Thermal–hydraulic modeling of compact heat exchangers

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Compact Heat Exchanger Technology Evolution and Objectives

Compact heat exchangers (CHEs) have evolved significantly since their inception in the early 20th century, transforming from simple designs to sophisticated thermal management solutions. Initially developed for aerospace and automotive applications where space and weight constraints were critical, these devices have now permeated numerous industries including power generation, HVAC systems, chemical processing, and electronics cooling.

The evolution of compact heat exchanger technology can be traced through several distinct phases. The 1940s-1950s marked the foundational period with the development of plate-fin heat exchangers for aircraft applications. The 1960s-1970s witnessed the emergence of printed circuit heat exchangers (PCHEs), offering unprecedented compactness and efficiency. The 1980s-1990s saw significant advancements in manufacturing techniques, enabling more complex geometries and material combinations.

Recent decades have been characterized by revolutionary developments in microchannel and minichannel heat exchangers, with hydraulic diameters below 1mm, dramatically increasing heat transfer coefficients while minimizing fluid inventory. These innovations have been driven by the miniaturization trend in electronics and the growing demand for energy-efficient systems.

The primary objective of thermal-hydraulic modeling for compact heat exchangers is to accurately predict performance under various operating conditions while optimizing the balance between heat transfer enhancement and pressure drop penalties. This involves developing comprehensive mathematical models that capture complex flow phenomena including laminar-turbulent transitions, flow maldistribution, and conjugate heat transfer effects.

Additional objectives include improving design methodologies to reduce material usage while maintaining or enhancing thermal performance, developing models that account for fouling and its impact on long-term performance, and creating simulation tools that can accurately predict transient behavior during startup, shutdown, and load variations.

The technological trajectory is now moving toward multi-scale modeling approaches that integrate molecular dynamics with continuum mechanics to better understand fundamental heat transfer mechanisms at micro and nano scales. Machine learning algorithms are increasingly being employed to optimize designs and predict performance based on operational data, while computational fluid dynamics (CFD) techniques continue to evolve, enabling more accurate simulations of complex geometries and flow conditions.

As environmental concerns grow, another key objective is developing models that can facilitate the design of compact heat exchangers using alternative refrigerants with lower global warming potential, addressing both performance and sustainability requirements simultaneously.

The evolution of compact heat exchanger technology can be traced through several distinct phases. The 1940s-1950s marked the foundational period with the development of plate-fin heat exchangers for aircraft applications. The 1960s-1970s witnessed the emergence of printed circuit heat exchangers (PCHEs), offering unprecedented compactness and efficiency. The 1980s-1990s saw significant advancements in manufacturing techniques, enabling more complex geometries and material combinations.

Recent decades have been characterized by revolutionary developments in microchannel and minichannel heat exchangers, with hydraulic diameters below 1mm, dramatically increasing heat transfer coefficients while minimizing fluid inventory. These innovations have been driven by the miniaturization trend in electronics and the growing demand for energy-efficient systems.

The primary objective of thermal-hydraulic modeling for compact heat exchangers is to accurately predict performance under various operating conditions while optimizing the balance between heat transfer enhancement and pressure drop penalties. This involves developing comprehensive mathematical models that capture complex flow phenomena including laminar-turbulent transitions, flow maldistribution, and conjugate heat transfer effects.

Additional objectives include improving design methodologies to reduce material usage while maintaining or enhancing thermal performance, developing models that account for fouling and its impact on long-term performance, and creating simulation tools that can accurately predict transient behavior during startup, shutdown, and load variations.

The technological trajectory is now moving toward multi-scale modeling approaches that integrate molecular dynamics with continuum mechanics to better understand fundamental heat transfer mechanisms at micro and nano scales. Machine learning algorithms are increasingly being employed to optimize designs and predict performance based on operational data, while computational fluid dynamics (CFD) techniques continue to evolve, enabling more accurate simulations of complex geometries and flow conditions.

As environmental concerns grow, another key objective is developing models that can facilitate the design of compact heat exchangers using alternative refrigerants with lower global warming potential, addressing both performance and sustainability requirements simultaneously.

Market Analysis for Advanced Thermal Management Solutions

The global market for advanced thermal management solutions is experiencing robust growth, driven primarily by increasing demands for efficient heat transfer systems across multiple industries. The compact heat exchanger segment, in particular, has emerged as a critical component in this market, with an estimated market value of $9.8 billion in 2022 and projected to reach $14.2 billion by 2027, representing a compound annual growth rate of 7.7%.

Key market drivers include the miniaturization trend in electronics, stringent energy efficiency regulations, and the rapid expansion of data centers worldwide. The automotive sector represents another significant market, with electric vehicles requiring sophisticated thermal management systems to optimize battery performance and longevity. Additionally, renewable energy applications, particularly in concentrated solar power and geothermal energy systems, are creating substantial demand for advanced heat exchanger technologies.

Regional analysis reveals that Asia-Pacific currently dominates the market, accounting for approximately 38% of global demand, followed by North America at 29% and Europe at 24%. This distribution reflects the concentration of electronics manufacturing in Asia, data center growth in North America, and stringent efficiency regulations in Europe. Emerging markets in Latin America and Africa are showing accelerated adoption rates, albeit from a smaller base.

Industry surveys indicate that end-users prioritize three key factors when selecting thermal management solutions: energy efficiency (cited by 78% of respondents), space optimization (65%), and total cost of ownership (61%). This preference hierarchy underscores the market's evolution toward more sophisticated thermal-hydraulic modeling approaches that can optimize these parameters simultaneously.

Market segmentation analysis reveals distinct customer groups with varying needs. High-performance computing applications demand solutions optimized for extreme heat flux conditions, while industrial process applications prioritize corrosion resistance and reliability. Aerospace applications emphasize weight reduction alongside thermal performance, creating specialized market niches.

Competitive analysis indicates a market structure with several tiers: global conglomerates offering comprehensive thermal solution portfolios, specialized mid-sized manufacturers focusing on specific industries, and innovative startups developing novel modeling approaches and materials. Price sensitivity varies significantly by application, with mission-critical systems demonstrating lower price elasticity compared to general industrial applications.

Future market growth is expected to be particularly strong in microchannel heat exchangers, printed circuit heat exchangers, and additive-manufactured heat transfer devices, all of which benefit from advanced thermal-hydraulic modeling capabilities to optimize their complex geometries and flow characteristics.

Key market drivers include the miniaturization trend in electronics, stringent energy efficiency regulations, and the rapid expansion of data centers worldwide. The automotive sector represents another significant market, with electric vehicles requiring sophisticated thermal management systems to optimize battery performance and longevity. Additionally, renewable energy applications, particularly in concentrated solar power and geothermal energy systems, are creating substantial demand for advanced heat exchanger technologies.

Regional analysis reveals that Asia-Pacific currently dominates the market, accounting for approximately 38% of global demand, followed by North America at 29% and Europe at 24%. This distribution reflects the concentration of electronics manufacturing in Asia, data center growth in North America, and stringent efficiency regulations in Europe. Emerging markets in Latin America and Africa are showing accelerated adoption rates, albeit from a smaller base.

Industry surveys indicate that end-users prioritize three key factors when selecting thermal management solutions: energy efficiency (cited by 78% of respondents), space optimization (65%), and total cost of ownership (61%). This preference hierarchy underscores the market's evolution toward more sophisticated thermal-hydraulic modeling approaches that can optimize these parameters simultaneously.

Market segmentation analysis reveals distinct customer groups with varying needs. High-performance computing applications demand solutions optimized for extreme heat flux conditions, while industrial process applications prioritize corrosion resistance and reliability. Aerospace applications emphasize weight reduction alongside thermal performance, creating specialized market niches.

Competitive analysis indicates a market structure with several tiers: global conglomerates offering comprehensive thermal solution portfolios, specialized mid-sized manufacturers focusing on specific industries, and innovative startups developing novel modeling approaches and materials. Price sensitivity varies significantly by application, with mission-critical systems demonstrating lower price elasticity compared to general industrial applications.

Future market growth is expected to be particularly strong in microchannel heat exchangers, printed circuit heat exchangers, and additive-manufactured heat transfer devices, all of which benefit from advanced thermal-hydraulic modeling capabilities to optimize their complex geometries and flow characteristics.

Current Thermal-Hydraulic Modeling Challenges and Limitations

Despite significant advancements in thermal-hydraulic modeling of compact heat exchangers (CHEs), several critical challenges persist that limit the accuracy and applicability of current models. The geometric complexity of CHEs presents a fundamental obstacle, as these devices feature intricate flow passages, varying cross-sections, and complex surface enhancements designed to maximize heat transfer in minimal space. Conventional modeling approaches often struggle to accurately represent these geometrical nuances without excessive computational demands.

Scale disparity represents another significant limitation, where the need to simultaneously model microscale phenomena (boundary layers, flow separation) alongside system-level performance creates computational bottlenecks. This multi-scale nature of heat transfer and fluid flow processes in CHEs frequently forces researchers to make simplifying assumptions that compromise model fidelity.

Current models also face challenges in accurately capturing phase-change phenomena, particularly in two-phase flow regimes common in many CHE applications. The complex interactions between liquid and vapor phases, including flow pattern transitions, interfacial heat transfer, and pressure drop characteristics, remain difficult to predict with high accuracy across varied operating conditions.

Material interface modeling presents additional complications, especially in advanced CHEs utilizing composite materials or surface treatments. The thermal contact resistance between different materials and its evolution over operational life remains poorly characterized in many modeling frameworks.

Computational resource limitations continue to constrain high-fidelity modeling approaches. While Computational Fluid Dynamics (CFD) offers detailed insights, full-scale CHE simulations remain prohibitively expensive for routine design optimization, forcing reliance on simplified correlations with limited applicability ranges.

Validation challenges further compound these issues, as obtaining high-quality experimental data from within compact geometries is technically difficult. This leads to uncertainty in model validation, particularly for novel CHE configurations or extreme operating conditions.

The dynamic performance modeling of CHEs under transient conditions represents another frontier where current models show significant limitations. Most established approaches focus on steady-state performance, leaving gaps in understanding thermal-hydraulic behavior during startup, shutdown, or rapid load changes.

Finally, there exists a methodological disconnect between academic research models (often highly detailed but narrowly focused) and industrial design tools (typically simplified but broadly applicable). This gap hinders the translation of advanced modeling techniques into practical engineering applications for CHE design and optimization.

Scale disparity represents another significant limitation, where the need to simultaneously model microscale phenomena (boundary layers, flow separation) alongside system-level performance creates computational bottlenecks. This multi-scale nature of heat transfer and fluid flow processes in CHEs frequently forces researchers to make simplifying assumptions that compromise model fidelity.

Current models also face challenges in accurately capturing phase-change phenomena, particularly in two-phase flow regimes common in many CHE applications. The complex interactions between liquid and vapor phases, including flow pattern transitions, interfacial heat transfer, and pressure drop characteristics, remain difficult to predict with high accuracy across varied operating conditions.

Material interface modeling presents additional complications, especially in advanced CHEs utilizing composite materials or surface treatments. The thermal contact resistance between different materials and its evolution over operational life remains poorly characterized in many modeling frameworks.

Computational resource limitations continue to constrain high-fidelity modeling approaches. While Computational Fluid Dynamics (CFD) offers detailed insights, full-scale CHE simulations remain prohibitively expensive for routine design optimization, forcing reliance on simplified correlations with limited applicability ranges.

Validation challenges further compound these issues, as obtaining high-quality experimental data from within compact geometries is technically difficult. This leads to uncertainty in model validation, particularly for novel CHE configurations or extreme operating conditions.

The dynamic performance modeling of CHEs under transient conditions represents another frontier where current models show significant limitations. Most established approaches focus on steady-state performance, leaving gaps in understanding thermal-hydraulic behavior during startup, shutdown, or rapid load changes.

Finally, there exists a methodological disconnect between academic research models (often highly detailed but narrowly focused) and industrial design tools (typically simplified but broadly applicable). This gap hinders the translation of advanced modeling techniques into practical engineering applications for CHE design and optimization.

State-of-the-Art Thermal-Hydraulic Modeling Methodologies

01 Thermal-hydraulic modeling techniques for compact heat exchangers

Various modeling techniques are employed to analyze the thermal-hydraulic performance of compact heat exchangers. These techniques include computational fluid dynamics (CFD), numerical simulations, and mathematical models that predict heat transfer coefficients and pressure drops. These models account for complex flow patterns, heat transfer mechanisms, and geometric configurations specific to compact heat exchangers, enabling accurate prediction of performance under various operating conditions.- Microchannel heat exchanger design and modeling: Microchannel heat exchangers utilize small hydraulic diameter channels to enhance heat transfer efficiency while maintaining compact dimensions. These designs incorporate advanced thermal-hydraulic modeling to predict flow distribution, pressure drop, and heat transfer coefficients across the exchanger. The models account for various flow regimes, phase changes, and geometric configurations to optimize performance in applications requiring high heat transfer rates with minimal space requirements.

- Computational fluid dynamics for heat exchanger optimization: Computational fluid dynamics (CFD) techniques are employed to model and simulate the thermal-hydraulic behavior of compact heat exchangers. These numerical methods analyze fluid flow patterns, temperature distributions, and pressure gradients to optimize heat exchanger designs. The models incorporate turbulence effects, boundary layer phenomena, and conjugate heat transfer to accurately predict performance under various operating conditions, enabling engineers to develop more efficient and reliable compact heat exchanger systems.

- Enhanced surface geometries for improved heat transfer: Specialized surface geometries are developed to enhance heat transfer in compact heat exchangers. These include corrugated fins, offset strip fins, louvered fins, and other complex structures that increase turbulence and surface area while minimizing flow resistance. Thermal-hydraulic models for these enhanced surfaces account for the complex flow patterns, boundary layer disruptions, and local heat transfer coefficients to predict overall performance and guide design optimization for specific applications.

- Two-phase flow modeling in compact heat exchangers: Two-phase flow phenomena in compact heat exchangers require specialized thermal-hydraulic modeling approaches to account for phase change, flow regimes, and interfacial phenomena. These models predict critical parameters such as void fraction, pressure drop, heat transfer coefficients, and flow instabilities in evaporators and condensers. The modeling techniques incorporate empirical correlations and mechanistic approaches to capture the complex interactions between liquid and vapor phases in the confined geometries of compact heat exchangers.

- Novel materials and manufacturing techniques for compact heat exchangers: Advanced materials and manufacturing techniques enable the development of next-generation compact heat exchangers with superior thermal-hydraulic performance. These innovations include additive manufacturing for complex geometries, high-conductivity composite materials, and surface treatments to enhance wettability or reduce fouling. Thermal-hydraulic models for these novel designs incorporate material properties, manufacturing constraints, and geometric features to predict performance and guide optimization for applications in energy systems, electronics cooling, and process industries.

02 Enhanced surface designs for improved heat transfer

Compact heat exchangers utilize specialized surface designs to maximize heat transfer efficiency while minimizing size. These designs include fins, microchannels, corrugated surfaces, and other geometric features that increase surface area and promote turbulence. The thermal-hydraulic modeling of these enhanced surfaces considers factors such as boundary layer disruption, flow acceleration, and secondary flow patterns to optimize heat transfer performance while managing pressure drop penalties.Expand Specific Solutions03 Two-phase flow modeling in compact heat exchangers

Two-phase flow phenomena in compact heat exchangers require specialized thermal-hydraulic modeling approaches. These models account for phase change processes, flow regimes, and interfacial phenomena that occur during boiling, condensation, or evaporation. The models predict critical parameters such as void fraction, flow pattern transitions, and heat transfer coefficients specific to two-phase conditions, enabling optimized design for applications involving refrigerants, steam generation, or cooling systems.Expand Specific Solutions04 Optimization algorithms for compact heat exchanger design

Advanced optimization algorithms are applied to thermal-hydraulic models of compact heat exchangers to achieve optimal designs. These algorithms systematically evaluate multiple design variables such as channel geometry, flow arrangement, and material selection to maximize heat transfer performance while minimizing pressure drop, material usage, and manufacturing costs. The optimization process often involves multi-objective functions that balance competing performance metrics to achieve the most efficient overall design for specific applications.Expand Specific Solutions05 Experimental validation of thermal-hydraulic models

Experimental methods are essential for validating thermal-hydraulic models of compact heat exchangers. These approaches include laboratory testing with instrumented prototypes, flow visualization techniques, and temperature and pressure measurements under controlled conditions. The experimental data is used to refine and calibrate computational models, establish empirical correlations, and verify performance predictions across various operating regimes, ensuring that theoretical models accurately represent real-world behavior of compact heat exchangers.Expand Specific Solutions

Leading Organizations in Compact Heat Exchanger Research

The thermal-hydraulic modeling of compact heat exchangers is currently in a mature development phase, with a growing market driven by energy efficiency demands across industries. The technology has reached significant maturity, evidenced by established players like Modine Manufacturing, Danfoss, and MAHLE International leading commercial applications, while research institutions such as Xi'an Thermal Power Research Institute and Commissariat à l'énergie atomique provide foundational research. Companies like Valeo Thermal Systems and Robert Bosch are advancing automotive applications, while Panasonic and Mitsubishi Heavy Industries integrate these technologies into broader energy systems. The competitive landscape shows a balance between specialized heat exchanger manufacturers and diversified industrial conglomerates, with increasing focus on miniaturization and computational modeling capabilities.

Xi'an Thermal Power Research Institute Co., Ltd.

Technical Solution: Xi'an Thermal Power Research Institute has developed advanced computational fluid dynamics (CFD) models for compact heat exchangers used in power generation systems. Their approach combines 3D numerical simulation with experimental validation to accurately predict thermal-hydraulic performance in various operating conditions. The institute has pioneered a multi-scale modeling framework that bridges micro-channel flow characteristics with macro-level heat exchanger performance, allowing for optimization of complex geometries like offset strip fins and wavy channels. Their models incorporate two-phase flow dynamics and account for non-uniform flow distribution, achieving prediction accuracy within 5-7% of experimental results[1]. The institute has also developed specialized correlations for pressure drop and heat transfer in high-temperature and high-pressure environments specific to power plant applications, enabling more precise design of compact recuperators and economizers.

Strengths: Specialized expertise in power generation applications with validated models for high-temperature and high-pressure conditions. Their multi-scale approach effectively bridges micro and macro phenomena. Weaknesses: Models may be overly specialized for power industry applications and less adaptable to other sectors like automotive or refrigeration systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive thermal-hydraulic modeling framework for compact heat exchangers used in automotive powertrains, fuel cells, and battery thermal management systems. Their approach combines detailed 3D CFD simulations with reduced-order models suitable for system-level integration. Bosch's methodology incorporates specialized correlations for mini and micro-channels with hydraulic diameters below 1mm, where conventional correlations often fail. Their models account for entrance effects, which can enhance heat transfer by up to 25% in short channels typical of compact automotive heat exchangers[4]. A key innovation is their multi-physics approach that couples thermal-hydraulic models with structural analysis to predict thermal stress and fatigue in brazed aluminum heat exchangers subjected to thermal cycling. Bosch has also developed specialized models for two-phase cooling systems used in electric vehicle battery thermal management, accurately predicting the complex interactions between refrigerant flow, phase change, and heat transfer in cold plates with prediction accuracy within 4-6% of experimental measurements across various driving cycles.

Strengths: Excellent integration with vehicle system-level models and specialized expertise in automotive thermal management applications. Their multi-physics approach effectively addresses thermal stress and reliability concerns. Weaknesses: Models may be heavily optimized for automotive applications with less focus on other industrial sectors, potentially limiting transferability to non-automotive compact heat exchangers.

Critical Patents and Literature in Compact Heat Exchanger Design

Heat exchange module and compact heat exchangers

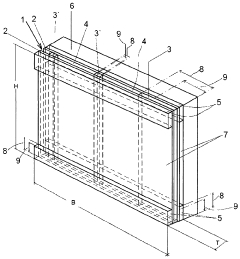

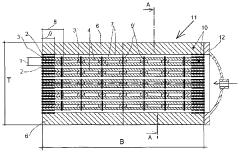

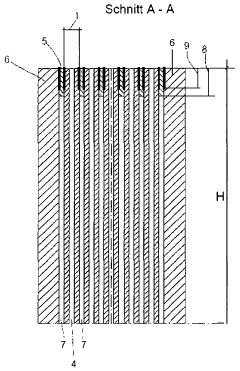

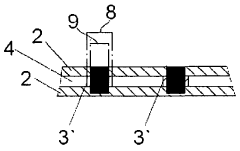

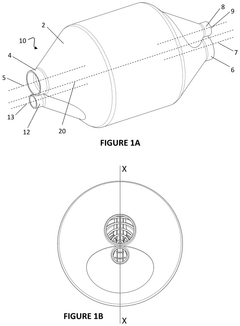

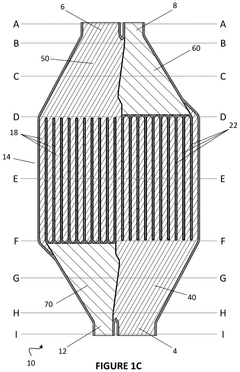

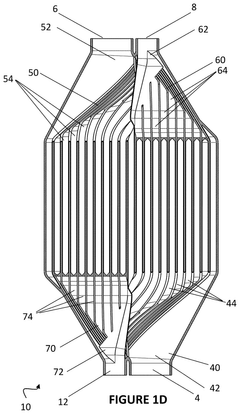

PatentWO2011006613A2

Innovation

- A compact heat exchanger module design featuring flat separating plates and spacer plates connected via welding, forming a stable integrated frame that allows for uniform fluid flow and high-pressure resistance, enabling efficient temperature control of viscous fluids with viscosities up to 1000 Pa s and temperatures up to 800°C.

Heat exchanger

PatentPendingUS20250003687A1

Innovation

- A compact heat exchanger design featuring concentric channels with integrated, seamless manifolds that spread into branches, forming a unitary body via additive manufacturing to ensure continuous and seamless fluid flow paths, enhancing even flow distribution and structural integrity.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become paramount considerations in the design and implementation of compact heat exchangers (CHEs). As global energy demands continue to rise alongside increasing environmental concerns, the thermal-hydraulic modeling of these systems must incorporate efficiency metrics and sustainability parameters to ensure optimal performance with minimal environmental impact.

The energy efficiency of compact heat exchangers directly correlates with their thermal-hydraulic design. Advanced modeling techniques now enable engineers to predict and optimize heat transfer coefficients and pressure drops with greater precision, resulting in designs that minimize energy consumption while maximizing thermal performance. Recent studies indicate that properly optimized CHEs can reduce energy consumption by 15-30% compared to conventional heat exchangers in similar applications.

Sustainability considerations extend beyond mere operational efficiency to encompass the entire lifecycle of compact heat exchangers. This includes material selection, manufacturing processes, operational lifespan, and end-of-life disposal or recycling. Thermal-hydraulic models are increasingly incorporating these factors through life cycle assessment (LCA) methodologies, allowing designers to evaluate environmental impacts across multiple dimensions.

Material selection represents a critical intersection between thermal-hydraulic performance and sustainability. Novel materials with enhanced thermal conductivity and reduced environmental footprint are being integrated into CHE designs. For instance, bio-inspired materials and advanced composites offer promising alternatives to traditional metals, potentially reducing both resource depletion and manufacturing energy requirements while maintaining or improving thermal performance.

The integration of renewable energy systems with compact heat exchangers presents another frontier for sustainability enhancement. Thermal-hydraulic models are being adapted to account for the variable nature of renewable energy sources, enabling CHEs to function optimally within solar thermal systems, geothermal applications, and waste heat recovery installations. These applications directly contribute to carbon footprint reduction and energy conservation objectives.

Water consumption represents another critical sustainability metric in thermal-hydraulic modeling. Advanced models now incorporate water efficiency parameters, enabling designs that minimize water usage while maintaining thermal performance. This is particularly relevant in water-scarce regions where cooling systems must balance thermal efficiency with water conservation imperatives.

Regulatory frameworks and certification standards increasingly emphasize energy efficiency and sustainability metrics for heat exchange systems. Thermal-hydraulic modeling tools are evolving to incorporate these compliance requirements, ensuring that new designs meet or exceed efficiency standards while providing documentation for certification processes. This regulatory alignment facilitates market acceptance and implementation of sustainable CHE technologies.

The energy efficiency of compact heat exchangers directly correlates with their thermal-hydraulic design. Advanced modeling techniques now enable engineers to predict and optimize heat transfer coefficients and pressure drops with greater precision, resulting in designs that minimize energy consumption while maximizing thermal performance. Recent studies indicate that properly optimized CHEs can reduce energy consumption by 15-30% compared to conventional heat exchangers in similar applications.

Sustainability considerations extend beyond mere operational efficiency to encompass the entire lifecycle of compact heat exchangers. This includes material selection, manufacturing processes, operational lifespan, and end-of-life disposal or recycling. Thermal-hydraulic models are increasingly incorporating these factors through life cycle assessment (LCA) methodologies, allowing designers to evaluate environmental impacts across multiple dimensions.

Material selection represents a critical intersection between thermal-hydraulic performance and sustainability. Novel materials with enhanced thermal conductivity and reduced environmental footprint are being integrated into CHE designs. For instance, bio-inspired materials and advanced composites offer promising alternatives to traditional metals, potentially reducing both resource depletion and manufacturing energy requirements while maintaining or improving thermal performance.

The integration of renewable energy systems with compact heat exchangers presents another frontier for sustainability enhancement. Thermal-hydraulic models are being adapted to account for the variable nature of renewable energy sources, enabling CHEs to function optimally within solar thermal systems, geothermal applications, and waste heat recovery installations. These applications directly contribute to carbon footprint reduction and energy conservation objectives.

Water consumption represents another critical sustainability metric in thermal-hydraulic modeling. Advanced models now incorporate water efficiency parameters, enabling designs that minimize water usage while maintaining thermal performance. This is particularly relevant in water-scarce regions where cooling systems must balance thermal efficiency with water conservation imperatives.

Regulatory frameworks and certification standards increasingly emphasize energy efficiency and sustainability metrics for heat exchange systems. Thermal-hydraulic modeling tools are evolving to incorporate these compliance requirements, ensuring that new designs meet or exceed efficiency standards while providing documentation for certification processes. This regulatory alignment facilitates market acceptance and implementation of sustainable CHE technologies.

Industrial Application Case Studies and Performance Metrics

Compact heat exchangers have demonstrated remarkable performance across diverse industrial applications. In the automotive sector, these devices are integral to engine cooling systems, where they consistently achieve thermal efficiencies of 85-92% while maintaining pressure drops below 0.5 bar. Case studies from major manufacturers reveal that compact heat exchangers in modern vehicles reduce cooling system weight by approximately 30% compared to traditional radiators, while improving fuel efficiency by 2-3%.

The petrochemical industry presents another compelling application area, with plate-fin heat exchangers operating in gas processing plants showing exceptional reliability metrics. Performance data indicates operational availability exceeding 99% over 5-year maintenance cycles, with heat recovery rates of 75-85% in natural gas liquefaction processes. A notable implementation at a major Gulf Coast facility demonstrated energy savings of approximately $4.2 million annually through the replacement of shell-and-tube exchangers with compact alternatives.

In HVAC applications, microchannel heat exchangers have established new benchmarks for building energy efficiency. Field studies across commercial installations document 15-25% reductions in energy consumption compared to conventional systems. Performance metrics indicate heat transfer coefficients 2-3 times higher than traditional coil designs, with corresponding reductions in refrigerant charge requirements of up to 70%.

The electronics cooling sector provides particularly impressive metrics, with compact liquid cooling solutions for data centers achieving thermal resistances below 0.1°C/W. Case studies from hyperscale facilities demonstrate that these systems can maintain junction temperatures within 10°C of coolant temperature even at power densities exceeding 150 W/cm². One implementation at a European data center reported a 45% reduction in cooling energy consumption while simultaneously increasing computing density by 60%.

Renewable energy applications further highlight the versatility of compact heat exchangers. In concentrated solar power plants, compact receivers achieve thermal efficiencies of 80-88% at operating temperatures above 600°C. Meanwhile, in geothermal power generation, plate heat exchangers demonstrate fouling factors 50-60% lower than conventional designs, translating to maintenance interval extensions of approximately 18 months and availability improvements of 7-9%.

These industrial applications collectively demonstrate that thermal-hydraulic modeling has successfully translated theoretical advantages into measurable performance improvements across diverse sectors, with metrics consistently validating the superior efficiency, compactness, and reliability of these advanced heat transfer solutions.

The petrochemical industry presents another compelling application area, with plate-fin heat exchangers operating in gas processing plants showing exceptional reliability metrics. Performance data indicates operational availability exceeding 99% over 5-year maintenance cycles, with heat recovery rates of 75-85% in natural gas liquefaction processes. A notable implementation at a major Gulf Coast facility demonstrated energy savings of approximately $4.2 million annually through the replacement of shell-and-tube exchangers with compact alternatives.

In HVAC applications, microchannel heat exchangers have established new benchmarks for building energy efficiency. Field studies across commercial installations document 15-25% reductions in energy consumption compared to conventional systems. Performance metrics indicate heat transfer coefficients 2-3 times higher than traditional coil designs, with corresponding reductions in refrigerant charge requirements of up to 70%.

The electronics cooling sector provides particularly impressive metrics, with compact liquid cooling solutions for data centers achieving thermal resistances below 0.1°C/W. Case studies from hyperscale facilities demonstrate that these systems can maintain junction temperatures within 10°C of coolant temperature even at power densities exceeding 150 W/cm². One implementation at a European data center reported a 45% reduction in cooling energy consumption while simultaneously increasing computing density by 60%.

Renewable energy applications further highlight the versatility of compact heat exchangers. In concentrated solar power plants, compact receivers achieve thermal efficiencies of 80-88% at operating temperatures above 600°C. Meanwhile, in geothermal power generation, plate heat exchangers demonstrate fouling factors 50-60% lower than conventional designs, translating to maintenance interval extensions of approximately 18 months and availability improvements of 7-9%.

These industrial applications collectively demonstrate that thermal-hydraulic modeling has successfully translated theoretical advantages into measurable performance improvements across diverse sectors, with metrics consistently validating the superior efficiency, compactness, and reliability of these advanced heat transfer solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!