3D printed heat exchangers for lightweight applications

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printed Heat Exchanger Technology Evolution

The evolution of 3D printed heat exchanger technology represents a significant advancement in thermal management systems, particularly for lightweight applications. The journey began in the early 2000s with rudimentary proof-of-concept designs that demonstrated the feasibility of creating complex internal geometries impossible with traditional manufacturing methods. These early prototypes, while limited in performance, established the foundation for future development.

By 2010-2015, the technology witnessed substantial progress with the introduction of metal-based additive manufacturing techniques, particularly selective laser melting (SLM) and direct metal laser sintering (DMLS). These processes enabled the production of heat exchangers with improved thermal conductivity and mechanical strength, addressing key limitations of earlier polymer-based designs. During this period, researchers began exploring lattice structures and topology optimization to enhance heat transfer efficiency while minimizing material usage.

The period from 2016 to 2020 marked a transformative phase characterized by significant advancements in multi-material printing capabilities. This innovation allowed engineers to strategically incorporate materials with different thermal properties within a single heat exchanger, optimizing performance for specific applications. Concurrently, the development of high-resolution printing techniques facilitated the creation of microchannels with dimensions below 500 microns, dramatically increasing surface area-to-volume ratios and heat transfer coefficients.

Recent developments (2021-present) have focused on scaling production capabilities while maintaining precision. Notable innovations include hybrid manufacturing approaches that combine additive and subtractive techniques to achieve superior surface finishes in critical flow channels. Additionally, the integration of computational fluid dynamics (CFD) with generative design algorithms has enabled the creation of biomimetic structures that emulate efficient natural heat transfer systems, such as vascular networks in living organisms.

Throughout this evolution, a consistent trend has been the progressive reduction in weight-to-performance ratios. Early 3D printed heat exchangers offered modest weight reductions of 10-15% compared to conventional designs, whereas current technologies can achieve weight reductions exceeding 50% while maintaining or improving thermal performance. This advancement has been particularly valuable for aerospace, automotive, and portable electronics applications where weight considerations are paramount.

The technology evolution has also been characterized by increasing design freedom, enabling engineers to create complex geometries optimized for specific flow conditions and thermal requirements. This capability has transformed heat exchanger design from a component-level consideration to a system-level integration opportunity, allowing thermal management to be incorporated into structural elements rather than added as separate components.

By 2010-2015, the technology witnessed substantial progress with the introduction of metal-based additive manufacturing techniques, particularly selective laser melting (SLM) and direct metal laser sintering (DMLS). These processes enabled the production of heat exchangers with improved thermal conductivity and mechanical strength, addressing key limitations of earlier polymer-based designs. During this period, researchers began exploring lattice structures and topology optimization to enhance heat transfer efficiency while minimizing material usage.

The period from 2016 to 2020 marked a transformative phase characterized by significant advancements in multi-material printing capabilities. This innovation allowed engineers to strategically incorporate materials with different thermal properties within a single heat exchanger, optimizing performance for specific applications. Concurrently, the development of high-resolution printing techniques facilitated the creation of microchannels with dimensions below 500 microns, dramatically increasing surface area-to-volume ratios and heat transfer coefficients.

Recent developments (2021-present) have focused on scaling production capabilities while maintaining precision. Notable innovations include hybrid manufacturing approaches that combine additive and subtractive techniques to achieve superior surface finishes in critical flow channels. Additionally, the integration of computational fluid dynamics (CFD) with generative design algorithms has enabled the creation of biomimetic structures that emulate efficient natural heat transfer systems, such as vascular networks in living organisms.

Throughout this evolution, a consistent trend has been the progressive reduction in weight-to-performance ratios. Early 3D printed heat exchangers offered modest weight reductions of 10-15% compared to conventional designs, whereas current technologies can achieve weight reductions exceeding 50% while maintaining or improving thermal performance. This advancement has been particularly valuable for aerospace, automotive, and portable electronics applications where weight considerations are paramount.

The technology evolution has also been characterized by increasing design freedom, enabling engineers to create complex geometries optimized for specific flow conditions and thermal requirements. This capability has transformed heat exchanger design from a component-level consideration to a system-level integration opportunity, allowing thermal management to be incorporated into structural elements rather than added as separate components.

Market Analysis for Lightweight Heat Exchange Solutions

The lightweight heat exchanger market is experiencing significant growth driven by increasing demand across multiple industries seeking to improve energy efficiency while reducing weight and space requirements. The global market for lightweight heat exchangers was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 10.2%. This growth trajectory is particularly pronounced in aerospace, automotive, and renewable energy sectors where weight reduction directly translates to performance gains and operational cost savings.

In the aerospace industry, lightweight heat exchangers are critical components in environmental control systems, engine cooling, and fuel systems. With commercial aircraft manufacturers striving to reduce fuel consumption by 15-20% in next-generation aircraft, the demand for lightweight thermal management solutions continues to surge. Boeing and Airbus have both announced initiatives to reduce aircraft weight by incorporating advanced materials and manufacturing technologies, including 3D printed components.

The automotive sector represents another substantial market, particularly with the rapid expansion of electric vehicles (EVs). The global EV market grew by 43% in 2022, creating unprecedented demand for efficient thermal management systems. Lightweight heat exchangers are essential for battery cooling systems, power electronics, and cabin climate control in EVs, where every kilogram saved extends vehicle range.

Renewable energy applications, particularly concentrated solar power and geothermal energy systems, are emerging as significant growth areas for lightweight heat exchange solutions. These applications benefit from the enhanced thermal efficiency and reduced material costs that advanced manufacturing techniques like 3D printing can provide.

Regional analysis indicates that North America and Europe currently lead the market with approximately 60% combined market share, driven by strong aerospace and automotive manufacturing bases. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.5% annually through 2028, fueled by rapid industrialization and increasing adoption of electric vehicles in China, Japan, and South Korea.

Customer requirements are evolving toward more compact, efficient designs with complex geometries that traditional manufacturing methods struggle to produce. Market surveys indicate that 78% of engineering decision-makers consider weight reduction a "very important" or "critical" factor when selecting heat exchange solutions, while 65% cite improved thermal performance as their primary consideration.

The competitive landscape features established thermal management companies like Danfoss and Alfa Laval increasingly facing competition from specialized additive manufacturing firms and materials science innovators. This market fragmentation is creating opportunities for new entrants with expertise in 3D printing technologies specifically optimized for heat exchange applications.

In the aerospace industry, lightweight heat exchangers are critical components in environmental control systems, engine cooling, and fuel systems. With commercial aircraft manufacturers striving to reduce fuel consumption by 15-20% in next-generation aircraft, the demand for lightweight thermal management solutions continues to surge. Boeing and Airbus have both announced initiatives to reduce aircraft weight by incorporating advanced materials and manufacturing technologies, including 3D printed components.

The automotive sector represents another substantial market, particularly with the rapid expansion of electric vehicles (EVs). The global EV market grew by 43% in 2022, creating unprecedented demand for efficient thermal management systems. Lightweight heat exchangers are essential for battery cooling systems, power electronics, and cabin climate control in EVs, where every kilogram saved extends vehicle range.

Renewable energy applications, particularly concentrated solar power and geothermal energy systems, are emerging as significant growth areas for lightweight heat exchange solutions. These applications benefit from the enhanced thermal efficiency and reduced material costs that advanced manufacturing techniques like 3D printing can provide.

Regional analysis indicates that North America and Europe currently lead the market with approximately 60% combined market share, driven by strong aerospace and automotive manufacturing bases. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.5% annually through 2028, fueled by rapid industrialization and increasing adoption of electric vehicles in China, Japan, and South Korea.

Customer requirements are evolving toward more compact, efficient designs with complex geometries that traditional manufacturing methods struggle to produce. Market surveys indicate that 78% of engineering decision-makers consider weight reduction a "very important" or "critical" factor when selecting heat exchange solutions, while 65% cite improved thermal performance as their primary consideration.

The competitive landscape features established thermal management companies like Danfoss and Alfa Laval increasingly facing competition from specialized additive manufacturing firms and materials science innovators. This market fragmentation is creating opportunities for new entrants with expertise in 3D printing technologies specifically optimized for heat exchange applications.

Technical Barriers in Additive Manufacturing for Heat Transfer

Despite significant advancements in additive manufacturing (AM) technologies, several technical barriers continue to impede the widespread adoption of 3D printed heat exchangers for lightweight applications. The primary challenge lies in material limitations, as the range of printable materials with suitable thermal conductivity remains restricted. While traditional heat exchangers often utilize copper, aluminum, or specialized alloys, many AM processes struggle to effectively process these materials with the required precision and material properties.

Surface finish and dimensional accuracy present another significant hurdle. The layer-by-layer building process inherent to AM technologies often results in surface roughness that can negatively impact fluid flow characteristics and heat transfer efficiency. This roughness increases pressure drop and creates turbulence patterns that differ from those in conventionally manufactured heat exchangers, complicating design optimization.

Internal channel complexity poses a substantial technical barrier, particularly regarding support structure removal. Complex internal geometries that maximize heat transfer surface area often require support structures during printing, which subsequently become extremely difficult or impossible to remove from enclosed channels. This limitation constrains design freedom and the achievable complexity of internal flow paths.

Porosity and microstructural defects represent critical concerns for heat exchanger applications. AM processes can introduce microscopic voids and inconsistencies in the material structure, potentially leading to fluid leakage, reduced mechanical strength, and compromised thermal performance. These defects are particularly problematic in high-pressure or safety-critical applications.

Scale-up challenges persist as most high-resolution AM technologies are limited in build volume, restricting the size of printable heat exchangers. While larger industrial systems exist, they often sacrifice resolution and surface quality, creating a difficult trade-off between size and performance characteristics.

Post-processing requirements add complexity and cost to the manufacturing workflow. Many 3D printed heat exchangers require extensive post-processing operations including heat treatment to relieve residual stresses, surface finishing to improve flow characteristics, and testing to verify leak-tightness and structural integrity.

Design tool limitations further complicate development efforts. Current CAD and simulation tools are not fully optimized for the unique capabilities and constraints of AM processes, making it difficult to fully leverage topology optimization and generative design approaches for heat exchanger applications. The lack of integrated design-to-manufacturing software solutions specifically tailored for thermal applications represents a significant barrier to innovation.

Surface finish and dimensional accuracy present another significant hurdle. The layer-by-layer building process inherent to AM technologies often results in surface roughness that can negatively impact fluid flow characteristics and heat transfer efficiency. This roughness increases pressure drop and creates turbulence patterns that differ from those in conventionally manufactured heat exchangers, complicating design optimization.

Internal channel complexity poses a substantial technical barrier, particularly regarding support structure removal. Complex internal geometries that maximize heat transfer surface area often require support structures during printing, which subsequently become extremely difficult or impossible to remove from enclosed channels. This limitation constrains design freedom and the achievable complexity of internal flow paths.

Porosity and microstructural defects represent critical concerns for heat exchanger applications. AM processes can introduce microscopic voids and inconsistencies in the material structure, potentially leading to fluid leakage, reduced mechanical strength, and compromised thermal performance. These defects are particularly problematic in high-pressure or safety-critical applications.

Scale-up challenges persist as most high-resolution AM technologies are limited in build volume, restricting the size of printable heat exchangers. While larger industrial systems exist, they often sacrifice resolution and surface quality, creating a difficult trade-off between size and performance characteristics.

Post-processing requirements add complexity and cost to the manufacturing workflow. Many 3D printed heat exchangers require extensive post-processing operations including heat treatment to relieve residual stresses, surface finishing to improve flow characteristics, and testing to verify leak-tightness and structural integrity.

Design tool limitations further complicate development efforts. Current CAD and simulation tools are not fully optimized for the unique capabilities and constraints of AM processes, making it difficult to fully leverage topology optimization and generative design approaches for heat exchanger applications. The lack of integrated design-to-manufacturing software solutions specifically tailored for thermal applications represents a significant barrier to innovation.

Current Additive Manufacturing Approaches for Heat Exchangers

01 Lightweight design techniques for 3D printed heat exchangers

Various design techniques can be employed to reduce the weight of 3D printed heat exchangers while maintaining thermal performance. These include topology optimization, lattice structures, and variable wall thickness designs that strategically place material only where needed for structural integrity and heat transfer. Advanced computational fluid dynamics simulations help identify areas where material can be removed without compromising functionality, resulting in significant weight reduction compared to traditionally manufactured heat exchangers.- Lightweight design techniques for 3D printed heat exchangers: Various design techniques can be employed to reduce the weight of 3D printed heat exchangers while maintaining thermal performance. These include topology optimization, lattice structures, and variable wall thickness designs that strategically place material only where needed for structural integrity and heat transfer. Advanced algorithms can identify optimal material distribution patterns that minimize weight while maximizing thermal efficiency.

- Advanced materials for lightweight 3D printed heat exchangers: Specialized materials can significantly reduce the weight of 3D printed heat exchangers. These include high-performance polymers, metal alloys with favorable strength-to-weight ratios, and composite materials that combine lightweight properties with excellent thermal conductivity. Material selection is critical for balancing weight reduction with thermal performance requirements in various operating environments.

- Innovative internal geometries for weight reduction: Novel internal geometries can be created through 3D printing to reduce heat exchanger weight. These include complex flow channels, conformal cooling passages, and fractal-inspired designs that maximize surface area while minimizing material usage. Such geometries, which would be impossible to manufacture using traditional methods, enable significant weight reduction while maintaining or improving heat transfer efficiency.

- Manufacturing processes for lightweight 3D printed heat exchangers: Specific 3D printing processes can be optimized for producing lightweight heat exchangers. These include selective laser melting, direct metal laser sintering, and electron beam melting techniques that can create fine features and hollow structures. Process parameters can be tuned to achieve optimal density and porosity levels that balance weight reduction with mechanical strength and thermal performance requirements.

- Integration of multifunctional features to reduce overall system weight: 3D printed heat exchangers can incorporate multifunctional features that reduce the overall system weight by eliminating the need for additional components. These integrated designs can combine structural support, fluid distribution, and thermal management functions into a single printed component. This approach not only reduces weight but also minimizes assembly requirements and potential failure points in the system.

02 Advanced materials for weight reduction in 3D printed heat exchangers

The use of advanced lightweight materials in 3D printed heat exchangers contributes significantly to weight reduction. Materials such as aluminum alloys, titanium alloys, and polymer composites with enhanced thermal conductivity properties can be processed through additive manufacturing techniques. These materials offer excellent strength-to-weight ratios while maintaining the thermal performance required for effective heat exchange, making them ideal for applications where weight is a critical factor.Expand Specific Solutions03 Innovative geometries enabled by 3D printing for weight optimization

3D printing enables the creation of complex geometries that would be impossible or impractical with traditional manufacturing methods. These innovative designs include conformal cooling channels, fractal-inspired flow paths, and biomimetic structures that maximize surface area while minimizing material usage. Such geometries can significantly reduce the weight of heat exchangers while improving heat transfer efficiency through optimized fluid flow patterns and enhanced surface area-to-volume ratios.Expand Specific Solutions04 Multi-functional integration to reduce overall system weight

3D printing allows for the integration of multiple functions into a single component, reducing the overall system weight by eliminating the need for separate parts, joints, and fasteners. Heat exchangers can be printed with integrated mounting features, flow distributors, and structural elements. This consolidation of components not only reduces weight but also improves reliability by eliminating potential leak points and reducing assembly complexity in thermal management systems.Expand Specific Solutions05 Process optimization for weight-efficient 3D printed heat exchangers

Optimizing the 3D printing process itself contributes to weight reduction in heat exchangers. Parameters such as layer thickness, print orientation, support structure design, and post-processing techniques can be fine-tuned to minimize material usage while ensuring structural integrity. Advanced printing techniques like selective laser melting with optimized process parameters can produce parts with thinner walls and more precise features, directly contributing to weight reduction while maintaining the necessary thermal and mechanical properties.Expand Specific Solutions

Leading Companies in 3D Printed Heat Exchanger Industry

The 3D printed heat exchanger market for lightweight applications is in a growth phase, characterized by increasing adoption across aerospace, automotive, and energy sectors. Market size is expanding rapidly due to demand for efficient thermal management solutions in weight-sensitive applications. From a technological maturity perspective, the landscape shows varied development stages with established industrial players like Boeing, Honda Motor, and Alfa Laval leading commercial applications, while research institutions such as Xi'an Jiaotong University, Shandong University, and Fraunhofer-Gesellschaft drive fundamental innovation. Specialized additive manufacturing companies like Divergent Technologies and Shenzhen Huayang New Material Technology are accelerating commercialization through advanced manufacturing capabilities, creating a competitive ecosystem balancing traditional heat exchanger expertise with emerging 3D printing technologies.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has established itself as a leader in research on 3D printed heat exchangers through its comprehensive approach combining materials science, process engineering, and design optimization. Their technology focuses on selective laser melting (SLM) and electron beam melting (EBM) processes to create lightweight heat exchangers with complex internal geometries. Fraunhofer's research has demonstrated the ability to create heat exchangers with wall thicknesses as low as 0.15mm and feature sizes down to 0.3mm, enabling exceptional surface area-to-volume ratios[8]. Their designs incorporate nature-inspired flow channels that create controlled turbulence patterns to enhance heat transfer while minimizing pressure drop. Fraunhofer has developed specialized aluminum, titanium, and stainless steel alloys optimized for additive manufacturing, achieving weight reductions of 40-50% compared to conventional heat exchangers while maintaining equivalent thermal performance[9]. Their research also encompasses hybrid manufacturing approaches that combine the benefits of additive and subtractive processes to achieve optimal surface finishes and dimensional accuracy. Fraunhofer has implemented comprehensive simulation and testing protocols to validate the performance and durability of their 3D printed heat exchangers under various operating conditions.

Strengths: Comprehensive research approach covering materials, design, and manufacturing processes; ability to create multi-material solutions through hybrid manufacturing; extensive testing and validation capabilities. Weaknesses: Technology primarily focused on research applications rather than mass production; higher costs associated with specialized materials and equipment; challenges in standardization across different manufacturing platforms.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed an innovative approach to 3D printed heat exchangers that leverages their extensive experience in thermal transfer technologies. Their research focuses on powder bed fusion techniques to create compact, lightweight heat exchangers with complex internal geometries that maximize heat transfer efficiency. Alfa Laval's technology enables the creation of heat exchangers with integrated distribution systems that reduce pressure drop while improving thermal performance. Their designs incorporate thin-walled structures (down to 0.4mm) with optimized flow channels that create turbulent flow patterns to enhance heat transfer coefficients[7]. Alfa Laval has demonstrated weight reductions of 25-35% compared to conventional plate heat exchangers while maintaining equivalent thermal performance. The company has developed specialized stainless steel and titanium alloy formulations optimized for their additive manufacturing process, enabling heat exchangers that can operate in corrosive environments at temperatures up to 350°C. Their research has also focused on surface treatments and finishing processes that enhance the durability and performance of 3D printed heat exchangers in demanding industrial applications.

Strengths: Extensive experience in heat exchanger design translated to AM processes; ability to create corrosion-resistant solutions for demanding environments; integrated quality control systems throughout the manufacturing process. Weaknesses: Higher production costs for complex geometries; challenges in scaling to very large heat exchanger sizes; limited material options compared to conventional manufacturing.

Key Patents in 3D Printed Thermal Management Systems

Additively manufactured heat exchangers

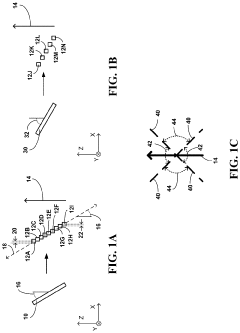

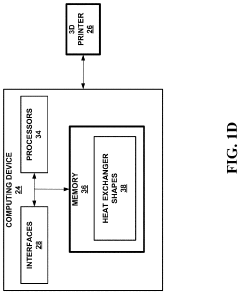

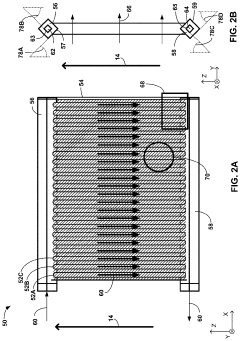

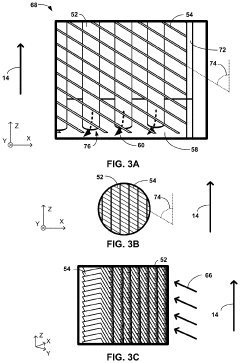

PatentActiveUS10843267B2

Innovation

- The development of heat exchangers using 3D printers that configure tubes and fins to define supported slopes within a threshold angle relative to the print direction, allowing for the additive manufacturing of heat exchangers with features like lenticular tubes and offset strip fins, enabling the formation of complex geometries without violating maximum angle thresholds.

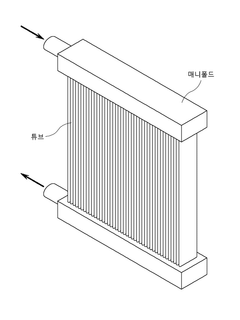

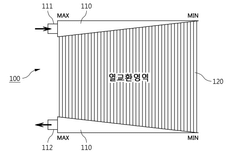

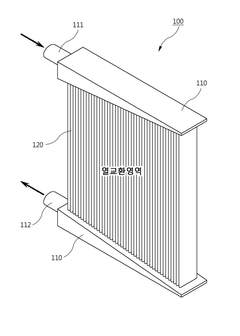

Heat exchanger

PatentInactiveKR1020210001185A

Innovation

- The heat exchanger is designed with a manifold cross-sectional area that progressively decreases from the maximum flow rate position to the minimum flow rate position, allowing even distribution of the heat exchange medium and increasing the core area, while being manufactured using a 3D printing layered method.

Material Science Advancements for 3D Printed Heat Exchangers

The evolution of materials science has been pivotal in advancing 3D printed heat exchangers for lightweight applications. Traditional manufacturing methods often limited material selection to conventional metals like aluminum and copper, which while thermally efficient, presented challenges in weight optimization. Recent breakthroughs in material science have expanded the palette of printable materials with enhanced thermal properties while maintaining structural integrity at reduced weights.

Polymer-metal composites represent a significant advancement, combining the lightweight nature of polymers with the thermal conductivity of metals. These composites, typically consisting of a polymer matrix embedded with metallic particles or fibers, offer thermal conductivity values approaching 20 W/mK while maintaining densities below 2 g/cm³. This represents a substantial improvement over traditional polymers, which typically exhibit thermal conductivities below 0.5 W/mK.

Metal matrix composites (MMCs) have emerged as another promising material category. Aluminum-silicon carbide composites, for instance, demonstrate thermal conductivities exceeding 180 W/mK while achieving up to 15% weight reduction compared to pure aluminum. These materials maintain excellent mechanical properties at elevated temperatures, making them suitable for demanding aerospace and automotive applications.

Lattice-structured metallic materials represent perhaps the most revolutionary development. By precisely controlling the internal geometry of printed parts, engineers can create structures that are simultaneously lightweight and thermally efficient. Titanium lattice structures with relative densities of 30-40% have demonstrated effective thermal conductivities of approximately 60-70% of solid titanium, while reducing weight by 60-70%.

Surface modification techniques have further enhanced the performance of 3D printed heat exchangers. Nano-coatings applied to printed surfaces can increase heat transfer coefficients by up to 40% through improved wettability and reduced thermal contact resistance. These coatings, often just a few microns thick, add negligible weight while significantly boosting thermal performance.

Functionally graded materials (FGMs) represent the cutting edge of material science for heat exchangers. These materials feature spatially varying compositions or microstructures, allowing engineers to optimize thermal and mechanical properties throughout different regions of a single component. For instance, copper-rich regions can be strategically placed at critical heat transfer interfaces, while lightweight aluminum alloys comprise the bulk structure, achieving optimal performance with minimal weight penalties.

Polymer-metal composites represent a significant advancement, combining the lightweight nature of polymers with the thermal conductivity of metals. These composites, typically consisting of a polymer matrix embedded with metallic particles or fibers, offer thermal conductivity values approaching 20 W/mK while maintaining densities below 2 g/cm³. This represents a substantial improvement over traditional polymers, which typically exhibit thermal conductivities below 0.5 W/mK.

Metal matrix composites (MMCs) have emerged as another promising material category. Aluminum-silicon carbide composites, for instance, demonstrate thermal conductivities exceeding 180 W/mK while achieving up to 15% weight reduction compared to pure aluminum. These materials maintain excellent mechanical properties at elevated temperatures, making them suitable for demanding aerospace and automotive applications.

Lattice-structured metallic materials represent perhaps the most revolutionary development. By precisely controlling the internal geometry of printed parts, engineers can create structures that are simultaneously lightweight and thermally efficient. Titanium lattice structures with relative densities of 30-40% have demonstrated effective thermal conductivities of approximately 60-70% of solid titanium, while reducing weight by 60-70%.

Surface modification techniques have further enhanced the performance of 3D printed heat exchangers. Nano-coatings applied to printed surfaces can increase heat transfer coefficients by up to 40% through improved wettability and reduced thermal contact resistance. These coatings, often just a few microns thick, add negligible weight while significantly boosting thermal performance.

Functionally graded materials (FGMs) represent the cutting edge of material science for heat exchangers. These materials feature spatially varying compositions or microstructures, allowing engineers to optimize thermal and mechanical properties throughout different regions of a single component. For instance, copper-rich regions can be strategically placed at critical heat transfer interfaces, while lightweight aluminum alloys comprise the bulk structure, achieving optimal performance with minimal weight penalties.

Sustainability Impact of Additive Manufacturing Thermal Solutions

The adoption of additive manufacturing for thermal solutions represents a significant advancement in sustainable industrial practices. 3D printed heat exchangers for lightweight applications offer substantial environmental benefits throughout their lifecycle. The reduced material usage—often 30-40% less than conventional manufacturing—directly translates to conservation of raw resources and decreased extraction impacts.

Energy consumption during production shows promising reductions, with studies indicating up to 25% lower energy requirements compared to traditional manufacturing processes. This efficiency stems from the elimination of multiple production steps and the ability to produce complex geometries in single operations. The localized nature of additive manufacturing further contributes to sustainability by enabling on-demand production that reduces transportation emissions and inventory waste.

From a lifecycle perspective, the lightweight characteristics of 3D printed heat exchangers deliver ongoing environmental dividends. In automotive and aerospace applications, weight reductions of 15-30% have been documented, directly correlating to fuel efficiency improvements and reduced operational carbon footprints. The enhanced thermal efficiency achieved through complex geometries impossible with conventional manufacturing also contributes to lower energy consumption during product operation.

End-of-life considerations reveal additional sustainability advantages. The mono-material design approach often employed in additive manufacturing simplifies recycling processes. Materials such as aluminum alloys used in these heat exchangers maintain high recoverability rates, with potential recycling efficiencies exceeding 90% in optimal conditions.

Circular economy principles are inherently supported through the additive manufacturing process. The precise material deposition minimizes waste generation, with material utilization rates frequently exceeding 95% compared to 60-70% in subtractive manufacturing. Additionally, the digital nature of the production process facilitates design iterations that can continuously improve sustainability metrics without tooling changes or material waste.

Quantitative lifecycle assessments of 3D printed heat exchangers indicate potential carbon footprint reductions of 20-40% compared to conventional alternatives when considering the complete product lifecycle. These environmental benefits are particularly pronounced in applications requiring customized thermal solutions with complex geometries, where traditional manufacturing would necessitate multiple components, joining processes, and associated material waste.

Energy consumption during production shows promising reductions, with studies indicating up to 25% lower energy requirements compared to traditional manufacturing processes. This efficiency stems from the elimination of multiple production steps and the ability to produce complex geometries in single operations. The localized nature of additive manufacturing further contributes to sustainability by enabling on-demand production that reduces transportation emissions and inventory waste.

From a lifecycle perspective, the lightweight characteristics of 3D printed heat exchangers deliver ongoing environmental dividends. In automotive and aerospace applications, weight reductions of 15-30% have been documented, directly correlating to fuel efficiency improvements and reduced operational carbon footprints. The enhanced thermal efficiency achieved through complex geometries impossible with conventional manufacturing also contributes to lower energy consumption during product operation.

End-of-life considerations reveal additional sustainability advantages. The mono-material design approach often employed in additive manufacturing simplifies recycling processes. Materials such as aluminum alloys used in these heat exchangers maintain high recoverability rates, with potential recycling efficiencies exceeding 90% in optimal conditions.

Circular economy principles are inherently supported through the additive manufacturing process. The precise material deposition minimizes waste generation, with material utilization rates frequently exceeding 95% compared to 60-70% in subtractive manufacturing. Additionally, the digital nature of the production process facilitates design iterations that can continuously improve sustainability metrics without tooling changes or material waste.

Quantitative lifecycle assessments of 3D printed heat exchangers indicate potential carbon footprint reductions of 20-40% compared to conventional alternatives when considering the complete product lifecycle. These environmental benefits are particularly pronounced in applications requiring customized thermal solutions with complex geometries, where traditional manufacturing would necessitate multiple components, joining processes, and associated material waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!