Additive manufacturing of microchannel heat exchangers

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM Microchannel HX Background & Objectives

Additive manufacturing (AM) has emerged as a transformative technology in the manufacturing landscape over the past three decades, evolving from rapid prototyping to a viable production method for complex components. Within this broader context, the application of AM to microchannel heat exchangers represents a significant technological frontier with substantial implications for thermal management systems across multiple industries.

Microchannel heat exchangers, characterized by fluid channels with hydraulic diameters below 1 mm, have traditionally offered superior heat transfer performance compared to conventional designs. However, their widespread adoption has been hindered by manufacturing constraints using traditional fabrication methods such as etching, micro-machining, and diffusion bonding, which impose limitations on geometric complexity and increase production costs.

The convergence of AM technologies with microchannel heat exchanger design presents an opportunity to overcome these historical limitations. AM processes such as powder bed fusion (PBF), directed energy deposition (DED), and vat photopolymerization enable the creation of complex internal geometries previously impossible to manufacture. This capability allows for optimized fluid flow paths, customized channel geometries, and integrated manifold designs that can significantly enhance thermal-hydraulic performance.

The evolution of AM technologies has progressed through several key phases: from early stereolithography systems in the 1980s to the current multi-material, high-resolution systems capable of producing functional metal components. Parallel advancements in computational fluid dynamics (CFD) and topology optimization have further accelerated the potential for revolutionary heat exchanger designs that can be realized through AM.

The primary objective of exploring AM for microchannel heat exchangers is to achieve step-change improvements in heat transfer efficiency while reducing material usage, component weight, and assembly complexity. Secondary goals include enabling greater design freedom for application-specific optimization, reducing manufacturing lead times, and facilitating on-demand production of specialized thermal management solutions.

Current research trajectories indicate growing interest in multi-scale approaches that combine macro-level system integration with micro-level enhancement features. The field is moving toward functionally graded materials and structures that can address varying thermal loads within a single component, as well as hybrid manufacturing approaches that leverage the strengths of both additive and traditional manufacturing methods.

As industries increasingly demand more compact, efficient, and lightweight thermal management solutions, AM microchannel heat exchangers represent a promising technological pathway with potential applications spanning aerospace, automotive, electronics cooling, energy systems, and medical devices.

Microchannel heat exchangers, characterized by fluid channels with hydraulic diameters below 1 mm, have traditionally offered superior heat transfer performance compared to conventional designs. However, their widespread adoption has been hindered by manufacturing constraints using traditional fabrication methods such as etching, micro-machining, and diffusion bonding, which impose limitations on geometric complexity and increase production costs.

The convergence of AM technologies with microchannel heat exchanger design presents an opportunity to overcome these historical limitations. AM processes such as powder bed fusion (PBF), directed energy deposition (DED), and vat photopolymerization enable the creation of complex internal geometries previously impossible to manufacture. This capability allows for optimized fluid flow paths, customized channel geometries, and integrated manifold designs that can significantly enhance thermal-hydraulic performance.

The evolution of AM technologies has progressed through several key phases: from early stereolithography systems in the 1980s to the current multi-material, high-resolution systems capable of producing functional metal components. Parallel advancements in computational fluid dynamics (CFD) and topology optimization have further accelerated the potential for revolutionary heat exchanger designs that can be realized through AM.

The primary objective of exploring AM for microchannel heat exchangers is to achieve step-change improvements in heat transfer efficiency while reducing material usage, component weight, and assembly complexity. Secondary goals include enabling greater design freedom for application-specific optimization, reducing manufacturing lead times, and facilitating on-demand production of specialized thermal management solutions.

Current research trajectories indicate growing interest in multi-scale approaches that combine macro-level system integration with micro-level enhancement features. The field is moving toward functionally graded materials and structures that can address varying thermal loads within a single component, as well as hybrid manufacturing approaches that leverage the strengths of both additive and traditional manufacturing methods.

As industries increasingly demand more compact, efficient, and lightweight thermal management solutions, AM microchannel heat exchangers represent a promising technological pathway with potential applications spanning aerospace, automotive, electronics cooling, energy systems, and medical devices.

Market Analysis for AM Heat Exchangers

The global market for additive manufacturing (AM) of microchannel heat exchangers is experiencing robust growth, driven by increasing demand for compact, efficient thermal management solutions across multiple industries. Current market valuations indicate that the AM heat exchanger segment represents approximately 5-7% of the overall heat exchanger market, which was valued at $19.14 billion in 2022. This specialized segment is projected to grow at a compound annual growth rate (CAGR) of 13.2% through 2030, significantly outpacing the broader heat exchanger market's growth rate of 6.8%.

Aerospace and defense sectors currently dominate the market adoption, accounting for nearly 38% of AM heat exchanger applications. These industries value the weight reduction capabilities and complex geometries achievable through additive manufacturing, resulting in fuel savings and enhanced performance. The automotive sector follows closely at 24% market share, particularly in high-performance and electric vehicle thermal management systems where space constraints and cooling efficiency are critical factors.

Electronics cooling represents the fastest-growing application segment with a 17.5% CAGR, driven by increasing power densities in computing hardware and the miniaturization trend in consumer electronics. Industrial processing applications constitute approximately 15% of the market, while emerging applications in renewable energy systems account for the remaining 6%.

Regionally, North America leads with 42% market share due to strong aerospace and defense industries, followed by Europe at 31% where automotive applications predominate. The Asia-Pacific region, while currently representing 21% of the market, is expected to exhibit the highest growth rate at 16.8% CAGR through 2030, fueled by rapid industrialization and technology adoption in China, Japan, and South Korea.

Key market drivers include the growing demand for lightweight components in transportation sectors, increasing thermal management requirements in electronics, and the push for energy efficiency across all industries. Additionally, the ability of AM to enable complex internal geometries that optimize fluid flow and heat transfer characteristics provides significant performance advantages over conventionally manufactured heat exchangers.

Market restraints include high initial equipment costs, material limitations, and quality consistency challenges. The average cost premium for AM heat exchangers remains 30-40% above conventional manufacturing methods, though this gap is narrowing as technology matures and production volumes increase. Despite these challenges, the unique design freedom and performance benefits continue to drive market expansion, particularly in high-value applications where thermal management is critical to system performance.

Aerospace and defense sectors currently dominate the market adoption, accounting for nearly 38% of AM heat exchanger applications. These industries value the weight reduction capabilities and complex geometries achievable through additive manufacturing, resulting in fuel savings and enhanced performance. The automotive sector follows closely at 24% market share, particularly in high-performance and electric vehicle thermal management systems where space constraints and cooling efficiency are critical factors.

Electronics cooling represents the fastest-growing application segment with a 17.5% CAGR, driven by increasing power densities in computing hardware and the miniaturization trend in consumer electronics. Industrial processing applications constitute approximately 15% of the market, while emerging applications in renewable energy systems account for the remaining 6%.

Regionally, North America leads with 42% market share due to strong aerospace and defense industries, followed by Europe at 31% where automotive applications predominate. The Asia-Pacific region, while currently representing 21% of the market, is expected to exhibit the highest growth rate at 16.8% CAGR through 2030, fueled by rapid industrialization and technology adoption in China, Japan, and South Korea.

Key market drivers include the growing demand for lightweight components in transportation sectors, increasing thermal management requirements in electronics, and the push for energy efficiency across all industries. Additionally, the ability of AM to enable complex internal geometries that optimize fluid flow and heat transfer characteristics provides significant performance advantages over conventionally manufactured heat exchangers.

Market restraints include high initial equipment costs, material limitations, and quality consistency challenges. The average cost premium for AM heat exchangers remains 30-40% above conventional manufacturing methods, though this gap is narrowing as technology matures and production volumes increase. Despite these challenges, the unique design freedom and performance benefits continue to drive market expansion, particularly in high-value applications where thermal management is critical to system performance.

Technical Challenges in AM Microchannel Fabrication

Despite the promising potential of additive manufacturing (AM) for microchannel heat exchangers, several significant technical challenges impede widespread implementation. Material selection presents a primary obstacle, as materials must simultaneously possess high thermal conductivity, mechanical strength, and compatibility with AM processes. Currently available AM-compatible materials often exhibit inferior thermal properties compared to traditional metals used in heat exchangers, creating a fundamental performance limitation.

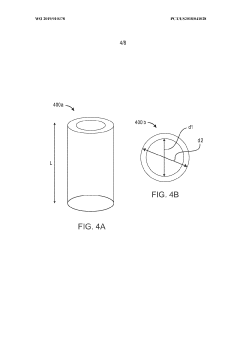

Resolution constraints of various AM technologies directly impact the achievable microchannel dimensions. Powder-based methods like Selective Laser Melting (SLM) typically struggle to produce channels smaller than 500 μm due to powder particle size limitations and the challenge of removing unfused powder from intricate internal geometries. Stereolithography (SLA) offers better resolution but with compromised material properties for thermal applications.

Surface roughness represents another critical challenge, as the layer-by-layer building process inherently creates microscopic irregularities along channel walls. These imperfections significantly increase flow resistance, causing pressure drops that reduce overall heat exchanger efficiency. Post-processing techniques to smooth internal surfaces remain limited by accessibility to complex internal geometries.

Dimensional accuracy and repeatability issues plague AM microchannel fabrication. Thermal distortion during printing and solidification can cause warping and internal stress, leading to deviations from designed specifications. This becomes particularly problematic for microchannels where even minor dimensional variations can substantially alter flow characteristics and heat transfer performance.

Support structure management presents unique difficulties in microchannel manufacturing. While supports are necessary for overhanging features, their removal from internal microchannels is extremely challenging without damaging the delicate structures. This often necessitates design compromises that limit geometric optimization potential.

Process parameter optimization remains largely empirical and material-specific. The complex relationships between laser power, scan speed, layer thickness, and resulting microchannel quality require extensive experimentation. The lack of standardized parameters across different AM systems further complicates consistent production.

Quality control and inspection of internal microchannels present formidable challenges. Non-destructive testing methods like X-ray computed tomography offer limited resolution for detecting microscale defects, while destructive testing eliminates the examined part. This creates significant uncertainty in quality assurance for critical applications requiring high reliability.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, fluid dynamics, thermal engineering, and advanced manufacturing. Progress in overcoming these barriers will determine the timeline for widespread adoption of AM microchannel heat exchangers in high-performance thermal management applications.

Resolution constraints of various AM technologies directly impact the achievable microchannel dimensions. Powder-based methods like Selective Laser Melting (SLM) typically struggle to produce channels smaller than 500 μm due to powder particle size limitations and the challenge of removing unfused powder from intricate internal geometries. Stereolithography (SLA) offers better resolution but with compromised material properties for thermal applications.

Surface roughness represents another critical challenge, as the layer-by-layer building process inherently creates microscopic irregularities along channel walls. These imperfections significantly increase flow resistance, causing pressure drops that reduce overall heat exchanger efficiency. Post-processing techniques to smooth internal surfaces remain limited by accessibility to complex internal geometries.

Dimensional accuracy and repeatability issues plague AM microchannel fabrication. Thermal distortion during printing and solidification can cause warping and internal stress, leading to deviations from designed specifications. This becomes particularly problematic for microchannels where even minor dimensional variations can substantially alter flow characteristics and heat transfer performance.

Support structure management presents unique difficulties in microchannel manufacturing. While supports are necessary for overhanging features, their removal from internal microchannels is extremely challenging without damaging the delicate structures. This often necessitates design compromises that limit geometric optimization potential.

Process parameter optimization remains largely empirical and material-specific. The complex relationships between laser power, scan speed, layer thickness, and resulting microchannel quality require extensive experimentation. The lack of standardized parameters across different AM systems further complicates consistent production.

Quality control and inspection of internal microchannels present formidable challenges. Non-destructive testing methods like X-ray computed tomography offer limited resolution for detecting microscale defects, while destructive testing eliminates the examined part. This creates significant uncertainty in quality assurance for critical applications requiring high reliability.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, fluid dynamics, thermal engineering, and advanced manufacturing. Progress in overcoming these barriers will determine the timeline for widespread adoption of AM microchannel heat exchangers in high-performance thermal management applications.

Current AM Techniques for Microchannel Production

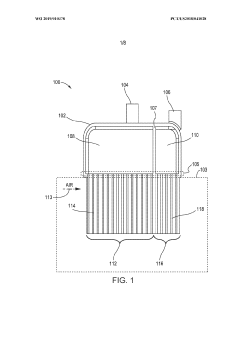

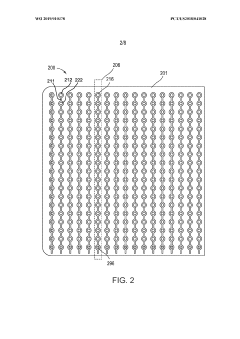

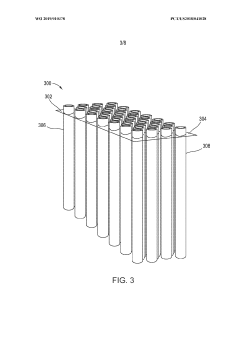

01 Microchannel heat exchanger design and structure

Microchannel heat exchangers utilize small diameter channels to enhance heat transfer efficiency. The design typically includes parallel microchannels that maximize surface area while minimizing material usage. These structures often incorporate fins, headers, and manifolds to distribute fluid flow evenly across the channels. The compact design allows for higher heat transfer coefficients and improved thermal performance compared to conventional heat exchangers.- Design and structure of microchannel heat exchangers: Microchannel heat exchangers utilize small channels with hydraulic diameters typically less than 1mm to enhance heat transfer efficiency. The design includes parallel microchannels that maximize surface area-to-volume ratio, allowing for improved thermal performance in compact dimensions. These structures can be manufactured using various techniques including etching, micromachining, and additive manufacturing processes to create precise channel geometries optimized for specific applications.

- Cooling applications in electronics and power systems: Microchannel heat exchangers are extensively used for thermal management in electronics and power systems where high heat flux removal is required in limited spaces. These systems enable efficient cooling of semiconductor devices, power electronics, and high-performance computing components. The microchannels allow for direct cooling near heat sources, reducing thermal resistance and enabling higher power densities in electronic devices while maintaining safe operating temperatures.

- Advanced manufacturing techniques for microchannel fabrication: Various manufacturing methods are employed to create microchannel heat exchangers, including precision machining, chemical etching, additive manufacturing, and micro-extrusion processes. These techniques enable the production of complex channel geometries with high aspect ratios and precise dimensions. Advanced manufacturing approaches allow for optimization of channel cross-sections, surface features, and integration of multiple functions within a single component, enhancing overall thermal performance.

- Flow distribution and optimization in microchannel systems: Effective flow distribution is critical in microchannel heat exchangers to ensure uniform cooling and prevent hotspots. Design considerations include manifold configurations, header designs, and channel arrangements that promote balanced flow across all microchannels. Computational fluid dynamics and experimental validation are used to optimize flow parameters such as pressure drop, flow velocity, and turbulence characteristics to maximize heat transfer while minimizing pumping power requirements.

- Materials and surface enhancements for microchannel heat exchangers: Material selection and surface modifications play crucial roles in microchannel heat exchanger performance. High thermal conductivity materials like aluminum, copper, and silicon are commonly used as base materials. Surface enhancements including micro-fins, structured surfaces, and coatings can significantly improve heat transfer coefficients. Advanced materials such as metal foams, phase change materials, and nanofluids are also being integrated with microchannel designs to further enhance thermal performance and energy efficiency.

02 Manufacturing methods for microchannel heat exchangers

Various manufacturing techniques are employed to produce microchannel heat exchangers, including extrusion, etching, micromachining, and additive manufacturing. These processes enable the creation of precise channel geometries and complex internal structures. Advanced joining methods such as brazing, diffusion bonding, and welding are used to assemble the components while maintaining structural integrity and preventing leakage between fluid passages.Expand Specific Solutions03 Cooling applications in electronics and power systems

Microchannel heat exchangers are increasingly used for thermal management in electronics and power systems. They provide efficient cooling for high-power density components such as processors, power modules, and batteries. The small channel dimensions allow for direct integration with electronic packages, enabling more effective heat removal and temperature control. These cooling solutions help prevent thermal throttling and extend the lifespan of electronic devices.Expand Specific Solutions04 Enhanced heat transfer through surface modifications and flow optimization

Heat transfer in microchannels can be enhanced through various surface modifications and flow optimization techniques. These include structured surfaces with micro-fins, dimples, or grooves that increase turbulence and surface area. Flow distributors, vortex generators, and specially designed inlet/outlet configurations improve fluid distribution and reduce pressure drop. Some designs incorporate phase-change materials or nanofluids to further enhance thermal performance.Expand Specific Solutions05 Novel materials and applications for microchannel heat exchangers

Innovative materials are being developed for microchannel heat exchangers to improve performance in specialized applications. These include corrosion-resistant alloys for chemical processing, high-temperature materials for energy recovery systems, and lightweight composites for aerospace applications. Microchannel technology is expanding into new fields such as renewable energy systems, fuel cells, and biomedical devices, where compact and efficient heat transfer is critical.Expand Specific Solutions

Leading Companies in AM Heat Exchanger Industry

Additive manufacturing of microchannel heat exchangers is currently in the growth phase, with an expanding market driven by increasing demand for efficient thermal management solutions. The global market is projected to reach significant scale as industries recognize the benefits of these compact, high-performance heat transfer devices. Technologically, the field shows varying maturity levels across players. Companies like Conflux Technology and GE Avio have established advanced capabilities in metal additive manufacturing for heat exchangers, while Danfoss, Midea, and TCL are integrating these technologies into commercial HVAC applications. Research institutions including Xiamen University and Xi'an Jiaotong University are advancing fundamental innovations, particularly in microchannel design optimization and novel materials. Porsche and RTX represent the high-end application segment, implementing these technologies in automotive and aerospace applications where thermal efficiency is critical.

General Electric Company

Technical Solution: General Electric has developed comprehensive additive manufacturing capabilities for microchannel heat exchangers through its GE Additive division. Their approach combines direct metal laser melting (DMLM) and electron beam melting (EBM) technologies to create complex internal cooling geometries impossible with traditional manufacturing. GE's process enables the production of heat exchangers with wall thicknesses down to 200 microns and aspect ratios exceeding 100:1. The company has implemented specialized powder handling systems and parameter optimization for high-temperature alloys including Inconel 718 and titanium alloys. GE's microchannel heat exchangers feature triply periodic minimal surface (TPMS) internal structures that maximize surface area while minimizing pressure drop. Testing has demonstrated heat transfer coefficient improvements of 30-60% compared to conventional designs, with weight reductions of up to 50%. GE has integrated these heat exchangers into aviation and power generation applications.

Strengths: Extensive materials science expertise; vertical integration from powder production to final part qualification; established quality control systems for critical applications. Weaknesses: High capital investment requirements; longer development cycles for new applications; challenges in scaling down to very small production runs cost-effectively.

Divergent Technologies, Inc.

Technical Solution: Divergent Technologies has developed a specialized additive manufacturing platform for microchannel heat exchangers as part of their automotive manufacturing ecosystem. Their approach utilizes a hybrid process combining direct metal laser sintering (DMLS) with subsequent CNC machining for critical interfaces. Divergent's heat exchangers feature optimized lattice structures with variable density to enhance heat transfer in targeted areas while maintaining structural integrity. The company employs generative design algorithms that automatically optimize channel geometry based on computational fluid dynamics simulations and thermal load requirements. Their manufacturing process enables the creation of integrated cooling systems with wall thicknesses as low as 250 microns and complex three-dimensional flow paths. Divergent has demonstrated the ability to produce heat exchangers with 25-35% higher cooling capacity than conventional designs while reducing weight by up to 40%. Their technology has been implemented in high-performance automotive cooling systems.

Strengths: Advanced integration of computational design and manufacturing processes; proven applications in demanding automotive environments; ability to rapidly iterate designs. Weaknesses: Less experience in non-automotive applications; higher unit costs for low-volume production; limited public technical documentation of thermal performance metrics.

Key Patents in AM Microchannel Technology

Apparatus and methods for additively manufacturing microtube heat exchangers

PatentWO2019010378A1

Innovation

- The development of additively manufactured microtube heat exchangers with high-density microtube arrays and integrated headers, allowing for complex geometries and fluid separation, enabling heat transfer between different types of fluids and achieving high heat transfer effectiveness and surface area densities through 3D printing techniques.

Composite process and system for preparing profiled microchannel plate heat exchanger

PatentInactiveUS20240383080A1

Innovation

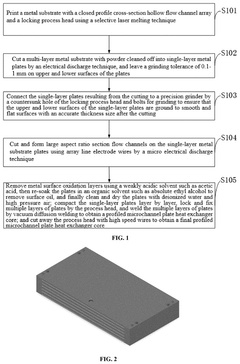

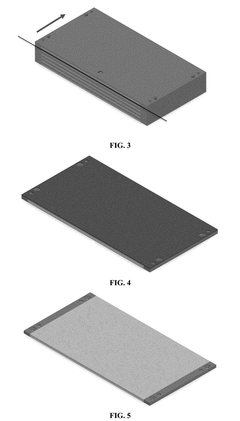

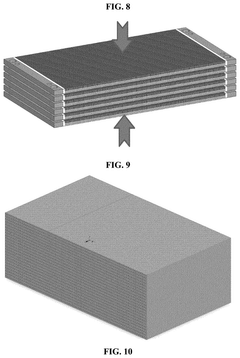

- A composite process combining selective laser melting, electrical discharge cutting, precision grinding, micro electrical discharge forming, and vacuum diffusion welding to create profiled microchannel plate heat exchangers with advanced design freedom and improved structural integrity.

Material Selection for AM Microchannel HX

Material selection represents a critical factor in the successful development of additively manufactured microchannel heat exchangers (AM-MCHX). The choice of materials significantly impacts thermal performance, mechanical integrity, manufacturability, and overall system reliability. Current material options for AM-MCHX can be categorized into metals, polymers, ceramics, and composites, each offering distinct advantages and limitations.

Metal alloys remain the predominant material choice for high-performance heat exchangers due to their superior thermal conductivity. Aluminum alloys (particularly AlSi10Mg) are widely utilized in powder bed fusion processes, offering an excellent balance between thermal conductivity (approximately 170 W/m·K) and processability. Copper and copper alloys provide even higher thermal conductivity (up to 400 W/m·K) but present challenges in laser-based AM processes due to their high reflectivity and thermal conductivity.

Nickel-based superalloys such as Inconel 718 and 625 are preferred for high-temperature applications, maintaining structural integrity at temperatures exceeding 700°C while offering good corrosion resistance. However, their relatively lower thermal conductivity (approximately 11-15 W/m·K) limits their heat transfer efficiency compared to aluminum or copper alternatives.

Polymer-based materials, including high-performance thermoplastics like PEEK and ULTEM, have emerged as viable options for low-pressure, moderate-temperature applications. These materials offer advantages in chemical compatibility, weight reduction, and cost-effectiveness, though their thermal conductivity remains significantly lower than metallic counterparts (typically 0.2-0.5 W/m·K).

Recent developments in ceramic AM processes have enabled the fabrication of silicon carbide and aluminum oxide heat exchangers, offering exceptional chemical resistance and high-temperature stability. These materials are particularly valuable in corrosive environments where metals would rapidly degrade.

Material selection must also consider the specific AM process constraints. Powder bed fusion techniques require materials with suitable powder characteristics (flowability, particle size distribution, and sphericity), while material extrusion methods demand appropriate rheological properties. The thermal history during fabrication significantly impacts microstructure development, potentially leading to anisotropic properties that must be accounted for in design.

Surface finish quality represents another critical consideration, as the inherent roughness of as-built AM components can increase pressure drop and reduce heat transfer efficiency in microchannels. Post-processing techniques such as chemical etching, electropolishing, or mechanical finishing may be necessary depending on the selected material and application requirements.

Metal alloys remain the predominant material choice for high-performance heat exchangers due to their superior thermal conductivity. Aluminum alloys (particularly AlSi10Mg) are widely utilized in powder bed fusion processes, offering an excellent balance between thermal conductivity (approximately 170 W/m·K) and processability. Copper and copper alloys provide even higher thermal conductivity (up to 400 W/m·K) but present challenges in laser-based AM processes due to their high reflectivity and thermal conductivity.

Nickel-based superalloys such as Inconel 718 and 625 are preferred for high-temperature applications, maintaining structural integrity at temperatures exceeding 700°C while offering good corrosion resistance. However, their relatively lower thermal conductivity (approximately 11-15 W/m·K) limits their heat transfer efficiency compared to aluminum or copper alternatives.

Polymer-based materials, including high-performance thermoplastics like PEEK and ULTEM, have emerged as viable options for low-pressure, moderate-temperature applications. These materials offer advantages in chemical compatibility, weight reduction, and cost-effectiveness, though their thermal conductivity remains significantly lower than metallic counterparts (typically 0.2-0.5 W/m·K).

Recent developments in ceramic AM processes have enabled the fabrication of silicon carbide and aluminum oxide heat exchangers, offering exceptional chemical resistance and high-temperature stability. These materials are particularly valuable in corrosive environments where metals would rapidly degrade.

Material selection must also consider the specific AM process constraints. Powder bed fusion techniques require materials with suitable powder characteristics (flowability, particle size distribution, and sphericity), while material extrusion methods demand appropriate rheological properties. The thermal history during fabrication significantly impacts microstructure development, potentially leading to anisotropic properties that must be accounted for in design.

Surface finish quality represents another critical consideration, as the inherent roughness of as-built AM components can increase pressure drop and reduce heat transfer efficiency in microchannels. Post-processing techniques such as chemical etching, electropolishing, or mechanical finishing may be necessary depending on the selected material and application requirements.

Design Optimization for AM Heat Exchangers

Design optimization for additive manufacturing (AM) heat exchangers represents a critical frontier in maximizing the performance advantages offered by this revolutionary manufacturing approach. Traditional design methodologies prove inadequate when applied to AM heat exchangers due to the unique capabilities and constraints of layer-by-layer fabrication processes. Topology optimization algorithms have emerged as powerful tools, enabling designers to explore complex geometries that would be impossible with conventional manufacturing techniques.

Multi-objective optimization frameworks have been developed specifically for AM heat exchangers, simultaneously addressing thermal performance, pressure drop, material usage, and manufacturability constraints. These frameworks typically employ computational fluid dynamics (CFD) coupled with genetic algorithms or adjoint-based methods to navigate the vast design space efficiently. Recent advances in machine learning techniques have further accelerated this process, reducing computational costs while maintaining solution quality.

Lattice structures and triply periodic minimal surfaces (TPMS) have gained significant attention as promising design templates for AM heat exchangers. These structures offer exceptional surface-area-to-volume ratios while maintaining mechanical integrity and fluid flow characteristics. Research indicates that gyroid and Schwarz-P structures demonstrate particularly favorable heat transfer performance when properly optimized for specific operating conditions.

Design for additive manufacturing (DfAM) principles must be integrated throughout the optimization process. This includes considerations for build orientation, support structures, residual stresses, and post-processing requirements. Advanced simulation tools now incorporate these manufacturing constraints directly into the optimization workflow, ensuring that optimized designs remain manufacturable while maximizing performance benefits.

Generative design approaches have revolutionized the conceptualization phase by automatically generating numerous design alternatives based on specified performance targets and constraints. These approaches leverage the geometric freedom of AM to create non-intuitive solutions that often outperform conventional designs by 30-50% in terms of heat transfer efficiency and material utilization.

Multi-scale optimization techniques address the challenge of designing across different length scales simultaneously. This approach optimizes both macro-level flow paths and micro-level surface features to enhance heat transfer through boundary layer disruption and secondary flow generation, while maintaining acceptable pressure drops and mechanical properties.

Multi-objective optimization frameworks have been developed specifically for AM heat exchangers, simultaneously addressing thermal performance, pressure drop, material usage, and manufacturability constraints. These frameworks typically employ computational fluid dynamics (CFD) coupled with genetic algorithms or adjoint-based methods to navigate the vast design space efficiently. Recent advances in machine learning techniques have further accelerated this process, reducing computational costs while maintaining solution quality.

Lattice structures and triply periodic minimal surfaces (TPMS) have gained significant attention as promising design templates for AM heat exchangers. These structures offer exceptional surface-area-to-volume ratios while maintaining mechanical integrity and fluid flow characteristics. Research indicates that gyroid and Schwarz-P structures demonstrate particularly favorable heat transfer performance when properly optimized for specific operating conditions.

Design for additive manufacturing (DfAM) principles must be integrated throughout the optimization process. This includes considerations for build orientation, support structures, residual stresses, and post-processing requirements. Advanced simulation tools now incorporate these manufacturing constraints directly into the optimization workflow, ensuring that optimized designs remain manufacturable while maximizing performance benefits.

Generative design approaches have revolutionized the conceptualization phase by automatically generating numerous design alternatives based on specified performance targets and constraints. These approaches leverage the geometric freedom of AM to create non-intuitive solutions that often outperform conventional designs by 30-50% in terms of heat transfer efficiency and material utilization.

Multi-scale optimization techniques address the challenge of designing across different length scales simultaneously. This approach optimizes both macro-level flow paths and micro-level surface features to enhance heat transfer through boundary layer disruption and secondary flow generation, while maintaining acceptable pressure drops and mechanical properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!