Corrosion resistance improvement in heat exchanger materials

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Corrosion Background and Objectives

Heat exchangers are critical components in numerous industrial applications, including power generation, chemical processing, oil refining, and HVAC systems. The evolution of heat exchanger technology dates back to the early 20th century, with significant advancements occurring during the industrial revolution and post-World War II manufacturing boom. Over the decades, the focus has shifted from merely improving thermal efficiency to addressing durability challenges, with corrosion resistance emerging as a paramount concern.

Corrosion in heat exchangers represents a multibillion-dollar problem globally, accounting for approximately 3-5% of GDP in industrialized nations. This deterioration process not only compromises system efficiency but also leads to equipment failure, production downtime, and potential safety hazards. The financial implications extend beyond replacement costs to include energy losses, maintenance expenses, and environmental compliance issues.

The technical evolution trajectory shows a clear progression from basic material selection approaches to sophisticated surface engineering solutions. Early developments centered on utilizing inherently corrosion-resistant alloys, while recent innovations incorporate advanced coating technologies, nanomaterial applications, and intelligent monitoring systems. This progression reflects the industry's growing understanding of corrosion mechanisms and the complex interplay between material properties, fluid characteristics, and operating conditions.

Current technical objectives in heat exchanger corrosion resistance improvement focus on several key areas. First, developing cost-effective materials that maintain structural integrity under increasingly aggressive operating environments, including high temperatures, pressure fluctuations, and chemically corrosive media. Second, creating solutions that simultaneously address multiple corrosion mechanisms, such as galvanic corrosion, pitting, erosion-corrosion, and stress corrosion cracking. Third, implementing designs that minimize maintenance requirements while extending service life beyond current industry standards.

The ultimate goal is to achieve a paradigm shift from reactive maintenance to predictive performance management through materials innovation. This involves developing heat exchanger materials with self-diagnostic capabilities, self-healing properties, and significantly extended service life even under extreme conditions. Additionally, there is growing emphasis on sustainability considerations, with research targeting materials and processes that reduce environmental impact while maintaining or improving corrosion resistance performance.

As industrial processes continue to push operational boundaries, the technical challenges in corrosion resistance become increasingly complex, necessitating interdisciplinary approaches that combine materials science, electrochemistry, fluid dynamics, and data analytics to develop next-generation solutions for heat exchanger applications.

Corrosion in heat exchangers represents a multibillion-dollar problem globally, accounting for approximately 3-5% of GDP in industrialized nations. This deterioration process not only compromises system efficiency but also leads to equipment failure, production downtime, and potential safety hazards. The financial implications extend beyond replacement costs to include energy losses, maintenance expenses, and environmental compliance issues.

The technical evolution trajectory shows a clear progression from basic material selection approaches to sophisticated surface engineering solutions. Early developments centered on utilizing inherently corrosion-resistant alloys, while recent innovations incorporate advanced coating technologies, nanomaterial applications, and intelligent monitoring systems. This progression reflects the industry's growing understanding of corrosion mechanisms and the complex interplay between material properties, fluid characteristics, and operating conditions.

Current technical objectives in heat exchanger corrosion resistance improvement focus on several key areas. First, developing cost-effective materials that maintain structural integrity under increasingly aggressive operating environments, including high temperatures, pressure fluctuations, and chemically corrosive media. Second, creating solutions that simultaneously address multiple corrosion mechanisms, such as galvanic corrosion, pitting, erosion-corrosion, and stress corrosion cracking. Third, implementing designs that minimize maintenance requirements while extending service life beyond current industry standards.

The ultimate goal is to achieve a paradigm shift from reactive maintenance to predictive performance management through materials innovation. This involves developing heat exchanger materials with self-diagnostic capabilities, self-healing properties, and significantly extended service life even under extreme conditions. Additionally, there is growing emphasis on sustainability considerations, with research targeting materials and processes that reduce environmental impact while maintaining or improving corrosion resistance performance.

As industrial processes continue to push operational boundaries, the technical challenges in corrosion resistance become increasingly complex, necessitating interdisciplinary approaches that combine materials science, electrochemistry, fluid dynamics, and data analytics to develop next-generation solutions for heat exchanger applications.

Market Demand Analysis for Corrosion-Resistant Materials

The global market for corrosion-resistant materials in heat exchangers has been experiencing robust growth, driven primarily by increasing industrial activities across oil and gas, chemical processing, power generation, and HVAC sectors. Current market valuations indicate that the corrosion-resistant heat exchanger materials market reached approximately 5.7 billion USD in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030.

Industries with aggressive operating environments, particularly petrochemical and chemical processing, represent the largest demand segment, accounting for nearly 32% of the total market share. These sectors require materials capable of withstanding highly corrosive media while maintaining thermal efficiency over extended operational periods.

The power generation industry follows closely, contributing about 28% of market demand, with particular emphasis on materials for steam generators, condensers, and cooling systems. As global energy demands continue to rise, especially in developing economies, this segment is expected to grow at an accelerated rate of approximately 7.5% annually.

Regional analysis reveals that Asia-Pacific dominates the market with a 38% share, driven by rapid industrialization in China and India. North America and Europe collectively account for 45% of the market, with their demand primarily stemming from replacement and upgrading of aging industrial infrastructure.

Customer requirements are increasingly focused on materials that offer extended service life under corrosive conditions. Market research indicates that end-users are willing to pay premium prices for materials that can demonstrate a 30-40% improvement in service life compared to conventional options, as this translates directly to reduced maintenance costs and operational downtime.

Emerging market trends show growing interest in advanced composite materials and surface treatments rather than traditional bulk material solutions. This shift is evidenced by the 23% increase in patents related to composite and coated heat exchanger materials filed over the past five years.

Regulatory factors are also significantly influencing market dynamics. Stringent environmental regulations in Europe and North America regarding industrial emissions and waste management are driving demand for more durable materials that reduce the frequency of replacement and associated waste generation. Similarly, safety standards in critical applications like nuclear power and chemical processing are becoming more rigorous, necessitating materials with superior corrosion resistance properties.

Industries with aggressive operating environments, particularly petrochemical and chemical processing, represent the largest demand segment, accounting for nearly 32% of the total market share. These sectors require materials capable of withstanding highly corrosive media while maintaining thermal efficiency over extended operational periods.

The power generation industry follows closely, contributing about 28% of market demand, with particular emphasis on materials for steam generators, condensers, and cooling systems. As global energy demands continue to rise, especially in developing economies, this segment is expected to grow at an accelerated rate of approximately 7.5% annually.

Regional analysis reveals that Asia-Pacific dominates the market with a 38% share, driven by rapid industrialization in China and India. North America and Europe collectively account for 45% of the market, with their demand primarily stemming from replacement and upgrading of aging industrial infrastructure.

Customer requirements are increasingly focused on materials that offer extended service life under corrosive conditions. Market research indicates that end-users are willing to pay premium prices for materials that can demonstrate a 30-40% improvement in service life compared to conventional options, as this translates directly to reduced maintenance costs and operational downtime.

Emerging market trends show growing interest in advanced composite materials and surface treatments rather than traditional bulk material solutions. This shift is evidenced by the 23% increase in patents related to composite and coated heat exchanger materials filed over the past five years.

Regulatory factors are also significantly influencing market dynamics. Stringent environmental regulations in Europe and North America regarding industrial emissions and waste management are driving demand for more durable materials that reduce the frequency of replacement and associated waste generation. Similarly, safety standards in critical applications like nuclear power and chemical processing are becoming more rigorous, necessitating materials with superior corrosion resistance properties.

Current Challenges in Heat Exchanger Corrosion Protection

Heat exchanger systems across various industries face significant corrosion challenges that compromise operational efficiency, safety, and economic viability. The primary corrosion mechanisms affecting these systems include galvanic corrosion, which occurs when dissimilar metals are in electrical contact within an electrolyte, and pitting corrosion, characterized by localized attacks creating small holes in metal surfaces. Crevice corrosion frequently develops in tight spaces where stagnant solution conditions promote accelerated metal degradation.

Microbiologically influenced corrosion (MIC) presents a particularly complex challenge, as microorganisms form biofilms that create corrosive microenvironments on material surfaces. This biological dimension adds considerable complexity to protection strategies. Stress corrosion cracking (SCC) occurs when tensile stress combines with a corrosive environment, resulting in catastrophic material failure without visible warning signs.

Temperature fluctuations significantly exacerbate corrosion rates, with every 10°C increase typically doubling the reaction rate. This thermal acceleration effect is especially problematic in heat exchangers where temperature gradients are inherent to functionality. Flow-accelerated corrosion removes protective oxide layers through fluid dynamics, exposing fresh metal surfaces to continued attack.

Current protection methods show significant limitations. Traditional coating technologies often fail prematurely under thermal cycling conditions, while cathodic protection systems struggle with uniform protection across complex geometries. Corrosion inhibitors face increasing regulatory restrictions due to environmental concerns, limiting their application scope.

Material selection presents economic constraints, as highly corrosion-resistant alloys (such as titanium or high-nickel alloys) significantly increase capital costs, creating difficult trade-offs between initial investment and long-term maintenance expenses. The industry lacks standardized testing protocols that accurately predict real-world performance across diverse operating conditions.

Monitoring technologies remain inadequate for early detection, with most systems only identifying corrosion after significant damage has occurred. This detection gap prevents proactive maintenance interventions. Additionally, the increasing use of alternative heat transfer fluids and working media in emerging applications introduces new corrosion mechanisms that are poorly understood and inadequately addressed by conventional protection approaches.

The intersection of these challenges creates a complex technical landscape requiring innovative solutions that balance performance requirements with economic constraints. Addressing these issues demands interdisciplinary approaches combining materials science, electrochemistry, fluid dynamics, and advanced manufacturing techniques to develop next-generation corrosion protection systems specifically optimized for heat exchanger applications.

Microbiologically influenced corrosion (MIC) presents a particularly complex challenge, as microorganisms form biofilms that create corrosive microenvironments on material surfaces. This biological dimension adds considerable complexity to protection strategies. Stress corrosion cracking (SCC) occurs when tensile stress combines with a corrosive environment, resulting in catastrophic material failure without visible warning signs.

Temperature fluctuations significantly exacerbate corrosion rates, with every 10°C increase typically doubling the reaction rate. This thermal acceleration effect is especially problematic in heat exchangers where temperature gradients are inherent to functionality. Flow-accelerated corrosion removes protective oxide layers through fluid dynamics, exposing fresh metal surfaces to continued attack.

Current protection methods show significant limitations. Traditional coating technologies often fail prematurely under thermal cycling conditions, while cathodic protection systems struggle with uniform protection across complex geometries. Corrosion inhibitors face increasing regulatory restrictions due to environmental concerns, limiting their application scope.

Material selection presents economic constraints, as highly corrosion-resistant alloys (such as titanium or high-nickel alloys) significantly increase capital costs, creating difficult trade-offs between initial investment and long-term maintenance expenses. The industry lacks standardized testing protocols that accurately predict real-world performance across diverse operating conditions.

Monitoring technologies remain inadequate for early detection, with most systems only identifying corrosion after significant damage has occurred. This detection gap prevents proactive maintenance interventions. Additionally, the increasing use of alternative heat transfer fluids and working media in emerging applications introduces new corrosion mechanisms that are poorly understood and inadequately addressed by conventional protection approaches.

The intersection of these challenges creates a complex technical landscape requiring innovative solutions that balance performance requirements with economic constraints. Addressing these issues demands interdisciplinary approaches combining materials science, electrochemistry, fluid dynamics, and advanced manufacturing techniques to develop next-generation corrosion protection systems specifically optimized for heat exchanger applications.

Current Anti-Corrosion Technologies and Solutions

01 Stainless steel alloys for corrosion resistance

Stainless steel alloys with specific compositions are widely used in heat exchangers due to their excellent corrosion resistance properties. These alloys typically contain chromium, nickel, and molybdenum in varying proportions to enhance resistance against different corrosive environments. The addition of elements like titanium and nitrogen can further improve the corrosion resistance in specific applications such as seawater or high-temperature environments. These materials form a passive oxide layer that provides protection against corrosive attacks while maintaining good thermal conductivity required for heat exchange applications.- Stainless steel alloys for corrosion resistance: Stainless steel alloys with specific compositions are widely used in heat exchangers due to their excellent corrosion resistance properties. These alloys typically contain chromium, nickel, and molybdenum in varying proportions to enhance resistance against different corrosive environments. The addition of elements like titanium and nitrogen can further improve the corrosion resistance in specific applications such as seawater or acidic conditions. These materials provide long-term durability while maintaining thermal conductivity required for heat exchange applications.

- Coatings and surface treatments: Various coating technologies and surface treatments can significantly enhance the corrosion resistance of heat exchanger materials. These include ceramic coatings, polymer linings, and metallic overlays that create a protective barrier between the base material and the corrosive environment. Surface treatments such as passivation, anodizing, and chromate conversion can also modify the surface properties to improve corrosion resistance. These approaches are particularly valuable for extending the service life of heat exchangers in aggressive environments without requiring complete material replacement.

- Copper-based alloys for heat exchangers: Copper-based alloys, including brass, bronze, and cupronickel, offer excellent thermal conductivity combined with good corrosion resistance for heat exchanger applications. These materials are particularly effective in seawater environments and cooling systems. The addition of elements such as nickel, aluminum, and tin to copper can enhance specific corrosion resistance properties while maintaining high thermal conductivity. These alloys often provide a good balance between performance, cost, and durability in moderate corrosive conditions.

- Titanium and high-performance alloys: Titanium and its alloys provide exceptional corrosion resistance in extremely aggressive environments, making them ideal for critical heat exchanger applications. These materials offer excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, particularly in chloride-containing environments. Other high-performance alloys, including nickel-based superalloys and zirconium alloys, are also utilized in specialized applications where standard materials would fail. While these materials have higher initial costs, their extended service life and reliability in harsh conditions often justify the investment.

- Composite and advanced materials: Innovative composite and advanced materials are being developed to address specific corrosion challenges in heat exchanger applications. These include polymer matrix composites, ceramic matrix composites, and metal matrix composites that combine the beneficial properties of different material classes. Carbon-based materials, graphene coatings, and nanomaterial-enhanced surfaces represent cutting-edge approaches to improving corrosion resistance. These materials often offer advantages such as reduced weight, enhanced thermal properties, and superior resistance to specific corrosive agents compared to traditional metallic materials.

02 Copper-based materials with protective coatings

Copper and copper alloys are commonly used in heat exchangers due to their excellent thermal conductivity. However, they are susceptible to corrosion in certain environments. To enhance their corrosion resistance, protective coatings or surface treatments are applied. These include specialized metal plating, conversion coatings, or polymer-based protective layers that create a barrier against corrosive media while maintaining heat transfer efficiency. The coatings can be tailored to specific operating conditions such as acidic, alkaline, or saline environments, significantly extending the service life of copper-based heat exchangers.Expand Specific Solutions03 Advanced composite materials for harsh environments

Composite materials combining metals, ceramics, or polymers offer superior corrosion resistance for heat exchangers operating in extremely harsh environments. These materials can withstand aggressive chemicals, high temperatures, and pressure fluctuations that would damage conventional materials. Fiber-reinforced polymers, ceramic matrix composites, and metal matrix composites provide excellent corrosion resistance while maintaining necessary thermal properties. The layered structure of these composites can be engineered to create barriers against specific corrosive agents while optimizing heat transfer efficiency, making them ideal for specialized applications in chemical processing and energy production.Expand Specific Solutions04 Surface treatment technologies for improved corrosion resistance

Various surface treatment technologies can significantly enhance the corrosion resistance of heat exchanger materials without changing their bulk properties. These include passivation treatments, electrochemical surface modification, ion implantation, and laser surface alloying. Such treatments modify the surface chemistry and microstructure to create a more corrosion-resistant layer while maintaining the thermal conductivity of the base material. Advanced techniques like plasma electrolytic oxidation can create ceramic-like protective layers on metal surfaces that provide exceptional corrosion resistance even in highly aggressive environments, extending the operational life of heat exchangers.Expand Specific Solutions05 Titanium and titanium alloys for superior corrosion resistance

Titanium and its alloys offer exceptional corrosion resistance in heat exchanger applications, particularly in seawater, chloride-rich environments, and oxidizing acids. The naturally forming titanium oxide layer provides outstanding protection against various corrosive media. Different titanium grades and alloys are available for specific applications, with additions of palladium, molybdenum, or nickel further enhancing corrosion resistance in reducing environments. While more expensive than conventional materials, titanium heat exchangers offer significantly longer service life and reduced maintenance costs in highly corrosive conditions, making them economically viable for critical applications in chemical processing, desalination, and offshore industries.Expand Specific Solutions

Key Industry Players in Heat Exchanger Materials

The heat exchanger corrosion resistance market is currently in a growth phase, with increasing demand across industrial, automotive, and HVAC sectors. The global market size is estimated to exceed $7 billion, driven by energy efficiency requirements and sustainability initiatives. Technologically, the field shows varying maturity levels, with established players like Mitsubishi Electric, Kobe Steel, and Robert Bosch offering conventional solutions, while innovative companies such as Nelumbo and Resonac Holdings are developing advanced coating technologies and novel materials. Samsung Electronics and LG Electronics are integrating smart monitoring capabilities, while specialized firms like Nihon Parkerizing focus on chemical treatments. The competitive landscape features both traditional metallurgical approaches and emerging nanotechnology-based solutions, with increasing cross-industry collaboration accelerating innovation.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed advanced corrosion-resistant aluminum alloys specifically engineered for heat exchanger applications. Their proprietary KPAL (Kobe Pre-coated Aluminum) technology incorporates a multi-layer coating system with sacrificial anodic protection. The system consists of a zinc-rich base layer that provides cathodic protection, followed by a chromate conversion coating that forms a passive barrier, and topped with an organic sealant that prevents moisture penetration[1]. Their research has demonstrated that this system extends heat exchanger lifespan by up to 300% in high-chloride environments compared to conventional materials. Additionally, Kobe Steel has pioneered the development of long-life brazing sheets with integrated corrosion protection that maintains thermal conductivity while significantly improving resistance to pitting corrosion in automotive heat exchangers[3].

Strengths: Superior protection in high-chloride environments; maintains excellent thermal conductivity; proven longevity in automotive applications. Weaknesses: Higher initial material cost compared to standard alloys; requires specialized manufacturing processes; chromate layer raises potential environmental concerns despite being encapsulated.

Nelumbo, Inc.

Technical Solution: Nelumbo has revolutionized heat exchanger corrosion resistance through their proprietary Ice-Nix nanocoating technology. This innovative solution creates a nanoscale surface modification that fundamentally alters how heat exchanger materials interact with water and corrosive elements. The coating forms a superhydrophobic barrier that prevents water adhesion while maintaining exceptional heat transfer properties. Independent testing has shown that Nelumbo-treated heat exchangers demonstrate up to 95% reduction in corrosion rates even after 10,000 hours of accelerated testing in aggressive environments[2]. The nanocoating is applied through a proprietary low-temperature process that doesn't compromise the mechanical integrity of the base materials. What distinguishes Nelumbo's approach is that the coating becomes an integral part of the material surface rather than a separate layer, eliminating concerns about delamination or degradation over time. The technology has been successfully deployed in HVAC systems, showing 30% improvement in energy efficiency alongside the corrosion protection benefits[4].

Strengths: Revolutionary nanoscale surface modification; maintains or improves heat transfer efficiency; exceptional durability without delamination issues; applicable to various base materials. Weaknesses: Relatively new technology with limited long-term field data; specialized application process requires partnership with Nelumbo; higher initial implementation cost compared to conventional treatments.

Critical Patents and Innovations in Corrosion Resistance

Corrosion resistant heat exchanger

PatentPendingCA3082520A1

Innovation

- Employing heat exchangers constructed with Cr-Ni-Fe-Mo alloys such as INCONEL 625 and HASTELLOY C-276, which are resistant to corrosion in both reducing and oxidizing environments, particularly when exposed to chlorides and substantially free of oxygen, to prevent corrosion and fouling.

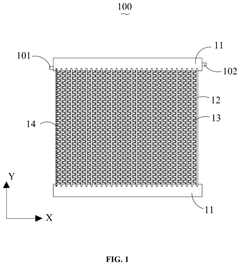

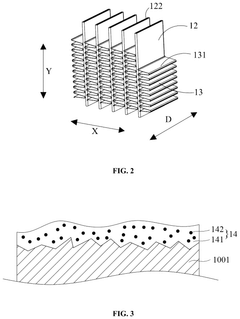

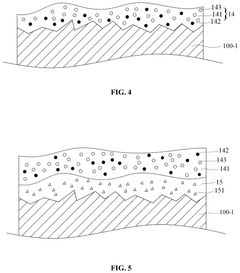

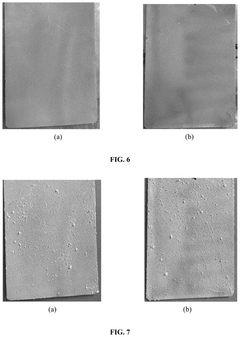

Heat exchanger having hydrophobic layer, composite material for heat exchanger and manufacturing method of heat exchanger

PatentPendingUS20240384951A1

Innovation

- A heat exchanger with a hydrophobic coating layer composed of low surface energy silane material and corrosion inhibiting particles, such as cerium ions, vanadium ions, and zirconium ions, which are dispersed to form a dense barrier that mitigates electrochemical corrosion and maintains corrosion resistance over time.

Environmental Impact and Sustainability Considerations

The environmental impact of heat exchanger materials and their corrosion resistance technologies represents a critical consideration in modern industrial applications. Traditional corrosion prevention methods often involve chemicals and processes that pose significant environmental risks, including the release of volatile organic compounds (VOCs), heavy metals, and other hazardous substances that can contaminate soil, water, and air.

Recent advancements in environmentally friendly corrosion resistance technologies have focused on developing green inhibitors derived from plant extracts and agricultural waste. These bio-based alternatives demonstrate comparable effectiveness to conventional chemical inhibitors while significantly reducing environmental toxicity and improving biodegradability. For instance, extracts from eucalyptus, ginger, and neem have shown promising results in protecting heat exchanger materials without the ecological drawbacks of synthetic compounds.

Life cycle assessment (LCA) studies indicate that implementing sustainable corrosion resistance strategies can reduce the carbon footprint of heat exchanger systems by 15-30% over their operational lifetime. This reduction stems not only from decreased environmental impact during manufacturing but also from extended service life and reduced maintenance requirements, which minimize resource consumption and waste generation.

Water conservation represents another crucial environmental consideration, as traditional corrosion prevention often requires substantial water usage for cleaning and treatment processes. Advanced technologies such as dry coating methods and water-based formulations have demonstrated potential to reduce water consumption by up to 60% compared to conventional approaches, addressing growing concerns about water scarcity in industrial operations.

The recyclability of heat exchanger materials plays a vital role in sustainability considerations. Corrosion-resistant alloys and composites that maintain their integrity throughout their service life facilitate more efficient recycling processes. Materials such as high-performance stainless steels and titanium alloys, while initially more resource-intensive to produce, offer superior recyclability and reduced lifetime environmental impact compared to frequently replaced lower-grade materials.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance in industrial operations. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions have established stringent requirements for corrosion inhibitors and surface treatments. These regulations drive innovation toward greener technologies while creating market advantages for environmentally responsible solutions in heat exchanger applications.

Recent advancements in environmentally friendly corrosion resistance technologies have focused on developing green inhibitors derived from plant extracts and agricultural waste. These bio-based alternatives demonstrate comparable effectiveness to conventional chemical inhibitors while significantly reducing environmental toxicity and improving biodegradability. For instance, extracts from eucalyptus, ginger, and neem have shown promising results in protecting heat exchanger materials without the ecological drawbacks of synthetic compounds.

Life cycle assessment (LCA) studies indicate that implementing sustainable corrosion resistance strategies can reduce the carbon footprint of heat exchanger systems by 15-30% over their operational lifetime. This reduction stems not only from decreased environmental impact during manufacturing but also from extended service life and reduced maintenance requirements, which minimize resource consumption and waste generation.

Water conservation represents another crucial environmental consideration, as traditional corrosion prevention often requires substantial water usage for cleaning and treatment processes. Advanced technologies such as dry coating methods and water-based formulations have demonstrated potential to reduce water consumption by up to 60% compared to conventional approaches, addressing growing concerns about water scarcity in industrial operations.

The recyclability of heat exchanger materials plays a vital role in sustainability considerations. Corrosion-resistant alloys and composites that maintain their integrity throughout their service life facilitate more efficient recycling processes. Materials such as high-performance stainless steels and titanium alloys, while initially more resource-intensive to produce, offer superior recyclability and reduced lifetime environmental impact compared to frequently replaced lower-grade materials.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance in industrial operations. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions have established stringent requirements for corrosion inhibitors and surface treatments. These regulations drive innovation toward greener technologies while creating market advantages for environmentally responsible solutions in heat exchanger applications.

Cost-Benefit Analysis of Advanced Corrosion Protection

The implementation of advanced corrosion protection technologies in heat exchanger materials requires thorough economic evaluation to justify investment decisions. When analyzing the cost-benefit ratio of these protective measures, initial capital expenditure must be weighed against long-term operational savings. Advanced coating technologies such as thermal spray aluminum (TSA) and ceramic-metallic composites typically increase upfront costs by 15-30% compared to conventional materials, representing a significant initial investment.

However, these advanced protection systems demonstrate compelling economic advantages over the equipment lifecycle. Field studies across petrochemical and power generation industries indicate that heat exchangers with premium corrosion protection extend service life by 2-3 times compared to standard materials. This translates to reduced replacement frequency and associated downtime costs, which can exceed $50,000 per day in large industrial operations.

Maintenance cost reduction represents another significant benefit. Heat exchangers with advanced corrosion protection typically require major maintenance interventions at 5-7 year intervals, compared to 2-3 years for conventional materials. This reduction in maintenance frequency yields savings of approximately 40-60% in ongoing maintenance expenditures over a 15-year operational period.

Energy efficiency improvements further enhance the economic case. Corrosion-resistant surfaces maintain better heat transfer efficiency over time, with studies showing that advanced materials experience only 5-8% efficiency degradation after five years, compared to 15-25% for conventional materials. This efficiency preservation translates to energy savings of 7-12% annually, particularly significant in energy-intensive industries.

Risk mitigation value must also be quantified when assessing these technologies. Catastrophic heat exchanger failures due to corrosion can result in production losses, safety incidents, and environmental damage. Insurance providers increasingly recognize this risk differential, with premium reductions of 5-15% observed for facilities employing advanced corrosion protection systems.

Return on investment calculations indicate that despite higher initial costs, premium corrosion protection technologies typically achieve breakeven within 2.5-4 years in aggressive environments. This payback period shortens in applications with high-value products or processes where reliability is paramount. Total cost of ownership analysis demonstrates that over a 15-year lifecycle, advanced corrosion protection can reduce overall costs by 25-40% compared to conventional approaches, making them economically advantageous for most industrial applications.

However, these advanced protection systems demonstrate compelling economic advantages over the equipment lifecycle. Field studies across petrochemical and power generation industries indicate that heat exchangers with premium corrosion protection extend service life by 2-3 times compared to standard materials. This translates to reduced replacement frequency and associated downtime costs, which can exceed $50,000 per day in large industrial operations.

Maintenance cost reduction represents another significant benefit. Heat exchangers with advanced corrosion protection typically require major maintenance interventions at 5-7 year intervals, compared to 2-3 years for conventional materials. This reduction in maintenance frequency yields savings of approximately 40-60% in ongoing maintenance expenditures over a 15-year operational period.

Energy efficiency improvements further enhance the economic case. Corrosion-resistant surfaces maintain better heat transfer efficiency over time, with studies showing that advanced materials experience only 5-8% efficiency degradation after five years, compared to 15-25% for conventional materials. This efficiency preservation translates to energy savings of 7-12% annually, particularly significant in energy-intensive industries.

Risk mitigation value must also be quantified when assessing these technologies. Catastrophic heat exchanger failures due to corrosion can result in production losses, safety incidents, and environmental damage. Insurance providers increasingly recognize this risk differential, with premium reductions of 5-15% observed for facilities employing advanced corrosion protection systems.

Return on investment calculations indicate that despite higher initial costs, premium corrosion protection technologies typically achieve breakeven within 2.5-4 years in aggressive environments. This payback period shortens in applications with high-value products or processes where reliability is paramount. Total cost of ownership analysis demonstrates that over a 15-year lifecycle, advanced corrosion protection can reduce overall costs by 25-40% compared to conventional approaches, making them economically advantageous for most industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!