How to Integrate Ultrafiltration in Hybrid Water Treatment Approaches

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration technology emerged in the 1960s as a membrane-based separation process, initially developed for industrial applications before expanding into water treatment. The technology utilizes semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers, enabling the removal of suspended solids, bacteria, viruses, and macromolecules while allowing water and dissolved substances to pass through.

The evolution of ultrafiltration has been marked by significant advancements in membrane materials, from early cellulose acetate membranes to modern polysulfone, polyethersulfone, and PVDF membranes. These innovations have dramatically improved filtration efficiency, membrane lifespan, and operational flexibility, while reducing energy consumption and maintenance requirements.

In recent years, ultrafiltration has gained prominence as a critical component in hybrid water treatment systems, where it is strategically combined with other treatment technologies to address complex water quality challenges. The integration of ultrafiltration with processes such as coagulation, activated carbon filtration, reverse osmosis, and advanced oxidation has opened new possibilities for comprehensive water treatment solutions.

The primary objective of integrating ultrafiltration in hybrid approaches is to develop more efficient, sustainable, and adaptable water treatment systems capable of addressing diverse water quality issues across different applications. This includes producing potable water from challenging source waters, treating industrial wastewater for reuse, and developing decentralized treatment solutions for remote communities.

Technical goals include optimizing membrane performance in hybrid systems, minimizing fouling and concentration polarization, extending membrane life, reducing energy consumption, and developing intelligent control systems for automated operation. Research is also focused on creating more robust membranes capable of withstanding harsh operating conditions and chemical cleaning regimes.

The long-term vision encompasses the development of next-generation hybrid systems where ultrafiltration serves as a versatile platform technology, adaptable to various water sources and quality requirements. This includes exploring novel membrane materials, module designs, and system configurations that can be tailored to specific applications while maintaining cost-effectiveness and operational simplicity.

As water scarcity intensifies globally and water quality regulations become more stringent, the integration of ultrafiltration in hybrid treatment approaches represents a promising pathway toward sustainable water management, resource recovery, and environmental protection.

The evolution of ultrafiltration has been marked by significant advancements in membrane materials, from early cellulose acetate membranes to modern polysulfone, polyethersulfone, and PVDF membranes. These innovations have dramatically improved filtration efficiency, membrane lifespan, and operational flexibility, while reducing energy consumption and maintenance requirements.

In recent years, ultrafiltration has gained prominence as a critical component in hybrid water treatment systems, where it is strategically combined with other treatment technologies to address complex water quality challenges. The integration of ultrafiltration with processes such as coagulation, activated carbon filtration, reverse osmosis, and advanced oxidation has opened new possibilities for comprehensive water treatment solutions.

The primary objective of integrating ultrafiltration in hybrid approaches is to develop more efficient, sustainable, and adaptable water treatment systems capable of addressing diverse water quality issues across different applications. This includes producing potable water from challenging source waters, treating industrial wastewater for reuse, and developing decentralized treatment solutions for remote communities.

Technical goals include optimizing membrane performance in hybrid systems, minimizing fouling and concentration polarization, extending membrane life, reducing energy consumption, and developing intelligent control systems for automated operation. Research is also focused on creating more robust membranes capable of withstanding harsh operating conditions and chemical cleaning regimes.

The long-term vision encompasses the development of next-generation hybrid systems where ultrafiltration serves as a versatile platform technology, adaptable to various water sources and quality requirements. This includes exploring novel membrane materials, module designs, and system configurations that can be tailored to specific applications while maintaining cost-effectiveness and operational simplicity.

As water scarcity intensifies globally and water quality regulations become more stringent, the integration of ultrafiltration in hybrid treatment approaches represents a promising pathway toward sustainable water management, resource recovery, and environmental protection.

Market Analysis for Hybrid Water Treatment Solutions

The global market for hybrid water treatment solutions is experiencing robust growth, driven by increasing water scarcity concerns and stringent regulations regarding water quality. The integration of ultrafiltration (UF) within hybrid treatment systems represents a significant market opportunity, with the global water treatment market projected to reach $211 billion by 2025, growing at a CAGR of 7.1% from 2020.

Ultrafiltration-based hybrid systems are gaining particular traction in municipal water treatment, which currently accounts for approximately 65% of the total market share. Industrial applications follow closely, representing about 30% of market demand, with commercial applications comprising the remaining 5%. Regionally, Asia-Pacific dominates the market with 40% share, followed by North America (25%) and Europe (20%), with emerging economies in Africa and Latin America showing the highest growth rates.

The demand for hybrid water treatment solutions incorporating ultrafiltration is being fueled by several key factors. Water scarcity affects over 2.8 billion people globally, with this figure expected to rise to 3.9 billion by 2030. Additionally, regulatory frameworks such as the EU Water Framework Directive and the US Clean Water Act continue to tighten quality standards, necessitating more sophisticated treatment approaches.

Market segmentation reveals that UF-RO (Reverse Osmosis) hybrid systems hold the largest market share at 45%, followed by UF-MBR (Membrane Bioreactor) combinations at 30%. Emerging hybrid configurations including UF-Advanced Oxidation Processes (AOPs) and UF-Activated Carbon systems are showing promising growth rates of 12% and 9% respectively.

Customer needs analysis indicates shifting priorities, with 78% of municipal customers citing operational efficiency as their primary concern, while 65% of industrial users prioritize water recovery rates. Total cost of ownership has become increasingly important across all segments, with energy consumption reduction being a critical factor in purchasing decisions.

Competitive analysis shows market consolidation among major players, with the top five companies controlling 62% of the global market. However, regional specialists and technology-focused startups are disrupting traditional market dynamics by offering specialized hybrid solutions for specific contaminants or applications.

Future market projections indicate that ultrafiltration-integrated hybrid systems will continue to gain market share, potentially reaching 40% of all water treatment installations by 2030. The fastest growth is expected in decentralized systems for remote communities and industrial applications requiring high-purity process water, with projected CAGRs of 14% and 11% respectively through 2028.

Ultrafiltration-based hybrid systems are gaining particular traction in municipal water treatment, which currently accounts for approximately 65% of the total market share. Industrial applications follow closely, representing about 30% of market demand, with commercial applications comprising the remaining 5%. Regionally, Asia-Pacific dominates the market with 40% share, followed by North America (25%) and Europe (20%), with emerging economies in Africa and Latin America showing the highest growth rates.

The demand for hybrid water treatment solutions incorporating ultrafiltration is being fueled by several key factors. Water scarcity affects over 2.8 billion people globally, with this figure expected to rise to 3.9 billion by 2030. Additionally, regulatory frameworks such as the EU Water Framework Directive and the US Clean Water Act continue to tighten quality standards, necessitating more sophisticated treatment approaches.

Market segmentation reveals that UF-RO (Reverse Osmosis) hybrid systems hold the largest market share at 45%, followed by UF-MBR (Membrane Bioreactor) combinations at 30%. Emerging hybrid configurations including UF-Advanced Oxidation Processes (AOPs) and UF-Activated Carbon systems are showing promising growth rates of 12% and 9% respectively.

Customer needs analysis indicates shifting priorities, with 78% of municipal customers citing operational efficiency as their primary concern, while 65% of industrial users prioritize water recovery rates. Total cost of ownership has become increasingly important across all segments, with energy consumption reduction being a critical factor in purchasing decisions.

Competitive analysis shows market consolidation among major players, with the top five companies controlling 62% of the global market. However, regional specialists and technology-focused startups are disrupting traditional market dynamics by offering specialized hybrid solutions for specific contaminants or applications.

Future market projections indicate that ultrafiltration-integrated hybrid systems will continue to gain market share, potentially reaching 40% of all water treatment installations by 2030. The fastest growth is expected in decentralized systems for remote communities and industrial applications requiring high-purity process water, with projected CAGRs of 14% and 11% respectively through 2028.

Current Ultrafiltration Integration Challenges

Despite the proven effectiveness of ultrafiltration (UF) in water treatment, several significant challenges impede its seamless integration into hybrid treatment systems. One primary obstacle is membrane fouling, which occurs when particles, colloids, and organic matter accumulate on membrane surfaces, reducing permeability and increasing operational costs. This fouling phenomenon is particularly problematic in hybrid systems where upstream processes may not adequately remove fouling agents, creating compatibility issues between treatment stages.

Energy consumption represents another substantial challenge, as UF systems require continuous pumping to maintain transmembrane pressure. When integrated into multi-stage treatment trains, the cumulative energy demands can become economically prohibitive, especially for large-scale applications or in regions with limited energy resources. This challenge is compounded by the need to optimize pressure differentials across various treatment components.

System complexity increases significantly in hybrid configurations, requiring sophisticated control systems to manage varying flow rates, backwashing cycles, and chemical cleaning regimes. The integration of UF with other technologies such as advanced oxidation processes, ion exchange, or biological treatment introduces operational complexities that demand specialized expertise and monitoring capabilities that many utilities lack.

Pretreatment optimization remains a critical challenge, as inadequate pretreatment can accelerate membrane fouling and reduce system efficiency. Determining the optimal sequence and intensity of pretreatment steps in relation to UF placement within the treatment train requires extensive pilot testing and operational experience, which may not be readily available.

Cost considerations present significant barriers to widespread adoption, with capital expenditures for UF integration often exceeding conventional treatment alternatives. The economic equation becomes more complex when factoring in membrane replacement costs, specialized cleaning chemicals, and the potential need for redundant systems to ensure continuous operation during maintenance.

Regulatory compliance adds another layer of complexity, as water quality standards continue to evolve, particularly regarding emerging contaminants. Hybrid systems incorporating UF must demonstrate consistent compliance across varying influent conditions, which can be challenging when treatment stages interact in unpredictable ways.

Scale-up challenges persist when transitioning from pilot to full-scale implementation, as hydraulic conditions, fouling behaviors, and treatment efficiencies often differ significantly between scales. This scaling discrepancy can lead to unexpected performance issues when integrating UF into existing treatment infrastructure.

Waste stream management presents environmental concerns, as concentrated reject streams from UF systems require appropriate handling and disposal. In hybrid configurations, these waste streams may contain chemicals from other treatment processes, complicating their management and potentially increasing the environmental footprint of the overall system.

Energy consumption represents another substantial challenge, as UF systems require continuous pumping to maintain transmembrane pressure. When integrated into multi-stage treatment trains, the cumulative energy demands can become economically prohibitive, especially for large-scale applications or in regions with limited energy resources. This challenge is compounded by the need to optimize pressure differentials across various treatment components.

System complexity increases significantly in hybrid configurations, requiring sophisticated control systems to manage varying flow rates, backwashing cycles, and chemical cleaning regimes. The integration of UF with other technologies such as advanced oxidation processes, ion exchange, or biological treatment introduces operational complexities that demand specialized expertise and monitoring capabilities that many utilities lack.

Pretreatment optimization remains a critical challenge, as inadequate pretreatment can accelerate membrane fouling and reduce system efficiency. Determining the optimal sequence and intensity of pretreatment steps in relation to UF placement within the treatment train requires extensive pilot testing and operational experience, which may not be readily available.

Cost considerations present significant barriers to widespread adoption, with capital expenditures for UF integration often exceeding conventional treatment alternatives. The economic equation becomes more complex when factoring in membrane replacement costs, specialized cleaning chemicals, and the potential need for redundant systems to ensure continuous operation during maintenance.

Regulatory compliance adds another layer of complexity, as water quality standards continue to evolve, particularly regarding emerging contaminants. Hybrid systems incorporating UF must demonstrate consistent compliance across varying influent conditions, which can be challenging when treatment stages interact in unpredictable ways.

Scale-up challenges persist when transitioning from pilot to full-scale implementation, as hydraulic conditions, fouling behaviors, and treatment efficiencies often differ significantly between scales. This scaling discrepancy can lead to unexpected performance issues when integrating UF into existing treatment infrastructure.

Waste stream management presents environmental concerns, as concentrated reject streams from UF systems require appropriate handling and disposal. In hybrid configurations, these waste streams may contain chemicals from other treatment processes, complicating their management and potentially increasing the environmental footprint of the overall system.

Existing Hybrid Ultrafiltration Implementation Methods

01 Ultrafiltration membrane technology and materials

Ultrafiltration membranes are key components in filtration systems, designed with specific materials and structures to achieve optimal separation performance. These membranes can be made from various polymeric materials or ceramic compounds with controlled pore sizes to selectively filter particles and molecules. Advanced membrane designs incorporate features that enhance durability, reduce fouling, and improve flux rates while maintaining high rejection capabilities for targeted substances.- Ultrafiltration membrane technology and materials: Ultrafiltration membranes are key components in filtration systems, designed with specific materials and structures to achieve optimal separation performance. These membranes can be made from various polymers or ceramic materials with controlled pore sizes to selectively filter particles and molecules. Advanced membrane designs incorporate features to minimize fouling and enhance durability while maintaining high flux rates. The membrane configuration and material selection significantly impact the efficiency and application range of ultrafiltration systems.

- Industrial wastewater treatment applications: Ultrafiltration systems are widely employed in industrial wastewater treatment to remove suspended solids, colloids, bacteria, and high molecular weight contaminants. These systems can be integrated into comprehensive treatment trains to handle various industrial effluents including those from chemical processing, textile manufacturing, and food production facilities. The technology enables water recycling and resource recovery while ensuring compliance with discharge regulations. Process optimization in industrial applications focuses on balancing filtration efficiency with energy consumption and operational costs.

- Ultrafiltration system design and process optimization: The design of ultrafiltration systems involves careful consideration of flow dynamics, pressure distribution, and module configuration to maximize efficiency. Process optimization techniques include cross-flow operation, backwashing protocols, and chemical cleaning regimes to maintain membrane performance over time. Advanced control systems monitor key parameters such as transmembrane pressure, flux rates, and permeate quality to automate operation and respond to changing feed conditions. Innovations in system design focus on reducing energy consumption, minimizing chemical usage, and extending membrane lifetime.

- Biological and pharmaceutical applications: Ultrafiltration plays a crucial role in biological and pharmaceutical processing, including protein concentration, virus removal, and fractionation of biomolecules. The technology enables gentle separation of sensitive biological materials while maintaining their structural integrity and activity. In pharmaceutical manufacturing, ultrafiltration serves as a critical step in downstream processing to ensure product purity and consistency. Specialized ultrafiltration systems are designed to meet stringent regulatory requirements for bioprocessing applications, with features that enable validation and cleaning-in-place operations.

- Hybrid and integrated filtration processes: Hybrid filtration processes combine ultrafiltration with other separation technologies such as microfiltration, nanofiltration, or reverse osmosis to achieve comprehensive treatment objectives. These integrated approaches leverage the strengths of each technology to address complex separation challenges. Pre-treatment systems protect ultrafiltration membranes from fouling while post-treatment stages further refine the filtrate quality. The integration of ultrafiltration with adsorption, oxidation, or biological treatment processes creates synergistic effects that enhance overall system performance and expand the range of treatable contaminants.

02 Industrial wastewater treatment applications

Ultrafiltration systems are widely employed in industrial wastewater treatment to remove suspended solids, colloids, bacteria, and high molecular weight contaminants. These systems can be integrated into comprehensive treatment trains to handle various industrial effluents from manufacturing, chemical processing, and food production facilities. The technology enables water reuse opportunities, reduces environmental impact, and helps industries comply with discharge regulations by producing consistently high-quality treated water.Expand Specific Solutions03 Ultrafiltration system design and process optimization

Effective ultrafiltration systems require careful design considerations including flow configuration, operating parameters, and control strategies. Process optimization involves balancing factors such as transmembrane pressure, cross-flow velocity, temperature, and cleaning protocols to maximize efficiency and membrane lifespan. Advanced system designs incorporate features like automated backwashing, air scouring, and chemical cleaning sequences to maintain consistent performance and reduce operational costs over time.Expand Specific Solutions04 Biotechnology and pharmaceutical applications

Ultrafiltration plays a crucial role in biotechnology and pharmaceutical manufacturing processes for protein concentration, buffer exchange, virus removal, and product purification. The technology enables gentle separation of biomolecules without thermal or chemical degradation, making it suitable for processing heat-sensitive biological products. Specialized ultrafiltration systems with validated performance characteristics are used to ensure product quality, consistency, and regulatory compliance in biopharmaceutical production.Expand Specific Solutions05 Hybrid and integrated filtration systems

Hybrid filtration systems combine ultrafiltration with other separation technologies such as microfiltration, nanofiltration, reverse osmosis, or conventional treatment processes to address complex separation challenges. These integrated approaches leverage the strengths of each technology to achieve superior overall performance. Multi-stage systems can be designed to progressively remove contaminants of decreasing size, while hybrid configurations may incorporate physical, chemical, or biological treatment steps to handle diverse water quality issues efficiently.Expand Specific Solutions

Leading Companies in Ultrafiltration and Hybrid Treatment

# Ultrafiltration in Hybrid Water Treatment: Competitive Landscape

The integration of ultrafiltration in hybrid water treatment approaches is in a growth phase, with the global market expected to reach $8.1 billion by 2026, expanding at a CAGR of 9.2%. Technologically, the field is maturing rapidly with varying levels of implementation sophistication. Leading players include Dow Global Technologies and Pentair Water Pool & Spa focusing on industrial applications, while Organo Corp. and Beijing Water Business Doctor specialize in municipal solutions. Research institutions like Federal University of Rio de Janeiro and Research Center for Eco-Environmental Sciences are advancing membrane technology innovations. Merck Patent GmbH and Pfizer are exploring pharmaceutical-grade water treatment applications, while regional players like Hunan Junxin and Daeyang Enbio are developing market-specific solutions. The competitive landscape reflects a blend of established multinational corporations and specialized regional providers across the value chain.

The integration of ultrafiltration in hybrid water treatment approaches is in a growth phase, with the global market expected to reach $8.1 billion by 2026, expanding at a CAGR of 9.2%. Technologically, the field is maturing rapidly with varying levels of implementation sophistication. Leading players include Dow Global Technologies and Pentair Water Pool & Spa focusing on industrial applications, while Organo Corp. and Beijing Water Business Doctor specialize in municipal solutions. Research institutions like Federal University of Rio de Janeiro and Research Center for Eco-Environmental Sciences are advancing membrane technology innovations. Merck Patent GmbH and Pfizer are exploring pharmaceutical-grade water treatment applications, while regional players like Hunan Junxin and Daeyang Enbio are developing market-specific solutions. The competitive landscape reflects a blend of established multinational corporations and specialized regional providers across the value chain.

Dow Global Technologies LLC

Technical Solution: Dow's hybrid water treatment approach integrates ultrafiltration (UF) with reverse osmosis (RO) and ion exchange technologies in a multi-barrier system. Their FILMTEC™ membranes utilize cross-flow filtration where water passes through semi-permeable membranes while contaminants are rejected. The UF component typically employs hollow fiber membranes with pore sizes of approximately 0.01-0.02 microns, effectively removing suspended solids, bacteria, and viruses. Dow's IntegraFlux™ UF modules feature high surface area-to-volume ratio and operate at low transmembrane pressures (typically 0.2-1.0 bar), enabling energy-efficient filtration. The integration with RO systems allows for comprehensive treatment, with UF serving as pretreatment to remove particles that could foul RO membranes, extending their operational life by up to 30% and reducing cleaning frequency.

Strengths: Superior membrane technology with high flux rates and fouling resistance; comprehensive integration capabilities with other treatment technologies; extensive global implementation experience. Weaknesses: Higher initial capital investment compared to conventional treatments; requires specialized expertise for optimal system design and operation; membrane replacement costs can be significant over system lifetime.

Pentair Water Pool & Spa, Inc.

Technical Solution: Pentair has developed a comprehensive hybrid water treatment approach that integrates ultrafiltration with advanced oxidation processes (AOPs) and granular media filtration. Their X-Flow™ ultrafiltration technology utilizes PES (polyethersulfone) hollow fiber membranes with pore sizes around 0.02 microns in a pressurized outside-in configuration. The system operates at pressures between 1-3 bar and incorporates a unique air-assisted backwash mechanism that enhances cleaning efficiency while reducing water consumption. Pentair's hybrid approach positions ultrafiltration as an intermediate treatment step between conventional media filtration and advanced oxidation, creating a multi-barrier system that addresses a wide spectrum of contaminants. The media filtration removes larger particles, extending UF membrane life, while the downstream AOP system (typically UV/H₂O₂) addresses dissolved organics and micropollutants that pass through the UF membranes. This integrated approach has been successfully implemented in municipal drinking water applications, achieving turbidity levels consistently below 0.1 NTU and 4-log removal of pathogens while minimizing disinfection byproduct formation through the reduction of precursor compounds.

Strengths: Comprehensive treatment approach addressing multiple contaminant classes; reduced membrane fouling due to pretreatment; excellent finished water quality suitable for stringent regulatory requirements. Weaknesses: Higher system complexity requires sophisticated control systems; greater spatial requirements than standalone technologies; higher initial capital investment compared to conventional treatment trains.

Key Patents and Innovations in Membrane Technology

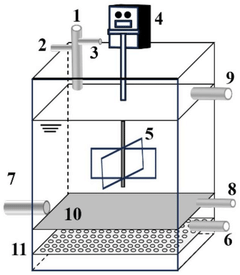

Coagulation/ferrate oxidation interaction enhancement-ultrafiltration integrated device for drinking water treatment and application technology thereof

PatentPendingCN119612690A

Innovation

- The integrated coagulation/ferrate oxidation interaction strengthening-ultrafiltration device is adopted to achieve the synchronous removal of suspended substances, colloidal particles, soluble organic matter and new pollutants in water through the interaction between coagulation and ferrate oxidation.

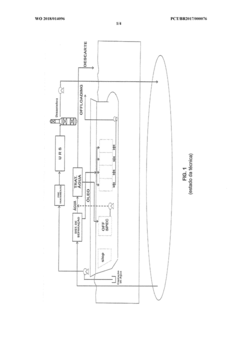

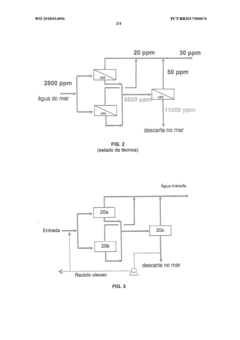

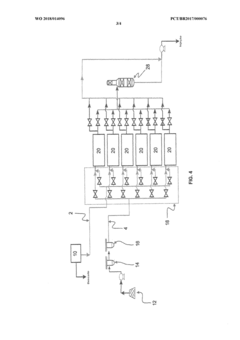

Hybrid system and method for treating produced water and sea water to be re-injected into a subsea oil reservoir

PatentWO2018014096A1

Innovation

- A hybrid treatment system utilizing micro/ultrafiltration and nanofiltration membranes to treat produced water and seawater separately, directing water to either micro/ultrafiltration or nanofiltration modules based on quality, allowing for efficient removal of oils, solids, and sulfate ions without the need for an additional treatment system, with interchangeable membrane configurations and a backwash procedure for membrane maintenance.

Energy Efficiency Considerations in Hybrid Treatment

Energy efficiency has emerged as a critical factor in the design and implementation of hybrid water treatment systems incorporating ultrafiltration (UF) technology. The integration of UF membranes within hybrid treatment trains presents both opportunities and challenges for optimizing energy consumption while maintaining effective water purification performance.

Ultrafiltration processes typically require significant energy input for maintaining transmembrane pressure and overcoming hydraulic resistance. In hybrid systems, strategic positioning of UF components can substantially impact overall energy requirements. When placed as a pre-treatment step before reverse osmosis or nanofiltration, UF can reduce downstream membrane fouling, thereby decreasing the energy needed for high-pressure operations and extending membrane life cycles.

Advanced energy recovery devices (ERDs) have demonstrated considerable potential for improving the energy profile of hybrid UF systems. Pressure exchangers, turbochargers, and energy recovery pumps can recapture between 25-60% of the energy that would otherwise be lost in concentrate streams, particularly in larger-scale applications where the energy savings justify the capital investment in recovery equipment.

Process optimization through intelligent control systems represents another frontier in energy efficiency. Real-time monitoring coupled with automated adjustment of operational parameters such as flux rates, backwash frequency, and chemical cleaning cycles can reduce unnecessary energy expenditure while maintaining filtration performance. Studies indicate that dynamic flux control alone can achieve energy savings of 15-30% compared to fixed-parameter operation.

Membrane material innovations continue to drive energy efficiency improvements. Novel low-fouling membranes with optimized pore structures require less frequent backwashing and chemical cleaning, directly translating to energy savings. Additionally, emerging hydrophilic nanocomposite membranes demonstrate enhanced permeability, allowing operation at lower transmembrane pressures while maintaining equivalent throughput.

The integration of renewable energy sources presents a promising approach for reducing the carbon footprint of UF hybrid systems. Solar-powered UF installations have proven particularly effective in remote locations and developing regions, where grid reliability may be compromised. Wind and small-scale hydropower have also been successfully coupled with UF systems in appropriate geographical contexts.

Temperature management strategies significantly impact energy consumption in UF operations. Research indicates that a 1°C increase in feed water temperature can reduce energy requirements by approximately 2-3% due to decreased viscosity and improved membrane permeability. Heat recovery systems and strategic scheduling of energy-intensive operations during warmer periods can therefore contribute to overall energy optimization in hybrid treatment facilities.

Ultrafiltration processes typically require significant energy input for maintaining transmembrane pressure and overcoming hydraulic resistance. In hybrid systems, strategic positioning of UF components can substantially impact overall energy requirements. When placed as a pre-treatment step before reverse osmosis or nanofiltration, UF can reduce downstream membrane fouling, thereby decreasing the energy needed for high-pressure operations and extending membrane life cycles.

Advanced energy recovery devices (ERDs) have demonstrated considerable potential for improving the energy profile of hybrid UF systems. Pressure exchangers, turbochargers, and energy recovery pumps can recapture between 25-60% of the energy that would otherwise be lost in concentrate streams, particularly in larger-scale applications where the energy savings justify the capital investment in recovery equipment.

Process optimization through intelligent control systems represents another frontier in energy efficiency. Real-time monitoring coupled with automated adjustment of operational parameters such as flux rates, backwash frequency, and chemical cleaning cycles can reduce unnecessary energy expenditure while maintaining filtration performance. Studies indicate that dynamic flux control alone can achieve energy savings of 15-30% compared to fixed-parameter operation.

Membrane material innovations continue to drive energy efficiency improvements. Novel low-fouling membranes with optimized pore structures require less frequent backwashing and chemical cleaning, directly translating to energy savings. Additionally, emerging hydrophilic nanocomposite membranes demonstrate enhanced permeability, allowing operation at lower transmembrane pressures while maintaining equivalent throughput.

The integration of renewable energy sources presents a promising approach for reducing the carbon footprint of UF hybrid systems. Solar-powered UF installations have proven particularly effective in remote locations and developing regions, where grid reliability may be compromised. Wind and small-scale hydropower have also been successfully coupled with UF systems in appropriate geographical contexts.

Temperature management strategies significantly impact energy consumption in UF operations. Research indicates that a 1°C increase in feed water temperature can reduce energy requirements by approximately 2-3% due to decreased viscosity and improved membrane permeability. Heat recovery systems and strategic scheduling of energy-intensive operations during warmer periods can therefore contribute to overall energy optimization in hybrid treatment facilities.

Regulatory Framework for Advanced Water Treatment

The regulatory landscape for advanced water treatment technologies, particularly those incorporating ultrafiltration in hybrid systems, has evolved significantly in response to growing water scarcity and quality concerns. At the international level, the World Health Organization (WHO) has established guidelines for drinking water quality that many national regulatory frameworks reference, providing baseline standards for pathogen removal that ultrafiltration systems must achieve.

In the United States, the Environmental Protection Agency (EPA) regulates water treatment technologies through the Safe Drinking Water Act (SDWA) and the Clean Water Act (CWA). The Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) specifically addresses filtration technologies, requiring 99.9% (3-log) removal of Cryptosporidium for surface water systems. Ultrafiltration, when integrated into hybrid treatment approaches, must demonstrate compliance with these microbial removal standards while also meeting disinfection byproduct regulations.

The European Union's Drinking Water Directive (98/83/EC, updated in 2020) establishes stringent parameters for water quality, emphasizing a risk-based approach that favors multi-barrier treatment systems. This regulatory framework has accelerated the adoption of hybrid ultrafiltration systems across European municipalities, particularly in water-stressed regions of Southern Europe.

In Asia, regulatory frameworks vary significantly by country, with Japan and Singapore implementing some of the most progressive regulations for water reuse and advanced treatment. Singapore's NEWater initiative has established comprehensive quality standards for reclaimed water that have become a benchmark for ultrafiltration-based hybrid systems globally.

Emerging regulatory trends include increased focus on contaminants of emerging concern (CECs), including pharmaceuticals, personal care products, and microplastics. These contaminants often require hybrid treatment approaches, as ultrafiltration alone cannot remove dissolved chemical compounds. This has led to new testing and monitoring requirements in several jurisdictions, particularly for systems incorporating both ultrafiltration and advanced oxidation or activated carbon processes.

Regulatory approval processes for novel hybrid water treatment technologies typically require extensive pilot testing and validation studies. The NSF/ANSI 61 standard in North America and similar certification programs worldwide evaluate materials safety and performance claims for water treatment components, including ultrafiltration membranes used in hybrid systems.

Climate change adaptation policies are increasingly influencing regulatory frameworks, with many jurisdictions now requiring water utilities to demonstrate resilience through diversified treatment approaches. This regulatory shift has created new opportunities for hybrid ultrafiltration systems that can adapt to varying source water qualities and treatment demands.

In the United States, the Environmental Protection Agency (EPA) regulates water treatment technologies through the Safe Drinking Water Act (SDWA) and the Clean Water Act (CWA). The Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) specifically addresses filtration technologies, requiring 99.9% (3-log) removal of Cryptosporidium for surface water systems. Ultrafiltration, when integrated into hybrid treatment approaches, must demonstrate compliance with these microbial removal standards while also meeting disinfection byproduct regulations.

The European Union's Drinking Water Directive (98/83/EC, updated in 2020) establishes stringent parameters for water quality, emphasizing a risk-based approach that favors multi-barrier treatment systems. This regulatory framework has accelerated the adoption of hybrid ultrafiltration systems across European municipalities, particularly in water-stressed regions of Southern Europe.

In Asia, regulatory frameworks vary significantly by country, with Japan and Singapore implementing some of the most progressive regulations for water reuse and advanced treatment. Singapore's NEWater initiative has established comprehensive quality standards for reclaimed water that have become a benchmark for ultrafiltration-based hybrid systems globally.

Emerging regulatory trends include increased focus on contaminants of emerging concern (CECs), including pharmaceuticals, personal care products, and microplastics. These contaminants often require hybrid treatment approaches, as ultrafiltration alone cannot remove dissolved chemical compounds. This has led to new testing and monitoring requirements in several jurisdictions, particularly for systems incorporating both ultrafiltration and advanced oxidation or activated carbon processes.

Regulatory approval processes for novel hybrid water treatment technologies typically require extensive pilot testing and validation studies. The NSF/ANSI 61 standard in North America and similar certification programs worldwide evaluate materials safety and performance claims for water treatment components, including ultrafiltration membranes used in hybrid systems.

Climate change adaptation policies are increasingly influencing regulatory frameworks, with many jurisdictions now requiring water utilities to demonstrate resilience through diversified treatment approaches. This regulatory shift has created new opportunities for hybrid ultrafiltration systems that can adapt to varying source water qualities and treatment demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!