Design of high-efficiency condensers for HVAC systems

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HVAC Condenser Technology Evolution and Objectives

The evolution of HVAC condenser technology spans over a century, beginning with early refrigeration systems in the late 19th century. The first commercial air conditioning system, developed by Willis Carrier in 1902, utilized primitive condensers that were inefficient by today's standards. Through the mid-20th century, technological advancements focused primarily on size reduction and improved heat transfer capabilities, with significant progress occurring during the post-World War II construction boom.

The 1970s energy crisis marked a pivotal turning point, driving research toward energy efficiency as a primary design consideration. This period saw the introduction of enhanced tube surfaces and improved fin designs that substantially increased heat transfer efficiency. The 1990s brought computerized design tools that enabled more precise thermal modeling and optimization of condenser geometries, leading to further efficiency gains.

Recent technological trends have centered on sustainability and environmental concerns. The phase-out of harmful refrigerants under the Montreal Protocol and subsequent international agreements has necessitated redesigns compatible with new refrigerant types. Simultaneously, miniaturization efforts have yielded more compact condensers without sacrificing performance, particularly important for residential and commercial applications where space constraints are significant.

Current research objectives in high-efficiency condenser design focus on several key areas. Material science innovations are exploring advanced heat-conductive materials, including specialized copper alloys, aluminum composites, and emerging nanomaterials that promise superior thermal conductivity. Surface engineering research aims to optimize microscale features that enhance heat transfer while minimizing airflow resistance.

Smart condenser technology represents another frontier, incorporating sensors and adaptive controls that optimize performance based on real-time environmental conditions and system demands. This approach enables dynamic adjustment of operating parameters to maintain peak efficiency across varying loads and ambient conditions.

The ultimate technical objectives include achieving energy efficiency ratings that exceed current best-in-class systems by 30-40%, reducing material usage by 25% through optimized designs, and developing condensers capable of operating efficiently across wider temperature ranges. Additionally, there are goals to create systems that integrate seamlessly with renewable energy sources and smart building management systems.

These objectives align with broader industry trends toward net-zero buildings and reduced environmental impact, positioning high-efficiency condenser technology as a critical component in sustainable HVAC system development. The convergence of computational fluid dynamics, advanced materials, and intelligent control systems is expected to drive the next generation of breakthroughs in this field.

The 1970s energy crisis marked a pivotal turning point, driving research toward energy efficiency as a primary design consideration. This period saw the introduction of enhanced tube surfaces and improved fin designs that substantially increased heat transfer efficiency. The 1990s brought computerized design tools that enabled more precise thermal modeling and optimization of condenser geometries, leading to further efficiency gains.

Recent technological trends have centered on sustainability and environmental concerns. The phase-out of harmful refrigerants under the Montreal Protocol and subsequent international agreements has necessitated redesigns compatible with new refrigerant types. Simultaneously, miniaturization efforts have yielded more compact condensers without sacrificing performance, particularly important for residential and commercial applications where space constraints are significant.

Current research objectives in high-efficiency condenser design focus on several key areas. Material science innovations are exploring advanced heat-conductive materials, including specialized copper alloys, aluminum composites, and emerging nanomaterials that promise superior thermal conductivity. Surface engineering research aims to optimize microscale features that enhance heat transfer while minimizing airflow resistance.

Smart condenser technology represents another frontier, incorporating sensors and adaptive controls that optimize performance based on real-time environmental conditions and system demands. This approach enables dynamic adjustment of operating parameters to maintain peak efficiency across varying loads and ambient conditions.

The ultimate technical objectives include achieving energy efficiency ratings that exceed current best-in-class systems by 30-40%, reducing material usage by 25% through optimized designs, and developing condensers capable of operating efficiently across wider temperature ranges. Additionally, there are goals to create systems that integrate seamlessly with renewable energy sources and smart building management systems.

These objectives align with broader industry trends toward net-zero buildings and reduced environmental impact, positioning high-efficiency condenser technology as a critical component in sustainable HVAC system development. The convergence of computational fluid dynamics, advanced materials, and intelligent control systems is expected to drive the next generation of breakthroughs in this field.

Market Demand Analysis for High-Efficiency HVAC Systems

The global HVAC market is experiencing significant growth driven by increasing demand for energy-efficient solutions. The high-efficiency condenser segment specifically is projected to grow at a CAGR of 6.8% through 2030, outpacing the broader HVAC market. This accelerated growth reflects the urgent need for systems that reduce energy consumption while maintaining or improving cooling performance.

Commercial buildings represent the largest market segment for high-efficiency condensers, accounting for approximately 45% of the total market share. This dominance stems from stringent energy regulations and the substantial cost savings potential for large-scale operations. The residential sector follows with growing adoption rates as consumers become more environmentally conscious and utility costs continue to rise.

Regionally, North America and Europe lead in high-efficiency condenser adoption due to established regulatory frameworks promoting energy efficiency. The Asia-Pacific region, particularly China and India, represents the fastest-growing market with urbanization and rising disposable incomes driving demand for advanced HVAC systems. Middle Eastern countries show increasing interest in high-efficiency condensers due to extreme climate conditions and growing focus on sustainable development.

Market research indicates that end-users are willing to pay a premium of 15-20% for high-efficiency condensers that demonstrate energy savings of 30% or more compared to conventional systems. The return on investment period is a critical factor, with most commercial customers expecting payback within 2-3 years and residential users within 3-5 years.

Key market drivers include increasingly stringent energy efficiency regulations worldwide, rising energy costs, growing environmental awareness, and technological advancements enabling better performance. The push toward smart buildings and IoT integration is creating additional demand for condensers that can communicate with building management systems for optimized performance.

Challenges in market adoption include higher initial costs, lack of awareness about long-term benefits, and installation complexities. The retrofit market presents significant opportunities but faces technical constraints when integrating new high-efficiency condensers with existing HVAC infrastructure.

Industry surveys reveal that reliability, energy efficiency, and maintenance costs are the top three factors influencing purchasing decisions for HVAC condensers. Noise levels and physical footprint are becoming increasingly important considerations, particularly in urban residential applications.

Commercial buildings represent the largest market segment for high-efficiency condensers, accounting for approximately 45% of the total market share. This dominance stems from stringent energy regulations and the substantial cost savings potential for large-scale operations. The residential sector follows with growing adoption rates as consumers become more environmentally conscious and utility costs continue to rise.

Regionally, North America and Europe lead in high-efficiency condenser adoption due to established regulatory frameworks promoting energy efficiency. The Asia-Pacific region, particularly China and India, represents the fastest-growing market with urbanization and rising disposable incomes driving demand for advanced HVAC systems. Middle Eastern countries show increasing interest in high-efficiency condensers due to extreme climate conditions and growing focus on sustainable development.

Market research indicates that end-users are willing to pay a premium of 15-20% for high-efficiency condensers that demonstrate energy savings of 30% or more compared to conventional systems. The return on investment period is a critical factor, with most commercial customers expecting payback within 2-3 years and residential users within 3-5 years.

Key market drivers include increasingly stringent energy efficiency regulations worldwide, rising energy costs, growing environmental awareness, and technological advancements enabling better performance. The push toward smart buildings and IoT integration is creating additional demand for condensers that can communicate with building management systems for optimized performance.

Challenges in market adoption include higher initial costs, lack of awareness about long-term benefits, and installation complexities. The retrofit market presents significant opportunities but faces technical constraints when integrating new high-efficiency condensers with existing HVAC infrastructure.

Industry surveys reveal that reliability, energy efficiency, and maintenance costs are the top three factors influencing purchasing decisions for HVAC condensers. Noise levels and physical footprint are becoming increasingly important considerations, particularly in urban residential applications.

Current Condenser Technology Landscape and Barriers

The HVAC condenser technology landscape has evolved significantly over the past decades, with several distinct categories dominating the market. Air-cooled condensers remain the most widely deployed solution due to their simplicity and lower installation costs, particularly in residential and light commercial applications. Water-cooled condensers, while more energy-efficient, are primarily utilized in larger commercial and industrial settings where their higher efficiency justifies increased installation and maintenance expenses. Evaporative condensers represent a middle-ground solution, offering improved efficiency over air-cooled systems while avoiding some of the complexity of water-cooled designs.

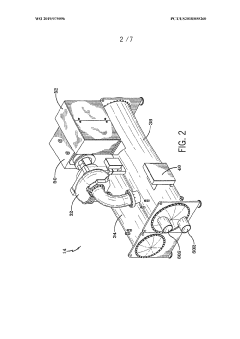

Recent technological advancements have introduced microchannel condensers, which utilize aluminum flat tubes with multiple small channels to enhance heat transfer efficiency while reducing refrigerant charge. Variable speed condenser fans have also gained prominence, allowing systems to modulate capacity based on demand rather than operating in simple on/off cycles, thereby improving part-load efficiency and system longevity.

Despite these innovations, the condenser technology landscape faces significant barriers to further advancement. Heat transfer limitations represent a fundamental physical constraint, as conventional designs approach theoretical efficiency limits. The trade-off between pressure drop and heat transfer efficiency remains a persistent challenge, with increased turbulence improving heat transfer but requiring greater fan or pump energy.

Material constraints also pose substantial challenges, with copper—the traditional material of choice for its excellent thermal conductivity—facing price volatility and sustainability concerns. Alternative materials often present compromises in either thermal performance, durability, or cost-effectiveness. Refrigerant compatibility issues have become increasingly prominent as the industry transitions away from high-GWP refrigerants toward more environmentally friendly alternatives, requiring redesigns of heat exchanger geometries and materials.

Space constraints represent another significant barrier, particularly in retrofit applications and urban environments where available installation space is limited. This drives the need for more compact designs without sacrificing performance. Manufacturing complexity and cost barriers also impede widespread adoption of advanced technologies like microchannel condensers, which require specialized production processes and quality control measures.

Fouling and maintenance challenges persist across all condenser types, with performance degradation over time due to dust accumulation, scale formation, or biological growth. This necessitates regular maintenance that is often neglected in practice, leading to significant efficiency losses in real-world operations. Finally, integration challenges with building management systems and smart grid capabilities limit the potential for system-level optimization, representing a frontier for future development.

Recent technological advancements have introduced microchannel condensers, which utilize aluminum flat tubes with multiple small channels to enhance heat transfer efficiency while reducing refrigerant charge. Variable speed condenser fans have also gained prominence, allowing systems to modulate capacity based on demand rather than operating in simple on/off cycles, thereby improving part-load efficiency and system longevity.

Despite these innovations, the condenser technology landscape faces significant barriers to further advancement. Heat transfer limitations represent a fundamental physical constraint, as conventional designs approach theoretical efficiency limits. The trade-off between pressure drop and heat transfer efficiency remains a persistent challenge, with increased turbulence improving heat transfer but requiring greater fan or pump energy.

Material constraints also pose substantial challenges, with copper—the traditional material of choice for its excellent thermal conductivity—facing price volatility and sustainability concerns. Alternative materials often present compromises in either thermal performance, durability, or cost-effectiveness. Refrigerant compatibility issues have become increasingly prominent as the industry transitions away from high-GWP refrigerants toward more environmentally friendly alternatives, requiring redesigns of heat exchanger geometries and materials.

Space constraints represent another significant barrier, particularly in retrofit applications and urban environments where available installation space is limited. This drives the need for more compact designs without sacrificing performance. Manufacturing complexity and cost barriers also impede widespread adoption of advanced technologies like microchannel condensers, which require specialized production processes and quality control measures.

Fouling and maintenance challenges persist across all condenser types, with performance degradation over time due to dust accumulation, scale formation, or biological growth. This necessitates regular maintenance that is often neglected in practice, leading to significant efficiency losses in real-world operations. Finally, integration challenges with building management systems and smart grid capabilities limit the potential for system-level optimization, representing a frontier for future development.

Current High-Efficiency Condenser Design Approaches

01 Design improvements for condenser efficiency

Various design improvements can enhance condenser efficiency, including optimized tube arrangements, improved heat transfer surfaces, and innovative structural configurations. These design elements help to maximize heat exchange, reduce thermal resistance, and improve overall performance of condensers in various applications.- Design improvements for condenser efficiency: Various design improvements can enhance condenser efficiency. These include optimized tube arrangements, improved heat transfer surfaces, and innovative structural designs that minimize thermal resistance. By implementing these design modifications, condensers can achieve better heat exchange rates, reduced energy consumption, and overall improved performance in various applications.

- Enhanced heat transfer mechanisms: Heat transfer in condensers can be enhanced through various mechanisms such as turbulence promotion, surface area optimization, and improved material conductivity. These mechanisms facilitate better thermal exchange between the working fluid and cooling medium, resulting in more efficient condensation processes. Techniques may include specialized fins, surface treatments, or flow pattern modifications that maximize the heat transfer coefficient.

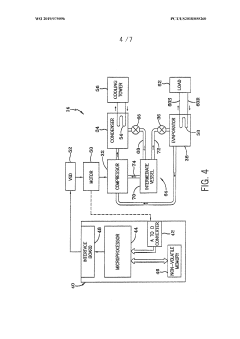

- Cooling system configurations: Different cooling system configurations can significantly impact condenser efficiency. These include air-cooled, water-cooled, and hybrid systems, each with specific advantages for particular applications. The arrangement of cooling elements, flow paths, and integration with other system components can be optimized to reduce energy consumption while maintaining or improving condensation performance.

- Pressure and flow optimization: Optimizing pressure conditions and flow characteristics within condensers can lead to significant efficiency improvements. This includes managing pressure drops, controlling flow rates, and ensuring proper distribution of working fluids. By carefully balancing these parameters, condensation can occur more effectively, reducing energy requirements and improving overall system performance.

- Material selection and surface treatments: The choice of materials and surface treatments plays a crucial role in condenser efficiency. High thermal conductivity materials, corrosion-resistant alloys, and specialized coatings can enhance heat transfer while extending operational life. Surface modifications such as micro-structuring or hydrophobic/hydrophilic treatments can also improve condensation behavior and reduce fouling, maintaining efficiency over longer periods.

02 Surface enhancement techniques for condensers

Surface enhancement techniques involve modifying the condenser surfaces to improve heat transfer. This includes creating specialized surface textures, coatings, or structures that promote condensation, reduce fouling, and enhance thermal conductivity, thereby improving the overall efficiency of the condenser system.Expand Specific Solutions03 Cooling system optimization for condensers

Optimizing cooling systems for condensers involves improving the flow of cooling media, enhancing heat dissipation mechanisms, and implementing advanced cooling techniques. These optimizations help to maintain ideal temperature gradients and maximize the efficiency of the condensation process.Expand Specific Solutions04 Material selection for improved condenser performance

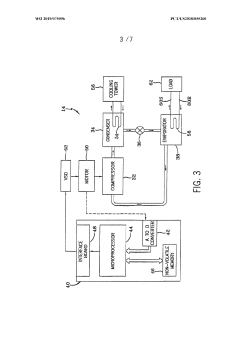

The selection of appropriate materials for condenser construction significantly impacts efficiency. Materials with high thermal conductivity, corrosion resistance, and durability can enhance heat transfer rates, extend operational lifespan, and reduce maintenance requirements, leading to improved overall condenser efficiency.Expand Specific Solutions05 Advanced control systems for condenser operation

Implementing advanced control systems allows for real-time monitoring and adjustment of condenser operating parameters. These systems can optimize flow rates, pressure levels, and temperature differentials based on changing conditions, ensuring that condensers operate at peak efficiency under varying loads and environmental conditions.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The high-efficiency condenser market for HVAC systems is currently in a growth phase, with increasing demand driven by energy efficiency regulations and sustainability concerns. The market is projected to reach significant scale as global HVAC installations continue to rise. Leading players include established HVAC manufacturers like Johnson Controls, which dominates through innovation in thermal management technologies, and Gree Electric Appliances, leveraging its manufacturing scale. Other significant competitors include DENSO, Valeo Thermal Systems, and Lennox Industries, each bringing specialized expertise in heat exchange technology. The technology landscape shows varying maturity levels, with traditional air-cooled condensers being well-established while advanced technologies like microchannel condensers and liquid cooling systems (developed by companies like Sugon Data Energy) represent emerging innovations with superior efficiency potential.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed a multi-path heat exchange condenser technology that significantly improves HVAC efficiency. Their design incorporates microchannel heat exchangers with optimized refrigerant flow paths that increase the heat transfer coefficient by up to 30% compared to traditional tube-fin condensers. The system features a unique refrigerant distribution system that ensures uniform cooling across the entire condenser surface, minimizing hotspots and improving overall thermal performance. Gree's condensers also implement advanced hydrophilic aluminum fin coatings that enhance condensate drainage and prevent performance degradation over time. Their latest R32 refrigerant-compatible condensers incorporate specially designed pressure drop management systems that optimize refrigerant flow while maintaining high heat rejection rates even under varying ambient conditions.

Strengths: Superior heat transfer efficiency with up to 30% improvement over conventional designs; excellent condensate management through hydrophilic coatings; optimized for newer, environmentally friendly refrigerants. Weaknesses: Higher initial manufacturing costs; more complex design requires specialized manufacturing processes; potential for increased maintenance requirements due to smaller flow channels.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has pioneered the York® OptiSpeed™ variable-speed condenser technology that dynamically adjusts fan speeds based on real-time system demands and ambient conditions. Their condensers incorporate advanced microchannel coil designs with optimized tube geometries that increase heat transfer surface area by up to 40% while reducing refrigerant charge requirements by approximately 30%. The company's Smart Equipment™ control system integrates with these high-efficiency condensers to provide predictive maintenance capabilities and adaptive performance optimization. Johnson Controls' condensers also feature proprietary coil coatings that extend equipment life in corrosive environments while maintaining thermal efficiency. Their latest innovations include integrated free cooling economizers that can bypass the compressor during favorable ambient conditions, reducing energy consumption by up to 75% during partial load operation.

Strengths: Intelligent control systems that optimize performance across varying conditions; reduced refrigerant requirements providing environmental and cost benefits; superior corrosion resistance extending equipment life. Weaknesses: Higher upfront costs compared to conventional systems; more complex control systems require specialized maintenance personnel; potential for increased fan power consumption in certain operating modes.

Critical Patents and Innovations in Condenser Technology

Systems and methods for low pressure condenser inlet baffles

PatentWO2019075096A1

Innovation

- The implementation of a condenser design with a refrigerant inlet baffle placement that optimizes the balance between pressure drop and tube layout room by using a bell mouth tapered inlet pipe and a vertically positioned inlet baffle, where the upper layout height is between 0.25 to 0.50 of the inlet pipe's inner diameter, allowing for efficient distribution of low-pressure refrigerant gas and heat exchange across a tube bundle.

Condenser

PatentWO2019039401A1

Innovation

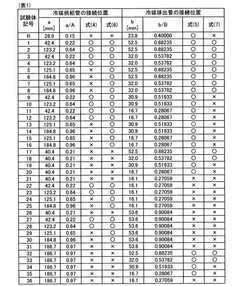

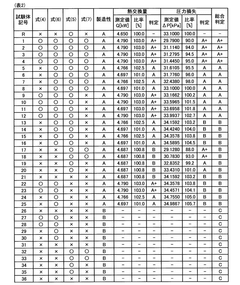

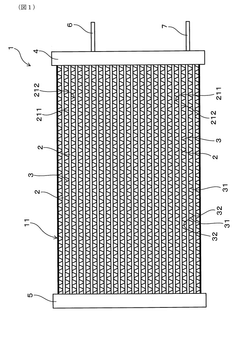

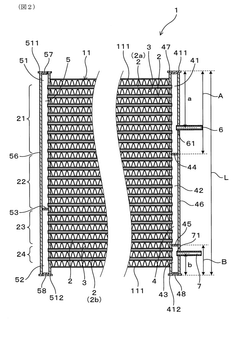

- A condenser design with a core of parallel flat tubes and fins, optimized header configurations, and specific ratios for tube group distribution and header lengths to enhance heat transfer area and reduce pressure loss, tailored for dedicated cooling operations.

Energy Efficiency Standards and Regulations

The regulatory landscape for HVAC condenser efficiency has evolved significantly over the past decades, with increasingly stringent standards driving innovation in the industry. The U.S. Department of Energy (DOE) has established minimum efficiency requirements for air conditioning and heat pump systems through its Appliance and Equipment Standards Program, with the most recent updates requiring higher Seasonal Energy Efficiency Ratio (SEER) and Energy Efficiency Ratio (EER) ratings. These standards directly impact condenser design, as manufacturers must achieve specified performance levels while maintaining competitive pricing.

The European Union's Ecodesign Directive similarly imposes strict efficiency requirements through its Seasonal Coefficient of Performance (SCOP) and Seasonal Energy Efficiency Ratio (SEER) metrics. These regulations have accelerated the transition from traditional refrigerants to more environmentally friendly alternatives with lower Global Warming Potential (GWP), necessitating redesigns of condenser coils and heat exchange surfaces.

ASHRAE Standard 90.1, which is widely adopted in building codes across North America, provides comprehensive efficiency requirements for HVAC systems in commercial buildings. The standard's periodic updates have consistently raised the bar for minimum condenser efficiency, pushing manufacturers toward more advanced heat transfer technologies and optimized airflow designs.

International standards such as ISO 16358 establish testing methodologies for determining cooling seasonal performance factors, ensuring consistency in efficiency measurements across global markets. This standardization has facilitated meaningful comparisons between different condenser technologies and designs, driving competitive innovation in the marketplace.

Energy labeling programs like ENERGY STAR in the United States and the European Energy Label have created market incentives for manufacturers to exceed minimum efficiency requirements. These voluntary programs highlight high-efficiency condensers, creating consumer awareness and market differentiation for superior products. Research indicates that ENERGY STAR certified units typically achieve 10-15% greater efficiency than standard models through advanced condenser designs.

Green building certification systems, including LEED and BREEAM, award points for high-efficiency HVAC systems, further incentivizing advanced condenser technologies. These programs have spurred adoption of micro-channel condensers, variable-speed fan motors, and optimized coil geometries that significantly outperform regulatory minimums.

Looking forward, regulatory roadmaps indicate continued tightening of efficiency standards through 2030, with particular emphasis on part-load efficiency and seasonal performance metrics. This regulatory trajectory will necessitate further innovations in condenser design, potentially including advanced materials with enhanced thermal conductivity, hybrid cooling approaches, and intelligent control systems that optimize performance across varying operating conditions.

The European Union's Ecodesign Directive similarly imposes strict efficiency requirements through its Seasonal Coefficient of Performance (SCOP) and Seasonal Energy Efficiency Ratio (SEER) metrics. These regulations have accelerated the transition from traditional refrigerants to more environmentally friendly alternatives with lower Global Warming Potential (GWP), necessitating redesigns of condenser coils and heat exchange surfaces.

ASHRAE Standard 90.1, which is widely adopted in building codes across North America, provides comprehensive efficiency requirements for HVAC systems in commercial buildings. The standard's periodic updates have consistently raised the bar for minimum condenser efficiency, pushing manufacturers toward more advanced heat transfer technologies and optimized airflow designs.

International standards such as ISO 16358 establish testing methodologies for determining cooling seasonal performance factors, ensuring consistency in efficiency measurements across global markets. This standardization has facilitated meaningful comparisons between different condenser technologies and designs, driving competitive innovation in the marketplace.

Energy labeling programs like ENERGY STAR in the United States and the European Energy Label have created market incentives for manufacturers to exceed minimum efficiency requirements. These voluntary programs highlight high-efficiency condensers, creating consumer awareness and market differentiation for superior products. Research indicates that ENERGY STAR certified units typically achieve 10-15% greater efficiency than standard models through advanced condenser designs.

Green building certification systems, including LEED and BREEAM, award points for high-efficiency HVAC systems, further incentivizing advanced condenser technologies. These programs have spurred adoption of micro-channel condensers, variable-speed fan motors, and optimized coil geometries that significantly outperform regulatory minimums.

Looking forward, regulatory roadmaps indicate continued tightening of efficiency standards through 2030, with particular emphasis on part-load efficiency and seasonal performance metrics. This regulatory trajectory will necessitate further innovations in condenser design, potentially including advanced materials with enhanced thermal conductivity, hybrid cooling approaches, and intelligent control systems that optimize performance across varying operating conditions.

Environmental Impact and Refrigerant Considerations

The environmental impact of HVAC condensers has become increasingly significant as global climate regulations tighten. Traditional refrigerants such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) have been phased out due to their ozone depletion potential, while hydrofluorocarbons (HFCs) are being restricted because of their high global warming potential (GWP). This regulatory landscape necessitates a fundamental shift in condenser design to accommodate more environmentally friendly refrigerants.

Natural refrigerants including ammonia (R717), carbon dioxide (R744), and hydrocarbons like propane (R290) and isobutane (R600a) are gaining prominence in high-efficiency condenser applications. These alternatives offer significantly lower GWP values compared to synthetic refrigerants, with some approaching zero. However, their implementation introduces design challenges including higher operating pressures for CO2 systems, flammability concerns with hydrocarbons, and toxicity considerations with ammonia.

Condenser designs must now incorporate specific material compatibility requirements for these alternative refrigerants. For instance, CO2 systems operate at pressures up to 120 bar, necessitating robust heat exchanger designs and specialized components. This has driven innovation in microchannel and printed circuit heat exchangers that can withstand these extreme conditions while maintaining thermal efficiency.

Energy consumption represents another critical environmental consideration, as operational emissions often exceed the direct impact of refrigerant leakage. Advanced condenser designs incorporating variable speed fans, optimized tube geometries, and enhanced heat transfer surfaces can reduce energy consumption by 15-30% compared to conventional models. These improvements directly translate to reduced carbon footprints during the operational lifecycle of HVAC systems.

Water conservation has emerged as an additional environmental priority for condenser design, particularly in water-cooled systems. Hybrid condensers that combine evaporative cooling with air-cooled operation can reduce water consumption by up to 80% compared to traditional cooling towers, while maintaining efficiency in varying ambient conditions. These systems incorporate sophisticated control algorithms that optimize the balance between water and energy usage based on real-time conditions.

Lifecycle assessment methodologies are increasingly being applied to condenser design, considering environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal. This holistic approach has revealed opportunities for using recycled materials in condenser construction and designing components for easier disassembly and recycling, further reducing environmental footprint beyond refrigerant and energy considerations.

Natural refrigerants including ammonia (R717), carbon dioxide (R744), and hydrocarbons like propane (R290) and isobutane (R600a) are gaining prominence in high-efficiency condenser applications. These alternatives offer significantly lower GWP values compared to synthetic refrigerants, with some approaching zero. However, their implementation introduces design challenges including higher operating pressures for CO2 systems, flammability concerns with hydrocarbons, and toxicity considerations with ammonia.

Condenser designs must now incorporate specific material compatibility requirements for these alternative refrigerants. For instance, CO2 systems operate at pressures up to 120 bar, necessitating robust heat exchanger designs and specialized components. This has driven innovation in microchannel and printed circuit heat exchangers that can withstand these extreme conditions while maintaining thermal efficiency.

Energy consumption represents another critical environmental consideration, as operational emissions often exceed the direct impact of refrigerant leakage. Advanced condenser designs incorporating variable speed fans, optimized tube geometries, and enhanced heat transfer surfaces can reduce energy consumption by 15-30% compared to conventional models. These improvements directly translate to reduced carbon footprints during the operational lifecycle of HVAC systems.

Water conservation has emerged as an additional environmental priority for condenser design, particularly in water-cooled systems. Hybrid condensers that combine evaporative cooling with air-cooled operation can reduce water consumption by up to 80% compared to traditional cooling towers, while maintaining efficiency in varying ambient conditions. These systems incorporate sophisticated control algorithms that optimize the balance between water and energy usage based on real-time conditions.

Lifecycle assessment methodologies are increasingly being applied to condenser design, considering environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal. This holistic approach has revealed opportunities for using recycled materials in condenser construction and designing components for easier disassembly and recycling, further reducing environmental footprint beyond refrigerant and energy considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!