Heat exchanger design for cryogenic systems

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Heat Exchanger Background and Objectives

Cryogenic heat exchangers represent a critical component in low-temperature systems, with applications spanning from industrial gas liquefaction to aerospace propulsion and scientific research facilities. The evolution of these specialized heat transfer devices dates back to the early 20th century, coinciding with advancements in gas liquefaction processes. Over the decades, significant technological improvements have transformed these components from rudimentary designs to sophisticated systems capable of operating efficiently at temperatures approaching absolute zero.

The technological trajectory of cryogenic heat exchangers has been characterized by continuous innovation in materials science, manufacturing techniques, and thermal design principles. Early aluminum plate-fin exchangers have given way to more advanced configurations including spiral-wound, printed circuit, and microchannel designs that offer enhanced performance characteristics. Recent developments have focused on optimizing heat transfer efficiency while minimizing entropy generation, a particularly crucial consideration in cryogenic applications where energy losses translate directly to increased operational costs.

Current market trends indicate growing demand for cryogenic heat exchangers across multiple sectors, driven primarily by expanding liquefied natural gas (LNG) infrastructure, hydrogen economy initiatives, and increasing investments in space exploration. The technical objectives for next-generation designs center on addressing several persistent challenges: minimizing temperature approach differences, reducing pressure drops, preventing thermal stress-induced failures, and enhancing resistance to fouling under extreme temperature conditions.

Material selection remains a fundamental consideration, as conventional engineering materials exhibit dramatically altered properties at cryogenic temperatures. Research objectives include developing novel composite materials and surface treatments that maintain ductility and thermal conductivity while resisting embrittlement at ultra-low temperatures. Parallel efforts focus on advancing manufacturing capabilities to produce increasingly complex geometries that optimize fluid distribution and heat transfer surface area.

Computational modeling and simulation have emerged as essential tools in the design process, enabling engineers to predict performance characteristics with increasing accuracy. Future objectives include developing more sophisticated multi-physics models that can simultaneously account for phase change phenomena, thermal contraction effects, and flow distribution across complex geometries. These advancements aim to reduce the reliance on costly experimental prototyping while accelerating the innovation cycle.

The ultimate technological goal remains the development of cryogenic heat exchangers with near-perfect effectiveness, minimal exergy destruction, compact form factors, and extended operational lifespans under extreme temperature cycling conditions. Achieving these objectives will require interdisciplinary collaboration across thermodynamics, materials science, manufacturing technology, and computational engineering domains.

The technological trajectory of cryogenic heat exchangers has been characterized by continuous innovation in materials science, manufacturing techniques, and thermal design principles. Early aluminum plate-fin exchangers have given way to more advanced configurations including spiral-wound, printed circuit, and microchannel designs that offer enhanced performance characteristics. Recent developments have focused on optimizing heat transfer efficiency while minimizing entropy generation, a particularly crucial consideration in cryogenic applications where energy losses translate directly to increased operational costs.

Current market trends indicate growing demand for cryogenic heat exchangers across multiple sectors, driven primarily by expanding liquefied natural gas (LNG) infrastructure, hydrogen economy initiatives, and increasing investments in space exploration. The technical objectives for next-generation designs center on addressing several persistent challenges: minimizing temperature approach differences, reducing pressure drops, preventing thermal stress-induced failures, and enhancing resistance to fouling under extreme temperature conditions.

Material selection remains a fundamental consideration, as conventional engineering materials exhibit dramatically altered properties at cryogenic temperatures. Research objectives include developing novel composite materials and surface treatments that maintain ductility and thermal conductivity while resisting embrittlement at ultra-low temperatures. Parallel efforts focus on advancing manufacturing capabilities to produce increasingly complex geometries that optimize fluid distribution and heat transfer surface area.

Computational modeling and simulation have emerged as essential tools in the design process, enabling engineers to predict performance characteristics with increasing accuracy. Future objectives include developing more sophisticated multi-physics models that can simultaneously account for phase change phenomena, thermal contraction effects, and flow distribution across complex geometries. These advancements aim to reduce the reliance on costly experimental prototyping while accelerating the innovation cycle.

The ultimate technological goal remains the development of cryogenic heat exchangers with near-perfect effectiveness, minimal exergy destruction, compact form factors, and extended operational lifespans under extreme temperature cycling conditions. Achieving these objectives will require interdisciplinary collaboration across thermodynamics, materials science, manufacturing technology, and computational engineering domains.

Market Analysis for Cryogenic Heat Exchange Systems

The global market for cryogenic heat exchange systems has been experiencing robust growth, driven by increasing applications in various industries including healthcare, energy, metallurgy, and aerospace. The market size was valued at approximately $2.3 billion in 2022 and is projected to reach $3.5 billion by 2028, representing a compound annual growth rate (CAGR) of 7.2% during the forecast period.

Healthcare sector remains the largest end-user of cryogenic heat exchangers, accounting for nearly 35% of the total market share. This dominance is primarily attributed to the growing demand for medical gases, MRI systems, and cryosurgery equipment. The liquefaction of gases such as nitrogen, oxygen, and helium for medical applications requires efficient heat exchange systems capable of operating at extremely low temperatures.

The energy sector follows closely, with significant demand coming from natural gas processing and liquefaction facilities. As countries worldwide transition toward cleaner energy sources, the demand for liquefied natural gas (LNG) has surged, consequently driving the need for advanced cryogenic heat exchangers. This segment is expected to witness the fastest growth rate of approximately 9.5% during the forecast period.

Regionally, North America currently leads the market with a share of 32%, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is anticipated to exhibit the highest growth rate in the coming years due to rapid industrialization, increasing healthcare infrastructure, and growing investments in LNG terminals in countries like China, India, and South Korea.

From a competitive landscape perspective, the market is moderately consolidated with the top five players accounting for approximately 45% of the total market share. Key players include Chart Industries, Linde Engineering, Fives Group, Sumitomo Precision Products, and Kobe Steel. These companies are focusing on technological innovations to enhance the efficiency and reliability of cryogenic heat exchangers while reducing their size and weight.

Customer requirements are increasingly shifting toward compact, high-efficiency heat exchangers with improved thermal performance and reduced pressure drop. There is also a growing demand for customized solutions that can address specific application requirements across different industries. Additionally, sustainability concerns are driving the development of eco-friendly refrigerants and energy-efficient designs.

Price sensitivity varies across different market segments, with healthcare and aerospace industries prioritizing performance and reliability over cost, while industrial gas and energy sectors are more price-conscious due to the large-scale deployment of these systems. The average selling price of industrial-grade cryogenic heat exchangers has decreased by approximately 5% over the past three years due to increased competition and manufacturing efficiencies.

Healthcare sector remains the largest end-user of cryogenic heat exchangers, accounting for nearly 35% of the total market share. This dominance is primarily attributed to the growing demand for medical gases, MRI systems, and cryosurgery equipment. The liquefaction of gases such as nitrogen, oxygen, and helium for medical applications requires efficient heat exchange systems capable of operating at extremely low temperatures.

The energy sector follows closely, with significant demand coming from natural gas processing and liquefaction facilities. As countries worldwide transition toward cleaner energy sources, the demand for liquefied natural gas (LNG) has surged, consequently driving the need for advanced cryogenic heat exchangers. This segment is expected to witness the fastest growth rate of approximately 9.5% during the forecast period.

Regionally, North America currently leads the market with a share of 32%, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is anticipated to exhibit the highest growth rate in the coming years due to rapid industrialization, increasing healthcare infrastructure, and growing investments in LNG terminals in countries like China, India, and South Korea.

From a competitive landscape perspective, the market is moderately consolidated with the top five players accounting for approximately 45% of the total market share. Key players include Chart Industries, Linde Engineering, Fives Group, Sumitomo Precision Products, and Kobe Steel. These companies are focusing on technological innovations to enhance the efficiency and reliability of cryogenic heat exchangers while reducing their size and weight.

Customer requirements are increasingly shifting toward compact, high-efficiency heat exchangers with improved thermal performance and reduced pressure drop. There is also a growing demand for customized solutions that can address specific application requirements across different industries. Additionally, sustainability concerns are driving the development of eco-friendly refrigerants and energy-efficient designs.

Price sensitivity varies across different market segments, with healthcare and aerospace industries prioritizing performance and reliability over cost, while industrial gas and energy sectors are more price-conscious due to the large-scale deployment of these systems. The average selling price of industrial-grade cryogenic heat exchangers has decreased by approximately 5% over the past three years due to increased competition and manufacturing efficiencies.

Current Challenges in Cryogenic Heat Transfer Technology

Cryogenic heat transfer technology faces significant challenges that impede the advancement of efficient heat exchanger designs for ultra-low temperature applications. The fundamental difficulty lies in the extreme temperature gradients, which can span from ambient conditions to near absolute zero. These gradients create severe thermal stresses that compromise structural integrity and operational reliability of heat exchange systems.

Material selection represents one of the most critical challenges in cryogenic heat exchanger design. Traditional materials exhibit drastically altered properties at cryogenic temperatures, with many becoming brittle or losing thermal conductivity efficiency. While copper and aluminum alloys maintain reasonable thermal performance, their mechanical properties often deteriorate. Specialized materials like stainless steel offer better mechanical stability but suffer from reduced thermal conductivity, creating an ongoing engineering trade-off.

Phase change phenomena present another substantial hurdle. The behavior of cryogenic fluids during boiling and condensation differs significantly from room temperature conditions, with nucleate boiling becoming particularly unpredictable. This unpredictability leads to difficulties in accurately modeling heat transfer coefficients and designing stable systems that avoid critical heat flux conditions that could trigger system failure.

Flow instabilities constitute a persistent challenge in cryogenic systems. Two-phase flow regimes at extremely low temperatures can create pressure oscillations and flow maldistribution, leading to thermal cycling that accelerates component fatigue. These instabilities are particularly problematic in compact heat exchangers where channel dimensions are small and flow distribution is critical.

Thermal insulation effectiveness represents another major obstacle. The substantial temperature differentials between cryogenic fluids and the environment necessitate exceptional insulation systems. Current vacuum-jacketed designs with multi-layer insulation (MLI) still permit heat leakage that significantly impacts system efficiency, especially in smaller-scale applications where insulation thickness is limited by space constraints.

Computational modeling limitations further complicate design processes. Existing simulation tools struggle to accurately predict cryogenic heat transfer behavior, particularly for two-phase flows and complex geometries. The scarcity of comprehensive experimental data at ultra-low temperatures compounds this problem, making validation of computational models exceptionally difficult.

Manufacturing constraints add another layer of complexity. Fabrication of compact, high-efficiency heat exchangers requires precise manufacturing techniques that become increasingly challenging when working with cryogenically compatible materials. Techniques like diffusion bonding and additive manufacturing show promise but remain limited in their ability to create the intricate internal geometries ideal for cryogenic applications while maintaining structural integrity.

Material selection represents one of the most critical challenges in cryogenic heat exchanger design. Traditional materials exhibit drastically altered properties at cryogenic temperatures, with many becoming brittle or losing thermal conductivity efficiency. While copper and aluminum alloys maintain reasonable thermal performance, their mechanical properties often deteriorate. Specialized materials like stainless steel offer better mechanical stability but suffer from reduced thermal conductivity, creating an ongoing engineering trade-off.

Phase change phenomena present another substantial hurdle. The behavior of cryogenic fluids during boiling and condensation differs significantly from room temperature conditions, with nucleate boiling becoming particularly unpredictable. This unpredictability leads to difficulties in accurately modeling heat transfer coefficients and designing stable systems that avoid critical heat flux conditions that could trigger system failure.

Flow instabilities constitute a persistent challenge in cryogenic systems. Two-phase flow regimes at extremely low temperatures can create pressure oscillations and flow maldistribution, leading to thermal cycling that accelerates component fatigue. These instabilities are particularly problematic in compact heat exchangers where channel dimensions are small and flow distribution is critical.

Thermal insulation effectiveness represents another major obstacle. The substantial temperature differentials between cryogenic fluids and the environment necessitate exceptional insulation systems. Current vacuum-jacketed designs with multi-layer insulation (MLI) still permit heat leakage that significantly impacts system efficiency, especially in smaller-scale applications where insulation thickness is limited by space constraints.

Computational modeling limitations further complicate design processes. Existing simulation tools struggle to accurately predict cryogenic heat transfer behavior, particularly for two-phase flows and complex geometries. The scarcity of comprehensive experimental data at ultra-low temperatures compounds this problem, making validation of computational models exceptionally difficult.

Manufacturing constraints add another layer of complexity. Fabrication of compact, high-efficiency heat exchangers requires precise manufacturing techniques that become increasingly challenging when working with cryogenically compatible materials. Techniques like diffusion bonding and additive manufacturing show promise but remain limited in their ability to create the intricate internal geometries ideal for cryogenic applications while maintaining structural integrity.

State-of-the-Art Cryogenic Heat Exchanger Solutions

01 Plate heat exchanger designs

Plate heat exchangers utilize multiple plates stacked together to create flow channels for heat transfer between fluids. These designs offer high efficiency in a compact form factor, with improved heat transfer coefficients compared to traditional shell and tube designs. Innovations in this category include specialized plate geometries, sealing mechanisms, and assembly methods that enhance thermal performance while minimizing pressure drop and material usage.- Heat exchanger design configurations: Various design configurations of heat exchangers are available to optimize heat transfer efficiency. These include plate heat exchangers, shell and tube designs, and compact heat exchangers with specialized geometries. The configuration choice depends on application requirements, space constraints, and the fluids involved in the heat transfer process. Innovative designs focus on maximizing surface area while minimizing pressure drop and material usage.

- Materials and coatings for heat exchangers: Advanced materials and specialized coatings are used in heat exchangers to enhance performance and durability. These materials are selected based on thermal conductivity, corrosion resistance, and mechanical properties. Coatings can prevent fouling, reduce friction, or improve heat transfer characteristics. Novel composite materials and alloys are being developed to withstand extreme operating conditions while maintaining efficient heat transfer properties.

- Flow optimization techniques: Flow optimization in heat exchangers involves designing flow paths that maximize heat transfer while minimizing pressure drop. Techniques include turbulence promoters, flow distributors, and specialized channel geometries. Computational fluid dynamics is used to model and optimize flow patterns. These techniques help prevent dead zones, reduce fouling, and ensure uniform temperature distribution across the heat exchanger surface.

- Energy efficiency improvements: Innovations focused on improving the energy efficiency of heat exchangers include waste heat recovery systems, enhanced surface technologies, and smart control systems. These improvements reduce energy consumption, lower operating costs, and decrease environmental impact. Multi-stage heat exchange processes and regenerative systems are implemented to maximize thermal efficiency and minimize entropy generation.

- Application-specific heat exchanger solutions: Heat exchangers designed for specific applications such as HVAC systems, automotive cooling, industrial processes, or renewable energy systems. These specialized solutions address unique challenges like extreme temperatures, corrosive environments, or space constraints. Custom heat exchanger designs may incorporate features such as self-cleaning mechanisms, modular construction, or integration with other system components to optimize overall performance for the intended application.

02 Microchannel heat exchanger technology

Microchannel heat exchangers feature small diameter channels that increase surface area to volume ratio, resulting in enhanced heat transfer efficiency. These designs typically use aluminum or other highly conductive materials with extruded or brazed construction methods. The small hydraulic diameter channels provide improved thermal performance while reducing refrigerant charge requirements, making them particularly suitable for HVAC, automotive, and electronics cooling applications.Expand Specific Solutions03 Heat exchanger manufacturing methods

Advanced manufacturing techniques for heat exchangers include specialized brazing processes, additive manufacturing, and novel joining methods that improve structural integrity and thermal performance. These methods enable the creation of complex geometries that would be difficult to achieve with traditional manufacturing approaches. Innovations in this area focus on reducing production costs, improving reliability, and enabling mass production of high-efficiency heat transfer devices.Expand Specific Solutions04 Enhanced surface technologies

Surface enhancement technologies for heat exchangers include specialized fin designs, surface treatments, and microstructures that increase turbulence and heat transfer area. These innovations can include corrugated fins, louvered surfaces, dimpled tubes, or hydrophilic/hydrophobic coatings that modify fluid behavior at the interface. Such enhancements significantly improve heat transfer coefficients while managing the trade-off with pressure drop penalties.Expand Specific Solutions05 Heat exchanger materials and corrosion resistance

Material selection plays a crucial role in heat exchanger performance and longevity. Innovations in this area include the use of specialized alloys, composite materials, and surface treatments that enhance corrosion resistance, thermal conductivity, and mechanical properties. These advancements address challenges in harsh operating environments, including high-temperature applications, exposure to corrosive fluids, and scenarios requiring biocompatibility or chemical resistance.Expand Specific Solutions

Leading Companies in Cryogenic Equipment Manufacturing

The cryogenic heat exchanger market is currently in a growth phase, driven by increasing demand in LNG processing, aerospace, and healthcare sectors. The global market size is estimated to exceed $2 billion, with projected annual growth of 6-8% through 2030. Technologically, the field shows varying maturity levels across applications, with companies like Air Liquide, Linde (Praxair), and CIMC demonstrating advanced capabilities in industrial-scale systems. Research institutions including Korea Institute of Machinery & Materials and Technical Institute of Physics & Chemistry CAS are pushing boundaries in novel materials and designs. Emerging players such as Cryoshelter and Shift Thermal are introducing innovations in specialized applications, while established manufacturers like Midea Group are expanding their presence through enhanced efficiency solutions for commercial applications.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced spiral-wound heat exchangers specifically designed for cryogenic applications. Their technology utilizes aluminum alloy plates with spacers to create multiple flow passages in a compact design. The company's proprietary brazed aluminum heat exchangers feature high thermal efficiency with temperature approaches as low as 1-2K. For LNG applications, their heat exchangers can handle thermal duties exceeding 100 MW while maintaining high efficiency. Air Liquide's cryogenic heat exchangers incorporate specialized flow distribution systems that minimize pressure drop while maximizing heat transfer coefficients. Their designs include features to accommodate thermal contraction during cooldown, preventing mechanical stress failures common in cryogenic systems.

Strengths: Industry-leading thermal efficiency with minimal temperature approach; compact design with high surface area density; extensive operational experience across multiple cryogenic applications. Weaknesses: Higher initial capital cost compared to conventional heat exchangers; requires specialized manufacturing facilities; limited flexibility for design modifications after fabrication.

Praxair Technology, Inc.

Technical Solution: Praxair has pioneered advanced plate-fin heat exchangers (PFHE) for cryogenic applications, featuring aluminum construction with brazed joints capable of withstanding extreme temperature differentials. Their proprietary designs incorporate specialized fin geometries that enhance heat transfer while minimizing pressure drop, achieving effectiveness values exceeding 98% in many applications. Praxair's cryogenic heat exchangers utilize multi-stream capabilities, allowing up to 12 process streams to exchange heat within a single unit, significantly reducing footprint and capital costs. Their technology includes specialized distribution systems that ensure uniform flow across the entire heat transfer matrix, preventing localized freezing and flow instabilities common in cryogenic operations. Praxair's heat exchangers incorporate robust mechanical design features to handle thermal cycling between ambient and cryogenic temperatures without compromising structural integrity.

Strengths: Superior thermal performance with high effectiveness; multi-stream capability reduces overall system complexity; proven reliability in industrial-scale applications with decades of operational data. Weaknesses: Complex manufacturing process increases production lead times; higher weight compared to some competing technologies; limited flexibility for in-field modifications.

Key Patents and Research in Cryogenic Heat Transfer

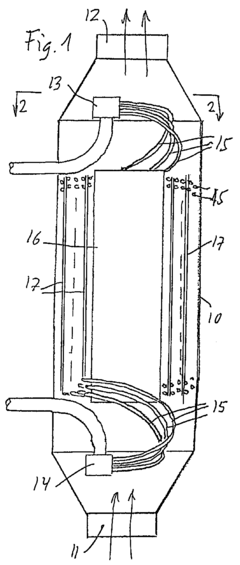

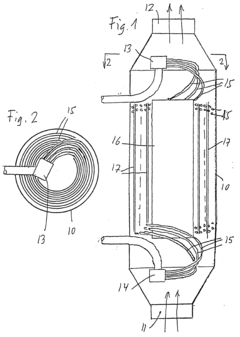

Cryogenic heat exchanger

PatentInactiveEP0942250A1

Innovation

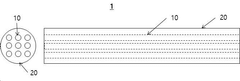

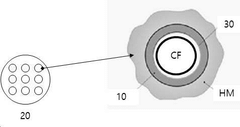

- A low-temperature heat exchanger design featuring a bundle of thin, thin-walled stainless steel tubes spirally wound around a cylindrical core, with a cylindrical outer shell, replacing bulky exchange surface elements to minimize dimensions and pressure losses, and using a cross-counterflow configuration for enhanced heat transfer.

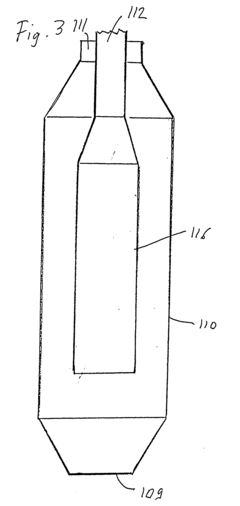

Wire coil implemented cryogenic heat exchanger

PatentActiveKR1020230092446A

Innovation

- Incorporating a wire coil within the tube to induce swirl and turbulent flow of cryogenic fluids, combined with an elliptical cross-section and anti-icing coatings to enhance heat exchange efficiency and compactness.

Materials Science Advancements for Extreme Cold Applications

The evolution of cryogenic systems has been significantly influenced by breakthroughs in materials science. Traditional materials like stainless steel and aluminum alloys, while functional at moderately low temperatures, exhibit brittleness and reduced thermal conductivity when exposed to extreme cryogenic environments below 20K. Recent advancements in composite materials have revolutionized heat exchanger design capabilities, with carbon fiber reinforced polymers (CFRPs) demonstrating exceptional strength-to-weight ratios while maintaining dimensional stability at temperatures approaching absolute zero.

Nano-engineered materials represent another frontier in cryogenic applications. Multi-walled carbon nanotubes (MWCNTs) incorporated into metal matrices have shown up to 35% improvement in thermal conductivity compared to conventional materials, while simultaneously reducing thermal expansion coefficients by approximately 40%. These properties are particularly valuable for maintaining seal integrity and preventing thermal stress fractures in cryogenic heat exchangers.

Advanced ceramic materials, particularly silicon carbide and aluminum nitride, have emerged as promising candidates for cryogenic heat exchanger components. Their exceptional hardness, wear resistance, and thermal stability make them ideal for high-pressure differential applications. Recent developments in ceramic manufacturing techniques, including additive manufacturing processes, have overcome traditional limitations in forming complex geometries necessary for efficient heat exchanger designs.

Surface modification technologies have also contributed significantly to enhancing heat transfer efficiency. Micro-textured surfaces created through laser ablation techniques have demonstrated up to 25% improvement in heat transfer coefficients by optimizing nucleate boiling characteristics in cryogenic fluids. Similarly, hydrophobic coatings have proven effective in reducing frost formation, addressing a persistent challenge in cryogenic operations.

Metamaterials engineered with specific thermal conductivity properties represent the cutting edge of materials science for cryogenic applications. These materials can be designed with anisotropic thermal properties, directing heat flow along predetermined pathways to maximize efficiency. Preliminary research indicates potential efficiency improvements of 15-20% in next-generation cryogenic heat exchangers utilizing these advanced materials.

Superconducting materials, particularly high-temperature superconductors (HTS), are increasingly being integrated into cryogenic system designs. While primarily valued for their electrical properties, these materials also demonstrate unique thermal characteristics that can be leveraged in specialized heat exchanger applications, particularly in systems where electromagnetic fields are present.

Nano-engineered materials represent another frontier in cryogenic applications. Multi-walled carbon nanotubes (MWCNTs) incorporated into metal matrices have shown up to 35% improvement in thermal conductivity compared to conventional materials, while simultaneously reducing thermal expansion coefficients by approximately 40%. These properties are particularly valuable for maintaining seal integrity and preventing thermal stress fractures in cryogenic heat exchangers.

Advanced ceramic materials, particularly silicon carbide and aluminum nitride, have emerged as promising candidates for cryogenic heat exchanger components. Their exceptional hardness, wear resistance, and thermal stability make them ideal for high-pressure differential applications. Recent developments in ceramic manufacturing techniques, including additive manufacturing processes, have overcome traditional limitations in forming complex geometries necessary for efficient heat exchanger designs.

Surface modification technologies have also contributed significantly to enhancing heat transfer efficiency. Micro-textured surfaces created through laser ablation techniques have demonstrated up to 25% improvement in heat transfer coefficients by optimizing nucleate boiling characteristics in cryogenic fluids. Similarly, hydrophobic coatings have proven effective in reducing frost formation, addressing a persistent challenge in cryogenic operations.

Metamaterials engineered with specific thermal conductivity properties represent the cutting edge of materials science for cryogenic applications. These materials can be designed with anisotropic thermal properties, directing heat flow along predetermined pathways to maximize efficiency. Preliminary research indicates potential efficiency improvements of 15-20% in next-generation cryogenic heat exchangers utilizing these advanced materials.

Superconducting materials, particularly high-temperature superconductors (HTS), are increasingly being integrated into cryogenic system designs. While primarily valued for their electrical properties, these materials also demonstrate unique thermal characteristics that can be leveraged in specialized heat exchanger applications, particularly in systems where electromagnetic fields are present.

Energy Efficiency Considerations in Cryogenic Systems

Energy efficiency represents a critical dimension in the design and operation of cryogenic systems, particularly in heat exchanger applications. The fundamental challenge stems from the inherent thermodynamic inefficiency when operating at extremely low temperatures, where the Carnot efficiency imposes theoretical limitations on performance. Modern cryogenic systems typically require between 3-10 kW of input power to extract 1 W of cooling at liquid helium temperatures (4.2K), highlighting the significant energy intensity of these processes.

The primary energy consumption in cryogenic heat exchangers occurs during the cooling process, where substantial power is required to maintain temperature differentials against natural entropy production. Recent advancements have focused on reducing this consumption through multi-stage cooling architectures, which distribute the cooling load across temperature ranges to optimize efficiency at each stage. These staged systems have demonstrated energy savings of 15-30% compared to conventional single-stage approaches.

Material selection plays a crucial role in energy efficiency optimization. Advanced materials with superior thermal conductivity at cryogenic temperatures, such as high-purity copper and aluminum alloys, significantly reduce thermal resistance. Notably, recent developments in rare-earth-doped composite materials have shown promising results, with thermal conductivity improvements of up to 40% at temperatures below 20K, directly translating to proportional reductions in energy requirements.

Heat leak minimization represents another essential strategy for efficiency enhancement. Modern vacuum-insulated multilayer designs incorporate radiation shields and specialized low-emissivity coatings that can reduce parasitic heat loads by up to 85% compared to conventional insulation methods. These improvements directly reduce the cooling power requirements and consequently the overall energy consumption of the system.

Regenerative cooling techniques have emerged as particularly promising for energy conservation in cryogenic heat exchangers. Pulse tube refrigerators and Gifford-McMahon cycles utilize regenerative heat exchange principles to recover cooling capacity that would otherwise be lost. Implementation of these technologies has demonstrated coefficient of performance (COP) improvements of 20-35% in laboratory settings, though commercial integration remains challenging due to reliability concerns.

The integration of digital control systems with machine learning algorithms represents the cutting edge of efficiency optimization. Adaptive control strategies that continuously adjust operating parameters based on real-time performance metrics have shown energy savings of 10-25% in field applications. These systems are particularly effective in applications with variable cooling loads, where traditional fixed-parameter controls would operate sub-optimally during partial-load conditions.

The primary energy consumption in cryogenic heat exchangers occurs during the cooling process, where substantial power is required to maintain temperature differentials against natural entropy production. Recent advancements have focused on reducing this consumption through multi-stage cooling architectures, which distribute the cooling load across temperature ranges to optimize efficiency at each stage. These staged systems have demonstrated energy savings of 15-30% compared to conventional single-stage approaches.

Material selection plays a crucial role in energy efficiency optimization. Advanced materials with superior thermal conductivity at cryogenic temperatures, such as high-purity copper and aluminum alloys, significantly reduce thermal resistance. Notably, recent developments in rare-earth-doped composite materials have shown promising results, with thermal conductivity improvements of up to 40% at temperatures below 20K, directly translating to proportional reductions in energy requirements.

Heat leak minimization represents another essential strategy for efficiency enhancement. Modern vacuum-insulated multilayer designs incorporate radiation shields and specialized low-emissivity coatings that can reduce parasitic heat loads by up to 85% compared to conventional insulation methods. These improvements directly reduce the cooling power requirements and consequently the overall energy consumption of the system.

Regenerative cooling techniques have emerged as particularly promising for energy conservation in cryogenic heat exchangers. Pulse tube refrigerators and Gifford-McMahon cycles utilize regenerative heat exchange principles to recover cooling capacity that would otherwise be lost. Implementation of these technologies has demonstrated coefficient of performance (COP) improvements of 20-35% in laboratory settings, though commercial integration remains challenging due to reliability concerns.

The integration of digital control systems with machine learning algorithms represents the cutting edge of efficiency optimization. Adaptive control strategies that continuously adjust operating parameters based on real-time performance metrics have shown energy savings of 10-25% in field applications. These systems are particularly effective in applications with variable cooling loads, where traditional fixed-parameter controls would operate sub-optimally during partial-load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!