Phase-change-assisted heat exchanger design

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phase Change Heat Exchange Technology Background and Objectives

Phase-change heat exchange technology has evolved significantly over the past several decades, transforming from basic heat transfer mechanisms to sophisticated systems that leverage the latent heat properties of materials during phase transitions. The fundamental principle behind this technology dates back to the early 20th century, but substantial advancements have emerged since the 1970s with the development of more efficient materials and designs.

The evolution of phase-change heat exchangers has been driven by increasing demands for energy efficiency across multiple industries, including HVAC, power generation, electronics cooling, and renewable energy systems. Traditional heat exchangers rely primarily on sensible heat transfer, whereas phase-change systems capitalize on the substantially higher energy transfer potential during state transitions, offering theoretical efficiency improvements of 5-10 times compared to conventional systems.

Recent technological breakthroughs have focused on enhancing the heat transfer coefficients at phase-change interfaces, addressing issues such as flow instability, pressure drop optimization, and material compatibility. The miniaturization trend in electronics has particularly accelerated research in micro-channel phase-change heat exchangers, which demonstrate remarkable heat flux capabilities exceeding 500 W/cm² in laboratory settings.

The primary objective of current phase-change-assisted heat exchanger design is to develop systems that maximize thermal performance while minimizing energy consumption, physical footprint, and manufacturing costs. This involves optimizing geometries, material selection, and flow arrangements to enhance phase-change phenomena such as nucleate boiling, film condensation, and two-phase flow dynamics.

Another critical goal is to overcome persistent challenges in phase-change heat exchange, including flow maldistribution, thermal resistance at interfaces, fouling susceptibility, and long-term reliability under cyclic thermal loading. Researchers aim to develop predictive models that accurately capture the complex multiphysics of phase-change processes, enabling more precise design optimization and performance forecasting.

From a sustainability perspective, modern phase-change heat exchanger development increasingly focuses on compatibility with low-GWP (Global Warming Potential) refrigerants and natural working fluids. This aligns with global environmental regulations and represents a significant shift from earlier designs optimized for traditional refrigerants with higher environmental impact.

The convergence of advanced manufacturing techniques, such as 3D printing and microfabrication, with computational fluid dynamics and machine learning approaches, is opening new frontiers in phase-change heat exchanger design. These technologies enable previously impossible geometries and surface modifications that can dramatically enhance nucleation site density, wettability control, and overall heat transfer performance.

The evolution of phase-change heat exchangers has been driven by increasing demands for energy efficiency across multiple industries, including HVAC, power generation, electronics cooling, and renewable energy systems. Traditional heat exchangers rely primarily on sensible heat transfer, whereas phase-change systems capitalize on the substantially higher energy transfer potential during state transitions, offering theoretical efficiency improvements of 5-10 times compared to conventional systems.

Recent technological breakthroughs have focused on enhancing the heat transfer coefficients at phase-change interfaces, addressing issues such as flow instability, pressure drop optimization, and material compatibility. The miniaturization trend in electronics has particularly accelerated research in micro-channel phase-change heat exchangers, which demonstrate remarkable heat flux capabilities exceeding 500 W/cm² in laboratory settings.

The primary objective of current phase-change-assisted heat exchanger design is to develop systems that maximize thermal performance while minimizing energy consumption, physical footprint, and manufacturing costs. This involves optimizing geometries, material selection, and flow arrangements to enhance phase-change phenomena such as nucleate boiling, film condensation, and two-phase flow dynamics.

Another critical goal is to overcome persistent challenges in phase-change heat exchange, including flow maldistribution, thermal resistance at interfaces, fouling susceptibility, and long-term reliability under cyclic thermal loading. Researchers aim to develop predictive models that accurately capture the complex multiphysics of phase-change processes, enabling more precise design optimization and performance forecasting.

From a sustainability perspective, modern phase-change heat exchanger development increasingly focuses on compatibility with low-GWP (Global Warming Potential) refrigerants and natural working fluids. This aligns with global environmental regulations and represents a significant shift from earlier designs optimized for traditional refrigerants with higher environmental impact.

The convergence of advanced manufacturing techniques, such as 3D printing and microfabrication, with computational fluid dynamics and machine learning approaches, is opening new frontiers in phase-change heat exchanger design. These technologies enable previously impossible geometries and surface modifications that can dramatically enhance nucleation site density, wettability control, and overall heat transfer performance.

Market Analysis for Phase Change Heat Exchangers

The global market for phase change heat exchangers is experiencing robust growth, driven primarily by increasing energy efficiency demands across multiple industries. Current market valuation stands at approximately 3.2 billion USD with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is supported by stringent environmental regulations worldwide that mandate reduced energy consumption and lower carbon emissions in industrial processes.

The HVAC sector represents the largest application segment, accounting for nearly 38% of the total market share. Commercial buildings and residential complexes are increasingly adopting phase change heat exchanger technology to optimize energy usage while maintaining desired thermal comfort levels. The industrial processing sector follows closely, with applications in chemical manufacturing, food processing, and pharmaceutical production showing significant adoption rates.

Geographically, North America and Europe currently dominate the market landscape, collectively holding about 58% of the global market share. This dominance stems from advanced technological infrastructure and early adoption of energy-efficient solutions. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected growth rate of 8.5% annually, primarily driven by rapid industrialization in China and India, coupled with increasing awareness about energy conservation.

Market segmentation by technology type reveals that plate heat exchangers incorporating phase change materials lead with approximately 42% market share, followed by shell and tube designs at 31%. Microchannel heat exchangers, though currently representing only 15% of the market, are showing the highest growth potential due to their superior heat transfer efficiency and compact design advantages.

Consumer demand patterns indicate a strong preference for solutions offering demonstrable return on investment through energy savings. The average payback period expected by end-users has decreased from 4-5 years to 2-3 years, reflecting heightened cost sensitivity and performance expectations.

Key market drivers include rising energy costs, which have increased by an average of 4.2% annually over the past five years, creating stronger economic incentives for energy-efficient solutions. Additionally, building code revisions in major markets now specifically address thermal efficiency standards, creating regulatory pressure for adoption of advanced heat exchange technologies.

Market challenges primarily revolve around high initial investment costs, which can be 30-40% higher than conventional systems, and integration complexities with existing infrastructure. These factors particularly affect small and medium-sized enterprises with limited capital expenditure budgets.

The HVAC sector represents the largest application segment, accounting for nearly 38% of the total market share. Commercial buildings and residential complexes are increasingly adopting phase change heat exchanger technology to optimize energy usage while maintaining desired thermal comfort levels. The industrial processing sector follows closely, with applications in chemical manufacturing, food processing, and pharmaceutical production showing significant adoption rates.

Geographically, North America and Europe currently dominate the market landscape, collectively holding about 58% of the global market share. This dominance stems from advanced technological infrastructure and early adoption of energy-efficient solutions. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected growth rate of 8.5% annually, primarily driven by rapid industrialization in China and India, coupled with increasing awareness about energy conservation.

Market segmentation by technology type reveals that plate heat exchangers incorporating phase change materials lead with approximately 42% market share, followed by shell and tube designs at 31%. Microchannel heat exchangers, though currently representing only 15% of the market, are showing the highest growth potential due to their superior heat transfer efficiency and compact design advantages.

Consumer demand patterns indicate a strong preference for solutions offering demonstrable return on investment through energy savings. The average payback period expected by end-users has decreased from 4-5 years to 2-3 years, reflecting heightened cost sensitivity and performance expectations.

Key market drivers include rising energy costs, which have increased by an average of 4.2% annually over the past five years, creating stronger economic incentives for energy-efficient solutions. Additionally, building code revisions in major markets now specifically address thermal efficiency standards, creating regulatory pressure for adoption of advanced heat exchange technologies.

Market challenges primarily revolve around high initial investment costs, which can be 30-40% higher than conventional systems, and integration complexities with existing infrastructure. These factors particularly affect small and medium-sized enterprises with limited capital expenditure budgets.

Technical Challenges in Phase Change Heat Transfer

Phase change heat transfer in heat exchangers presents significant technical challenges that must be addressed to optimize performance and efficiency. The complexity of phase transitions between liquid and vapor states introduces multifaceted issues that engineers continue to grapple with despite decades of research.

Heat transfer coefficient prediction during phase change remains problematic due to the dynamic nature of the process. The coefficient can vary by orders of magnitude across different regions of the heat exchanger, making accurate modeling extremely difficult. Current correlations often fail to account for the full spectrum of operating conditions, geometries, and working fluids, resulting in substantial discrepancies between predicted and actual performance.

Flow instabilities represent another major challenge, particularly in two-phase flow regimes. These instabilities can manifest as pressure oscillations, flow reversal, or maldistribution of the working fluid, leading to reduced thermal performance and potential mechanical damage. The transition between flow patterns (such as bubbly, slug, annular, and mist flow) further complicates the design process, as each pattern exhibits distinct heat transfer characteristics.

Fouling and scaling issues are exacerbated during phase change processes. The temperature gradients and concentration effects near phase boundaries can accelerate deposit formation, particularly in industrial applications where water or process fluids serve as the working medium. These deposits create additional thermal resistance, degrading heat exchanger performance over time and necessitating maintenance interventions.

Material selection presents unique challenges in phase change applications due to thermal cycling and potential corrosion. The repeated expansion and contraction from temperature fluctuations can lead to fatigue failure, while the presence of both liquid and vapor phases may create localized corrosion cells. Advanced materials that offer both thermal efficiency and durability under these conditions often come with prohibitive cost implications.

Miniaturization efforts for compact heat exchangers face particular difficulties with phase change processes. As channel dimensions decrease, surface tension effects become increasingly dominant, altering flow patterns and heat transfer mechanisms. Bubble nucleation, growth, and departure dynamics change dramatically at small scales, requiring new design approaches and correlations.

Energy efficiency optimization remains challenging due to the inherent irreversibilities in phase change processes. The temperature differences required to drive phase transitions introduce thermodynamic penalties, while pressure drops associated with two-phase flow contribute to pumping power requirements. Balancing these competing factors to achieve optimal system performance requires sophisticated modeling and design methodologies that are still evolving.

Heat transfer coefficient prediction during phase change remains problematic due to the dynamic nature of the process. The coefficient can vary by orders of magnitude across different regions of the heat exchanger, making accurate modeling extremely difficult. Current correlations often fail to account for the full spectrum of operating conditions, geometries, and working fluids, resulting in substantial discrepancies between predicted and actual performance.

Flow instabilities represent another major challenge, particularly in two-phase flow regimes. These instabilities can manifest as pressure oscillations, flow reversal, or maldistribution of the working fluid, leading to reduced thermal performance and potential mechanical damage. The transition between flow patterns (such as bubbly, slug, annular, and mist flow) further complicates the design process, as each pattern exhibits distinct heat transfer characteristics.

Fouling and scaling issues are exacerbated during phase change processes. The temperature gradients and concentration effects near phase boundaries can accelerate deposit formation, particularly in industrial applications where water or process fluids serve as the working medium. These deposits create additional thermal resistance, degrading heat exchanger performance over time and necessitating maintenance interventions.

Material selection presents unique challenges in phase change applications due to thermal cycling and potential corrosion. The repeated expansion and contraction from temperature fluctuations can lead to fatigue failure, while the presence of both liquid and vapor phases may create localized corrosion cells. Advanced materials that offer both thermal efficiency and durability under these conditions often come with prohibitive cost implications.

Miniaturization efforts for compact heat exchangers face particular difficulties with phase change processes. As channel dimensions decrease, surface tension effects become increasingly dominant, altering flow patterns and heat transfer mechanisms. Bubble nucleation, growth, and departure dynamics change dramatically at small scales, requiring new design approaches and correlations.

Energy efficiency optimization remains challenging due to the inherent irreversibilities in phase change processes. The temperature differences required to drive phase transitions introduce thermodynamic penalties, while pressure drops associated with two-phase flow contribute to pumping power requirements. Balancing these competing factors to achieve optimal system performance requires sophisticated modeling and design methodologies that are still evolving.

Current Phase Change Heat Exchanger Design Solutions

01 Heat exchanger design optimization

Optimizing the design of heat exchangers can significantly improve heat exchange efficiency. This includes considerations such as the shape, size, and arrangement of heat transfer surfaces, flow path design, and material selection. Advanced design techniques can minimize thermal resistance and maximize the heat transfer area, leading to enhanced overall performance and energy efficiency.- Heat exchanger design optimization: Optimizing the design of heat exchangers can significantly improve heat exchange efficiency. This includes considerations such as the shape, size, and arrangement of heat transfer surfaces, flow path design, and material selection. Advanced design techniques can minimize pressure drop while maximizing heat transfer area, resulting in more efficient heat exchange systems.

- Enhanced heat transfer surfaces: Incorporating specialized heat transfer surfaces can increase the efficiency of heat exchangers. These include finned surfaces, micro-channels, corrugated plates, and textured surfaces that increase turbulence and surface area. Such modifications promote better thermal contact between the heat transfer medium and the exchanger surface, leading to improved heat exchange rates and overall system efficiency.

- Flow arrangement and turbulence promotion: Strategic flow arrangements and turbulence promotion techniques can enhance heat exchange efficiency. This includes counter-flow configurations, baffles, vortex generators, and other flow disruptors that increase mixing and reduce boundary layer thickness. These approaches ensure better contact between the fluid and heat transfer surfaces, minimizing thermal resistance and improving overall performance.

- Advanced materials and coatings: Utilizing advanced materials and specialized coatings can improve heat exchanger efficiency. High thermal conductivity materials, nano-enhanced surfaces, and anti-fouling coatings help maintain optimal heat transfer rates over time. These materials can reduce thermal resistance, prevent performance degradation due to scaling or fouling, and extend the operational life of heat exchange equipment.

- Intelligent control and monitoring systems: Implementing intelligent control and monitoring systems can optimize heat exchanger operation under varying conditions. These systems include sensors, automated flow control mechanisms, and predictive maintenance capabilities that adjust operating parameters in real-time. By continuously optimizing flow rates, temperatures, and other variables, these systems ensure maximum heat exchange efficiency throughout different operational phases.

02 Enhanced heat transfer surfaces

Incorporating specialized heat transfer surfaces, such as fins, corrugated plates, or micro-channels, can significantly increase the heat exchange efficiency. These surfaces increase the contact area between the heat transfer medium and the exchanger walls, promoting turbulent flow and reducing thermal boundary layers. Such enhancements can lead to higher heat transfer coefficients and improved overall system performance.Expand Specific Solutions03 Flow arrangement and distribution optimization

Optimizing the flow arrangement and distribution within heat exchangers can enhance heat exchange efficiency. This includes implementing counter-flow or cross-flow configurations, ensuring uniform fluid distribution, and minimizing pressure drops. Proper flow management reduces dead zones and hot spots, leading to more effective heat transfer across the entire exchanger surface.Expand Specific Solutions04 Advanced materials and coatings

Utilizing advanced materials and specialized coatings can improve heat exchange efficiency. High thermal conductivity materials reduce thermal resistance, while corrosion-resistant coatings extend operational life. Nanomaterials and composite structures can provide enhanced thermal properties, and hydrophilic or hydrophobic coatings can improve condensation or evaporation processes, respectively, leading to better overall heat transfer performance.Expand Specific Solutions05 Intelligent control and monitoring systems

Implementing intelligent control and monitoring systems can optimize heat exchanger operation in real-time. These systems can adjust flow rates, temperatures, and other parameters based on changing conditions and demand. Advanced sensors and predictive algorithms enable proactive maintenance, prevent fouling, and ensure the heat exchanger operates at peak efficiency throughout its lifecycle, resulting in significant energy savings and extended equipment life.Expand Specific Solutions

Leading Companies in Phase Change Heat Exchange Industry

The phase-change-assisted heat exchanger design market is currently in a growth stage, characterized by increasing research and commercial applications across multiple industries. The global market size is expanding, driven by energy efficiency demands and sustainable cooling solutions, with projections indicating significant growth over the next decade. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include established industrial giants like Valeo Thermal Systems, DENSO, DAIKIN, and Midea Group focusing on commercial applications, while research institutions such as Xi'an Jiaotong University, Southeast University, and Commissariat à l'énergie atomique et aux énergies Alternatives drive fundamental advancements. Major corporations like Boeing and Raytheon are exploring specialized high-performance applications, indicating the technology's strategic importance across aerospace, automotive, and energy sectors.

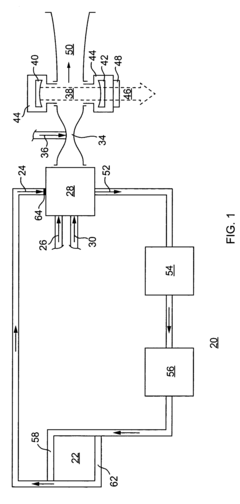

Rocky Research

Technical Solution: Rocky Research has developed specialized phase-change-assisted heat exchanger technology focused on high-efficiency thermal management systems for both commercial and military applications. Their proprietary designs incorporate advanced phase change materials (PCMs) strategically integrated within heat exchanger structures to provide enhanced thermal buffering and temperature stabilization. Rocky Research's heat exchangers feature innovative flow distribution systems that ensure uniform phase change behavior across the entire heat transfer surface, maximizing thermal efficiency while minimizing pressure drops. The company has pioneered composite heat exchanger materials that combine high thermal conductivity with corrosion resistance, extending operational life in demanding environments. Their technology incorporates specialized surface treatments that enhance nucleate boiling and dropwise condensation, significantly improving heat transfer coefficients during phase transitions.

Strengths: Exceptional thermal stability during transient operations; robust performance in extreme environmental conditions; excellent energy storage capabilities integrated with heat transfer functions. Weaknesses: Higher manufacturing complexity and cost; larger physical footprint compared to some competing technologies; requires specialized maintenance procedures.

DENSO Corp.

Technical Solution: DENSO has pioneered phase-change-assisted heat exchanger technology specifically for automotive thermal management systems. Their design incorporates a dual-phase heat exchange mechanism that utilizes both latent and sensible heat transfer to maximize thermal efficiency. DENSO's heat exchangers feature precision-engineered microchannels with optimized geometries that enhance phase change dynamics while minimizing pressure drops. The company has developed specialized surface treatments that promote nucleate boiling and condensation, significantly improving heat transfer coefficients during phase transitions. Their systems incorporate intelligent flow distribution manifolds that ensure uniform refrigerant distribution across multiple parallel channels, preventing flow maldistribution that can reduce efficiency. DENSO has also integrated advanced phase change materials (PCMs) within their heat exchanger designs to provide thermal buffering capabilities during transient operating conditions.

Strengths: Exceptional thermal performance in compact packaging suitable for space-constrained automotive applications; robust design capable of withstanding vibration and thermal cycling; excellent weight-to-performance ratio. Weaknesses: Manufacturing complexity leads to higher production costs; requires precise control of refrigerant charge; performance sensitivity to operating conditions.

Key Patents and Innovations in Phase Change Heat Transfer

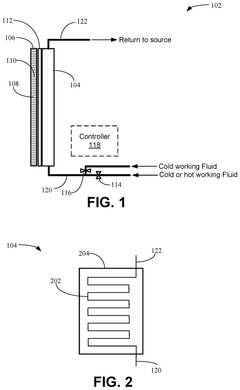

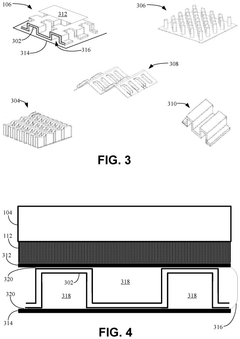

Phase-change heat exchanger

PatentInactiveUS7106777B2

Innovation

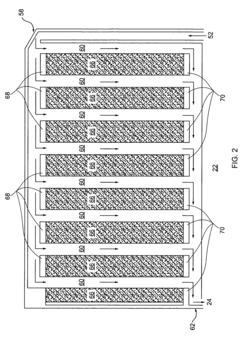

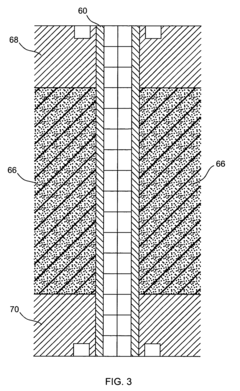

- A phase-change heat exchanger is designed with conduits and a foam structure having a three-dimensional reticulated structure of open cells, where the phase-change material is contained within these cells, enhancing thermal energy transfer through the ligaments, thereby improving heat transfer rates into and out of the phase-change material.

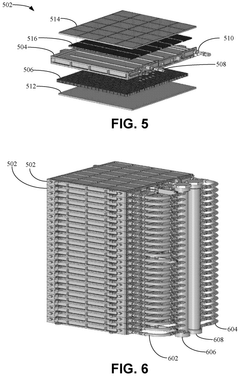

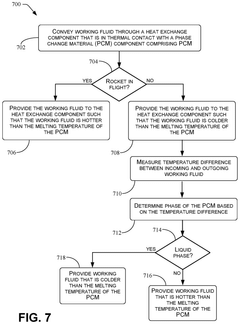

Modular double brazed phase-change material heat exchanger

PatentPendingUS20240353184A1

Innovation

- A phase change material (PCM) heat exchanger system with a modular, integrated double brazed layout and lanced offset fin configuration that uses a non-flow phase change material for heat storage, reducing the need for complex control systems and minimizing weight, and includes a working fluid supply system to manage temperature based on location and phase of the PCM.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become paramount considerations in the development of phase-change-assisted heat exchanger designs. These systems leverage the high energy density associated with phase transitions to achieve superior thermal management capabilities while potentially reducing overall energy consumption. When properly optimized, phase-change heat exchangers can achieve energy efficiency improvements of 20-40% compared to conventional single-phase systems, representing significant operational cost savings and reduced environmental impact.

The integration of phase-change materials (PCMs) into heat exchanger designs offers unique sustainability advantages through thermal energy storage capabilities. This enables load shifting and peak demand reduction, which are critical for integrating renewable energy sources with intermittent availability. By storing excess thermal energy during periods of abundance and releasing it during peak demand, these systems help balance grid loads and reduce the need for fossil fuel-based peaking power plants.

Material selection represents a critical sustainability consideration in phase-change heat exchanger development. Traditional refrigerants with high global warming potential (GWP) are being replaced by natural alternatives such as CO2, ammonia, and hydrocarbons, or new synthetic options with minimal environmental impact. The lifecycle assessment of these materials must account for manufacturing energy requirements, operational efficiency, longevity, and end-of-life recyclability.

Water consumption optimization is another key sustainability factor, particularly in industrial cooling applications. Phase-change systems can significantly reduce water usage compared to conventional cooling towers through closed-loop designs and improved heat transfer efficiency. In regions facing water scarcity, this benefit can be as important as energy efficiency improvements.

Manufacturing processes for advanced phase-change heat exchangers are evolving to incorporate sustainable practices. Additive manufacturing techniques enable complex geometries that maximize heat transfer while minimizing material usage. These processes reduce waste and allow for the use of recycled materials in certain applications, further enhancing sustainability credentials.

The economic viability of sustainable phase-change heat exchangers continues to improve as manufacturing scales increase and technology matures. While initial capital costs may exceed conventional alternatives by 15-30%, the total cost of ownership analysis frequently demonstrates favorable economics when accounting for energy savings, maintenance requirements, and extended operational lifespans. Government incentives for energy-efficient technologies further enhance the business case for these advanced systems.

The integration of phase-change materials (PCMs) into heat exchanger designs offers unique sustainability advantages through thermal energy storage capabilities. This enables load shifting and peak demand reduction, which are critical for integrating renewable energy sources with intermittent availability. By storing excess thermal energy during periods of abundance and releasing it during peak demand, these systems help balance grid loads and reduce the need for fossil fuel-based peaking power plants.

Material selection represents a critical sustainability consideration in phase-change heat exchanger development. Traditional refrigerants with high global warming potential (GWP) are being replaced by natural alternatives such as CO2, ammonia, and hydrocarbons, or new synthetic options with minimal environmental impact. The lifecycle assessment of these materials must account for manufacturing energy requirements, operational efficiency, longevity, and end-of-life recyclability.

Water consumption optimization is another key sustainability factor, particularly in industrial cooling applications. Phase-change systems can significantly reduce water usage compared to conventional cooling towers through closed-loop designs and improved heat transfer efficiency. In regions facing water scarcity, this benefit can be as important as energy efficiency improvements.

Manufacturing processes for advanced phase-change heat exchangers are evolving to incorporate sustainable practices. Additive manufacturing techniques enable complex geometries that maximize heat transfer while minimizing material usage. These processes reduce waste and allow for the use of recycled materials in certain applications, further enhancing sustainability credentials.

The economic viability of sustainable phase-change heat exchangers continues to improve as manufacturing scales increase and technology matures. While initial capital costs may exceed conventional alternatives by 15-30%, the total cost of ownership analysis frequently demonstrates favorable economics when accounting for energy savings, maintenance requirements, and extended operational lifespans. Government incentives for energy-efficient technologies further enhance the business case for these advanced systems.

Materials Science Advancements for Phase Change Applications

Recent advancements in materials science have revolutionized phase change applications, particularly in heat exchanger design. The development of novel phase change materials (PCMs) with enhanced thermal properties has enabled significant improvements in heat transfer efficiency and energy storage capabilities. These materials exhibit controlled phase transitions between solid and liquid states, allowing them to absorb, store, and release large amounts of thermal energy at nearly constant temperatures.

Metallic PCMs, including gallium-based alloys and low-melting-point metals, have gained attention for their exceptional thermal conductivity and high energy density. These properties make them ideal for high-performance heat exchangers where rapid thermal response is critical. Researchers have successfully manipulated the microstructure of these materials to optimize their phase transition characteristics while maintaining mechanical stability during repeated thermal cycling.

Polymer-based PCMs represent another promising category, offering advantages in terms of flexibility, weight reduction, and cost-effectiveness. Recent innovations include the development of form-stable composite PCMs that incorporate high-conductivity fillers such as graphene, carbon nanotubes, and metallic nanoparticles. These composites effectively address the inherent low thermal conductivity of polymeric materials while preserving their beneficial properties.

Encapsulation technologies have advanced significantly, enabling the integration of PCMs into various heat exchanger designs without leakage concerns. Micro- and nano-encapsulation techniques now allow for precise control over the shell thickness, permeability, and mechanical strength, ensuring long-term stability and performance reliability. These encapsulated PCMs can be incorporated into heat exchanger structures as coatings, embedded components, or discrete modules.

Surface engineering approaches have emerged as critical enablers for phase change heat transfer enhancement. Engineered surfaces with controlled wettability, porosity, and topography can significantly influence phase change phenomena at interfaces. Bioinspired surfaces mimicking natural structures like lotus leaves or butterfly wings have demonstrated remarkable capabilities in promoting nucleation, reducing thermal resistance, and preventing fouling during phase transitions.

Computational materials science has accelerated the discovery and optimization of PCMs through high-throughput screening and machine learning algorithms. These computational tools enable researchers to predict thermal properties, phase transition behaviors, and long-term stability of candidate materials before experimental validation, substantially reducing development time and costs. Molecular dynamics simulations provide insights into nanoscale heat transfer mechanisms, guiding the rational design of next-generation PCMs with tailored properties.

Metallic PCMs, including gallium-based alloys and low-melting-point metals, have gained attention for their exceptional thermal conductivity and high energy density. These properties make them ideal for high-performance heat exchangers where rapid thermal response is critical. Researchers have successfully manipulated the microstructure of these materials to optimize their phase transition characteristics while maintaining mechanical stability during repeated thermal cycling.

Polymer-based PCMs represent another promising category, offering advantages in terms of flexibility, weight reduction, and cost-effectiveness. Recent innovations include the development of form-stable composite PCMs that incorporate high-conductivity fillers such as graphene, carbon nanotubes, and metallic nanoparticles. These composites effectively address the inherent low thermal conductivity of polymeric materials while preserving their beneficial properties.

Encapsulation technologies have advanced significantly, enabling the integration of PCMs into various heat exchanger designs without leakage concerns. Micro- and nano-encapsulation techniques now allow for precise control over the shell thickness, permeability, and mechanical strength, ensuring long-term stability and performance reliability. These encapsulated PCMs can be incorporated into heat exchanger structures as coatings, embedded components, or discrete modules.

Surface engineering approaches have emerged as critical enablers for phase change heat transfer enhancement. Engineered surfaces with controlled wettability, porosity, and topography can significantly influence phase change phenomena at interfaces. Bioinspired surfaces mimicking natural structures like lotus leaves or butterfly wings have demonstrated remarkable capabilities in promoting nucleation, reducing thermal resistance, and preventing fouling during phase transitions.

Computational materials science has accelerated the discovery and optimization of PCMs through high-throughput screening and machine learning algorithms. These computational tools enable researchers to predict thermal properties, phase transition behaviors, and long-term stability of candidate materials before experimental validation, substantially reducing development time and costs. Molecular dynamics simulations provide insights into nanoscale heat transfer mechanisms, guiding the rational design of next-generation PCMs with tailored properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!