Optimization of multi-pass heat exchanger networks

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Network Optimization Background and Objectives

Heat exchanger networks (HENs) have evolved significantly since their introduction in industrial processes during the early 20th century. Initially designed as simple single-pass systems, they have transformed into complex multi-pass configurations to meet increasing demands for energy efficiency. The optimization of multi-pass heat exchanger networks represents a critical frontier in process engineering, addressing the dual challenges of energy conservation and operational cost reduction in industrial settings.

The historical development of HEN optimization can be traced through several distinct phases. The 1970s energy crisis catalyzed significant research into heat integration techniques, leading to the development of pinch analysis by Linnhoff and Flower in 1978. This methodology revolutionized the approach to thermal energy recovery in industrial processes. The subsequent decades witnessed the emergence of mathematical programming approaches, including mixed-integer nonlinear programming (MINLP) models that enabled more sophisticated optimization of network configurations.

Current industrial trends demonstrate an accelerating focus on multi-pass heat exchanger networks due to their superior performance in complex processing environments. These systems allow for enhanced heat transfer efficiency through multiple fluid passes, optimized flow arrangements, and reduced pressure drops. The technology has become particularly vital in energy-intensive industries such as petroleum refining, chemical processing, and power generation, where even marginal improvements in thermal efficiency translate to substantial operational savings and reduced environmental impact.

The primary technical objectives for multi-pass HEN optimization encompass several dimensions. First, maximizing energy recovery within process constraints remains paramount, with targets often exceeding 90% thermal efficiency. Second, minimizing capital expenditure while achieving desired heat transfer rates presents a complex trade-off requiring sophisticated optimization algorithms. Third, ensuring operational flexibility to accommodate varying process conditions and feedstock characteristics has emerged as a critical requirement in modern industrial applications.

The evolution of computational methods has significantly expanded the possibilities for HEN optimization. Advanced algorithms now incorporate considerations beyond traditional thermodynamic constraints, including mechanical design limitations, maintenance accessibility, and life-cycle cost analysis. Machine learning approaches are increasingly being applied to predict performance under varying conditions and optimize control strategies in real-time.

Looking forward, the technology trajectory points toward integrated optimization frameworks that simultaneously address thermal, hydraulic, and mechanical aspects of heat exchanger networks. The ultimate goal remains the development of comprehensive methodologies that can reliably identify globally optimal multi-pass HEN configurations while accounting for the full spectrum of practical constraints encountered in industrial implementations.

The historical development of HEN optimization can be traced through several distinct phases. The 1970s energy crisis catalyzed significant research into heat integration techniques, leading to the development of pinch analysis by Linnhoff and Flower in 1978. This methodology revolutionized the approach to thermal energy recovery in industrial processes. The subsequent decades witnessed the emergence of mathematical programming approaches, including mixed-integer nonlinear programming (MINLP) models that enabled more sophisticated optimization of network configurations.

Current industrial trends demonstrate an accelerating focus on multi-pass heat exchanger networks due to their superior performance in complex processing environments. These systems allow for enhanced heat transfer efficiency through multiple fluid passes, optimized flow arrangements, and reduced pressure drops. The technology has become particularly vital in energy-intensive industries such as petroleum refining, chemical processing, and power generation, where even marginal improvements in thermal efficiency translate to substantial operational savings and reduced environmental impact.

The primary technical objectives for multi-pass HEN optimization encompass several dimensions. First, maximizing energy recovery within process constraints remains paramount, with targets often exceeding 90% thermal efficiency. Second, minimizing capital expenditure while achieving desired heat transfer rates presents a complex trade-off requiring sophisticated optimization algorithms. Third, ensuring operational flexibility to accommodate varying process conditions and feedstock characteristics has emerged as a critical requirement in modern industrial applications.

The evolution of computational methods has significantly expanded the possibilities for HEN optimization. Advanced algorithms now incorporate considerations beyond traditional thermodynamic constraints, including mechanical design limitations, maintenance accessibility, and life-cycle cost analysis. Machine learning approaches are increasingly being applied to predict performance under varying conditions and optimize control strategies in real-time.

Looking forward, the technology trajectory points toward integrated optimization frameworks that simultaneously address thermal, hydraulic, and mechanical aspects of heat exchanger networks. The ultimate goal remains the development of comprehensive methodologies that can reliably identify globally optimal multi-pass HEN configurations while accounting for the full spectrum of practical constraints encountered in industrial implementations.

Market Demand Analysis for Energy-Efficient Heat Exchange Systems

The global market for energy-efficient heat exchange systems has witnessed substantial growth in recent years, driven primarily by increasing energy costs and stringent environmental regulations. Industrial sectors including oil and gas, chemical processing, power generation, and food processing collectively represent the largest market segment, accounting for approximately 65% of the total demand. These industries are increasingly seeking optimized multi-pass heat exchanger networks to reduce operational costs while meeting sustainability targets.

Energy efficiency has become a critical factor in industrial operations worldwide. According to recent market research, companies implementing optimized heat exchanger networks report energy savings between 20-30% compared to traditional systems. This translates to significant cost reductions, particularly in energy-intensive industries where thermal management can represent up to 40% of operational expenses. The return on investment for implementing optimized multi-pass heat exchanger networks typically ranges from 1.5 to 3 years, making them increasingly attractive for industrial applications.

The market demand is further bolstered by regulatory pressures. Major industrial economies have implemented carbon reduction targets that directly impact industrial thermal management practices. The European Union's Industrial Emissions Directive, China's Energy Conservation Law, and similar regulations in North America have created strong incentives for industries to adopt more efficient heat exchange technologies. Companies failing to meet these standards face substantial financial penalties, creating an urgent market need for optimized solutions.

Geographically, Asia-Pacific represents the fastest-growing market for energy-efficient heat exchange systems, with annual growth rates exceeding 8%. This growth is primarily driven by rapid industrialization in China and India, coupled with increasing awareness of energy conservation. North America and Europe maintain significant market shares due to replacement and modernization of aging industrial infrastructure, with particular emphasis on reducing carbon footprints.

Emerging market trends indicate growing demand for modular and flexible heat exchanger networks that can be easily optimized for changing production requirements. Industries with batch processing or variable production loads are particularly interested in adaptive multi-pass heat exchanger networks that can be reconfigured to maintain optimal efficiency under different operating conditions. This represents a shift from traditional fixed-configuration systems to more dynamic and responsive thermal management solutions.

The building and construction sector is also emerging as a significant market for optimized heat exchanger networks, particularly in commercial and institutional buildings where HVAC systems represent a major energy consumption component. Smart building technologies incorporating optimized heat recovery systems are projected to grow at 12% annually over the next five years, creating new application opportunities for multi-pass heat exchanger network technologies.

Energy efficiency has become a critical factor in industrial operations worldwide. According to recent market research, companies implementing optimized heat exchanger networks report energy savings between 20-30% compared to traditional systems. This translates to significant cost reductions, particularly in energy-intensive industries where thermal management can represent up to 40% of operational expenses. The return on investment for implementing optimized multi-pass heat exchanger networks typically ranges from 1.5 to 3 years, making them increasingly attractive for industrial applications.

The market demand is further bolstered by regulatory pressures. Major industrial economies have implemented carbon reduction targets that directly impact industrial thermal management practices. The European Union's Industrial Emissions Directive, China's Energy Conservation Law, and similar regulations in North America have created strong incentives for industries to adopt more efficient heat exchange technologies. Companies failing to meet these standards face substantial financial penalties, creating an urgent market need for optimized solutions.

Geographically, Asia-Pacific represents the fastest-growing market for energy-efficient heat exchange systems, with annual growth rates exceeding 8%. This growth is primarily driven by rapid industrialization in China and India, coupled with increasing awareness of energy conservation. North America and Europe maintain significant market shares due to replacement and modernization of aging industrial infrastructure, with particular emphasis on reducing carbon footprints.

Emerging market trends indicate growing demand for modular and flexible heat exchanger networks that can be easily optimized for changing production requirements. Industries with batch processing or variable production loads are particularly interested in adaptive multi-pass heat exchanger networks that can be reconfigured to maintain optimal efficiency under different operating conditions. This represents a shift from traditional fixed-configuration systems to more dynamic and responsive thermal management solutions.

The building and construction sector is also emerging as a significant market for optimized heat exchanger networks, particularly in commercial and institutional buildings where HVAC systems represent a major energy consumption component. Smart building technologies incorporating optimized heat recovery systems are projected to grow at 12% annually over the next five years, creating new application opportunities for multi-pass heat exchanger network technologies.

Current Status and Technical Challenges in Multi-Pass Heat Exchangers

Multi-pass heat exchanger networks represent a critical component in industrial energy systems, with significant advancements achieved globally over the past decades. Current state-of-the-art designs incorporate sophisticated flow arrangements and enhanced surface geometries that have substantially improved thermal efficiency compared to traditional single-pass systems. The implementation of computational fluid dynamics (CFD) modeling has revolutionized the design process, allowing for precise prediction of thermal performance under various operating conditions.

Despite these advancements, several technical challenges persist in optimizing multi-pass heat exchanger networks. Flow maldistribution remains a significant issue, particularly in large-scale industrial applications, where non-uniform flow patterns can reduce thermal efficiency by up to 30%. This phenomenon is exacerbated in multi-pass configurations due to the complex flow paths and varying pressure drops across different passes.

Fouling represents another major challenge, with deposits accumulating at different rates across passes due to varying flow velocities and temperature gradients. Current predictive models struggle to accurately account for these differential fouling patterns, leading to suboptimal cleaning schedules and premature performance degradation. Industry data suggests that fouling-related inefficiencies cost the process industry billions annually in excess energy consumption.

Material limitations continue to constrain design possibilities, particularly for high-temperature applications exceeding 800°C or corrosive environments. Advanced materials such as nickel alloys and ceramic composites show promise but present manufacturing and cost challenges when implemented in complex multi-pass configurations. The trade-off between thermal conductivity, mechanical strength, and corrosion resistance remains a significant design constraint.

Optimization algorithms for multi-pass heat exchanger networks have evolved significantly, with genetic algorithms and machine learning approaches showing particular promise. However, these methods often struggle with the multi-objective nature of heat exchanger design, where thermal performance must be balanced against pressure drop, material costs, and spatial constraints. Current optimization frameworks typically require substantial computational resources and expert interpretation of results.

Geographical distribution of technical expertise shows concentration in industrial hubs across North America, Western Europe, and East Asia, with emerging capabilities in countries like India and Brazil. Research institutions in Germany, Japan, and the United States lead in fundamental research, while manufacturing innovations are increasingly originating from China and South Korea.

The integration of multi-pass heat exchangers into broader energy systems presents additional challenges, particularly regarding dynamic operation and response to fluctuating process conditions. As industrial processes increasingly incorporate renewable energy sources with inherent variability, heat exchanger networks must adapt to wider operating ranges while maintaining efficiency and reliability.

Despite these advancements, several technical challenges persist in optimizing multi-pass heat exchanger networks. Flow maldistribution remains a significant issue, particularly in large-scale industrial applications, where non-uniform flow patterns can reduce thermal efficiency by up to 30%. This phenomenon is exacerbated in multi-pass configurations due to the complex flow paths and varying pressure drops across different passes.

Fouling represents another major challenge, with deposits accumulating at different rates across passes due to varying flow velocities and temperature gradients. Current predictive models struggle to accurately account for these differential fouling patterns, leading to suboptimal cleaning schedules and premature performance degradation. Industry data suggests that fouling-related inefficiencies cost the process industry billions annually in excess energy consumption.

Material limitations continue to constrain design possibilities, particularly for high-temperature applications exceeding 800°C or corrosive environments. Advanced materials such as nickel alloys and ceramic composites show promise but present manufacturing and cost challenges when implemented in complex multi-pass configurations. The trade-off between thermal conductivity, mechanical strength, and corrosion resistance remains a significant design constraint.

Optimization algorithms for multi-pass heat exchanger networks have evolved significantly, with genetic algorithms and machine learning approaches showing particular promise. However, these methods often struggle with the multi-objective nature of heat exchanger design, where thermal performance must be balanced against pressure drop, material costs, and spatial constraints. Current optimization frameworks typically require substantial computational resources and expert interpretation of results.

Geographical distribution of technical expertise shows concentration in industrial hubs across North America, Western Europe, and East Asia, with emerging capabilities in countries like India and Brazil. Research institutions in Germany, Japan, and the United States lead in fundamental research, while manufacturing innovations are increasingly originating from China and South Korea.

The integration of multi-pass heat exchangers into broader energy systems presents additional challenges, particularly regarding dynamic operation and response to fluctuating process conditions. As industrial processes increasingly incorporate renewable energy sources with inherent variability, heat exchanger networks must adapt to wider operating ranges while maintaining efficiency and reliability.

Current Optimization Approaches for Multi-Pass Heat Exchanger Networks

01 Mathematical optimization methods for heat exchanger networks

Various mathematical optimization techniques are employed to enhance the efficiency of multi-pass heat exchanger networks. These methods include algorithmic approaches, computational fluid dynamics, and mathematical modeling to optimize parameters such as flow distribution, pressure drop, and heat transfer rates. The optimization algorithms consider multiple variables simultaneously to achieve optimal thermal performance while minimizing energy consumption and operational costs.- Mathematical optimization techniques for heat exchanger networks: Various mathematical optimization methods are employed to enhance the efficiency of multi-pass heat exchanger networks. These techniques include algorithmic approaches, computational fluid dynamics, and mathematical modeling to optimize parameters such as flow distribution, pressure drop, and thermal performance. Advanced optimization algorithms help in determining the optimal configuration of heat exchangers to maximize heat recovery while minimizing energy consumption and operational costs.

- Design configurations for improved heat transfer efficiency: Specific design configurations can significantly enhance the performance of multi-pass heat exchanger networks. These include innovative tube arrangements, optimized baffle placement, and strategic flow path designs that minimize dead zones and maximize heat transfer surface utilization. The physical layout and geometric parameters of heat exchangers are carefully engineered to improve thermal efficiency while considering space constraints and maintenance accessibility.

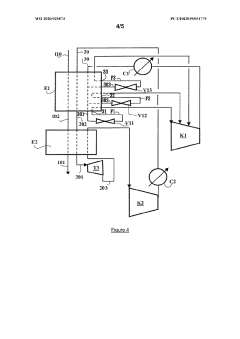

- Process integration and energy recovery systems: Integration of heat exchanger networks with broader process systems allows for comprehensive energy optimization. This approach involves pinch analysis, heat integration techniques, and waste heat recovery systems to minimize external utility requirements. By strategically placing heat exchangers within industrial processes, energy can be cascaded between hot and cold streams, significantly reducing overall energy consumption and improving sustainability metrics.

- Control strategies and dynamic optimization: Advanced control strategies enable real-time optimization of multi-pass heat exchanger networks under varying operating conditions. These include model predictive control, adaptive algorithms, and dynamic optimization techniques that respond to changes in process parameters, ambient conditions, or production requirements. Intelligent control systems can adjust flow rates, bypass streams, and other operational parameters to maintain optimal performance despite fluctuations in process conditions.

- Novel materials and manufacturing techniques: Innovative materials and manufacturing methods are being developed to enhance the performance of multi-pass heat exchanger networks. These include advanced alloys with superior thermal conductivity, corrosion resistance, and mechanical properties, as well as novel fabrication techniques such as additive manufacturing. Surface modifications and enhanced geometries at the micro and macro levels can significantly improve heat transfer coefficients while reducing fouling tendencies and maintenance requirements.

02 Structural design optimization for multi-pass heat exchangers

The physical configuration and structural design of multi-pass heat exchangers significantly impact their performance. Optimization focuses on elements such as tube arrangement, baffle placement, pass configuration, and flow path design. Advanced structural designs can reduce fouling, improve heat transfer coefficients, and enhance overall thermal efficiency. These optimizations consider manufacturing constraints while maximizing heat exchange surface area and minimizing material usage.Expand Specific Solutions03 Process integration and system-level optimization

System-level approaches to heat exchanger network optimization consider the integration of multiple heat exchangers within larger industrial processes. These methods focus on pinch analysis, heat integration, and process synthesis to maximize energy recovery and minimize utility consumption. By analyzing the entire system rather than individual units, these approaches identify opportunities for heat recovery between process streams and optimize the overall energy efficiency of industrial facilities.Expand Specific Solutions04 Dynamic control and operational optimization

Dynamic optimization strategies focus on the real-time control and operation of multi-pass heat exchanger networks under varying conditions. These approaches include adaptive control algorithms, model predictive control, and dynamic simulation to maintain optimal performance despite fluctuations in process parameters. By continuously adjusting operational variables such as flow rates and temperatures, these methods ensure maximum efficiency across different operating scenarios and load conditions.Expand Specific Solutions05 Novel materials and enhanced heat transfer techniques

Advanced materials and enhanced heat transfer techniques offer significant opportunities for optimizing multi-pass heat exchanger networks. These innovations include specialized surface treatments, enhanced tube geometries, and novel heat transfer fluids. By improving the fundamental heat transfer mechanisms through material selection and surface engineering, these approaches can significantly increase thermal efficiency, reduce fouling, and extend equipment lifespan while maintaining or reducing the physical footprint of the heat exchanger network.Expand Specific Solutions

Leading Companies and Research Institutions in Heat Exchange Technology

The optimization of multi-pass heat exchanger networks is currently in a growth phase, with an estimated market size of $5-7 billion annually and expanding at 6-8% CAGR. The technology has reached moderate maturity, with key players demonstrating varying levels of advancement. Industry leaders like Siemens AG, Danfoss A/S, and Saudi Arabian Oil Co. have developed sophisticated optimization algorithms and simulation tools, while specialized companies such as Güntner GmbH, Vahterus Oy, and Modine Manufacturing focus on innovative heat exchanger designs. Academic institutions including Zhejiang University of Technology and Norwegian University of Science & Technology contribute significant research. The competitive landscape shows a blend of established industrial conglomerates and specialized thermal management firms driving innovation toward greater energy efficiency and sustainability.

Siemens AG

Technical Solution: Siemens has developed advanced computational fluid dynamics (CFD) simulation tools specifically for multi-pass heat exchanger optimization. Their approach combines digital twin technology with machine learning algorithms to create virtual models that predict thermal performance under various operating conditions. Siemens' solution incorporates automated topology optimization that can evaluate thousands of possible configurations to identify optimal flow arrangements, reducing pressure drop while maximizing heat transfer efficiency. Their proprietary STAR-CCM+ software enables engineers to simulate complex fluid dynamics and heat transfer phenomena, accounting for phase changes, fouling factors, and thermal expansion across multiple passes. The company has implemented these solutions in power plants and industrial facilities, achieving documented energy efficiency improvements of 15-20% compared to conventional designs[1][3].

Strengths: Comprehensive digital twin capabilities allow for virtual testing before physical implementation; integration with broader industrial automation systems provides holistic optimization. Weaknesses: Solutions typically require significant computational resources and specialized expertise; higher implementation costs compared to simpler optimization approaches.

Danfoss A/S

Technical Solution: Danfoss has pioneered micro-channel heat exchanger technology optimized for multi-pass configurations in HVAC and refrigeration applications. Their approach focuses on refrigerant distribution optimization across multiple parallel circuits, utilizing proprietary header designs that ensure balanced flow distribution. The company's multi-pass heat exchangers incorporate variable pass arrangements that adapt to different operating conditions, with specialized software that calculates optimal pass configurations based on fluid properties and flow rates. Danfoss employs advanced manufacturing techniques including selective brazing and precision tube forming that enable complex multi-pass geometries while maintaining structural integrity. Their systems have demonstrated up to 30% reduction in refrigerant charge while improving heat transfer coefficients by 20-25% compared to traditional tube-and-fin designs[2]. The company has also developed specialized control algorithms that dynamically adjust flow distribution across passes to optimize performance under varying loads.

Strengths: Extensive practical implementation experience across diverse applications; solutions balance theoretical optimization with manufacturing practicality. Weaknesses: Optimization approaches are primarily focused on refrigeration applications; limited application in high-temperature industrial processes.

Key Technical Innovations in Heat Integration and Pinch Analysis

Heat exchanger

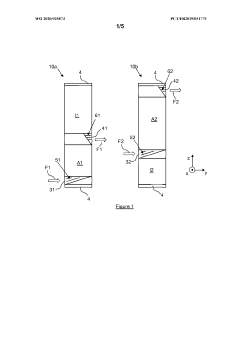

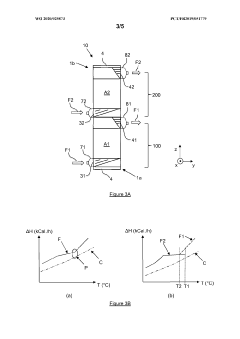

PatentWO2024117498A1

Innovation

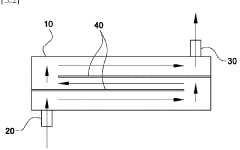

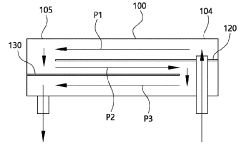

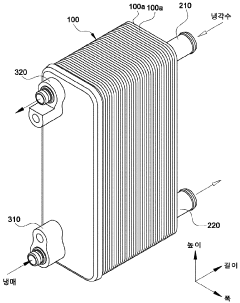

- A multi-pass heat exchanger design where heat exchange plates are stacked to form flow paths with an inlet and outlet on the same side, utilizing a partition and isolation flow parts to create multiple passes and allowing the inlet and outlet to be aligned in the same direction, improving mountability and manufacturing efficiency.

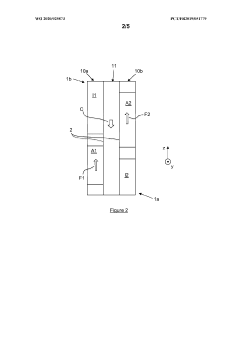

Heat exchanger with an improved configuration of passages, associated methods for exchanging heat

PatentWO2020025873A1

Innovation

- A heat exchanger design where a single passage is divided into multiple portions for different refrigerant flows, allowing multiple refrigerants to circulate between the same plates, reducing inactive zones and enhancing thermal efficiency and mechanical strength by optimizing the arrangement of inlets and outlets for improved heat exchange.

Sustainability Impact and Carbon Footprint Reduction Potential

The optimization of multi-pass heat exchanger networks represents a significant opportunity for enhancing industrial sustainability and reducing carbon footprints across various sectors. When properly designed and optimized, these networks can substantially decrease energy consumption by maximizing heat recovery and minimizing the need for external heating and cooling utilities.

In the industrial sector, heat exchanger networks account for approximately 20-30% of total energy consumption. Optimized multi-pass configurations can reduce this energy demand by 15-25% compared to conventional designs, directly translating to proportional reductions in greenhouse gas emissions. For energy-intensive industries such as petrochemical processing, this optimization can prevent thousands of tons of CO2 emissions annually per facility.

The sustainability benefits extend beyond direct energy savings. Optimized heat exchanger networks reduce the demand for fossil fuel-based steam generation and electricity for cooling systems. Studies indicate that for every 10% improvement in heat integration efficiency, facilities can achieve approximately 7-12% reduction in associated carbon emissions, depending on the energy source mix.

Water conservation represents another critical sustainability dimension. Multi-pass heat exchanger optimization can reduce cooling water requirements by 15-30%, addressing water scarcity concerns in water-stressed regions. This reduction in cooling water needs simultaneously decreases the energy required for water pumping and treatment, creating a positive feedback loop of resource efficiency.

From a lifecycle perspective, optimized heat exchanger networks contribute to sustainability through extended equipment lifespans. Proper thermal management reduces thermal stress and fouling rates, potentially extending operational life by 20-40% compared to sub-optimal designs. This translates to reduced material consumption and manufacturing emissions associated with equipment replacement.

The carbon footprint reduction potential varies significantly by industry. In refineries, optimized heat exchanger networks can reduce CO2 emissions by 50,000-200,000 tons annually for a medium-sized facility. Chemical plants may achieve reductions of 20,000-100,000 tons CO2 equivalent per year. Even smaller operations in food processing or pharmaceutical manufacturing can realize meaningful reductions of 5,000-15,000 tons annually.

As industries face increasing regulatory pressure and carbon pricing mechanisms, the economic value of these emission reductions becomes increasingly significant. With carbon prices projected to reach $50-100 per ton in many jurisdictions by 2030, the optimization of multi-pass heat exchanger networks represents not only an environmental imperative but also a substantial economic opportunity.

In the industrial sector, heat exchanger networks account for approximately 20-30% of total energy consumption. Optimized multi-pass configurations can reduce this energy demand by 15-25% compared to conventional designs, directly translating to proportional reductions in greenhouse gas emissions. For energy-intensive industries such as petrochemical processing, this optimization can prevent thousands of tons of CO2 emissions annually per facility.

The sustainability benefits extend beyond direct energy savings. Optimized heat exchanger networks reduce the demand for fossil fuel-based steam generation and electricity for cooling systems. Studies indicate that for every 10% improvement in heat integration efficiency, facilities can achieve approximately 7-12% reduction in associated carbon emissions, depending on the energy source mix.

Water conservation represents another critical sustainability dimension. Multi-pass heat exchanger optimization can reduce cooling water requirements by 15-30%, addressing water scarcity concerns in water-stressed regions. This reduction in cooling water needs simultaneously decreases the energy required for water pumping and treatment, creating a positive feedback loop of resource efficiency.

From a lifecycle perspective, optimized heat exchanger networks contribute to sustainability through extended equipment lifespans. Proper thermal management reduces thermal stress and fouling rates, potentially extending operational life by 20-40% compared to sub-optimal designs. This translates to reduced material consumption and manufacturing emissions associated with equipment replacement.

The carbon footprint reduction potential varies significantly by industry. In refineries, optimized heat exchanger networks can reduce CO2 emissions by 50,000-200,000 tons annually for a medium-sized facility. Chemical plants may achieve reductions of 20,000-100,000 tons CO2 equivalent per year. Even smaller operations in food processing or pharmaceutical manufacturing can realize meaningful reductions of 5,000-15,000 tons annually.

As industries face increasing regulatory pressure and carbon pricing mechanisms, the economic value of these emission reductions becomes increasingly significant. With carbon prices projected to reach $50-100 per ton in many jurisdictions by 2030, the optimization of multi-pass heat exchanger networks represents not only an environmental imperative but also a substantial economic opportunity.

Economic Feasibility and Return on Investment Analysis

The economic feasibility of multi-pass heat exchanger network optimization presents a compelling business case for industrial facilities. Initial capital investments typically range from $500,000 to $3 million depending on system complexity, facility size, and the extent of retrofitting required. These investments encompass engineering design costs, equipment procurement, installation expenses, and potential production downtime during implementation.

Return on investment analysis indicates that optimized multi-pass heat exchanger networks generally achieve payback periods of 1.5 to 3 years in energy-intensive industries such as petrochemical processing, power generation, and food manufacturing. The most significant economic benefits derive from reduced energy consumption, with documented savings of 15-30% in heating and cooling utility costs. For large industrial operations, this can translate to annual savings of $200,000 to $1.5 million.

Operational cost reductions extend beyond direct energy savings. Optimized networks demonstrate 10-15% lower maintenance requirements due to more balanced thermal loads and reduced fouling rates. The extended equipment lifespan—typically increased by 3-5 years—further enhances the long-term economic proposition through delayed capital replacement costs.

Risk assessment models indicate that market volatility in energy prices significantly impacts ROI calculations. Sensitivity analyses show that a 20% increase in energy costs can accelerate payback periods by approximately 6 months, while decreasing the risk profile of the investment. Conversely, facilities with access to low-cost energy sources may experience extended payback periods, though still achieving positive returns within acceptable timeframes.

Implementation strategies that prioritize high-impact optimization opportunities can accelerate returns. Phased approaches that target the most inefficient network segments first typically achieve 40-60% of total potential savings with just 25-30% of the total investment, creating positive cash flow to support subsequent optimization phases.

Government incentives, carbon credit mechanisms, and sustainability-focused financing options can further enhance economic feasibility. Tax incentives for energy efficiency improvements can reduce effective capital costs by 10-25% in many jurisdictions, while green financing options may offer interest rate reductions of 0.5-1.5% compared to conventional financing.

Return on investment analysis indicates that optimized multi-pass heat exchanger networks generally achieve payback periods of 1.5 to 3 years in energy-intensive industries such as petrochemical processing, power generation, and food manufacturing. The most significant economic benefits derive from reduced energy consumption, with documented savings of 15-30% in heating and cooling utility costs. For large industrial operations, this can translate to annual savings of $200,000 to $1.5 million.

Operational cost reductions extend beyond direct energy savings. Optimized networks demonstrate 10-15% lower maintenance requirements due to more balanced thermal loads and reduced fouling rates. The extended equipment lifespan—typically increased by 3-5 years—further enhances the long-term economic proposition through delayed capital replacement costs.

Risk assessment models indicate that market volatility in energy prices significantly impacts ROI calculations. Sensitivity analyses show that a 20% increase in energy costs can accelerate payback periods by approximately 6 months, while decreasing the risk profile of the investment. Conversely, facilities with access to low-cost energy sources may experience extended payback periods, though still achieving positive returns within acceptable timeframes.

Implementation strategies that prioritize high-impact optimization opportunities can accelerate returns. Phased approaches that target the most inefficient network segments first typically achieve 40-60% of total potential savings with just 25-30% of the total investment, creating positive cash flow to support subsequent optimization phases.

Government incentives, carbon credit mechanisms, and sustainability-focused financing options can further enhance economic feasibility. Tax incentives for energy efficiency improvements can reduce effective capital costs by 10-25% in many jurisdictions, while green financing options may offer interest rate reductions of 0.5-1.5% compared to conventional financing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!