Determining Cost-Effective Large-Scale Ultrafiltration Deployment

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration technology has evolved significantly over the past five decades, transitioning from laboratory-scale applications to industrial-scale water treatment solutions. Initially developed in the 1960s as a membrane separation process, ultrafiltration has become increasingly sophisticated with advancements in membrane materials, module designs, and operational protocols. The technology operates on the principle of size exclusion, utilizing semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers to remove suspended solids, bacteria, viruses, and high-molecular-weight compounds from water and other liquids.

The evolution of ultrafiltration has been marked by several key technological milestones. The introduction of hollow fiber membranes in the 1980s significantly increased filtration surface area per unit volume, enhancing efficiency. The development of more robust polymeric materials in the 1990s improved chemical resistance and operational lifespan. More recently, innovations in anti-fouling membrane technologies and energy-efficient designs have addressed persistent challenges in large-scale deployments.

Current market trends indicate a growing demand for ultrafiltration systems across municipal water treatment, industrial process water, and wastewater reclamation sectors. This growth is driven by increasingly stringent water quality regulations, growing water scarcity concerns, and the need for more sustainable water management practices globally. The compound annual growth rate for the ultrafiltration market is projected at 6.9% through 2028, with particular acceleration in developing economies.

The primary technical objectives for cost-effective large-scale ultrafiltration deployment center around four key areas: reducing energy consumption, extending membrane lifespan, minimizing chemical usage, and optimizing operational protocols. Energy efficiency remains a critical factor, as pumping requirements typically constitute 30-40% of operational costs in large-scale systems. Membrane longevity directly impacts replacement frequency and associated capital expenditures, while chemical usage for cleaning and maintenance affects both operational costs and environmental footprint.

Emerging research directions include the development of novel membrane materials incorporating nanomaterials and biomimetic designs, advanced module configurations for improved hydraulic performance, and intelligent control systems leveraging machine learning for predictive maintenance and operational optimization. These innovations aim to address the persistent challenges of membrane fouling, energy intensity, and operational complexity that currently limit the cost-effectiveness of large-scale deployments.

The ultimate goal of current ultrafiltration technology development is to achieve a paradigm shift in deployment economics, reducing the total cost of ownership while maintaining or improving filtration performance and reliability. This would enable broader adoption across various applications, particularly in resource-constrained environments where conventional treatment technologies remain predominant due to cost considerations.

The evolution of ultrafiltration has been marked by several key technological milestones. The introduction of hollow fiber membranes in the 1980s significantly increased filtration surface area per unit volume, enhancing efficiency. The development of more robust polymeric materials in the 1990s improved chemical resistance and operational lifespan. More recently, innovations in anti-fouling membrane technologies and energy-efficient designs have addressed persistent challenges in large-scale deployments.

Current market trends indicate a growing demand for ultrafiltration systems across municipal water treatment, industrial process water, and wastewater reclamation sectors. This growth is driven by increasingly stringent water quality regulations, growing water scarcity concerns, and the need for more sustainable water management practices globally. The compound annual growth rate for the ultrafiltration market is projected at 6.9% through 2028, with particular acceleration in developing economies.

The primary technical objectives for cost-effective large-scale ultrafiltration deployment center around four key areas: reducing energy consumption, extending membrane lifespan, minimizing chemical usage, and optimizing operational protocols. Energy efficiency remains a critical factor, as pumping requirements typically constitute 30-40% of operational costs in large-scale systems. Membrane longevity directly impacts replacement frequency and associated capital expenditures, while chemical usage for cleaning and maintenance affects both operational costs and environmental footprint.

Emerging research directions include the development of novel membrane materials incorporating nanomaterials and biomimetic designs, advanced module configurations for improved hydraulic performance, and intelligent control systems leveraging machine learning for predictive maintenance and operational optimization. These innovations aim to address the persistent challenges of membrane fouling, energy intensity, and operational complexity that currently limit the cost-effectiveness of large-scale deployments.

The ultimate goal of current ultrafiltration technology development is to achieve a paradigm shift in deployment economics, reducing the total cost of ownership while maintaining or improving filtration performance and reliability. This would enable broader adoption across various applications, particularly in resource-constrained environments where conventional treatment technologies remain predominant due to cost considerations.

Market Analysis for Large-Scale Ultrafiltration Systems

The global ultrafiltration market has experienced significant growth in recent years, driven by increasing water scarcity concerns and stricter environmental regulations. The market was valued at approximately $2.3 billion in 2021 and is projected to reach $5.1 billion by 2028, growing at a CAGR of 12.1% during the forecast period. This growth trajectory underscores the expanding demand for large-scale ultrafiltration systems across various industries.

Municipal water treatment represents the largest application segment, accounting for nearly 40% of the market share. This dominance stems from growing urbanization and the need for reliable drinking water infrastructure in developing regions. Industrial applications follow closely, with food and beverage, pharmaceutical, and chemical processing industries increasingly adopting ultrafiltration technology to meet stringent product quality and wastewater discharge requirements.

Geographically, Asia-Pacific leads the market with approximately 35% share, driven by rapid industrialization, population growth, and increasing water quality concerns in countries like China and India. North America and Europe collectively account for about 45% of the market, with mature infrastructure but growing replacement and upgrade demands.

The cost structure of large-scale ultrafiltration systems reveals that initial capital expenditure typically represents 40-50% of the total lifecycle cost, while operational expenses, including energy consumption, membrane replacement, and maintenance, constitute the remainder. Energy efficiency improvements have reduced operational costs by approximately 15% over the past decade, making these systems increasingly economically viable for broader applications.

Customer segmentation analysis indicates three primary buyer categories: municipal utilities (45%), industrial enterprises (35%), and commercial facilities (20%). Each segment exhibits distinct purchasing behaviors and cost sensitivity. Municipal buyers prioritize long-term reliability and compliance with regulatory standards, while industrial customers focus on return on investment and operational efficiency metrics.

Pricing trends show a gradual decrease of 3-5% annually in per-unit treatment costs, primarily due to technological advancements and increased competition among suppliers. However, regional variations exist, with prices in emerging markets typically 15-20% lower than in developed regions due to labor cost differentials and local manufacturing capabilities.

Market forecasts suggest that demand for cost-effective large-scale ultrafiltration systems will continue to grow, with particular emphasis on modular designs that allow for scalability and reduced installation costs. The market is also witnessing increased interest in integrated solutions that combine ultrafiltration with complementary technologies like reverse osmosis or UV disinfection, creating comprehensive water treatment packages that optimize overall system economics.

Municipal water treatment represents the largest application segment, accounting for nearly 40% of the market share. This dominance stems from growing urbanization and the need for reliable drinking water infrastructure in developing regions. Industrial applications follow closely, with food and beverage, pharmaceutical, and chemical processing industries increasingly adopting ultrafiltration technology to meet stringent product quality and wastewater discharge requirements.

Geographically, Asia-Pacific leads the market with approximately 35% share, driven by rapid industrialization, population growth, and increasing water quality concerns in countries like China and India. North America and Europe collectively account for about 45% of the market, with mature infrastructure but growing replacement and upgrade demands.

The cost structure of large-scale ultrafiltration systems reveals that initial capital expenditure typically represents 40-50% of the total lifecycle cost, while operational expenses, including energy consumption, membrane replacement, and maintenance, constitute the remainder. Energy efficiency improvements have reduced operational costs by approximately 15% over the past decade, making these systems increasingly economically viable for broader applications.

Customer segmentation analysis indicates three primary buyer categories: municipal utilities (45%), industrial enterprises (35%), and commercial facilities (20%). Each segment exhibits distinct purchasing behaviors and cost sensitivity. Municipal buyers prioritize long-term reliability and compliance with regulatory standards, while industrial customers focus on return on investment and operational efficiency metrics.

Pricing trends show a gradual decrease of 3-5% annually in per-unit treatment costs, primarily due to technological advancements and increased competition among suppliers. However, regional variations exist, with prices in emerging markets typically 15-20% lower than in developed regions due to labor cost differentials and local manufacturing capabilities.

Market forecasts suggest that demand for cost-effective large-scale ultrafiltration systems will continue to grow, with particular emphasis on modular designs that allow for scalability and reduced installation costs. The market is also witnessing increased interest in integrated solutions that combine ultrafiltration with complementary technologies like reverse osmosis or UV disinfection, creating comprehensive water treatment packages that optimize overall system economics.

Current Challenges in Cost-Effective Ultrafiltration

Ultrafiltration technology has emerged as a critical solution for water treatment across various industries, yet its large-scale deployment faces significant cost-effectiveness challenges. The capital expenditure for industrial-scale ultrafiltration systems remains prohibitively high, with membrane modules alone accounting for 30-40% of total system costs. This initial investment barrier often deters organizations from adopting this technology despite its proven efficiency.

Operational expenses present another major challenge, particularly energy consumption. Current ultrafiltration systems require substantial pumping power to maintain transmembrane pressure, typically consuming 0.2-0.5 kWh per cubic meter of treated water. This energy requirement significantly impacts the long-term economic viability of large-scale installations, especially in regions with high electricity costs.

Membrane fouling continues to be a persistent technical obstacle that directly affects cost-effectiveness. As membranes become fouled, both permeate flux and quality decrease, necessitating more frequent cleaning cycles or premature replacement. Studies indicate that fouling can reduce membrane lifespan by 30-50%, substantially increasing the total cost of ownership through replacement expenses and downtime.

Chemical cleaning requirements further compound operational costs. Conventional ultrafiltration systems require regular chemical cleaning using acids, bases, and disinfectants, which not only adds direct material costs but also creates secondary waste streams requiring treatment. The environmental compliance costs associated with chemical handling and disposal are increasingly significant in stringent regulatory environments.

Maintenance complexity represents another challenge, as large-scale ultrafiltration systems require specialized technical expertise for optimal operation. The shortage of qualified operators in many regions leads to either higher personnel costs or suboptimal system performance, both negatively impacting cost-effectiveness. Training programs and automation solutions add further to implementation costs.

Scale-up challenges create additional economic hurdles. Laboratory and pilot-scale successes often fail to translate directly to industrial applications due to flow distribution problems, pressure drop issues, and membrane packing inefficiencies. These scaling challenges can result in systems that perform below design specifications, reducing return on investment.

Integration with existing infrastructure presents compatibility issues that increase deployment costs. Retrofitting ultrafiltration technology into established water treatment facilities often requires significant modifications to piping, pumping, and control systems. These integration expenses can comprise 15-25% of total project costs, particularly in aging facilities with limited documentation or standardization.

Finally, the variability in feed water quality creates uncertainty in operational costs. Seasonal or process-related fluctuations in source water characteristics can dramatically affect membrane performance and cleaning requirements, making accurate long-term cost projections difficult and often leading to conservative over-design that further reduces cost-effectiveness.

Operational expenses present another major challenge, particularly energy consumption. Current ultrafiltration systems require substantial pumping power to maintain transmembrane pressure, typically consuming 0.2-0.5 kWh per cubic meter of treated water. This energy requirement significantly impacts the long-term economic viability of large-scale installations, especially in regions with high electricity costs.

Membrane fouling continues to be a persistent technical obstacle that directly affects cost-effectiveness. As membranes become fouled, both permeate flux and quality decrease, necessitating more frequent cleaning cycles or premature replacement. Studies indicate that fouling can reduce membrane lifespan by 30-50%, substantially increasing the total cost of ownership through replacement expenses and downtime.

Chemical cleaning requirements further compound operational costs. Conventional ultrafiltration systems require regular chemical cleaning using acids, bases, and disinfectants, which not only adds direct material costs but also creates secondary waste streams requiring treatment. The environmental compliance costs associated with chemical handling and disposal are increasingly significant in stringent regulatory environments.

Maintenance complexity represents another challenge, as large-scale ultrafiltration systems require specialized technical expertise for optimal operation. The shortage of qualified operators in many regions leads to either higher personnel costs or suboptimal system performance, both negatively impacting cost-effectiveness. Training programs and automation solutions add further to implementation costs.

Scale-up challenges create additional economic hurdles. Laboratory and pilot-scale successes often fail to translate directly to industrial applications due to flow distribution problems, pressure drop issues, and membrane packing inefficiencies. These scaling challenges can result in systems that perform below design specifications, reducing return on investment.

Integration with existing infrastructure presents compatibility issues that increase deployment costs. Retrofitting ultrafiltration technology into established water treatment facilities often requires significant modifications to piping, pumping, and control systems. These integration expenses can comprise 15-25% of total project costs, particularly in aging facilities with limited documentation or standardization.

Finally, the variability in feed water quality creates uncertainty in operational costs. Seasonal or process-related fluctuations in source water characteristics can dramatically affect membrane performance and cleaning requirements, making accurate long-term cost projections difficult and often leading to conservative over-design that further reduces cost-effectiveness.

Cost-Optimization Solutions for Large-Scale Deployment

01 Cost-benefit analysis of ultrafiltration systems

Cost-benefit analysis is essential for evaluating the economic viability of ultrafiltration systems. This involves comparing the initial investment costs with long-term operational benefits, including reduced maintenance expenses, extended equipment lifespan, and improved process efficiency. The analysis typically considers factors such as energy consumption, membrane replacement frequency, cleaning requirements, and overall system performance to determine the return on investment and payback period for ultrafiltration implementations.- Economic analysis of ultrafiltration systems: Economic analysis frameworks for evaluating the cost-effectiveness of ultrafiltration systems, including capital expenditure, operational costs, and return on investment calculations. These analyses help in determining the financial viability of implementing ultrafiltration technology in various applications, considering factors such as energy consumption, maintenance requirements, and system lifespan.

- Energy efficiency optimization in ultrafiltration: Methods and systems for optimizing energy efficiency in ultrafiltration processes to improve cost-effectiveness. This includes innovative designs for reducing power consumption, energy recovery systems, and smart control mechanisms that adjust operational parameters based on real-time conditions to minimize energy usage while maintaining filtration performance.

- Membrane technology advancements for cost reduction: Advancements in membrane technology that contribute to cost reduction in ultrafiltration systems. These innovations include development of longer-lasting membranes, fouling-resistant materials, and improved membrane configurations that enhance filtration efficiency while reducing replacement frequency and maintenance costs.

- Automated monitoring and maintenance systems: Implementation of automated monitoring and maintenance systems for ultrafiltration processes to optimize operational efficiency and reduce costs. These systems utilize sensors, data analytics, and predictive maintenance algorithms to detect potential issues before they cause system failures, thereby minimizing downtime and extending equipment lifespan.

- Comparative analysis with alternative filtration methods: Comparative analysis of ultrafiltration against alternative filtration methods to determine relative cost-effectiveness in different applications. These analyses consider factors such as initial investment, operational costs, filtration efficiency, space requirements, and environmental impact to provide comprehensive cost-benefit evaluations for decision-making processes.

02 Energy efficiency optimization in ultrafiltration processes

Optimizing energy efficiency is crucial for improving the cost-effectiveness of ultrafiltration systems. This involves implementing advanced control strategies, utilizing energy recovery devices, and selecting appropriate operating parameters to minimize power consumption while maintaining filtration performance. Innovations in membrane design and module configuration can significantly reduce the energy requirements for ultrafiltration processes, leading to substantial operational cost savings and improved environmental sustainability.Expand Specific Solutions03 Membrane lifespan extension and fouling reduction techniques

Extending membrane lifespan and reducing fouling are key factors in enhancing the cost-effectiveness of ultrafiltration systems. Various techniques have been developed to address these challenges, including optimized cleaning protocols, pretreatment strategies, and advanced anti-fouling membrane materials. By minimizing membrane replacement frequency and maintaining consistent flux rates, these approaches significantly reduce operational costs and downtime, improving the overall economic performance of ultrafiltration processes.Expand Specific Solutions04 Automated monitoring and predictive maintenance systems

Automated monitoring and predictive maintenance systems play a crucial role in optimizing the cost-effectiveness of ultrafiltration operations. These systems utilize sensors, data analytics, and machine learning algorithms to continuously monitor system performance, predict potential failures, and schedule maintenance activities proactively. By preventing unexpected downtime, optimizing cleaning cycles, and extending equipment lifespan, these technologies significantly reduce operational costs and improve the reliability of ultrafiltration processes.Expand Specific Solutions05 Integration of ultrafiltration with complementary technologies

Integrating ultrafiltration with complementary technologies can enhance overall system cost-effectiveness. Hybrid treatment trains that combine ultrafiltration with other processes such as reverse osmosis, ion exchange, or biological treatment can optimize performance while reducing total operational costs. These integrated approaches allow for more efficient resource utilization, improved water recovery rates, and enhanced removal of diverse contaminants, resulting in better economic outcomes for water and wastewater treatment applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The ultrafiltration market is currently in a growth phase, with increasing adoption across municipal and industrial water treatment sectors. The global market size is estimated to reach $3-4 billion by 2025, growing at a CAGR of approximately 6-8%. Technologically, ultrafiltration has reached commercial maturity but continues to evolve toward more cost-effective large-scale implementations. Leading players include established water treatment companies like DuPont Safety & Construction and IDE Technologies, who focus on membrane technology optimization, alongside research institutions such as Fraunhofer-Gesellschaft and National University of Singapore advancing novel materials. Chemical companies including BASF, Merck, and EMD Millipore are developing specialized filtration solutions, while engineering firms like Hitachi and Gree Electric are working on system integration for industrial applications, creating a competitive landscape balanced between innovation and commercialization.

IDE Technologies Ltd.

Technical Solution: IDE Technologies has developed advanced large-scale ultrafiltration (UF) deployment solutions focusing on cost optimization through their Integrated Membrane Solutions approach. Their technology combines UF with other membrane processes in a multi-barrier system that optimizes capital and operational expenditures. The company's PROGREEN™ system incorporates ultrafiltration as a critical pre-treatment step in desalination plants, reducing energy consumption by up to 35% compared to conventional systems. IDE's approach includes automated self-cleaning mechanisms that extend membrane life by up to 7 years, significantly reducing replacement costs which typically account for 30-40% of UF operational expenses. Their modular design philosophy allows for scalable implementation with 20-30% lower initial capital investment through standardized manufacturing and simplified installation procedures. IDE has also pioneered digital twin technology for UF systems, enabling predictive maintenance and real-time optimization that reduces chemical consumption by approximately 25% and energy usage by 15-20% in large installations.

Strengths: Exceptional integration capabilities with other water treatment technologies, proven track record in large-scale implementations, and advanced digital monitoring systems that optimize operational costs. Weaknesses: Higher initial capital costs compared to conventional filtration systems, requires specialized technical expertise for operation, and may face challenges in regions with limited infrastructure support.

EMD Millipore Corp.

Technical Solution: EMD Millipore has pioneered cost-effective large-scale ultrafiltration deployment through their Mobius® FlexReady Solution, specifically designed for biopharmaceutical applications. Their approach focuses on single-use technology that eliminates cleaning validation requirements, reducing water consumption by up to 80% and cleaning chemical usage by 90% compared to traditional stainless steel systems. The company's proprietary Pellicon® cassette technology features an asymmetric membrane structure that increases filtration efficiency by approximately 30%, allowing for higher throughput with smaller footprint requirements. EMD Millipore's economic model incorporates predictive algorithms for membrane fouling, extending operational cycles by 25-40% before cleaning is required. Their modular design philosophy enables capacity expansion with minimal disruption, allowing facilities to scale from 100L to 2000L with the same basic infrastructure. The company has also developed specialized pre-treatment protocols that reduce protein aggregation by up to 50%, significantly extending membrane life in high-value biopharmaceutical applications and reducing the total cost of ownership by approximately 25% over a five-year operational period.

Strengths: Industry-leading expertise in biopharmaceutical applications, innovative single-use technology reducing cleaning and validation costs, and comprehensive technical support services. Weaknesses: Solutions primarily optimized for pharmaceutical rather than municipal or industrial applications, higher consumable costs compared to reusable systems, and potential environmental concerns with disposable components.

Critical Patents and Innovations in Ultrafiltration

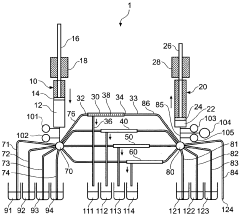

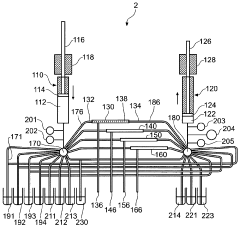

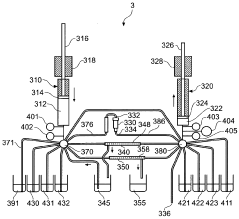

Automated low volume crossflow filtration

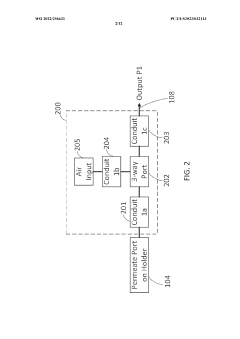

PatentWO2007110203A1

Innovation

- An automated crossflow filtration method and system that uses a dual-pump system with moveable walls and flow-directing valves to control membrane flux and pressure, allowing for precise separation of components in 50 ml or less of a solution, with the option to reuse membranes and implement computer-controlled processes.

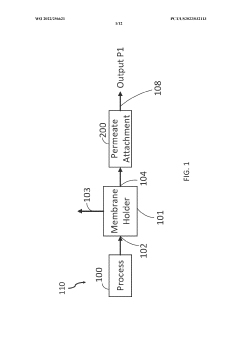

Particle filtration

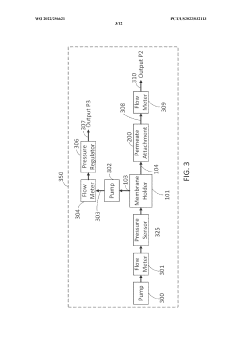

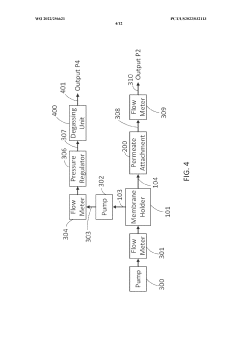

PatentWO2022256621A1

Innovation

- A modified UF/DF/TFF filtration system with a membrane holder, permeate attachment, flow meters, pressure sensors, and pulsating flow control to manage pressure and flow rates, reducing membrane fouling and enabling continuous operation with controlled concentration and cleaning capabilities.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become critical considerations in the deployment of large-scale ultrafiltration systems. The energy consumption of ultrafiltration processes primarily stems from pumping requirements to overcome membrane resistance and maintain adequate cross-flow velocities. Recent advancements in energy recovery devices have significantly improved the efficiency of ultrafiltration systems, with energy recovery rates reaching up to 60% in optimized configurations.

Membrane fouling presents a substantial challenge to energy efficiency, as it increases transmembrane pressure requirements and consequently energy consumption. Advanced pretreatment strategies and optimized cleaning protocols can reduce fouling rates by 30-45%, directly translating to energy savings. The implementation of variable frequency drives (VFDs) for pump control has demonstrated energy reductions of 15-25% compared to conventional fixed-speed operations.

Renewable energy integration represents a promising approach for enhancing the sustainability of ultrafiltration systems. Solar-powered ultrafiltration plants have been successfully deployed in several regions, reducing operational carbon footprints by up to 70% compared to grid-powered alternatives. Wind energy integration has shown similar benefits in suitable geographical locations, though with higher variability in performance.

Life cycle assessment (LCA) studies indicate that the environmental impact of ultrafiltration systems extends beyond operational energy consumption. The production and disposal of membrane materials contribute significantly to the overall environmental footprint. Recent innovations in bio-based membrane materials have shown potential to reduce manufacturing-related carbon emissions by 40-50% compared to conventional petroleum-based polymers.

Water recovery rates in modern ultrafiltration systems typically range from 85% to 95%, with higher recovery rates generally requiring additional energy input. Optimization algorithms that balance energy consumption against water recovery have demonstrated potential for reducing overall resource intensity by 20-30%. These algorithms typically incorporate real-time monitoring and adaptive control strategies to respond to variations in feed water quality.

Chemical usage for membrane cleaning and maintenance represents another sustainability consideration. Advanced cleaning protocols utilizing environmentally benign chemicals have reduced the environmental impact of cleaning operations by up to 60%. Additionally, the implementation of mechanical cleaning techniques, such as air scouring and backwashing optimization, has reduced chemical consumption by 25-35% in various applications.

The economic implications of energy efficiency improvements are substantial, with energy costs typically accounting for 30-50% of operational expenses in ultrafiltration systems. Investments in energy-efficient technologies generally demonstrate payback periods of 2-5 years, depending on local energy costs and system scale. Furthermore, carbon pricing mechanisms and sustainability incentives increasingly influence the economic calculus of ultrafiltration deployment decisions.

Membrane fouling presents a substantial challenge to energy efficiency, as it increases transmembrane pressure requirements and consequently energy consumption. Advanced pretreatment strategies and optimized cleaning protocols can reduce fouling rates by 30-45%, directly translating to energy savings. The implementation of variable frequency drives (VFDs) for pump control has demonstrated energy reductions of 15-25% compared to conventional fixed-speed operations.

Renewable energy integration represents a promising approach for enhancing the sustainability of ultrafiltration systems. Solar-powered ultrafiltration plants have been successfully deployed in several regions, reducing operational carbon footprints by up to 70% compared to grid-powered alternatives. Wind energy integration has shown similar benefits in suitable geographical locations, though with higher variability in performance.

Life cycle assessment (LCA) studies indicate that the environmental impact of ultrafiltration systems extends beyond operational energy consumption. The production and disposal of membrane materials contribute significantly to the overall environmental footprint. Recent innovations in bio-based membrane materials have shown potential to reduce manufacturing-related carbon emissions by 40-50% compared to conventional petroleum-based polymers.

Water recovery rates in modern ultrafiltration systems typically range from 85% to 95%, with higher recovery rates generally requiring additional energy input. Optimization algorithms that balance energy consumption against water recovery have demonstrated potential for reducing overall resource intensity by 20-30%. These algorithms typically incorporate real-time monitoring and adaptive control strategies to respond to variations in feed water quality.

Chemical usage for membrane cleaning and maintenance represents another sustainability consideration. Advanced cleaning protocols utilizing environmentally benign chemicals have reduced the environmental impact of cleaning operations by up to 60%. Additionally, the implementation of mechanical cleaning techniques, such as air scouring and backwashing optimization, has reduced chemical consumption by 25-35% in various applications.

The economic implications of energy efficiency improvements are substantial, with energy costs typically accounting for 30-50% of operational expenses in ultrafiltration systems. Investments in energy-efficient technologies generally demonstrate payback periods of 2-5 years, depending on local energy costs and system scale. Furthermore, carbon pricing mechanisms and sustainability incentives increasingly influence the economic calculus of ultrafiltration deployment decisions.

Total Cost of Ownership Analysis Framework

The Total Cost of Ownership (TCO) framework provides a comprehensive approach for evaluating the economic viability of large-scale ultrafiltration deployments across their complete lifecycle. This analytical structure encompasses both direct and indirect costs, enabling organizations to make informed investment decisions beyond initial capital expenditures.

At its foundation, the TCO framework for ultrafiltration systems categorizes expenses into four primary components: acquisition costs, operational expenses, maintenance requirements, and end-of-life considerations. Acquisition costs include equipment procurement, installation, commissioning, and initial training. Operational expenses encompass energy consumption, chemical usage, labor requirements, and water resource management. Maintenance factors incorporate membrane replacement schedules, cleaning protocols, and system downtime impacts. End-of-life considerations address decommissioning expenses and potential salvage value.

The framework employs time-value-of-money principles through discounted cash flow analysis, typically utilizing Net Present Value (NPV) calculations with appropriate discount rates reflecting organizational risk profiles. This approach normalizes expenditures occurring at different time points throughout the ultrafiltration system's operational lifespan, which commonly ranges from 15 to 25 years depending on application and environmental conditions.

Sensitivity analysis constitutes a critical element of the TCO framework, allowing decision-makers to understand how variations in key parameters—such as energy costs, membrane longevity, or regulatory requirements—might impact overall economics. This analysis typically identifies cost drivers with the greatest influence on long-term financial performance, guiding optimization efforts and risk management strategies.

The framework also incorporates comparative scenario modeling to evaluate different ultrafiltration technologies, deployment scales, and implementation timelines. These comparisons often reveal counterintuitive insights, such as cases where higher initial investments in premium membrane technologies or advanced monitoring systems yield superior long-term economics through reduced operational expenses or extended service intervals.

For large-scale municipal or industrial applications, the TCO framework additionally accounts for scalability factors, recognizing that economies of scale significantly influence per-unit treatment costs. This includes considerations for modular expansion capabilities, infrastructure requirements, and operational efficiency at varying capacity utilization levels.

Implementation of this analytical framework requires cross-functional collaboration between engineering, finance, and operations teams to ensure accurate data inputs and realistic operational assumptions. Organizations that successfully apply comprehensive TCO analysis typically achieve 15-30% lower lifetime costs compared to decisions based solely on capital expenditure considerations.

At its foundation, the TCO framework for ultrafiltration systems categorizes expenses into four primary components: acquisition costs, operational expenses, maintenance requirements, and end-of-life considerations. Acquisition costs include equipment procurement, installation, commissioning, and initial training. Operational expenses encompass energy consumption, chemical usage, labor requirements, and water resource management. Maintenance factors incorporate membrane replacement schedules, cleaning protocols, and system downtime impacts. End-of-life considerations address decommissioning expenses and potential salvage value.

The framework employs time-value-of-money principles through discounted cash flow analysis, typically utilizing Net Present Value (NPV) calculations with appropriate discount rates reflecting organizational risk profiles. This approach normalizes expenditures occurring at different time points throughout the ultrafiltration system's operational lifespan, which commonly ranges from 15 to 25 years depending on application and environmental conditions.

Sensitivity analysis constitutes a critical element of the TCO framework, allowing decision-makers to understand how variations in key parameters—such as energy costs, membrane longevity, or regulatory requirements—might impact overall economics. This analysis typically identifies cost drivers with the greatest influence on long-term financial performance, guiding optimization efforts and risk management strategies.

The framework also incorporates comparative scenario modeling to evaluate different ultrafiltration technologies, deployment scales, and implementation timelines. These comparisons often reveal counterintuitive insights, such as cases where higher initial investments in premium membrane technologies or advanced monitoring systems yield superior long-term economics through reduced operational expenses or extended service intervals.

For large-scale municipal or industrial applications, the TCO framework additionally accounts for scalability factors, recognizing that economies of scale significantly influence per-unit treatment costs. This includes considerations for modular expansion capabilities, infrastructure requirements, and operational efficiency at varying capacity utilization levels.

Implementation of this analytical framework requires cross-functional collaboration between engineering, finance, and operations teams to ensure accurate data inputs and realistic operational assumptions. Organizations that successfully apply comprehensive TCO analysis typically achieve 15-30% lower lifetime costs compared to decisions based solely on capital expenditure considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!