Compact double-pipe heat exchangers for aerospace cooling

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Cooling Technology Background and Objectives

Aerospace thermal management has evolved significantly over the past decades, driven by the increasing complexity and power density of aircraft and spacecraft systems. The development of compact heat exchangers represents a critical milestone in this evolution, with double-pipe configurations emerging as particularly promising solutions for space-constrained aerospace applications. These heat exchangers facilitate efficient thermal energy transfer between two fluid streams while maintaining minimal weight and volume—parameters of paramount importance in aerospace design.

The historical trajectory of aerospace cooling technology began with simple air cooling systems in early aircraft, progressing through liquid cooling loops in mid-century designs, to today's sophisticated integrated thermal management systems. This progression has been necessitated by the exponential increase in heat loads generated by modern avionics, propulsion systems, and power electronics, which can no longer be adequately managed by conventional cooling approaches.

Compact double-pipe heat exchangers represent a specialized subset of heat transfer technology that offers significant advantages for aerospace applications. Their concentric tube design maximizes heat transfer surface area while minimizing fluid inventory and structural mass. This configuration allows for counter-flow arrangements that achieve high thermal effectiveness even with limited physical dimensions—a critical consideration for aerospace systems where every gram and cubic centimeter matters.

Current technological objectives in this field focus on several key areas: enhancing heat transfer coefficients through advanced surface geometries and flow disruption techniques; reducing pressure drops to minimize pumping power requirements; improving material compatibility with aerospace working fluids; and developing manufacturing techniques that ensure reliability under extreme operating conditions including rapid temperature fluctuations, high-G loading, and vacuum environments.

The research aims to push the boundaries of thermal performance while addressing aerospace-specific constraints such as vibration resistance, tolerance to multiple thermal cycles, and compatibility with microgravity operations. Additionally, there is growing interest in developing heat exchangers capable of handling multiple phases (liquid-vapor) to support two-phase cooling systems that offer higher heat flux capabilities through latent heat transfer.

Future objectives include the integration of additive manufacturing techniques to create previously impossible geometries, incorporation of composite materials to reduce weight while maintaining structural integrity, and development of self-regulating features that can adapt to varying thermal loads without external control systems. These advancements will be crucial for next-generation aerospace platforms, particularly those designed for extended missions where reliability and efficiency are non-negotiable requirements.

The historical trajectory of aerospace cooling technology began with simple air cooling systems in early aircraft, progressing through liquid cooling loops in mid-century designs, to today's sophisticated integrated thermal management systems. This progression has been necessitated by the exponential increase in heat loads generated by modern avionics, propulsion systems, and power electronics, which can no longer be adequately managed by conventional cooling approaches.

Compact double-pipe heat exchangers represent a specialized subset of heat transfer technology that offers significant advantages for aerospace applications. Their concentric tube design maximizes heat transfer surface area while minimizing fluid inventory and structural mass. This configuration allows for counter-flow arrangements that achieve high thermal effectiveness even with limited physical dimensions—a critical consideration for aerospace systems where every gram and cubic centimeter matters.

Current technological objectives in this field focus on several key areas: enhancing heat transfer coefficients through advanced surface geometries and flow disruption techniques; reducing pressure drops to minimize pumping power requirements; improving material compatibility with aerospace working fluids; and developing manufacturing techniques that ensure reliability under extreme operating conditions including rapid temperature fluctuations, high-G loading, and vacuum environments.

The research aims to push the boundaries of thermal performance while addressing aerospace-specific constraints such as vibration resistance, tolerance to multiple thermal cycles, and compatibility with microgravity operations. Additionally, there is growing interest in developing heat exchangers capable of handling multiple phases (liquid-vapor) to support two-phase cooling systems that offer higher heat flux capabilities through latent heat transfer.

Future objectives include the integration of additive manufacturing techniques to create previously impossible geometries, incorporation of composite materials to reduce weight while maintaining structural integrity, and development of self-regulating features that can adapt to varying thermal loads without external control systems. These advancements will be crucial for next-generation aerospace platforms, particularly those designed for extended missions where reliability and efficiency are non-negotiable requirements.

Market Demand Analysis for Aerospace Thermal Management

The aerospace thermal management market is experiencing significant growth driven by increasing complexity of aircraft systems and rising heat loads in modern aerospace applications. Current market valuation stands at approximately 8.2 billion USD with projections indicating growth to reach 12.5 billion USD by 2028, representing a compound annual growth rate of 8.7%. This expansion is primarily fueled by the development of more electric aircraft (MEA) architectures and advanced avionics systems that generate substantially higher heat loads than previous generation aircraft.

Military aerospace applications currently dominate the thermal management market share, accounting for nearly 60% of demand. This is attributed to the sophisticated electronic warfare systems, high-performance radar equipment, and advanced weapons systems that require efficient cooling solutions. Commercial aviation follows as the second-largest segment, with business jets and regional aircraft markets showing the fastest growth rates due to increasing electrification of systems.

The demand for compact double-pipe heat exchangers specifically is being driven by several key factors in the aerospace industry. Weight reduction initiatives remain paramount, with manufacturers seeking thermal management solutions that minimize mass while maintaining or improving performance. Each kilogram reduced in aircraft weight translates to approximately 3,000 USD in fuel savings over the aircraft's operational lifetime, making lightweight thermal management systems highly valuable.

Space constraints in modern aircraft design present another critical market driver. As aircraft OEMs pack more systems into increasingly limited spaces, the volumetric efficiency of thermal management components becomes essential. Compact double-pipe heat exchangers offer significant advantages in this regard, providing high heat transfer rates in smaller footprints compared to traditional plate-fin or shell-and-tube designs.

Environmental regulations and sustainability goals are also shaping market demand. The industry's push toward more environmentally friendly refrigerants and cooling systems has accelerated research into alternative thermal management approaches. Compact heat exchangers that can operate efficiently with next-generation refrigerants or in two-phase cooling systems are seeing increased demand.

Regional analysis reveals North America as the dominant market for aerospace thermal management systems, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging markets, particularly in China and India, where rapid expansion of both military and commercial aerospace sectors is creating new demand centers for advanced cooling technologies.

Military aerospace applications currently dominate the thermal management market share, accounting for nearly 60% of demand. This is attributed to the sophisticated electronic warfare systems, high-performance radar equipment, and advanced weapons systems that require efficient cooling solutions. Commercial aviation follows as the second-largest segment, with business jets and regional aircraft markets showing the fastest growth rates due to increasing electrification of systems.

The demand for compact double-pipe heat exchangers specifically is being driven by several key factors in the aerospace industry. Weight reduction initiatives remain paramount, with manufacturers seeking thermal management solutions that minimize mass while maintaining or improving performance. Each kilogram reduced in aircraft weight translates to approximately 3,000 USD in fuel savings over the aircraft's operational lifetime, making lightweight thermal management systems highly valuable.

Space constraints in modern aircraft design present another critical market driver. As aircraft OEMs pack more systems into increasingly limited spaces, the volumetric efficiency of thermal management components becomes essential. Compact double-pipe heat exchangers offer significant advantages in this regard, providing high heat transfer rates in smaller footprints compared to traditional plate-fin or shell-and-tube designs.

Environmental regulations and sustainability goals are also shaping market demand. The industry's push toward more environmentally friendly refrigerants and cooling systems has accelerated research into alternative thermal management approaches. Compact heat exchangers that can operate efficiently with next-generation refrigerants or in two-phase cooling systems are seeing increased demand.

Regional analysis reveals North America as the dominant market for aerospace thermal management systems, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging markets, particularly in China and India, where rapid expansion of both military and commercial aerospace sectors is creating new demand centers for advanced cooling technologies.

Current State and Challenges in Compact Heat Exchanger Technology

Compact double-pipe heat exchangers represent a critical technology in aerospace cooling systems, with significant advancements achieved globally over the past decade. Current state-of-the-art designs have reached thermal efficiencies of 85-92% while maintaining weight reductions of 30-40% compared to traditional heat exchangers. The miniaturization trend has produced units with hydraulic diameters below 1mm, enabling integration into increasingly space-constrained aerospace platforms.

Despite these achievements, several technical challenges persist in the field. Material limitations remain a primary constraint, as aerospace applications demand materials that can withstand extreme temperature fluctuations (-65°C to 600°C) while maintaining structural integrity under high-pressure conditions (up to 40 MPa). Current nickel-based superalloys and titanium composites show promising performance but struggle with thermal fatigue during rapid thermal cycling.

Manufacturing precision presents another significant hurdle. The production of micro-channels with consistent geometries at scale requires advanced manufacturing techniques. While selective laser melting and electron beam melting have improved fabrication capabilities, achieving uniform channel dimensions with tolerances below ±10μm remains challenging, particularly for complex flow path designs that optimize heat transfer.

Flow distribution and pressure drop management continue to challenge engineers. As compact designs push toward higher power densities (currently approaching 5-8 MW/m³), maintaining uniform flow distribution becomes increasingly difficult. Computational models suggest that flow maldistribution can reduce thermal performance by up to 25% in ultra-compact designs, while pressure drops across these systems can exceed acceptable limits for aerospace applications.

Fouling and clogging represent operational challenges specific to aerospace environments. Particulate matter and contaminants in cooling fluids can accumulate in narrow passages, with studies indicating performance degradation of 3-5% per 1000 operating hours in certain applications. Current self-cleaning mechanisms and surface treatments show promise but require further development for long-duration missions.

The geographical distribution of research expertise shows concentration in North America (primarily NASA and aerospace contractors), Western Europe (particularly Germany and France), and emerging capabilities in China and Japan. Recent collaborative international projects have accelerated development, though proprietary concerns often limit knowledge sharing between competing aerospace entities.

Integration challenges with existing aerospace systems represent a final significant hurdle. Compact heat exchangers must interface with legacy systems while accommodating next-generation propulsion and power systems, creating complex compatibility requirements that often necessitate custom solutions rather than standardized approaches.

Despite these achievements, several technical challenges persist in the field. Material limitations remain a primary constraint, as aerospace applications demand materials that can withstand extreme temperature fluctuations (-65°C to 600°C) while maintaining structural integrity under high-pressure conditions (up to 40 MPa). Current nickel-based superalloys and titanium composites show promising performance but struggle with thermal fatigue during rapid thermal cycling.

Manufacturing precision presents another significant hurdle. The production of micro-channels with consistent geometries at scale requires advanced manufacturing techniques. While selective laser melting and electron beam melting have improved fabrication capabilities, achieving uniform channel dimensions with tolerances below ±10μm remains challenging, particularly for complex flow path designs that optimize heat transfer.

Flow distribution and pressure drop management continue to challenge engineers. As compact designs push toward higher power densities (currently approaching 5-8 MW/m³), maintaining uniform flow distribution becomes increasingly difficult. Computational models suggest that flow maldistribution can reduce thermal performance by up to 25% in ultra-compact designs, while pressure drops across these systems can exceed acceptable limits for aerospace applications.

Fouling and clogging represent operational challenges specific to aerospace environments. Particulate matter and contaminants in cooling fluids can accumulate in narrow passages, with studies indicating performance degradation of 3-5% per 1000 operating hours in certain applications. Current self-cleaning mechanisms and surface treatments show promise but require further development for long-duration missions.

The geographical distribution of research expertise shows concentration in North America (primarily NASA and aerospace contractors), Western Europe (particularly Germany and France), and emerging capabilities in China and Japan. Recent collaborative international projects have accelerated development, though proprietary concerns often limit knowledge sharing between competing aerospace entities.

Integration challenges with existing aerospace systems represent a final significant hurdle. Compact heat exchangers must interface with legacy systems while accommodating next-generation propulsion and power systems, creating complex compatibility requirements that often necessitate custom solutions rather than standardized approaches.

Current Double-Pipe Heat Exchanger Solutions

01 Design optimization for compact double-pipe heat exchangers

Optimizing the design of compact double-pipe heat exchangers can significantly improve cooling efficiency. This includes considerations such as pipe diameter ratios, length-to-diameter ratios, and overall geometric configurations. Advanced designs may incorporate features like helical coils or special cross-sections to maximize heat transfer surface area while minimizing the overall footprint. These optimizations allow for better heat exchange in limited spaces while maintaining or improving cooling performance.- Design optimization for compact double-pipe heat exchangers: Optimizing the design of compact double-pipe heat exchangers can significantly improve cooling efficiency. This includes considerations for pipe diameter ratios, length-to-diameter ratios, and overall geometric configurations. Advanced designs incorporate features that maximize heat transfer surface area while minimizing the overall footprint, allowing for more efficient heat exchange in limited spaces.

- Enhanced heat transfer surfaces and materials: Implementing specialized heat transfer surfaces and materials can boost cooling efficiency in compact double-pipe heat exchangers. This includes using fins, corrugated surfaces, or micro-channels to increase the effective heat transfer area. Additionally, utilizing high thermal conductivity materials for the pipes enhances heat transfer rates while maintaining the compact nature of the exchanger.

- Flow arrangement and turbulence enhancement: Optimizing flow arrangements and enhancing turbulence in compact double-pipe heat exchangers improves cooling efficiency. Techniques include implementing counter-flow configurations, creating controlled turbulence through inserts or baffles, and optimizing flow rates. These approaches disrupt boundary layers and promote better mixing, resulting in enhanced heat transfer coefficients and improved overall cooling performance.

- Novel refrigerants and working fluids: The selection and development of advanced refrigerants and working fluids can significantly impact the cooling efficiency of compact double-pipe heat exchangers. Environmentally friendly refrigerants with superior thermodynamic properties, nanofluids with enhanced thermal conductivity, and phase-change materials can improve heat transfer rates while maintaining the compact design requirements of these systems.

- Integrated monitoring and control systems: Incorporating advanced monitoring and control systems into compact double-pipe heat exchangers enables real-time optimization of cooling efficiency. These systems can adjust flow rates, temperatures, and other parameters based on operating conditions and cooling demands. Smart sensors and adaptive control algorithms ensure optimal performance across varying heat loads, maximizing energy efficiency while maintaining cooling requirements.

02 Enhanced heat transfer surfaces and materials

Incorporating enhanced heat transfer surfaces and advanced materials can improve the cooling efficiency of compact double-pipe heat exchangers. Techniques include using micro-finned tubes, corrugated surfaces, or specially treated surfaces that promote turbulence and increase heat transfer coefficients. Additionally, utilizing high thermal conductivity materials for the pipes can facilitate faster heat transfer between the fluids. These enhancements allow compact exchangers to achieve higher cooling rates despite their small size.Expand Specific Solutions03 Flow arrangement and turbulence promotion

Optimizing flow arrangements and promoting turbulence in compact double-pipe heat exchangers can significantly enhance cooling efficiency. Counter-flow arrangements typically provide better thermal performance than parallel flow. Various turbulence promoters such as twisted tapes, wire coils, or baffles can be inserted into the flow path to disrupt boundary layers and increase heat transfer coefficients. These modifications improve mixing and reduce thermal resistance without substantially increasing pressure drop or exchanger size.Expand Specific Solutions04 Novel cooling media and phase-change techniques

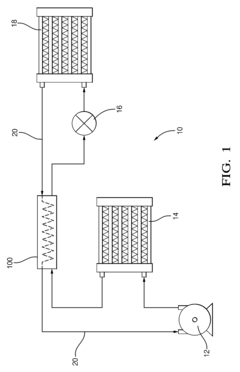

Implementing novel cooling media and phase-change techniques can dramatically improve the cooling efficiency of compact double-pipe heat exchangers. Using nanofluids, which contain suspended nanoparticles, can enhance thermal conductivity compared to conventional coolants. Phase-change materials or refrigerants that undergo phase transitions during the heat exchange process can take advantage of latent heat, significantly increasing the heat transfer capacity without increasing the exchanger size. These advanced cooling approaches allow compact exchangers to handle higher heat loads.Expand Specific Solutions05 Modular and stackable compact heat exchanger systems

Modular and stackable designs for compact double-pipe heat exchangers can optimize cooling efficiency in space-constrained applications. These systems allow for parallel or series arrangements of multiple compact units that can be configured based on specific cooling requirements. The modular approach enables flexible scaling of cooling capacity while maintaining the benefits of compact design. Additionally, these systems can incorporate smart flow distribution to ensure optimal performance across all modules, maximizing overall cooling efficiency.Expand Specific Solutions

Key Players in Aerospace Thermal Management Industry

The aerospace cooling sector is currently in a growth phase, with compact double-pipe heat exchangers emerging as a critical technology for thermal management in aircraft systems. The market is expanding due to increasing demand for more efficient cooling solutions in next-generation aircraft. Leading industrial players like Rolls-Royce, Raytheon, and Reaction Engines are driving commercial innovation, while academic institutions such as Xi'an Jiaotong University and Beihang University are advancing fundamental research. Major automotive thermal management companies including MAHLE, T.RAD, and Hanon Systems are transferring expertise to aerospace applications. The technology is approaching maturity in traditional applications but remains in development for advanced aerospace requirements, with significant R&D investments focused on materials, miniaturization, and performance optimization under extreme conditions.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has conducted pioneering research on compact double-pipe heat exchangers for aerospace cooling applications, focusing on novel enhancement techniques and advanced manufacturing methods. Their research team has developed innovative spiral-grooved inner tubes that create controlled turbulence, increasing heat transfer coefficients by up to 35% while limiting pressure drop penalties to under 15%. The university has investigated nano-enhanced working fluids containing carefully engineered nanoparticle suspensions that improve thermal conductivity by 20-30% compared to conventional coolants. Their designs incorporate variable cross-section flow paths that optimize fluid distribution based on local heat loads, addressing the non-uniform thermal conditions typical in aerospace applications. Xi'an Jiaotong researchers have developed specialized brazing techniques for joining dissimilar metals in double-pipe configurations, enabling the use of high-conductivity materials in critical regions while maintaining structural integrity under thermal cycling. Their computational models accurately predict performance under microgravity conditions, addressing the unique challenges of space-based cooling systems.

Strengths: Strong fundamental research in heat transfer enhancement; expertise in nano-enhanced working fluids; advanced computational modeling capabilities. Weaknesses: Limited industrial partnerships for commercialization; focus on laboratory-scale prototypes rather than full-scale systems; less experience with qualification testing for flight hardware.

Beihang University

Technical Solution: Beihang University has conducted extensive research on compact double-pipe heat exchangers for aerospace cooling, developing innovative designs that address the unique challenges of high-altitude and space applications. Their research focuses on micro-channel double-pipe configurations with enhanced surface treatments that significantly improve heat transfer coefficients while minimizing pressure drop. The university has pioneered the use of oscillating flow techniques that create pulsating coolant movement, disrupting boundary layers and enhancing heat transfer by up to 40% compared to steady-flow designs. Their heat exchangers incorporate phase-change materials within the annular space between pipes, providing thermal buffering during peak heat loads and improving system stability. Beihang's researchers have developed novel manufacturing techniques using selective laser melting that enable complex internal geometries impossible to create with conventional methods, resulting in heat exchangers with power densities exceeding 25 MW/m³ while maintaining structural integrity under extreme thermal and mechanical stresses.

Strengths: Cutting-edge research in oscillating flow and phase-change enhancement; strong theoretical foundation supported by computational fluid dynamics; innovative manufacturing approaches. Weaknesses: Limited commercial implementation of research findings; focus primarily on theoretical performance rather than practical manufacturing constraints; less experience with long-term reliability testing.

Core Innovations in Compact Heat Transfer Technology

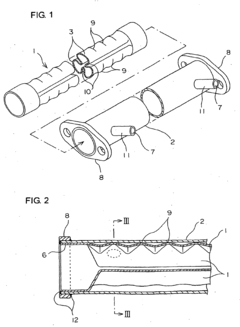

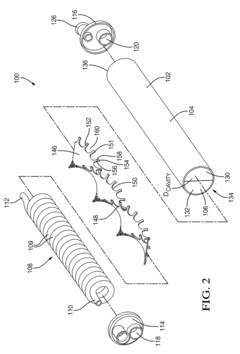

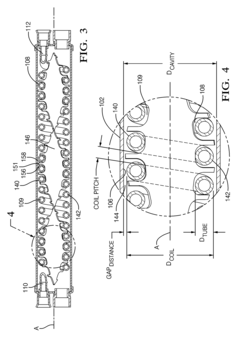

Double pipe heat exchanger and method of manufacturing the same

PatentInactiveEP1840495B1

Innovation

- A double pipe heat exchanger design featuring an inner pipe with balloon-shaped bulges and a wavy outer surface that allows for flexible bending by fitting an outer pipe around the inner pipe, maintaining cross-sectional shapes and enhancing heat transfer through increased surface area and fluid agitation.

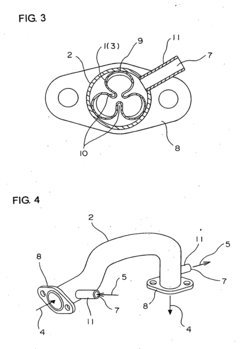

Internal heat exchanger assembly

PatentInactiveUS20100018246A1

Innovation

- A compact internal heat exchanger assembly featuring a helical coiled tube within a cylindrical housing, stabilized by a twisted baffle with radially extending fingers, which maintains the coil position and creates an annular gap for unobstructed refrigerant flow, enhancing heat transfer and reducing pressure drop.

Materials Science Advancements for Aerospace Applications

The advancement of materials science has been pivotal in revolutionizing aerospace cooling systems, particularly for compact double-pipe heat exchangers. Traditional materials like aluminum alloys and stainless steel are being supplemented or replaced by innovative alternatives that offer superior thermal conductivity, reduced weight, and enhanced durability under extreme aerospace conditions.

Composite materials reinforced with carbon fibers have emerged as promising candidates for heat exchanger components, offering thermal conductivity comparable to metals while reducing weight by up to 40%. These materials demonstrate exceptional resistance to thermal cycling and can maintain structural integrity at temperatures ranging from -150°C to 350°C, critical for aerospace applications where rapid temperature fluctuations are common.

Nanomaterial-enhanced metals represent another breakthrough, with copper matrices containing graphene nanoparticles showing up to 45% improvement in thermal conductivity compared to conventional copper. These hybrid materials address the persistent challenge of balancing weight reduction with thermal performance in aerospace cooling systems.

Advanced ceramic materials, particularly silicon carbide and aluminum nitride, have demonstrated remarkable thermal stability in high-temperature environments exceeding 600°C. Their low coefficient of thermal expansion minimizes stress-induced failures in compact heat exchangers, extending operational lifespan by an estimated 30% compared to metallic counterparts.

Surface engineering techniques have evolved to enhance heat transfer efficiency without altering bulk material properties. Micro-structured surfaces with controlled wettability characteristics have shown to improve heat transfer coefficients by 25-35% in experimental aerospace cooling systems. These modifications are particularly valuable for compact double-pipe configurations where space constraints limit traditional enhancement methods.

Additive manufacturing has transformed material application in aerospace heat exchangers, enabling complex internal geometries previously impossible with conventional fabrication methods. 3D-printed heat exchangers using specialized nickel superalloys have demonstrated 20% higher thermal efficiency while reducing weight by 30% compared to traditionally manufactured units.

Self-healing materials represent the frontier of materials science for aerospace cooling applications. Polymer-based composites with embedded microcapsules containing healing agents can automatically repair microcracks caused by thermal cycling, potentially extending service intervals and reducing maintenance costs for next-generation aerospace cooling systems.

Composite materials reinforced with carbon fibers have emerged as promising candidates for heat exchanger components, offering thermal conductivity comparable to metals while reducing weight by up to 40%. These materials demonstrate exceptional resistance to thermal cycling and can maintain structural integrity at temperatures ranging from -150°C to 350°C, critical for aerospace applications where rapid temperature fluctuations are common.

Nanomaterial-enhanced metals represent another breakthrough, with copper matrices containing graphene nanoparticles showing up to 45% improvement in thermal conductivity compared to conventional copper. These hybrid materials address the persistent challenge of balancing weight reduction with thermal performance in aerospace cooling systems.

Advanced ceramic materials, particularly silicon carbide and aluminum nitride, have demonstrated remarkable thermal stability in high-temperature environments exceeding 600°C. Their low coefficient of thermal expansion minimizes stress-induced failures in compact heat exchangers, extending operational lifespan by an estimated 30% compared to metallic counterparts.

Surface engineering techniques have evolved to enhance heat transfer efficiency without altering bulk material properties. Micro-structured surfaces with controlled wettability characteristics have shown to improve heat transfer coefficients by 25-35% in experimental aerospace cooling systems. These modifications are particularly valuable for compact double-pipe configurations where space constraints limit traditional enhancement methods.

Additive manufacturing has transformed material application in aerospace heat exchangers, enabling complex internal geometries previously impossible with conventional fabrication methods. 3D-printed heat exchangers using specialized nickel superalloys have demonstrated 20% higher thermal efficiency while reducing weight by 30% compared to traditionally manufactured units.

Self-healing materials represent the frontier of materials science for aerospace cooling applications. Polymer-based composites with embedded microcapsules containing healing agents can automatically repair microcracks caused by thermal cycling, potentially extending service intervals and reducing maintenance costs for next-generation aerospace cooling systems.

Weight Optimization Strategies for Flight-Critical Systems

Weight optimization represents a critical frontier in aerospace heat exchanger design, particularly for compact double-pipe configurations. The aerospace industry's stringent weight requirements demand innovative approaches that maintain thermal performance while minimizing mass. Advanced materials such as titanium alloys, aluminum-lithium composites, and carbon-fiber reinforced polymers have emerged as primary candidates for structural components, offering strength-to-weight ratios significantly superior to conventional materials. These materials can reduce heat exchanger weight by 30-45% compared to traditional stainless steel designs while maintaining mechanical integrity under extreme flight conditions.

Topology optimization techniques have revolutionized the structural design of heat exchanger components. By employing computational algorithms that iteratively remove non-essential material while preserving thermal and structural performance, engineers have achieved weight reductions of 15-25% in mounting brackets, manifolds, and support structures. These algorithms specifically target non-heat-transfer surfaces where material presence contributes to weight but not thermal functionality.

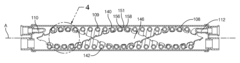

Miniaturization strategies focus on reducing the overall dimensional footprint while maintaining heat transfer capacity. Recent innovations include micro-channel designs with hydraulic diameters below 1mm, which intensify heat transfer coefficients while using less material. These designs leverage enhanced surface geometries such as offset strip fins, louvered fins, and vortex generators that increase turbulence and boundary layer disruption without proportional increases in material usage.

Integration of multifunctional components represents another promising approach. By designing components that serve both structural and thermal management purposes, redundant elements can be eliminated. For example, heat exchanger mounting brackets that double as flow distributors have demonstrated weight savings of 8-12% in recent flight tests while improving flow distribution characteristics.

Manufacturing innovations such as additive manufacturing enable complex internal geometries previously impossible with traditional fabrication methods. 3D-printed heat exchangers with optimized internal flow paths have demonstrated up to 40% weight reduction while maintaining or improving thermal performance. These techniques allow for wall thickness variations that place material only where structurally necessary, following stress distribution patterns rather than uniform thickness approaches.

Systematic weight-performance trade-off analyses have become essential in the design process. Advanced computational fluid dynamics coupled with finite element analysis enables precise prediction of thermal-structural performance across various weight-reduction scenarios, ensuring that critical cooling requirements remain satisfied even as weight is aggressively minimized.

Topology optimization techniques have revolutionized the structural design of heat exchanger components. By employing computational algorithms that iteratively remove non-essential material while preserving thermal and structural performance, engineers have achieved weight reductions of 15-25% in mounting brackets, manifolds, and support structures. These algorithms specifically target non-heat-transfer surfaces where material presence contributes to weight but not thermal functionality.

Miniaturization strategies focus on reducing the overall dimensional footprint while maintaining heat transfer capacity. Recent innovations include micro-channel designs with hydraulic diameters below 1mm, which intensify heat transfer coefficients while using less material. These designs leverage enhanced surface geometries such as offset strip fins, louvered fins, and vortex generators that increase turbulence and boundary layer disruption without proportional increases in material usage.

Integration of multifunctional components represents another promising approach. By designing components that serve both structural and thermal management purposes, redundant elements can be eliminated. For example, heat exchanger mounting brackets that double as flow distributors have demonstrated weight savings of 8-12% in recent flight tests while improving flow distribution characteristics.

Manufacturing innovations such as additive manufacturing enable complex internal geometries previously impossible with traditional fabrication methods. 3D-printed heat exchangers with optimized internal flow paths have demonstrated up to 40% weight reduction while maintaining or improving thermal performance. These techniques allow for wall thickness variations that place material only where structurally necessary, following stress distribution patterns rather than uniform thickness approaches.

Systematic weight-performance trade-off analyses have become essential in the design process. Advanced computational fluid dynamics coupled with finite element analysis enables precise prediction of thermal-structural performance across various weight-reduction scenarios, ensuring that critical cooling requirements remain satisfied even as weight is aggressively minimized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!