Microchannel network optimization for rapid heat transfer

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Heat Transfer Background and Objectives

Microchannel heat transfer technology has evolved significantly since its conceptual introduction in the 1980s, emerging as a revolutionary approach to thermal management challenges. The fundamental principle leverages microscale channels (typically 10-200 micrometers in hydraulic diameter) to dramatically increase surface area-to-volume ratios, enabling exceptional heat transfer coefficients compared to conventional cooling methods. This technology represents a paradigm shift in heat exchanger design, offering up to tenfold improvements in thermal performance within significantly reduced footprints.

The evolution of microchannel heat transfer has been accelerated by advances in microfabrication techniques, computational fluid dynamics, and materials science. Initially limited to silicon-based applications in electronics cooling, the technology has expanded across diverse industries including automotive, aerospace, energy systems, and biomedical devices. This cross-disciplinary adoption has driven continuous refinement in channel geometry optimization, surface enhancement techniques, and multi-phase flow management.

Current research focuses on addressing critical limitations including pressure drop penalties, flow maldistribution, and manufacturing scalability. The optimization of microchannel networks represents a complex multi-objective challenge balancing thermal performance, pumping power requirements, and system reliability. Recent developments in additive manufacturing have opened new possibilities for creating previously impossible geometries, further expanding the design space.

The primary objective of microchannel network optimization research is to develop next-generation thermal management solutions capable of dissipating heat fluxes exceeding 1000 W/cm² while maintaining acceptable pressure drops and uniform temperature distributions. This capability is increasingly critical for emerging technologies including high-performance computing, power electronics, concentrated photovoltaics, and advanced propulsion systems.

Secondary objectives include enhancing manufacturing scalability for cost-effective mass production, improving operational reliability through fouling resistance and mechanical robustness, and developing design methodologies that can predict performance across varying operating conditions. The integration of smart materials and adaptive control strategies represents an emerging frontier, potentially enabling responsive thermal management systems that dynamically adjust to changing heat loads.

The ultimate goal extends beyond performance metrics to address sustainability concerns through reduced material usage, lower pumping energy requirements, and compatibility with low-GWP refrigerants or non-phase change coolants. As thermal challenges continue to limit advancement across multiple technology domains, optimized microchannel networks stand as a critical enabling technology for next-generation systems where conventional cooling approaches have reached fundamental limitations.

The evolution of microchannel heat transfer has been accelerated by advances in microfabrication techniques, computational fluid dynamics, and materials science. Initially limited to silicon-based applications in electronics cooling, the technology has expanded across diverse industries including automotive, aerospace, energy systems, and biomedical devices. This cross-disciplinary adoption has driven continuous refinement in channel geometry optimization, surface enhancement techniques, and multi-phase flow management.

Current research focuses on addressing critical limitations including pressure drop penalties, flow maldistribution, and manufacturing scalability. The optimization of microchannel networks represents a complex multi-objective challenge balancing thermal performance, pumping power requirements, and system reliability. Recent developments in additive manufacturing have opened new possibilities for creating previously impossible geometries, further expanding the design space.

The primary objective of microchannel network optimization research is to develop next-generation thermal management solutions capable of dissipating heat fluxes exceeding 1000 W/cm² while maintaining acceptable pressure drops and uniform temperature distributions. This capability is increasingly critical for emerging technologies including high-performance computing, power electronics, concentrated photovoltaics, and advanced propulsion systems.

Secondary objectives include enhancing manufacturing scalability for cost-effective mass production, improving operational reliability through fouling resistance and mechanical robustness, and developing design methodologies that can predict performance across varying operating conditions. The integration of smart materials and adaptive control strategies represents an emerging frontier, potentially enabling responsive thermal management systems that dynamically adjust to changing heat loads.

The ultimate goal extends beyond performance metrics to address sustainability concerns through reduced material usage, lower pumping energy requirements, and compatibility with low-GWP refrigerants or non-phase change coolants. As thermal challenges continue to limit advancement across multiple technology domains, optimized microchannel networks stand as a critical enabling technology for next-generation systems where conventional cooling approaches have reached fundamental limitations.

Market Analysis for Microchannel Cooling Solutions

The global microchannel cooling solutions market is experiencing robust growth, driven primarily by increasing thermal management challenges across multiple industries. The market size was valued at approximately $2.5 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate (CAGR) of 11.2%. This growth trajectory is significantly outpacing traditional cooling technologies, which typically grow at 5-7% annually.

Electronics cooling represents the largest application segment, accounting for nearly 45% of the total market share. Within this segment, data centers and high-performance computing facilities are the primary adopters, seeking solutions to manage ever-increasing power densities. The automotive sector follows closely, particularly with the rapid expansion of electric vehicles requiring sophisticated battery thermal management systems.

Geographically, North America currently leads the market with approximately 35% share, followed by Asia-Pacific at 32% and Europe at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 13.8% through 2028, primarily due to the expanding electronics manufacturing base and increasing adoption of advanced cooling technologies in countries like China, South Korea, and Taiwan.

From an end-user perspective, the market demonstrates interesting segmentation patterns. Large enterprises account for 65% of current adoption, while small and medium enterprises represent a rapidly growing segment with 18% annual growth. This indicates a democratization of microchannel cooling technology as manufacturing costs decrease and standardized solutions become more widely available.

Customer demand is increasingly focused on several key performance metrics: thermal efficiency (measured by heat transfer coefficient), pressure drop characteristics, manufacturing scalability, and integration flexibility. Market research indicates that customers are willing to pay a premium of 15-20% for solutions that deliver 30% or greater improvement in thermal performance compared to conventional technologies.

The competitive landscape features both established thermal management companies and innovative startups. Traditional players like Boyd Corporation, Wolverine Tube, and Mikros Technologies hold approximately 45% of the market share collectively. However, emerging companies specializing exclusively in microchannel technology have captured 25% of the market in just the past five years, indicating significant disruption potential.

Market barriers include high initial manufacturing costs, design complexity, and integration challenges with existing systems. However, these barriers are gradually diminishing as advanced manufacturing techniques like selective laser melting and direct metal laser sintering become more accessible, reducing production costs by approximately 30% over the past three years.

Electronics cooling represents the largest application segment, accounting for nearly 45% of the total market share. Within this segment, data centers and high-performance computing facilities are the primary adopters, seeking solutions to manage ever-increasing power densities. The automotive sector follows closely, particularly with the rapid expansion of electric vehicles requiring sophisticated battery thermal management systems.

Geographically, North America currently leads the market with approximately 35% share, followed by Asia-Pacific at 32% and Europe at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 13.8% through 2028, primarily due to the expanding electronics manufacturing base and increasing adoption of advanced cooling technologies in countries like China, South Korea, and Taiwan.

From an end-user perspective, the market demonstrates interesting segmentation patterns. Large enterprises account for 65% of current adoption, while small and medium enterprises represent a rapidly growing segment with 18% annual growth. This indicates a democratization of microchannel cooling technology as manufacturing costs decrease and standardized solutions become more widely available.

Customer demand is increasingly focused on several key performance metrics: thermal efficiency (measured by heat transfer coefficient), pressure drop characteristics, manufacturing scalability, and integration flexibility. Market research indicates that customers are willing to pay a premium of 15-20% for solutions that deliver 30% or greater improvement in thermal performance compared to conventional technologies.

The competitive landscape features both established thermal management companies and innovative startups. Traditional players like Boyd Corporation, Wolverine Tube, and Mikros Technologies hold approximately 45% of the market share collectively. However, emerging companies specializing exclusively in microchannel technology have captured 25% of the market in just the past five years, indicating significant disruption potential.

Market barriers include high initial manufacturing costs, design complexity, and integration challenges with existing systems. However, these barriers are gradually diminishing as advanced manufacturing techniques like selective laser melting and direct metal laser sintering become more accessible, reducing production costs by approximately 30% over the past three years.

Current Challenges in Microchannel Network Design

Despite significant advancements in microchannel technology, several critical challenges persist in optimizing microchannel networks for rapid heat transfer applications. The primary obstacle remains the complex trade-off between pressure drop and heat transfer efficiency. As channel dimensions decrease to enhance heat transfer, the pressure drop increases exponentially, requiring substantially more pumping power and potentially negating efficiency gains in overall system performance.

Manufacturing constraints present another significant challenge. Current fabrication techniques struggle to consistently produce microchannels with precise dimensions at scale, particularly when complex geometries are required. The resulting dimensional variations can lead to flow maldistribution, creating hotspots and reducing overall thermal performance. Additionally, surface roughness control remains difficult yet crucial, as microscale surface features disproportionately affect flow characteristics compared to conventional channels.

Fouling and clogging represent persistent operational challenges that have not been adequately addressed. Microchannel networks are inherently susceptible to blockage from particulates or biological growth, particularly in long-term operations. This vulnerability necessitates either frequent maintenance or complex filtration systems, both of which add cost and complexity to practical implementations.

Flow distribution optimization across parallel microchannel networks continues to challenge designers. Achieving uniform flow distribution is essential for preventing localized overheating, yet becomes increasingly difficult as network complexity grows. Current mathematical models often fail to accurately predict flow behavior at junction points and manifolds, leading to suboptimal designs that require extensive empirical testing.

Material selection presents another significant hurdle. While high thermal conductivity materials are desirable for heat transfer, they must also withstand thermal cycling, resist corrosion, and maintain mechanical integrity under operating conditions. The limited selection of materials meeting all these criteria constrains design options and often forces compromises in performance.

Computational modeling capabilities, though improved, still struggle with multi-physics simulations that accurately capture all relevant phenomena at the microscale. The interaction between fluid dynamics, heat transfer, and potentially phase change processes requires enormous computational resources, making comprehensive optimization studies prohibitively expensive for many development teams.

Finally, scaling challenges persist when transitioning from laboratory prototypes to commercial applications. Promising microchannel designs often demonstrate excellent performance in controlled testing environments but fail to maintain this performance when scaled to practical dimensions or when integrated with other system components. This scaling gap represents perhaps the most significant barrier to widespread commercial adoption of advanced microchannel network technologies.

Manufacturing constraints present another significant challenge. Current fabrication techniques struggle to consistently produce microchannels with precise dimensions at scale, particularly when complex geometries are required. The resulting dimensional variations can lead to flow maldistribution, creating hotspots and reducing overall thermal performance. Additionally, surface roughness control remains difficult yet crucial, as microscale surface features disproportionately affect flow characteristics compared to conventional channels.

Fouling and clogging represent persistent operational challenges that have not been adequately addressed. Microchannel networks are inherently susceptible to blockage from particulates or biological growth, particularly in long-term operations. This vulnerability necessitates either frequent maintenance or complex filtration systems, both of which add cost and complexity to practical implementations.

Flow distribution optimization across parallel microchannel networks continues to challenge designers. Achieving uniform flow distribution is essential for preventing localized overheating, yet becomes increasingly difficult as network complexity grows. Current mathematical models often fail to accurately predict flow behavior at junction points and manifolds, leading to suboptimal designs that require extensive empirical testing.

Material selection presents another significant hurdle. While high thermal conductivity materials are desirable for heat transfer, they must also withstand thermal cycling, resist corrosion, and maintain mechanical integrity under operating conditions. The limited selection of materials meeting all these criteria constrains design options and often forces compromises in performance.

Computational modeling capabilities, though improved, still struggle with multi-physics simulations that accurately capture all relevant phenomena at the microscale. The interaction between fluid dynamics, heat transfer, and potentially phase change processes requires enormous computational resources, making comprehensive optimization studies prohibitively expensive for many development teams.

Finally, scaling challenges persist when transitioning from laboratory prototypes to commercial applications. Promising microchannel designs often demonstrate excellent performance in controlled testing environments but fail to maintain this performance when scaled to practical dimensions or when integrated with other system components. This scaling gap represents perhaps the most significant barrier to widespread commercial adoption of advanced microchannel network technologies.

State-of-the-Art Optimization Approaches

01 Microchannel design optimization for heat transfer enhancement

Optimized microchannel designs can significantly improve heat transfer efficiency in various applications. These designs focus on channel geometry, cross-sectional shapes, and dimensional parameters to maximize heat dissipation while minimizing pressure drop. Advanced configurations include tapered channels, variable cross-sections, and optimized aspect ratios that enhance fluid-wall contact and thermal exchange properties.- Microchannel heat exchanger design optimization: Optimized designs of microchannel heat exchangers enhance thermal performance through specific channel geometries, arrangements, and flow patterns. These designs include varying channel cross-sections, optimized manifold configurations, and strategic placement of microchannels to maximize heat transfer efficiency while minimizing pressure drop. Advanced manufacturing techniques enable complex microchannel networks with features that promote turbulence and increase surface area for improved heat exchange.

- Electronic cooling applications: Microchannel networks are increasingly used for thermal management in electronic devices, particularly for high-power density applications. These systems integrate directly with electronic components, providing efficient cooling through close proximity to heat sources. The microchannels can be incorporated into heat sinks, vapor chambers, or directly into semiconductor substrates, allowing for targeted cooling of hotspots and uniform temperature distribution across electronic components.

- Two-phase flow heat transfer enhancement: Two-phase flow in microchannels significantly enhances heat transfer capabilities through phase change processes. These systems utilize the latent heat of vaporization to remove large amounts of thermal energy. Special surface treatments, channel geometries, and flow control mechanisms are implemented to manage bubble formation, prevent flow instabilities, and maintain efficient heat transfer. This approach enables higher heat flux capabilities compared to single-phase liquid cooling systems.

- Advanced manufacturing techniques for microchannel networks: Novel manufacturing methods enable the creation of complex microchannel networks with precise geometries and surface features. These techniques include additive manufacturing, chemical etching, micro-machining, and advanced bonding processes that allow for three-dimensional channel networks with optimized flow paths. The manufacturing approaches enable integration of microchannels into various materials including metals, polymers, and ceramics, expanding application possibilities while maintaining high thermal performance.

- Integrated cooling systems with microchannel networks: Comprehensive cooling solutions incorporate microchannel networks as part of larger thermal management systems. These integrated approaches combine microchannels with pumps, reservoirs, heat exchangers, and control systems to create closed-loop cooling circuits. The systems may include multiple cooling zones with varying microchannel designs to address different thermal loads. Advanced control algorithms optimize flow distribution and pumping power based on real-time thermal demands, improving overall system efficiency.

02 Multi-layer microchannel networks for cooling electronic devices

Multi-layered microchannel networks provide effective cooling solutions for electronic components, particularly in high-power density applications. These systems utilize stacked layers of microchannels to increase cooling surface area while maintaining compact dimensions. The layered approach allows for targeted cooling of specific components and creates thermal gradients that enhance overall heat transfer efficiency in electronic packaging.Expand Specific Solutions03 Integration of phase change materials in microchannel heat exchangers

Incorporating phase change materials (PCMs) into microchannel heat exchangers creates hybrid cooling systems with enhanced thermal management capabilities. These systems utilize the latent heat absorption during phase transitions to buffer temperature fluctuations and provide more uniform cooling. The combination of microchannels with PCMs offers improved thermal energy storage and release characteristics for applications requiring precise temperature control.Expand Specific Solutions04 Additive manufacturing techniques for complex microchannel networks

Advanced additive manufacturing methods enable the fabrication of complex three-dimensional microchannel networks that would be impossible to create using traditional manufacturing processes. These techniques allow for optimized flow path designs, integrated manifolds, and customized channel geometries that maximize heat transfer performance. The freedom of design offered by 3D printing technologies facilitates the creation of application-specific microchannel heat exchangers with minimal material waste.Expand Specific Solutions05 Bifurcated and biomimetic microchannel structures

Biomimetic approaches to microchannel design, particularly those inspired by natural vascular systems, offer significant advantages for heat transfer applications. These designs feature hierarchical branching structures that optimize fluid distribution and minimize pressure drop across the network. Bifurcated channel arrangements provide more uniform cooling by ensuring balanced flow distribution and creating graduated thermal gradients that enhance overall heat transfer efficiency.Expand Specific Solutions

Leading Companies in Microchannel Heat Transfer

Microchannel network optimization for heat transfer is currently in a growth phase, with the market expanding due to increasing demands in thermal management across industries. The global market size is estimated to reach $5-7 billion by 2025, driven by applications in electronics cooling, automotive thermal management, and aerospace systems. Technologically, the field is advancing from early commercial adoption to mainstream implementation, with varying maturity levels across applications. Leading players include Carrier Corp. and Daikin Industries in HVAC applications, Honda Motor and Hanon Systems in automotive thermal management, and Thermavant Technologies specializing in oscillating heat pipe technology. Academic institutions like MIT, Xiamen University, and Rice University are contributing significant research advancements, while Intel and Honeywell are integrating these technologies into their electronic cooling solutions.

Carrier Corp.

Technical Solution: Carrier Corporation has developed proprietary microchannel heat exchanger technology optimized for HVAC and refrigeration applications. Their approach focuses on aluminum microchannel heat exchangers with flat multi-port tubes connected by louvered fins, creating compact, lightweight designs with superior heat transfer characteristics[1]. Carrier's optimization methodology employs computational fluid dynamics coupled with thermal stress analysis to balance thermal performance against manufacturing constraints and durability requirements. Their latest generation of microchannel condensers features asymmetric channel designs with variable hydraulic diameters optimized for refrigerant flow distribution, reducing refrigerant charge by up to 30% compared to conventional tube-fin heat exchangers while improving energy efficiency[2]. Carrier has also pioneered hybrid microchannel networks that strategically combine parallel and serpentine flow paths to optimize refrigerant distribution under varying load conditions, addressing traditional challenges with flow maldistribution in microchannel systems[3]. Their manufacturing process incorporates controlled brazing techniques that ensure uniform metallurgical bonds while maintaining precise channel geometries.

Strengths: Highly optimized for mass production; excellent corrosion resistance through proprietary coatings; significant weight and refrigerant charge reduction compared to conventional heat exchangers. Weaknesses: Limited flexibility for custom applications; potential for refrigerant maldistribution in larger systems; higher sensitivity to air-side fouling compared to traditional coil designs.

Thermavant Technologies LLC

Technical Solution: Thermavant Technologies has pioneered oscillating heat pipe (OHP) technology integrated with optimized microchannel networks for high-performance thermal management solutions. Their proprietary Oscillating Heat Pipe Exchanger (OHPX) technology utilizes self-sustaining thermally-driven oscillations within partially-filled microchannels to achieve effective thermal conductivities exceeding 10,000 W/m·K[1]. Thermavant's optimization approach focuses on channel geometry, working fluid selection, and fill ratio to maximize heat transfer while minimizing thermal resistance. Their microchannel networks feature precisely controlled hydraulic diameters (typically 0.8-2mm) with engineered surface characteristics that enhance liquid film dynamics during oscillatory flow[2]. A key innovation is their multi-layer microchannel architecture that enables three-dimensional heat spreading, effectively managing high heat fluxes exceeding 500 W/cm² with minimal temperature gradients. Thermavant has developed advanced manufacturing techniques including selective laser melting and diffusion bonding to create complex internal channel geometries while maintaining hermetic sealing essential for long-term reliability. Their latest designs incorporate adaptive channel cross-sections that optimize performance across varying heat loads and orientations, addressing traditional limitations of conventional heat pipes[3].

Strengths: Exceptional thermal performance with minimal temperature gradients; passive operation requiring no external power; ability to function effectively in various orientations including against gravity. Weaknesses: Performance sensitivity to working fluid fill ratio; operational limitations at extreme temperatures; manufacturing complexity for large-scale systems requiring extensive microchannel networks.

Critical Patents in Flow Distribution Techniques

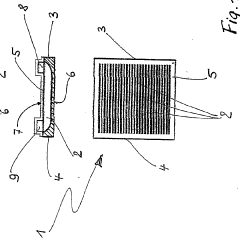

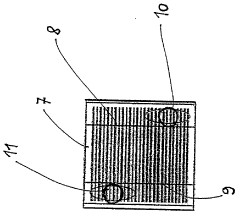

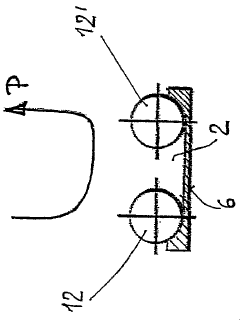

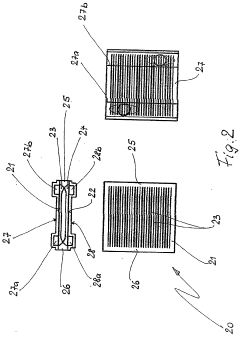

Micro-heat exchanger

PatentWO2006089597A1

Innovation

- The microchannels are introduced into a plate-shaped matrix element from above or below, with connections arranged on the top or sides, allowing for a simplified design and enhanced heat transfer by closing off the channels laterally and using cover plates for sealing, and integrating distribution channels for efficient medium distribution.

Micro-heat exchanger

PatentInactiveEP1856734A1

Innovation

- The microchannels are introduced into a plate-shaped matrix element from above or below, closing them off on the sides, with connections arranged on top or both sides, allowing for efficient entry and distribution of the flow medium, and the matrix elements are stacked with integrated distribution channels for enhanced heat transfer.

Materials Science Advancements for Microchannels

Recent advancements in materials science have significantly enhanced the performance and efficiency of microchannel heat exchangers. Traditional materials like copper and aluminum, while offering good thermal conductivity, have limitations in terms of weight, corrosion resistance, and manufacturing complexity. The emergence of novel materials and surface treatments has opened new possibilities for optimizing microchannel networks.

Silicon-based materials have gained prominence due to their compatibility with semiconductor manufacturing processes, allowing for precise fabrication of complex microchannel geometries. These materials enable integration of microchannels directly into electronic components, facilitating more efficient cooling solutions for high-performance computing systems.

Polymer-based microchannels represent another significant advancement, offering benefits such as low cost, ease of fabrication, and chemical resistance. Recent developments in thermally conductive polymers have addressed the historically poor thermal conductivity of these materials, making them viable alternatives for certain applications where weight and corrosion resistance are critical factors.

Carbon-based materials, particularly diamond films and carbon nanotubes, have demonstrated exceptional thermal conductivity properties. Diamond thin films can achieve thermal conductivity values exceeding 2000 W/m·K, significantly outperforming traditional metals. Integration of carbon nanotubes into microchannel walls has shown promise in enhancing heat transfer coefficients by up to 60% compared to conventional smooth channels.

Surface modification techniques have evolved to address the challenges of flow resistance and heat transfer enhancement. Hydrophilic and hydrophobic coatings can be strategically applied to manipulate fluid behavior within microchannels. Superhydrophobic surfaces have demonstrated the ability to reduce friction and promote dropwise condensation, enhancing phase-change heat transfer processes.

Nanostructured surfaces and hierarchical surface patterns have emerged as effective approaches to increasing the effective surface area for heat transfer while maintaining manageable pressure drops. These engineered surfaces can create localized turbulence and boundary layer disruption without significantly increasing overall system pressure requirements.

Composite materials combining metallic substrates with specialized coatings offer a balanced approach, leveraging the high thermal conductivity of metals with the enhanced surface properties of advanced materials. These hybrid solutions are particularly valuable in applications requiring both high heat flux handling and resistance to harsh operating environments.

Silicon-based materials have gained prominence due to their compatibility with semiconductor manufacturing processes, allowing for precise fabrication of complex microchannel geometries. These materials enable integration of microchannels directly into electronic components, facilitating more efficient cooling solutions for high-performance computing systems.

Polymer-based microchannels represent another significant advancement, offering benefits such as low cost, ease of fabrication, and chemical resistance. Recent developments in thermally conductive polymers have addressed the historically poor thermal conductivity of these materials, making them viable alternatives for certain applications where weight and corrosion resistance are critical factors.

Carbon-based materials, particularly diamond films and carbon nanotubes, have demonstrated exceptional thermal conductivity properties. Diamond thin films can achieve thermal conductivity values exceeding 2000 W/m·K, significantly outperforming traditional metals. Integration of carbon nanotubes into microchannel walls has shown promise in enhancing heat transfer coefficients by up to 60% compared to conventional smooth channels.

Surface modification techniques have evolved to address the challenges of flow resistance and heat transfer enhancement. Hydrophilic and hydrophobic coatings can be strategically applied to manipulate fluid behavior within microchannels. Superhydrophobic surfaces have demonstrated the ability to reduce friction and promote dropwise condensation, enhancing phase-change heat transfer processes.

Nanostructured surfaces and hierarchical surface patterns have emerged as effective approaches to increasing the effective surface area for heat transfer while maintaining manageable pressure drops. These engineered surfaces can create localized turbulence and boundary layer disruption without significantly increasing overall system pressure requirements.

Composite materials combining metallic substrates with specialized coatings offer a balanced approach, leveraging the high thermal conductivity of metals with the enhanced surface properties of advanced materials. These hybrid solutions are particularly valuable in applications requiring both high heat flux handling and resistance to harsh operating environments.

Computational Fluid Dynamics Simulation Methods

Computational Fluid Dynamics (CFD) has emerged as a critical tool for optimizing microchannel networks in heat transfer applications. Modern CFD simulations employ sophisticated numerical methods to solve the governing equations of fluid flow and heat transfer, including the Navier-Stokes equations, energy conservation equations, and continuity equations within complex microchannel geometries.

Multi-physics CFD approaches have gained significant traction in recent years, allowing simultaneous simulation of fluid flow, heat transfer, and sometimes even structural mechanics or electrokinetic effects. These integrated simulations provide more comprehensive insights into the behavior of microfluidic systems under various operating conditions, enabling more accurate optimization of channel geometries and flow parameters.

Mesh generation represents a fundamental challenge in microchannel CFD simulations. Adaptive mesh refinement techniques have proven particularly valuable, automatically increasing mesh density in regions with high gradients of velocity, pressure, or temperature. This approach significantly improves simulation accuracy while maintaining computational efficiency. For complex microchannel networks, unstructured meshes often provide better geometric flexibility compared to structured meshes.

Turbulence modeling presents another critical consideration in microchannel simulations. While many microchannel flows operate in the laminar regime, transitional and turbulent flows can occur at higher Reynolds numbers or in specific geometries. Advanced turbulence models such as Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) offer improved accuracy for these cases, though at significantly higher computational cost compared to Reynolds-Averaged Navier-Stokes (RANS) approaches.

Parallel computing and GPU acceleration have revolutionized CFD simulation capabilities for microchannel optimization. These technologies enable the handling of increasingly complex geometries and physics, reducing simulation time from days to hours. Commercial CFD packages like ANSYS Fluent, COMSOL Multiphysics, and open-source alternatives such as OpenFOAM have incorporated these capabilities, making advanced simulations more accessible to researchers and engineers.

Validation remains essential in CFD-based microchannel optimization. Experimental techniques including micro-PIV (Particle Image Velocimetry), infrared thermography, and microfluidic sensors provide crucial benchmark data for verifying simulation accuracy. The integration of machine learning approaches with CFD is an emerging trend, enabling surrogate modeling and rapid optimization of complex microchannel networks without requiring full simulations for every design iteration.

Multi-physics CFD approaches have gained significant traction in recent years, allowing simultaneous simulation of fluid flow, heat transfer, and sometimes even structural mechanics or electrokinetic effects. These integrated simulations provide more comprehensive insights into the behavior of microfluidic systems under various operating conditions, enabling more accurate optimization of channel geometries and flow parameters.

Mesh generation represents a fundamental challenge in microchannel CFD simulations. Adaptive mesh refinement techniques have proven particularly valuable, automatically increasing mesh density in regions with high gradients of velocity, pressure, or temperature. This approach significantly improves simulation accuracy while maintaining computational efficiency. For complex microchannel networks, unstructured meshes often provide better geometric flexibility compared to structured meshes.

Turbulence modeling presents another critical consideration in microchannel simulations. While many microchannel flows operate in the laminar regime, transitional and turbulent flows can occur at higher Reynolds numbers or in specific geometries. Advanced turbulence models such as Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) offer improved accuracy for these cases, though at significantly higher computational cost compared to Reynolds-Averaged Navier-Stokes (RANS) approaches.

Parallel computing and GPU acceleration have revolutionized CFD simulation capabilities for microchannel optimization. These technologies enable the handling of increasingly complex geometries and physics, reducing simulation time from days to hours. Commercial CFD packages like ANSYS Fluent, COMSOL Multiphysics, and open-source alternatives such as OpenFOAM have incorporated these capabilities, making advanced simulations more accessible to researchers and engineers.

Validation remains essential in CFD-based microchannel optimization. Experimental techniques including micro-PIV (Particle Image Velocimetry), infrared thermography, and microfluidic sensors provide crucial benchmark data for verifying simulation accuracy. The integration of machine learning approaches with CFD is an emerging trend, enabling surrogate modeling and rapid optimization of complex microchannel networks without requiring full simulations for every design iteration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!