membrane life. Market research indicates that total cost of ownership has surpassed initial capital expenditure as the primary decision factor for system procurement, highlighting the importance of performance trajectories and continuous improvement capabilities.

The healthcare sector presents a particularly promising growth opportunity, with demand for ultrafiltration systems in bioprocessing and pharmaceutical manufacturing expected to grow substantially. This is attributed to the expansion of biopharmaceutical production capacity globally and increasing adoption of single-use technologies that incorporate advanced filtration components.

Environmental sustainability has emerged as a significant market driver, with customers increasingly valuing systems that minimize waste generation, reduce chemical usage, and demonstrate lower carbon footprints. This trend aligns with broader corporate sustainability initiatives and regulatory pressures to reduce environmental impacts across industrial operations.

Market analysis reveals a growing preference for integrated solutions that combine ultrafiltration with complementary technologies such as reverse osmosis or ion exchange, creating comprehensive water treatment trains. This system integration approach addresses complex separation challenges while optimizing overall process efficiency and reliability.

Water treatment applications represent the largest market segment for advanced filtration systems, accounting for approximately 40% of total demand. Municipal water treatment facilities are increasingly adopting ultrafiltration technologies to meet more stringent drinking water standards and address emerging contaminants. Industrial applications follow closely, with food and beverage, pharmaceutical, and chemical processing industries driving significant demand for high-performance filtration solutions.

Geographically, Asia-Pacific represents the fastest-growing market for advanced filtration systems, particularly in China and India where rapid industrialization and urbanization have intensified water quality challenges. North America and Europe maintain substantial market shares, primarily driven by replacement demand and regulatory compliance requirements.

Consumer preferences are shifting toward filtration systems that offer improved energy efficiency, reduced maintenance requirements, and extended membrane life. Market research indicates that total cost of ownership has surpassed initial capital expenditure as the primary decision factor for system procurement, highlighting the importance of performance trajectories and continuous improvement capabilities.

The healthcare sector presents a particularly promising growth opportunity, with demand for ultrafiltration systems in bioprocessing and pharmaceutical manufacturing expected to grow substantially. This is attributed to the expansion of biopharmaceutical production capacity globally and increasing adoption of single-use technologies that incorporate advanced filtration components.

Environmental sustainability has emerged as a significant market driver, with customers increasingly valuing systems that minimize waste generation, reduce chemical usage, and demonstrate lower carbon footprints. This trend aligns with broader corporate sustainability initiatives and regulatory pressures to reduce environmental impacts across industrial operations.

Market analysis reveals a growing preference for integrated solutions that combine ultrafiltration with complementary technologies such as reverse osmosis or ion exchange, creating comprehensive water treatment trains. This system integration approach addresses complex separation challenges while optimizing overall process efficiency and reliability.

Current Ultrafiltration Challenges and Limitations

Despite significant advancements in ultrafiltration (UF) technology, several critical challenges continue to impede optimal system performance and efficiency. Membrane fouling remains the most persistent limitation, occurring when particulates, colloids, and biological materials accumulate on membrane surfaces, reducing permeability and flux rates. This phenomenon necessitates frequent cleaning cycles, increasing operational downtime and chemical consumption while shortening membrane lifespan. Current anti-fouling strategies provide only temporary solutions rather than fundamental prevention.

Energy consumption presents another significant challenge, with UF systems requiring substantial power for maintaining transmembrane pressure and flow rates. Most existing systems operate at energy efficiency levels far below theoretical optimums, particularly in large-scale industrial applications where energy costs constitute a major operational expense. The industry lacks standardized energy efficiency metrics, making comparative performance assessment difficult across different system configurations.

Membrane material limitations further constrain UF advancement. Contemporary polymeric membranes exhibit trade-offs between selectivity, permeability, and mechanical strength. While ceramic membranes offer superior chemical and thermal resistance, their high production costs restrict widespread adoption. Additionally, membrane uniformity issues during manufacturing lead to inconsistent pore size distribution, affecting separation precision and reliability.

Process control and automation systems for UF operations frequently lack sophistication. Many facilities still rely on basic monitoring parameters and manual interventions rather than advanced predictive analytics and real-time optimization algorithms. This results in suboptimal performance adaptation to varying feed conditions and operational requirements.

Concentration polarization effects create boundary layers near membrane surfaces where rejected solutes accumulate, increasing osmotic pressure and reducing effective driving force. Current hydrodynamic designs have not fully resolved this fundamental limitation, particularly in high-recovery applications.

Scale-up challenges persist when transitioning from laboratory to industrial implementation. Performance parameters achieved in controlled environments often deteriorate significantly in full-scale operations due to flow distribution issues, pressure drop variations, and module configuration inefficiencies.

Finally, the environmental footprint of UF systems remains problematic. Membrane disposal, chemical cleaning waste, and high water consumption during backwashing create sustainability concerns that have not been adequately addressed by current technologies. The industry lacks comprehensive life cycle assessment frameworks to evaluate and improve the environmental performance of ultrafiltration systems.

Energy consumption presents another significant challenge, with UF systems requiring substantial power for maintaining transmembrane pressure and flow rates. Most existing systems operate at energy efficiency levels far below theoretical optimums, particularly in large-scale industrial applications where energy costs constitute a major operational expense. The industry lacks standardized energy efficiency metrics, making comparative performance assessment difficult across different system configurations.

Membrane material limitations further constrain UF advancement. Contemporary polymeric membranes exhibit trade-offs between selectivity, permeability, and mechanical strength. While ceramic membranes offer superior chemical and thermal resistance, their high production costs restrict widespread adoption. Additionally, membrane uniformity issues during manufacturing lead to inconsistent pore size distribution, affecting separation precision and reliability.

Process control and automation systems for UF operations frequently lack sophistication. Many facilities still rely on basic monitoring parameters and manual interventions rather than advanced predictive analytics and real-time optimization algorithms. This results in suboptimal performance adaptation to varying feed conditions and operational requirements.

Concentration polarization effects create boundary layers near membrane surfaces where rejected solutes accumulate, increasing osmotic pressure and reducing effective driving force. Current hydrodynamic designs have not fully resolved this fundamental limitation, particularly in high-recovery applications.

Scale-up challenges persist when transitioning from laboratory to industrial implementation. Performance parameters achieved in controlled environments often deteriorate significantly in full-scale operations due to flow distribution issues, pressure drop variations, and module configuration inefficiencies.

Finally, the environmental footprint of UF systems remains problematic. Membrane disposal, chemical cleaning waste, and high water consumption during backwashing create sustainability concerns that have not been adequately addressed by current technologies. The industry lacks comprehensive life cycle assessment frameworks to evaluate and improve the environmental performance of ultrafiltration systems.

Current Performance Optimization Solutions

01 Membrane configuration and materials for ultrafiltration systems

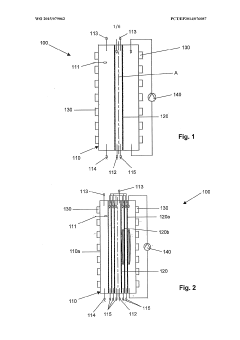

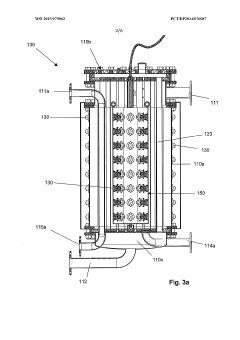

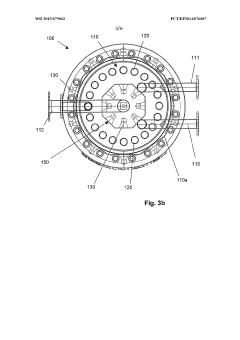

The performance of ultrafiltration systems is significantly influenced by membrane configuration and materials. Various membrane designs such as hollow fiber, spiral wound, and tubular configurations offer different advantages in terms of filtration efficiency, fouling resistance, and operational flexibility. Advanced materials including polymeric membranes, ceramic membranes, and composite materials can enhance separation capabilities, chemical resistance, and durability. The selection of appropriate membrane configurations and materials is crucial for optimizing filtration performance based on specific application requirements.- Membrane configuration and materials for ultrafiltration systems: The design and material selection of ultrafiltration membranes significantly impact system performance. Advanced membrane configurations such as hollow fiber, spiral wound, and tubular membranes offer different advantages in terms of filtration efficiency, fouling resistance, and energy consumption. Novel membrane materials including polymeric composites, ceramic materials, and surface-modified membranes can enhance separation capabilities, chemical resistance, and operational lifespan of ultrafiltration systems.

- Fouling control and cleaning strategies: Membrane fouling is a critical challenge affecting ultrafiltration system performance. Various strategies have been developed to mitigate fouling, including backwashing, chemical cleaning, air scouring, and feed pretreatment. Advanced cleaning protocols using specific chemical agents, optimized cleaning frequencies, and automated cleaning systems can effectively restore membrane permeability and maintain consistent filtration performance over extended operational periods.

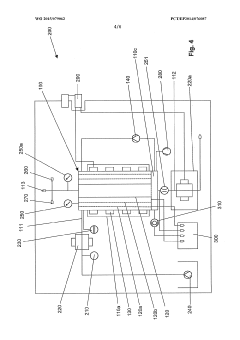

- Process optimization and control systems: Optimizing operational parameters and implementing advanced control systems can significantly enhance ultrafiltration performance. Key parameters include transmembrane pressure, cross-flow velocity, temperature, and filtration cycles. Automated monitoring and control systems utilizing sensors, real-time data analysis, and predictive algorithms enable dynamic adjustment of operational parameters to maintain optimal performance under varying feed conditions and system requirements.

- Hybrid and integrated ultrafiltration systems: Combining ultrafiltration with other separation technologies creates hybrid systems with enhanced performance capabilities. Integration with processes such as coagulation, adsorption, biological treatment, or other membrane technologies (like reverse osmosis or nanofiltration) can improve overall system efficiency, extend membrane life, and achieve superior filtrate quality. These integrated approaches are particularly effective for complex feed streams requiring multi-stage treatment.

- Energy efficiency and sustainable operation: Improving energy efficiency is crucial for sustainable ultrafiltration operations. Innovations in this area include energy recovery devices, low-energy membrane configurations, optimized hydraulic designs, and renewable energy integration. Advanced flow distribution systems, reduced pressure drop designs, and efficient pumping arrangements can significantly lower energy consumption while maintaining filtration performance. Additionally, sustainable practices such as concentrate recovery and reuse contribute to overall system efficiency.

02 Fouling control and cleaning strategies

Fouling is a major challenge affecting ultrafiltration system performance. Effective fouling control strategies include optimized pre-treatment processes, hydrodynamic modifications to reduce particle deposition, and implementation of air scouring techniques. Regular cleaning protocols using chemical agents such as acids, bases, and oxidants help restore membrane permeability. Advanced cleaning approaches like backwashing, forward flushing, and chemical enhanced backwash can significantly extend membrane life and maintain consistent filtration performance. Proper fouling management is essential for sustainable long-term operation of ultrafiltration systems.Expand Specific Solutions03 Process optimization and monitoring techniques

Optimizing ultrafiltration system performance requires sophisticated monitoring and control strategies. Real-time monitoring of parameters such as transmembrane pressure, flux, temperature, and permeate quality enables proactive system management. Advanced process control algorithms can automatically adjust operational parameters to maintain optimal performance under varying feed conditions. Data analytics and predictive maintenance approaches help identify performance trends and anticipate system issues before they impact filtration efficiency. Integration of sensors and automation systems enhances operational reliability and reduces energy consumption while maintaining consistent filtration quality.Expand Specific Solutions04 Energy efficiency and sustainable operation

Energy consumption is a significant factor in ultrafiltration system performance and operational costs. Innovative designs incorporating energy recovery devices, optimized pump systems, and efficient hydraulic configurations can substantially reduce power requirements. Variable frequency drives enable dynamic adjustment of energy input based on filtration demands. Sustainable operation approaches include optimizing backwash frequency, implementing intermittent operation modes, and utilizing renewable energy sources. These strategies not only reduce operational costs but also minimize environmental impact while maintaining high filtration performance.Expand Specific Solutions05 System integration and hybrid processes

Integrating ultrafiltration with complementary treatment processes can significantly enhance overall system performance. Hybrid systems combining ultrafiltration with other separation technologies such as reverse osmosis, nanofiltration, or adsorption processes offer synergistic benefits. Pre-treatment configurations using coagulation, flocculation, or sedimentation improve feed water quality and reduce membrane fouling. Post-treatment processes ensure final water quality meets specific requirements. These integrated approaches optimize resource utilization, improve treatment efficiency, and extend the application range of ultrafiltration technology across various industrial and municipal water treatment scenarios.Expand Specific Solutions

Key Industry Players in Ultrafiltration Market

The ultrafiltration system market is currently in a growth phase, characterized by increasing adoption across water treatment, healthcare, and industrial applications. The global market size is estimated to exceed $2 billion, with projected annual growth of 6-8% driven by stringent water quality regulations and healthcare demands. Technologically, the field shows varying maturity levels with companies at different development stages. Industry leaders like Gambro Lundia AB and NxStage Medical have established advanced healthcare filtration solutions, while Nomura Micro Science, Organo Corp, and WILO SE demonstrate strong industrial applications expertise. Emerging players such as Seccua GmbH are introducing innovations in membrane technology. The competitive landscape is diversifying with specialized applications from companies like Cytiva and Repligen in biopharmaceutical processing, indicating continuous performance improvement trajectories across multiple sectors.

Gambro Lundia AB

Technical Solution: Gambro Lundia AB has developed advanced ultrafiltration systems for hemodialysis applications with continuous performance improvement trajectories. Their technology utilizes a proprietary hollow fiber membrane design with optimized pore size distribution that enhances filtration efficiency while minimizing protein adsorption. The system incorporates real-time monitoring through integrated sensors that continuously measure transmembrane pressure, filtration rates, and membrane fouling indicators. This data feeds into their adaptive control algorithms that automatically adjust operational parameters to maintain optimal performance over extended periods. Their latest ultrafiltration platforms feature a modular design allowing for scalability and integration with existing treatment systems, while their membrane materials demonstrate superior biocompatibility and reduced immunogenic responses in clinical applications.

Strengths: Superior biocompatibility of membrane materials reduces adverse patient reactions and extends filter life. Advanced monitoring systems enable predictive maintenance and performance optimization. Weaknesses: Higher initial cost compared to conventional systems, and proprietary components may limit compatibility with third-party equipment.

NxStage Medical, Inc.

Technical Solution: NxStage Medical has pioneered portable ultrafiltration systems with continuous performance improvement trajectories focused on home hemodialysis applications. Their technology employs a unique cartridge-based filtration system that integrates multiple filtration stages within a compact, disposable unit. The system utilizes volumetric balancing technology that precisely controls ultrafiltration rates while maintaining pressure equilibrium across the membrane. Their performance improvement approach incorporates machine learning algorithms that analyze historical treatment data to identify optimal operational parameters for individual patients. NxStage's systems feature simplified user interfaces with automated self-diagnostic capabilities that detect potential performance issues before they affect treatment quality. The company has developed specialized membrane materials with enhanced durability that maintain consistent performance characteristics even after repeated use cycles, addressing one of the key challenges in long-term ultrafiltration system reliability.

Strengths: Highly portable and user-friendly design enables effective home-based treatments. Cartridge-based system simplifies maintenance and reduces technical complexity for users. Weaknesses: Limited filtration capacity compared to larger institutional systems, and relatively higher per-treatment consumable costs.

Critical Patents and Technical Innovations

Apparatus for extracorporeal blood treatment and method for managing such an apparatus

PatentActiveEP2362790A1

Innovation

- A method and apparatus that dynamically determine and adjust the ultrafiltration flow rate to achieve the maximum ultrafiltration coefficient by measuring transmembrane pressure and calculating the ultrafiltration coefficient, allowing for real-time optimization of the dialysis process to maintain optimal hydraulic permeability and efficiency.

Method and device for filtering liquids

PatentWO2015079062A1

Innovation

- The method involves monitoring operating pressure and hydraulic throughput during filtration, using ultrasound to prevent filter blockage, and implementing automatic cleaning cycles based on pre-defined thresholds, along with ultrasonic disinfection to reduce microbial load and biofouling, and employing cyclone flow and nanobubble introduction for enhanced cleaning.

Environmental Impact and Sustainability Considerations

Ultrafiltration systems represent a significant opportunity for enhancing environmental sustainability across various industrial applications. The environmental footprint of these systems extends beyond their operational efficiency to encompass resource consumption, waste generation, and long-term ecological impact. Modern ultrafiltration technologies demonstrate considerable potential for reducing water and energy usage compared to conventional filtration methods, with advanced membrane designs achieving up to 30% reduction in energy consumption and 25% decrease in water wastage during backwashing processes.

The life cycle assessment of ultrafiltration systems reveals critical environmental considerations at each stage. During manufacturing, the production of polymer membranes typically generates approximately 5-7 kg CO2 equivalent per square meter of membrane material. Operational phases contribute significantly to environmental impact through energy consumption, chemical usage for cleaning, and concentrate disposal. End-of-life management presents both challenges and opportunities, with emerging recycling technologies now capable of recovering up to 60% of membrane materials for reuse.

Chemical usage in membrane cleaning and maintenance represents a substantial environmental concern. Traditional cleaning regimens often employ harsh chemicals including sodium hypochlorite, citric acid, and various surfactants that may contribute to aquatic toxicity when improperly discharged. Recent innovations in environmentally friendly cleaning agents have demonstrated comparable cleaning efficacy while reducing ecological impact by up to 40%, presenting a promising avenue for sustainability enhancement.

Water recovery rates in ultrafiltration systems directly influence their environmental profile. Contemporary systems typically achieve recovery rates between 85-95%, with each percentage point improvement potentially conserving millions of gallons annually in large-scale applications. Advanced control algorithms that optimize backwash frequency and duration based on real-time fouling metrics have demonstrated capacity to increase recovery rates by 3-5% without compromising filtrate quality.

Carbon footprint reduction represents another dimension of environmental improvement in ultrafiltration systems. Integration with renewable energy sources, particularly solar photovoltaic arrays, has proven technically and economically viable for powering ultrafiltration operations. Case studies indicate that solar-powered ultrafiltration systems can reduce operational carbon emissions by 70-90% compared to grid-powered alternatives, with payback periods typically ranging from 4-7 years depending on regional energy costs and solar irradiance.

Regulatory frameworks increasingly recognize and incentivize environmental performance improvements in filtration technologies. Standards such as ISO 14001 and industry-specific certifications provide structured approaches for measuring and verifying environmental impact reductions. Organizations implementing comprehensive environmental management systems for their ultrafiltration operations report average compliance cost reductions of 15-20% and enhanced stakeholder relations, demonstrating that environmental sustainability initiatives often align with broader business objectives.

The life cycle assessment of ultrafiltration systems reveals critical environmental considerations at each stage. During manufacturing, the production of polymer membranes typically generates approximately 5-7 kg CO2 equivalent per square meter of membrane material. Operational phases contribute significantly to environmental impact through energy consumption, chemical usage for cleaning, and concentrate disposal. End-of-life management presents both challenges and opportunities, with emerging recycling technologies now capable of recovering up to 60% of membrane materials for reuse.

Chemical usage in membrane cleaning and maintenance represents a substantial environmental concern. Traditional cleaning regimens often employ harsh chemicals including sodium hypochlorite, citric acid, and various surfactants that may contribute to aquatic toxicity when improperly discharged. Recent innovations in environmentally friendly cleaning agents have demonstrated comparable cleaning efficacy while reducing ecological impact by up to 40%, presenting a promising avenue for sustainability enhancement.

Water recovery rates in ultrafiltration systems directly influence their environmental profile. Contemporary systems typically achieve recovery rates between 85-95%, with each percentage point improvement potentially conserving millions of gallons annually in large-scale applications. Advanced control algorithms that optimize backwash frequency and duration based on real-time fouling metrics have demonstrated capacity to increase recovery rates by 3-5% without compromising filtrate quality.

Carbon footprint reduction represents another dimension of environmental improvement in ultrafiltration systems. Integration with renewable energy sources, particularly solar photovoltaic arrays, has proven technically and economically viable for powering ultrafiltration operations. Case studies indicate that solar-powered ultrafiltration systems can reduce operational carbon emissions by 70-90% compared to grid-powered alternatives, with payback periods typically ranging from 4-7 years depending on regional energy costs and solar irradiance.

Regulatory frameworks increasingly recognize and incentivize environmental performance improvements in filtration technologies. Standards such as ISO 14001 and industry-specific certifications provide structured approaches for measuring and verifying environmental impact reductions. Organizations implementing comprehensive environmental management systems for their ultrafiltration operations report average compliance cost reductions of 15-20% and enhanced stakeholder relations, demonstrating that environmental sustainability initiatives often align with broader business objectives.

Regulatory Compliance Framework for Filtration Systems

Regulatory compliance for ultrafiltration systems has evolved significantly over the past decade, with increasingly stringent standards being implemented across different regions. The primary regulatory frameworks governing these systems include the Safe Drinking Water Act (SDWA) in the United States, the Drinking Water Directive in the European Union, and similar regulations in Asia-Pacific regions. These frameworks establish minimum requirements for filtration performance, contaminant removal efficiency, and operational safety.

The compliance landscape is characterized by a multi-tiered approach, with international standards organizations like ISO providing overarching guidelines, while national and regional bodies enforce specific requirements. ISO 13959 and ISO 23500 series specifically address water quality requirements for dialysis and related therapies, which have direct implications for ultrafiltration technologies in medical applications.

Performance validation protocols constitute a critical component of the regulatory framework. These protocols typically require manufacturers to demonstrate consistent removal of specific contaminants, maintenance of flow rates under varying conditions, and reliability over extended operational periods. The ASTM D6161 standard, for instance, provides test methods for evaluating ultrafiltration membrane performance.

Compliance documentation requirements have become increasingly comprehensive, necessitating detailed record-keeping of system performance metrics, maintenance activities, and quality control measures. This trend toward data-intensive compliance has accelerated the adoption of automated monitoring systems that can continuously track and report on key performance indicators.

Environmental regulations intersect with ultrafiltration compliance frameworks, particularly regarding concentrate disposal and energy efficiency. The circular economy principles are gradually being incorporated into regulatory expectations, with emphasis on sustainable materials, reduced waste generation, and lower energy consumption throughout the filtration system lifecycle.

Risk management frameworks, such as those outlined in ISO 14971, have been integrated into compliance requirements for ultrafiltration systems, especially in critical applications like pharmaceutical manufacturing and medical treatments. These frameworks mandate systematic identification, assessment, and mitigation of potential failure modes and their consequences.

The trajectory of regulatory development indicates a move toward performance-based standards rather than prescriptive requirements, allowing for greater innovation while maintaining safety and efficacy. This shift aligns with the continuous improvement philosophy underlying modern ultrafiltration system development, where incremental enhancements in membrane materials, module designs, and control systems can be rapidly implemented without necessitating complete regulatory reassessment.

The compliance landscape is characterized by a multi-tiered approach, with international standards organizations like ISO providing overarching guidelines, while national and regional bodies enforce specific requirements. ISO 13959 and ISO 23500 series specifically address water quality requirements for dialysis and related therapies, which have direct implications for ultrafiltration technologies in medical applications.

Performance validation protocols constitute a critical component of the regulatory framework. These protocols typically require manufacturers to demonstrate consistent removal of specific contaminants, maintenance of flow rates under varying conditions, and reliability over extended operational periods. The ASTM D6161 standard, for instance, provides test methods for evaluating ultrafiltration membrane performance.

Compliance documentation requirements have become increasingly comprehensive, necessitating detailed record-keeping of system performance metrics, maintenance activities, and quality control measures. This trend toward data-intensive compliance has accelerated the adoption of automated monitoring systems that can continuously track and report on key performance indicators.

Environmental regulations intersect with ultrafiltration compliance frameworks, particularly regarding concentrate disposal and energy efficiency. The circular economy principles are gradually being incorporated into regulatory expectations, with emphasis on sustainable materials, reduced waste generation, and lower energy consumption throughout the filtration system lifecycle.

Risk management frameworks, such as those outlined in ISO 14971, have been integrated into compliance requirements for ultrafiltration systems, especially in critical applications like pharmaceutical manufacturing and medical treatments. These frameworks mandate systematic identification, assessment, and mitigation of potential failure modes and their consequences.

The trajectory of regulatory development indicates a move toward performance-based standards rather than prescriptive requirements, allowing for greater innovation while maintaining safety and efficacy. This shift aligns with the continuous improvement philosophy underlying modern ultrafiltration system development, where incremental enhancements in membrane materials, module designs, and control systems can be rapidly implemented without necessitating complete regulatory reassessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!