Crossflow vs. counterflow heat exchanger configurations

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, with crossflow and counterflow configurations representing two fundamental design approaches that continue to shape modern thermal management systems. The historical development of heat exchanger technology can be traced back to the industrial revolution, where the need for efficient heat transfer mechanisms became critical for power generation and manufacturing processes. Over time, these systems have undergone substantial refinement, transitioning from simple shell-and-tube designs to complex, highly optimized configurations tailored for specific applications.

The technological trajectory of heat exchangers has been characterized by continuous innovation aimed at maximizing thermal efficiency while minimizing size, weight, and material costs. Crossflow heat exchangers, where fluid streams flow perpendicular to each other, emerged as practical solutions for applications with space constraints and moderate efficiency requirements. Counterflow designs, with fluids moving in opposite directions, developed in parallel, offering superior theoretical thermal performance at the expense of more complex manufacturing requirements.

Recent advancements in computational fluid dynamics (CFD) and materials science have accelerated the evolution of both configurations, enabling more precise optimization of flow channels, surface geometries, and overall exchanger architecture. The integration of enhanced surfaces, such as fins, dimples, and microchannels, has further expanded the performance envelope of both crossflow and counterflow designs, blurring traditional efficiency boundaries between these configurations.

The primary technical objective in heat exchanger development is to achieve optimal thermal performance while balancing practical constraints including pressure drop, fouling resistance, manufacturability, and cost-effectiveness. For crossflow and counterflow configurations specifically, research aims to quantify and optimize the inherent trade-offs between these factors across diverse operating conditions and application requirements.

Current technological goals include developing hybrid designs that combine the advantages of both configurations, creating adaptive systems capable of modifying flow patterns in response to changing thermal loads, and incorporating advanced materials that enhance heat transfer while reducing environmental impact. Additionally, miniaturization trends are driving research into micro-scale heat exchangers that maintain high efficiency despite reduced dimensions.

The evolution toward smart heat exchangers represents another significant trend, with embedded sensors and control systems enabling real-time performance monitoring and optimization. This integration of digital technology with traditional thermal engineering principles is expected to yield substantial efficiency improvements while extending equipment lifespan through predictive maintenance capabilities.

The technological trajectory of heat exchangers has been characterized by continuous innovation aimed at maximizing thermal efficiency while minimizing size, weight, and material costs. Crossflow heat exchangers, where fluid streams flow perpendicular to each other, emerged as practical solutions for applications with space constraints and moderate efficiency requirements. Counterflow designs, with fluids moving in opposite directions, developed in parallel, offering superior theoretical thermal performance at the expense of more complex manufacturing requirements.

Recent advancements in computational fluid dynamics (CFD) and materials science have accelerated the evolution of both configurations, enabling more precise optimization of flow channels, surface geometries, and overall exchanger architecture. The integration of enhanced surfaces, such as fins, dimples, and microchannels, has further expanded the performance envelope of both crossflow and counterflow designs, blurring traditional efficiency boundaries between these configurations.

The primary technical objective in heat exchanger development is to achieve optimal thermal performance while balancing practical constraints including pressure drop, fouling resistance, manufacturability, and cost-effectiveness. For crossflow and counterflow configurations specifically, research aims to quantify and optimize the inherent trade-offs between these factors across diverse operating conditions and application requirements.

Current technological goals include developing hybrid designs that combine the advantages of both configurations, creating adaptive systems capable of modifying flow patterns in response to changing thermal loads, and incorporating advanced materials that enhance heat transfer while reducing environmental impact. Additionally, miniaturization trends are driving research into micro-scale heat exchangers that maintain high efficiency despite reduced dimensions.

The evolution toward smart heat exchangers represents another significant trend, with embedded sensors and control systems enabling real-time performance monitoring and optimization. This integration of digital technology with traditional thermal engineering principles is expected to yield substantial efficiency improvements while extending equipment lifespan through predictive maintenance capabilities.

Market Demand Analysis for Heat Exchanger Configurations

The global heat exchanger market has witnessed substantial growth in recent years, driven by increasing industrialization and the growing emphasis on energy efficiency across various sectors. The market size for heat exchangers was valued at approximately $17.86 billion in 2022 and is projected to reach $28.5 billion by 2030, growing at a CAGR of around 6.0% during the forecast period. Within this market, the demand for different configurations, particularly crossflow and counterflow heat exchangers, shows distinct patterns based on application requirements and efficiency considerations.

Industrial sectors including HVAC, chemical processing, power generation, and oil & gas remain the primary demand drivers for heat exchanger technologies. The HVAC sector alone accounts for nearly 30% of the total market share, where both crossflow and counterflow configurations find extensive applications. However, the demand distribution between these configurations varies significantly across industries.

Counterflow heat exchangers are experiencing heightened demand in applications requiring maximum thermal efficiency, such as waste heat recovery systems and high-performance HVAC installations. This configuration can achieve theoretical thermal effectiveness approaching 100%, making it increasingly preferred in energy-intensive industries where operational cost reduction is paramount. Market research indicates that counterflow units command premium pricing, typically 15-25% higher than comparable crossflow units, reflecting their superior performance characteristics.

Crossflow heat exchangers, meanwhile, maintain strong market presence due to their compact design, lower pressure drop characteristics, and cost-effectiveness in applications where ultimate thermal efficiency is less critical. The automotive industry represents a significant market for crossflow configurations, particularly in radiator applications, where space constraints and moderate efficiency requirements align well with crossflow advantages.

Regional analysis reveals differentiated demand patterns, with developed markets in North America and Europe showing stronger preference for high-efficiency counterflow systems aligned with stringent energy regulations. Conversely, developing markets in Asia-Pacific, particularly China and India, demonstrate robust demand growth for both configurations, with crossflow units maintaining higher volume share due to cost considerations in rapidly expanding industrial bases.

Customer requirements are increasingly shifting toward customized solutions that optimize the trade-offs between thermal efficiency, pressure drop, size constraints, and cost. This trend is driving manufacturers to develop hybrid designs and innovative configurations that combine advantages of both crossflow and counterflow arrangements. The market is also witnessing growing demand for modular and easily serviceable heat exchanger units that can be adapted to changing operational requirements.

Industrial sectors including HVAC, chemical processing, power generation, and oil & gas remain the primary demand drivers for heat exchanger technologies. The HVAC sector alone accounts for nearly 30% of the total market share, where both crossflow and counterflow configurations find extensive applications. However, the demand distribution between these configurations varies significantly across industries.

Counterflow heat exchangers are experiencing heightened demand in applications requiring maximum thermal efficiency, such as waste heat recovery systems and high-performance HVAC installations. This configuration can achieve theoretical thermal effectiveness approaching 100%, making it increasingly preferred in energy-intensive industries where operational cost reduction is paramount. Market research indicates that counterflow units command premium pricing, typically 15-25% higher than comparable crossflow units, reflecting their superior performance characteristics.

Crossflow heat exchangers, meanwhile, maintain strong market presence due to their compact design, lower pressure drop characteristics, and cost-effectiveness in applications where ultimate thermal efficiency is less critical. The automotive industry represents a significant market for crossflow configurations, particularly in radiator applications, where space constraints and moderate efficiency requirements align well with crossflow advantages.

Regional analysis reveals differentiated demand patterns, with developed markets in North America and Europe showing stronger preference for high-efficiency counterflow systems aligned with stringent energy regulations. Conversely, developing markets in Asia-Pacific, particularly China and India, demonstrate robust demand growth for both configurations, with crossflow units maintaining higher volume share due to cost considerations in rapidly expanding industrial bases.

Customer requirements are increasingly shifting toward customized solutions that optimize the trade-offs between thermal efficiency, pressure drop, size constraints, and cost. This trend is driving manufacturers to develop hybrid designs and innovative configurations that combine advantages of both crossflow and counterflow arrangements. The market is also witnessing growing demand for modular and easily serviceable heat exchanger units that can be adapted to changing operational requirements.

Current State and Technical Challenges in Heat Exchanger Design

Heat exchanger technology has evolved significantly over the past decades, with crossflow and counterflow configurations representing two fundamental design approaches. Currently, the global heat exchanger market is dominated by plate heat exchangers (40%), shell and tube exchangers (30%), and air-cooled exchangers (15%), with various flow configurations implemented across these types. The market is projected to reach $28.5 billion by 2025, growing at a CAGR of 6.8%, driven primarily by industrial expansion and energy efficiency requirements.

In terms of technical development, counterflow heat exchangers have achieved theoretical thermal efficiencies of up to 95%, while crossflow designs typically operate at 60-75% efficiency. However, practical implementation often reduces these figures by 5-15% due to real-world constraints. Recent advancements in computational fluid dynamics (CFD) have enabled more precise modeling of flow patterns, reducing the gap between theoretical and actual performance.

Despite these advancements, significant challenges persist in heat exchanger design. Fouling remains a critical issue, reducing thermal efficiency by 10-40% over operational lifetimes and increasing maintenance costs by approximately 30%. This problem is particularly pronounced in crossflow configurations where flow distribution is less uniform, creating potential dead zones where deposits accumulate more readily.

Material limitations present another substantial challenge. While high-performance alloys and composites offer improved thermal conductivity and corrosion resistance, they increase manufacturing costs by 40-200% compared to traditional materials. The trade-off between performance and cost-effectiveness continues to constrain widespread adoption of optimal designs, particularly in price-sensitive markets.

Geometric constraints in installation spaces often force compromises in flow configuration selection. Crossflow designs typically require 20-30% less installation space in one dimension but sacrifice some thermal efficiency. This trade-off becomes particularly challenging in retrofit applications where space limitations may dictate configuration choices regardless of theoretical performance advantages.

Energy efficiency requirements are becoming increasingly stringent worldwide, with regulations in developed markets mandating minimum efficiency improvements of 15-25% over previous generation equipment. This regulatory pressure is driving innovation but also creating implementation challenges, especially for smaller manufacturers with limited R&D resources.

Flow distribution optimization remains technically challenging, particularly in larger heat exchangers where maintaining uniform flow across the entire heat transfer surface is difficult. Non-uniform flow can reduce effective heat transfer by up to 30% in poorly designed systems, with crossflow configurations generally more susceptible to this issue than counterflow designs.

In terms of technical development, counterflow heat exchangers have achieved theoretical thermal efficiencies of up to 95%, while crossflow designs typically operate at 60-75% efficiency. However, practical implementation often reduces these figures by 5-15% due to real-world constraints. Recent advancements in computational fluid dynamics (CFD) have enabled more precise modeling of flow patterns, reducing the gap between theoretical and actual performance.

Despite these advancements, significant challenges persist in heat exchanger design. Fouling remains a critical issue, reducing thermal efficiency by 10-40% over operational lifetimes and increasing maintenance costs by approximately 30%. This problem is particularly pronounced in crossflow configurations where flow distribution is less uniform, creating potential dead zones where deposits accumulate more readily.

Material limitations present another substantial challenge. While high-performance alloys and composites offer improved thermal conductivity and corrosion resistance, they increase manufacturing costs by 40-200% compared to traditional materials. The trade-off between performance and cost-effectiveness continues to constrain widespread adoption of optimal designs, particularly in price-sensitive markets.

Geometric constraints in installation spaces often force compromises in flow configuration selection. Crossflow designs typically require 20-30% less installation space in one dimension but sacrifice some thermal efficiency. This trade-off becomes particularly challenging in retrofit applications where space limitations may dictate configuration choices regardless of theoretical performance advantages.

Energy efficiency requirements are becoming increasingly stringent worldwide, with regulations in developed markets mandating minimum efficiency improvements of 15-25% over previous generation equipment. This regulatory pressure is driving innovation but also creating implementation challenges, especially for smaller manufacturers with limited R&D resources.

Flow distribution optimization remains technically challenging, particularly in larger heat exchangers where maintaining uniform flow across the entire heat transfer surface is difficult. Non-uniform flow can reduce effective heat transfer by up to 30% in poorly designed systems, with crossflow configurations generally more susceptible to this issue than counterflow designs.

Current Technical Solutions for Crossflow and Counterflow Designs

01 Counterflow heat exchanger design principles

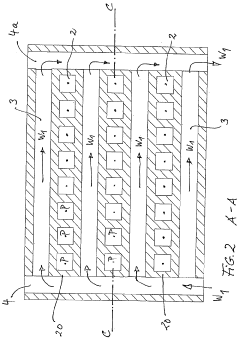

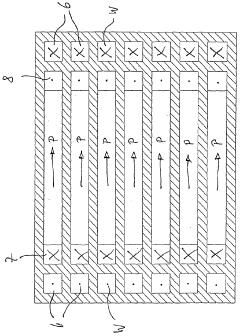

Counterflow heat exchangers are designed with fluid streams flowing in opposite directions, maximizing temperature differential throughout the exchanger. This configuration achieves higher thermal efficiency compared to other arrangements because it maintains a more consistent temperature difference between the two fluids. The design allows for more effective heat transfer with smaller heat exchange surface areas, making it ideal for applications requiring high efficiency in limited space.- Counterflow heat exchanger design principles: Counterflow heat exchangers are designed with fluid streams flowing in opposite directions, maximizing temperature differential throughout the exchanger. This configuration achieves higher thermal efficiency compared to other arrangements because it maintains a more consistent driving force for heat transfer. The design allows for closer approach temperatures between the hot and cold streams at the outlet, resulting in more effective heat recovery and higher overall heat transfer coefficients.

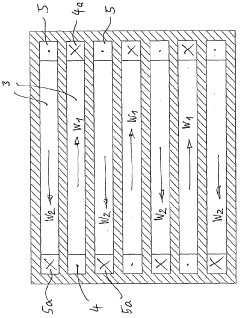

- Crossflow heat exchanger configurations: Crossflow heat exchangers feature fluid streams flowing perpendicular to each other, offering a balance between efficiency and design simplicity. This configuration is particularly advantageous in applications with space constraints or where one fluid must be distributed across a large surface area. While generally less efficient than counterflow designs, crossflow exchangers provide good performance in applications requiring compact dimensions and are often used in HVAC systems, automotive radiators, and air preheaters.

- Enhanced heat transfer surface technologies: Advanced surface technologies significantly improve heat exchanger efficiency regardless of flow configuration. These include micro-channel designs, extended surfaces (fins), turbulators, and specialized coatings that increase heat transfer area and promote turbulence. By disrupting boundary layers and increasing surface area-to-volume ratios, these technologies enhance convective heat transfer coefficients. Recent innovations include 3D-printed complex geometries and biomimetic surface patterns that optimize fluid flow patterns while minimizing pressure drop penalties.

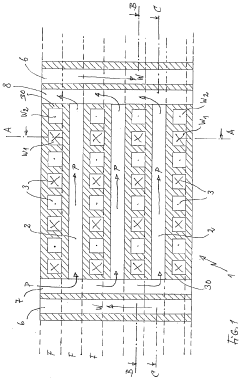

- Hybrid and multi-pass heat exchanger designs: Hybrid heat exchangers combine multiple flow configurations (counterflow, crossflow, and parallel flow) in a single unit to optimize performance for specific applications. Multi-pass designs direct fluids through the exchanger multiple times in different flow patterns to maximize heat transfer efficiency. These sophisticated arrangements allow for precise temperature control, reduced footprint, and improved thermal performance. The designs often incorporate flow distribution devices to ensure uniform fluid distribution and prevent localized hot or cold spots that would reduce overall efficiency.

- Computational modeling and efficiency optimization: Advanced computational fluid dynamics (CFD) modeling enables precise optimization of heat exchanger designs for maximum efficiency. These simulation tools analyze flow patterns, temperature distributions, and pressure drops to identify performance bottlenecks. Modern optimization approaches incorporate machine learning algorithms to explore vast design spaces and identify non-intuitive configurations that maximize heat transfer while minimizing pressure drop. These computational methods have led to significant improvements in heat exchanger performance by enabling engineers to evaluate hundreds of design iterations before physical prototyping.

02 Crossflow heat exchanger configurations

In crossflow heat exchangers, fluid streams flow perpendicular to each other, offering a balance between efficiency and design simplicity. This configuration is commonly used when one fluid is a gas and the other is a liquid, providing good heat transfer rates while being easier to construct than pure counterflow designs. Crossflow arrangements often incorporate fins or other extended surfaces to increase heat transfer area and compensate for the lower efficiency compared to counterflow designs.Expand Specific Solutions03 Hybrid and multi-pass heat exchanger designs

Hybrid heat exchangers combine multiple flow configurations (counterflow, crossflow, and parallel flow) to optimize heat transfer efficiency for specific applications. Multi-pass designs direct fluids through the exchanger multiple times, increasing residence time and heat transfer effectiveness. These sophisticated configurations can achieve higher overall thermal efficiency by leveraging the advantages of different flow patterns while minimizing their respective limitations.Expand Specific Solutions04 Enhanced surface technologies for heat exchangers

Heat exchanger efficiency can be significantly improved through specialized surface modifications and structures. These include micro-channel designs, corrugated surfaces, dimpled tubes, and various fin configurations that increase turbulence and surface area. Such enhancements promote better mixing of the fluid boundary layer, reducing thermal resistance and improving overall heat transfer coefficients without substantially increasing pressure drop or pumping power requirements.Expand Specific Solutions05 Optimization techniques for heat exchanger efficiency

Advanced optimization techniques focus on balancing heat transfer efficiency with practical constraints such as pressure drop, material costs, and space limitations. These include computational fluid dynamics modeling, thermodynamic analysis, and experimental validation to determine optimal flow rates, temperature distributions, and geometric parameters. Modern approaches also incorporate considerations for fouling resistance, thermal expansion, and maintenance accessibility to ensure long-term operational efficiency in real-world conditions.Expand Specific Solutions

Key Industry Players in Heat Exchanger Manufacturing

The heat exchanger market is currently in a mature growth phase with increasing demand for energy-efficient solutions driving innovation in both crossflow and counterflow configurations. The global heat exchanger market size is estimated at approximately $20 billion, with projected steady growth due to expanding HVAC, automotive, and industrial applications. Leading companies like Modine Manufacturing, Kelvion PHE, and Conflux Technology demonstrate varying levels of technical maturity, with established players focusing on incremental improvements while newer entrants like Thar Energy and Qingdao Haier Intelligent Technology pursue disruptive innovations. Major automotive manufacturers including Honda, Bosch, and Marelli are investing heavily in advanced heat exchanger technologies to meet stringent efficiency requirements, while research institutions like Fraunhofer-Gesellschaft and Shanghai University collaborate with industry to develop next-generation solutions.

MAHLE International GmbH

Technical Solution: MAHLE has established comprehensive expertise in both crossflow and counterflow heat exchanger technologies, with particular focus on automotive thermal management systems. Their crossflow designs feature optimized louvered fins with precisely controlled geometries that balance heat transfer performance with acceptable pressure drops. For counterflow applications, MAHLE employs their patented CooLED technology, which creates highly efficient layered flow paths with minimal thermal resistance between hot and cold streams. Their manufacturing processes incorporate advanced automated brazing techniques that ensure consistent joint quality across high-volume production. MAHLE's dual-flow radiators represent a hybrid approach that leverages benefits of both configurations, with measured performance improvements of up to 25% compared to traditional single-pass designs. Their research has demonstrated that optimized counterflow designs can achieve effectiveness values exceeding 95% in certain applications, though often with higher pressure penalties that must be balanced against system requirements.

Strengths: Extensive experience with automotive thermal management requirements; advanced manufacturing capabilities enabling complex internal geometries; comprehensive testing facilities for performance validation. Weaknesses: Solutions often optimized for specific automotive applications; higher costs associated with automotive durability requirements; some designs prioritize packaging constraints over maximum theoretical efficiency.

Conflux Technology Pty Ltd.

Technical Solution: Conflux Technology has revolutionized heat exchanger design through their proprietary additive manufacturing approach to both crossflow and counterflow configurations. Their crossflow heat exchangers feature complex internal geometries impossible to create with traditional manufacturing, including fractal-inspired flow paths that maximize surface area while minimizing pressure drop. For counterflow applications, Conflux employs their patented Cartrix technology, which creates perfectly aligned microchannels with wall thicknesses as low as 150 microns, enabling thermal efficiencies approaching theoretical limits. Their 3D-printed designs allow for integrated manifolds and optimized flow distribution, eliminating traditional performance bottlenecks. Independent testing has demonstrated that Conflux's additively manufactured heat exchangers achieve up to 60% higher heat transfer rates compared to conventional designs of similar size, with particular advantages in high-pressure applications where their monolithic construction eliminates potential leak paths.

Strengths: Unmatched design freedom enabling previously impossible geometries; excellent performance-to-weight ratios; ability to consolidate multiple components into single units. Weaknesses: Higher production costs for low-volume applications; limited maximum size due to 3D printing constraints; longer lead times for highly customized designs.

Core Technical Innovations in Heat Transfer Efficiency

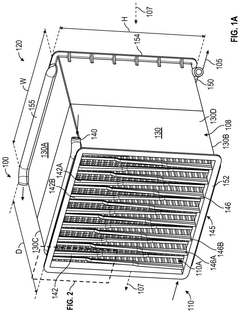

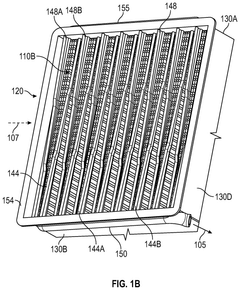

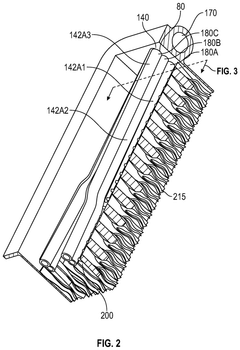

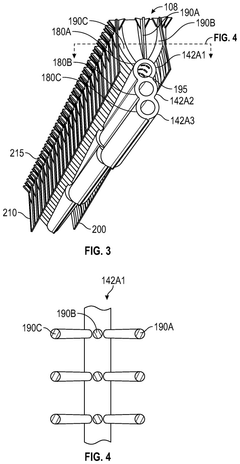

Crossflow heat exchanger with stacked distribution tubes

PatentActiveUS12130097B2

Innovation

- A crossflow heat exchanger design with stacked distribution tubes and core channels that connect inlet and outlet tubes in a specific configuration, including baffles and heat fins, to reduce pressure drop and enhance heat transfer efficiency.

Heat exchanger device for the rapid heating or cooling of fluids

PatentWO2007025766A1

Innovation

- A heat exchanger constructed from a stack of foils or plates with intersecting channels, where the heat transfer fluid flows antiparallel to the process fluid, creating a counterflow configuration that optimizes temperature differences and minimizes pressure drop through straight channel routing, combining the advantages of counterflow and crossflow heat exchangers.

Energy Efficiency Regulations Impact on Heat Exchanger Design

Energy efficiency regulations have become increasingly stringent worldwide, significantly influencing heat exchanger design and configuration selection. The choice between crossflow and counterflow arrangements is now heavily impacted by these regulatory frameworks, which typically mandate minimum efficiency standards for HVAC systems, industrial processes, and energy recovery applications.

In the United States, the Department of Energy (DOE) has established progressively stricter efficiency requirements through 10 CFR Part 430 and 431, directly affecting heat exchanger specifications in commercial and residential applications. Similarly, the European Union's Ecodesign Directive (2009/125/EC) has implemented minimum energy performance standards that favor more efficient heat exchanger configurations.

These regulations have accelerated the adoption of counterflow heat exchangers in many applications due to their inherently higher thermal effectiveness. With counterflow arrangements capable of achieving effectiveness values up to 95% compared to crossflow's typical maximum of 70-75%, manufacturers are increasingly defaulting to counterflow designs to meet regulatory thresholds, particularly in high-efficiency HVAC systems and energy recovery ventilators.

The regulatory landscape has also driven innovation in hybrid configurations that combine elements of both crossflow and counterflow designs. These hybrid approaches attempt to balance the space efficiency advantages of crossflow arrangements with the thermal performance benefits of counterflow, creating compact solutions that still satisfy regulatory requirements.

Certification programs like AHRI (Air-Conditioning, Heating, and Refrigeration Institute) in North America and Eurovent in Europe have established standardized testing protocols that quantify the performance differences between crossflow and counterflow configurations. These third-party verifications have become essential marketing tools for manufacturers and decision factors for engineers selecting appropriate heat exchanger technologies.

The economic impact of these regulations cannot be overlooked. While counterflow heat exchangers often require higher initial investment, lifecycle cost analyses increasingly favor these more efficient designs as energy prices rise and regulatory penalties for non-compliance increase. This has shifted the market dynamics significantly, with manufacturers investing heavily in R&D to optimize counterflow designs for cost-effectiveness.

For developing markets, the adoption of international efficiency standards has accelerated technology transfer, with crossflow designs increasingly limited to less demanding applications or scenarios where space constraints are paramount. The global harmonization of energy efficiency regulations continues to narrow the application range for traditional crossflow configurations in favor of higher-efficiency alternatives.

In the United States, the Department of Energy (DOE) has established progressively stricter efficiency requirements through 10 CFR Part 430 and 431, directly affecting heat exchanger specifications in commercial and residential applications. Similarly, the European Union's Ecodesign Directive (2009/125/EC) has implemented minimum energy performance standards that favor more efficient heat exchanger configurations.

These regulations have accelerated the adoption of counterflow heat exchangers in many applications due to their inherently higher thermal effectiveness. With counterflow arrangements capable of achieving effectiveness values up to 95% compared to crossflow's typical maximum of 70-75%, manufacturers are increasingly defaulting to counterflow designs to meet regulatory thresholds, particularly in high-efficiency HVAC systems and energy recovery ventilators.

The regulatory landscape has also driven innovation in hybrid configurations that combine elements of both crossflow and counterflow designs. These hybrid approaches attempt to balance the space efficiency advantages of crossflow arrangements with the thermal performance benefits of counterflow, creating compact solutions that still satisfy regulatory requirements.

Certification programs like AHRI (Air-Conditioning, Heating, and Refrigeration Institute) in North America and Eurovent in Europe have established standardized testing protocols that quantify the performance differences between crossflow and counterflow configurations. These third-party verifications have become essential marketing tools for manufacturers and decision factors for engineers selecting appropriate heat exchanger technologies.

The economic impact of these regulations cannot be overlooked. While counterflow heat exchangers often require higher initial investment, lifecycle cost analyses increasingly favor these more efficient designs as energy prices rise and regulatory penalties for non-compliance increase. This has shifted the market dynamics significantly, with manufacturers investing heavily in R&D to optimize counterflow designs for cost-effectiveness.

For developing markets, the adoption of international efficiency standards has accelerated technology transfer, with crossflow designs increasingly limited to less demanding applications or scenarios where space constraints are paramount. The global harmonization of energy efficiency regulations continues to narrow the application range for traditional crossflow configurations in favor of higher-efficiency alternatives.

Computational Fluid Dynamics Applications in Heat Exchanger Development

Computational Fluid Dynamics (CFD) has revolutionized the design and optimization of heat exchangers by providing detailed insights into fluid flow and heat transfer phenomena that were previously difficult to observe through experimental methods alone. When examining crossflow versus counterflow heat exchanger configurations, CFD simulations offer invaluable data for comparative analysis and performance prediction.

In crossflow arrangements, where fluids move perpendicular to each other, CFD models reveal complex three-dimensional flow patterns and temperature distributions that affect thermal efficiency. These simulations can identify areas of flow maldistribution, recirculation zones, and potential hotspots that might lead to thermal stress or reduced performance. The computational models typically employ k-ε turbulence models or Large Eddy Simulation (LES) approaches to capture the intricate flow dynamics.

For counterflow configurations, where fluids move parallel but in opposite directions, CFD applications focus on analyzing the nearly uniform temperature difference maintained throughout the heat exchanger length. These simulations help engineers understand how this arrangement maximizes the log mean temperature difference (LMTD) and achieves higher theoretical efficiency compared to crossflow designs.

Modern CFD tools incorporate multiphysics capabilities that simultaneously solve for fluid dynamics, heat transfer, and sometimes structural mechanics to provide comprehensive performance evaluations. Mesh refinement studies are particularly important in heat exchanger simulations to ensure accurate resolution of boundary layers where significant temperature gradients occur.

Parametric CFD studies allow designers to rapidly iterate through various geometric modifications and operating conditions to optimize performance metrics such as pressure drop, heat transfer coefficient, and overall thermal efficiency. For instance, simulations can determine the optimal fin spacing, tube arrangement, or baffle placement that balances heat transfer enhancement against pumping power requirements.

Advanced CFD techniques like adjoint optimization methods are increasingly being applied to heat exchanger design, enabling automatic shape optimization based on specified performance objectives. These methods can identify non-intuitive design improvements that might not emerge from traditional design approaches.

Validation of CFD results against experimental data remains essential, particularly for complex geometries where simplifying assumptions may affect accuracy. Researchers typically establish validation protocols comparing predicted temperature profiles, pressure drops, and overall heat transfer rates with laboratory measurements before relying on simulations for design decisions between crossflow and counterflow configurations.

In crossflow arrangements, where fluids move perpendicular to each other, CFD models reveal complex three-dimensional flow patterns and temperature distributions that affect thermal efficiency. These simulations can identify areas of flow maldistribution, recirculation zones, and potential hotspots that might lead to thermal stress or reduced performance. The computational models typically employ k-ε turbulence models or Large Eddy Simulation (LES) approaches to capture the intricate flow dynamics.

For counterflow configurations, where fluids move parallel but in opposite directions, CFD applications focus on analyzing the nearly uniform temperature difference maintained throughout the heat exchanger length. These simulations help engineers understand how this arrangement maximizes the log mean temperature difference (LMTD) and achieves higher theoretical efficiency compared to crossflow designs.

Modern CFD tools incorporate multiphysics capabilities that simultaneously solve for fluid dynamics, heat transfer, and sometimes structural mechanics to provide comprehensive performance evaluations. Mesh refinement studies are particularly important in heat exchanger simulations to ensure accurate resolution of boundary layers where significant temperature gradients occur.

Parametric CFD studies allow designers to rapidly iterate through various geometric modifications and operating conditions to optimize performance metrics such as pressure drop, heat transfer coefficient, and overall thermal efficiency. For instance, simulations can determine the optimal fin spacing, tube arrangement, or baffle placement that balances heat transfer enhancement against pumping power requirements.

Advanced CFD techniques like adjoint optimization methods are increasingly being applied to heat exchanger design, enabling automatic shape optimization based on specified performance objectives. These methods can identify non-intuitive design improvements that might not emerge from traditional design approaches.

Validation of CFD results against experimental data remains essential, particularly for complex geometries where simplifying assumptions may affect accuracy. Researchers typically establish validation protocols comparing predicted temperature profiles, pressure drops, and overall heat transfer rates with laboratory measurements before relying on simulations for design decisions between crossflow and counterflow configurations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!